Miniature diaphragm pump with precise flow adjusting device

A technology of flow regulating device and micro-diaphragm pump, which is applied in the direction of sampling device, pump with flexible working elements, etc. It can solve the problems of small effective measurement range, accelerated diaphragm corrosion and aging, and insensitivity to pressure changes, etc., to solve the problem of flow rate The effect of periodic fluctuations, prolonging the cleaning and maintenance cycle, and improving flow stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

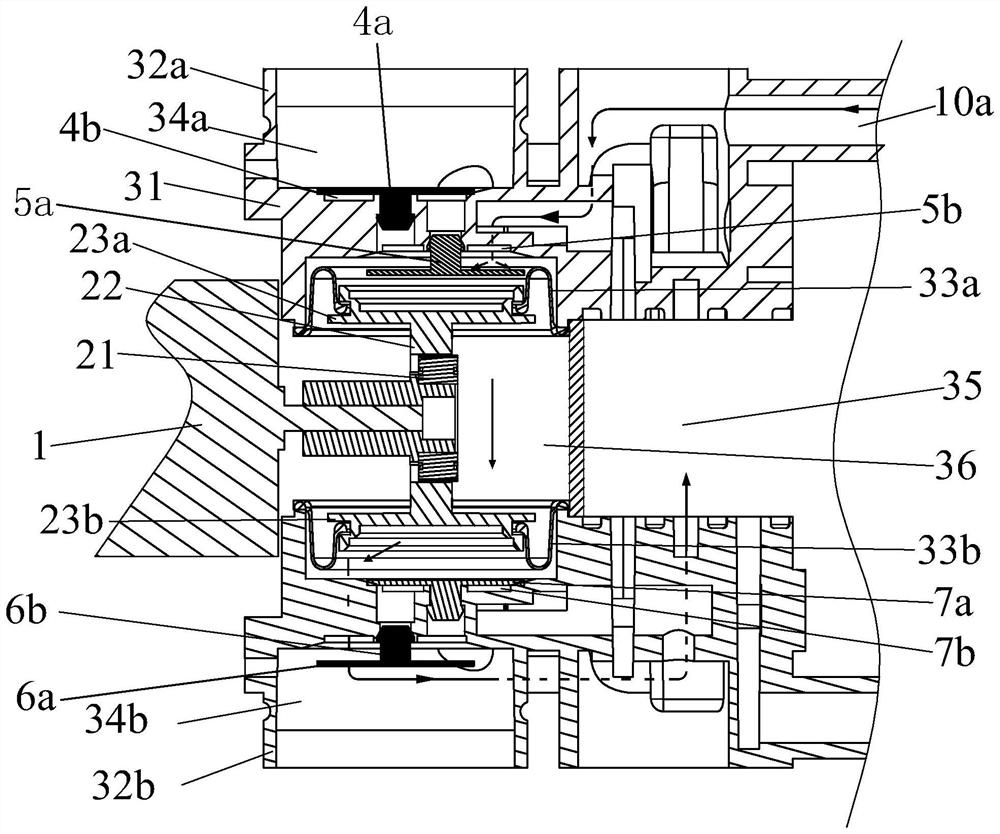

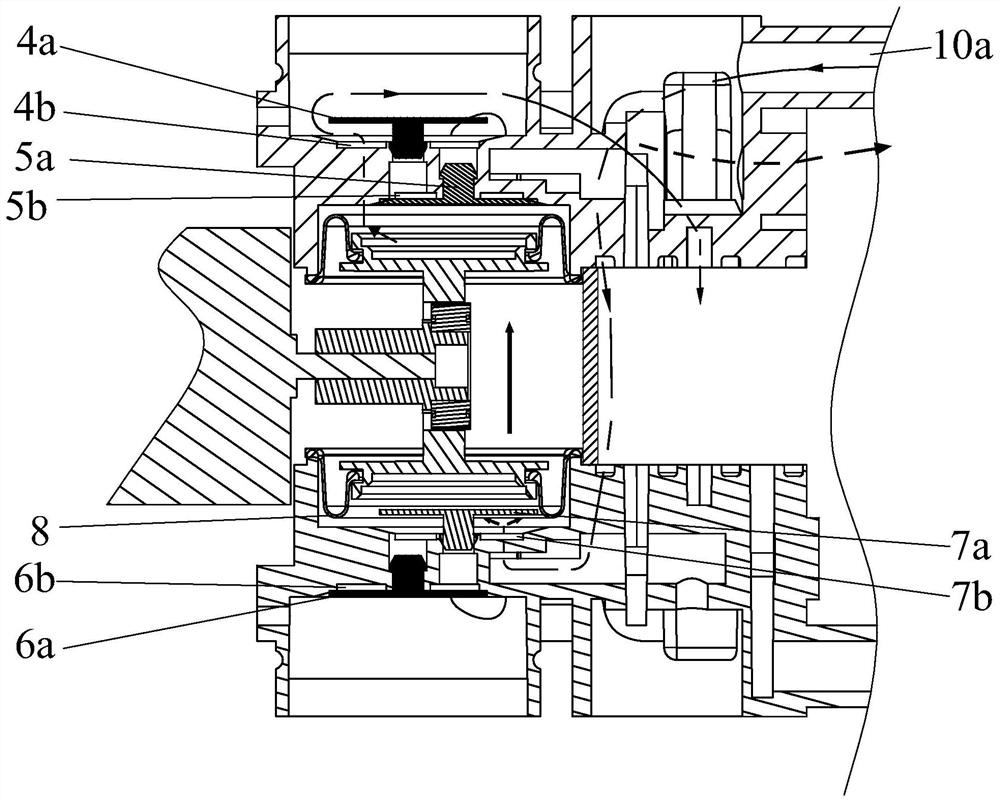

[0033] Embodiments of the present invention will now be described with reference to the drawings, in which like reference numerals represent like elements.

[0034]Wherein, in the description of the embodiments of the present disclosure, if the same or similar terms as “left”, “right”, “first”, “second” are involved, they are only used for the purpose of description, “left” or “right” It cannot be understood as indicating or implying the actual positional relationship. The features of "first" and "second" can expressly or implicitly indicate that they include one or more technical features that are identical or similar in structure and function, and cannot be understood as indicating Or imply the relationship of importance, primary and secondary.

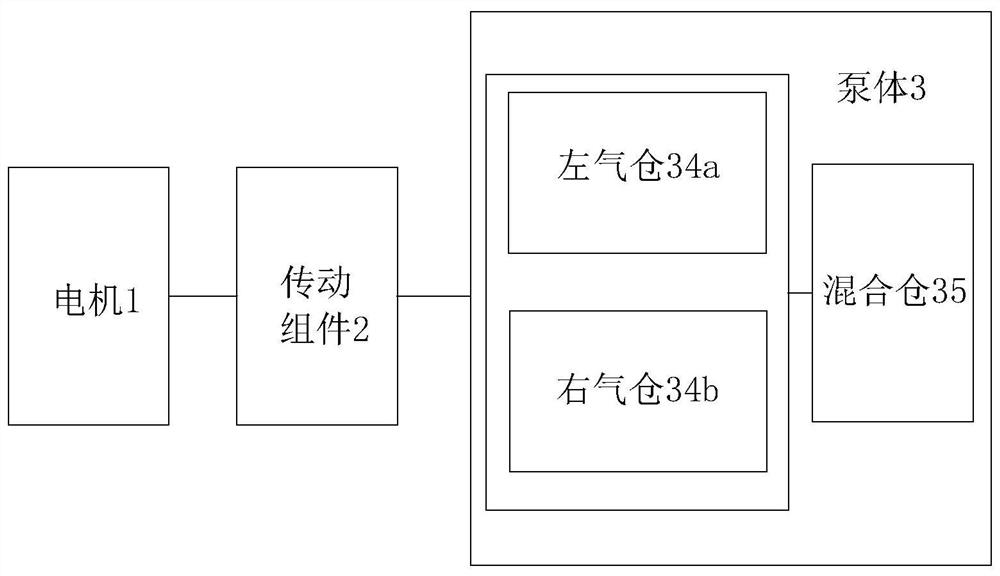

[0035] As mentioned above, such as figure 1 As shown, the embodiment of the present invention provides a micro-diaphragm pump with a precision flow regulating device, including: a motor 1 , a transmission assembly 2 and a pump body...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com