Rotary rubber ball automatic on-line continuous cleaning device and method

A cleaning device and rotary technology, which is applied in the direction of cleaning heat transfer devices, non-rotating equipment cleaning, climate sustainability, etc. Loss, energy consumption reduction, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

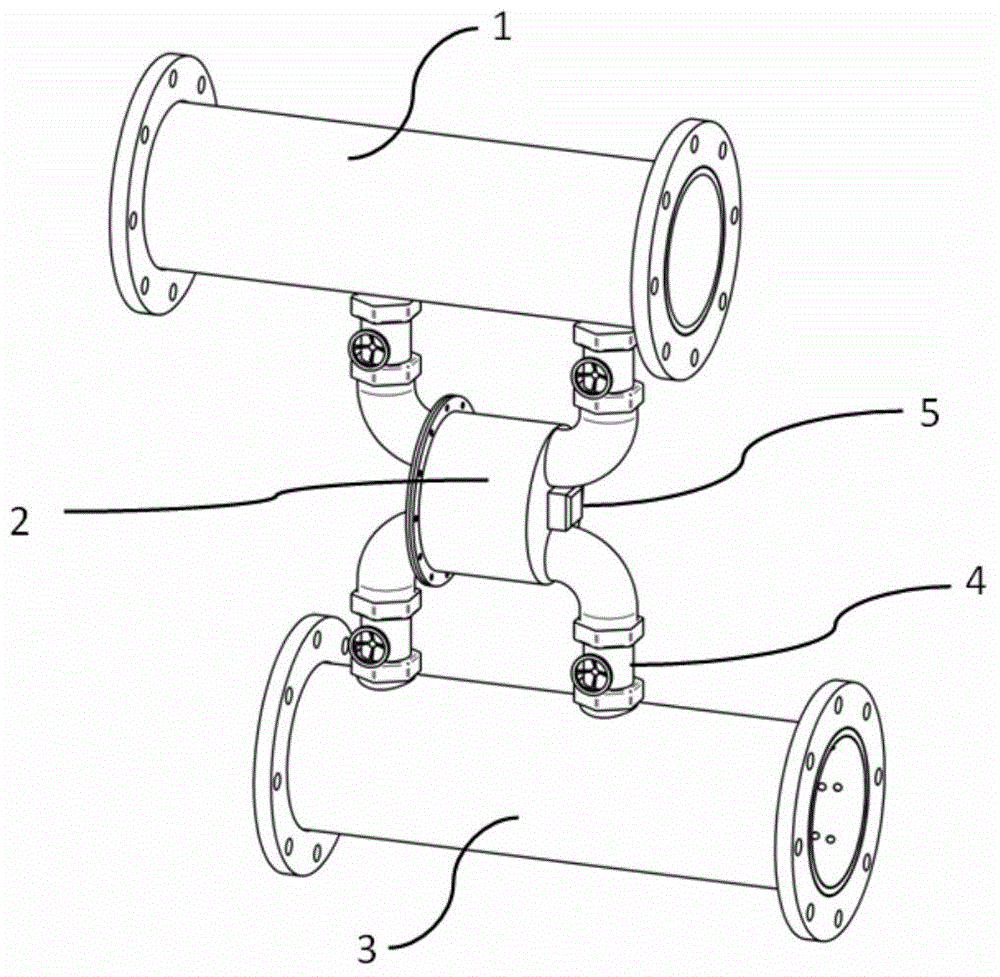

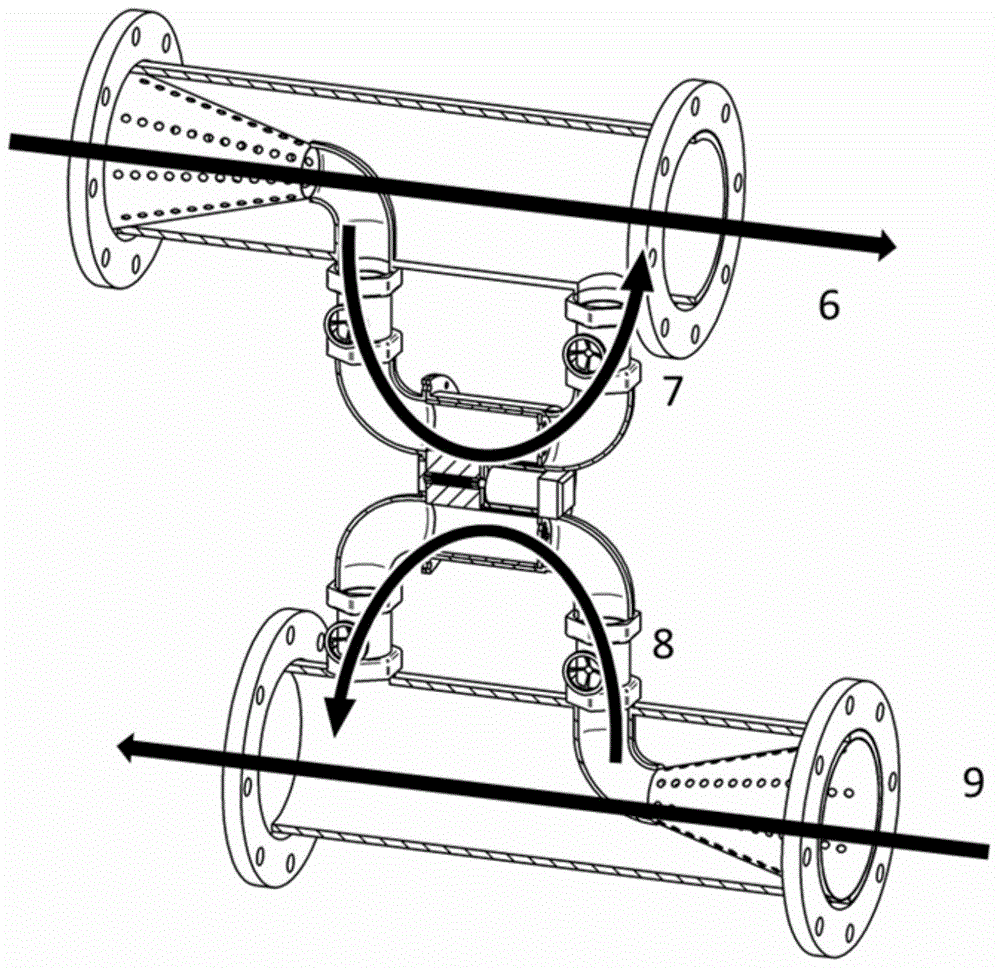

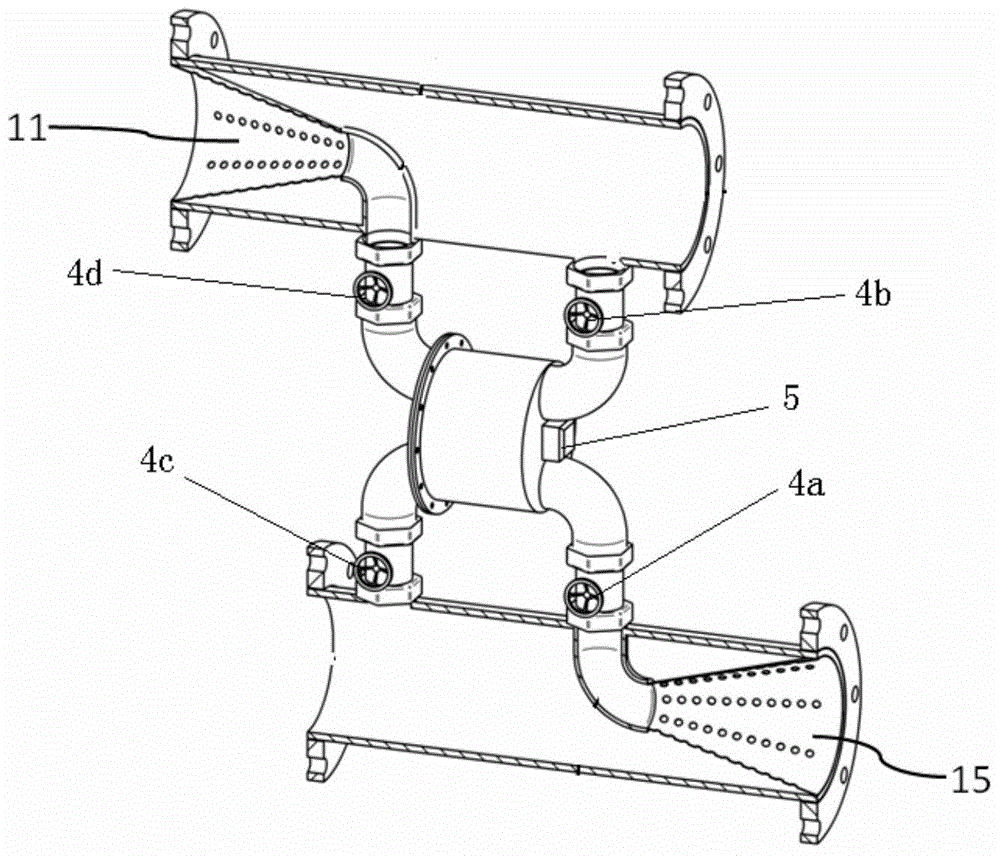

[0023] see Figure 1 to Figure 4 , a rotary automatic online continuous cleaning device for rubber balls, including a ball receiving cylinder 1, a ball storage cylinder 2, a ball injection cylinder 3, four ball valves 4 and an automatic control motor 5; the ball collection cylinder 1 is set above the ball storage cylinder 2, and the injection The ball cylinder 3 is arranged below the ball storage cylinder 2; the ball storage cylinder 2 includes a cover plate 21, an inner cylinder 23, a filter hole plate 26 and an outer cylinder 24; The outer cylinder 24 is sleeved outside the inner cylinder 23, and the top of the outer cylinder 24 is connected to the cover plate 21; the inner cylinder 23 is distributed along the circumference with several channels for storing rubber balls. Holes 17; a filter orifice 26 is provided between the inner cylinder 23 and the bottom plate of the outer cylinder 24; the cover plate 21 is provided with a ball receiving port 13 and a ball outlet 12; The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com