Gradable unloading sand box

A technology of sand box and inner vertical plate, which is used in the erection/assembly of bridges, bridges, buildings, etc., can solve the problems of easy agglomeration of the filled sand, failure to release smoothly, and easy blockage of the sand, etc. Stable, non-clogging effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

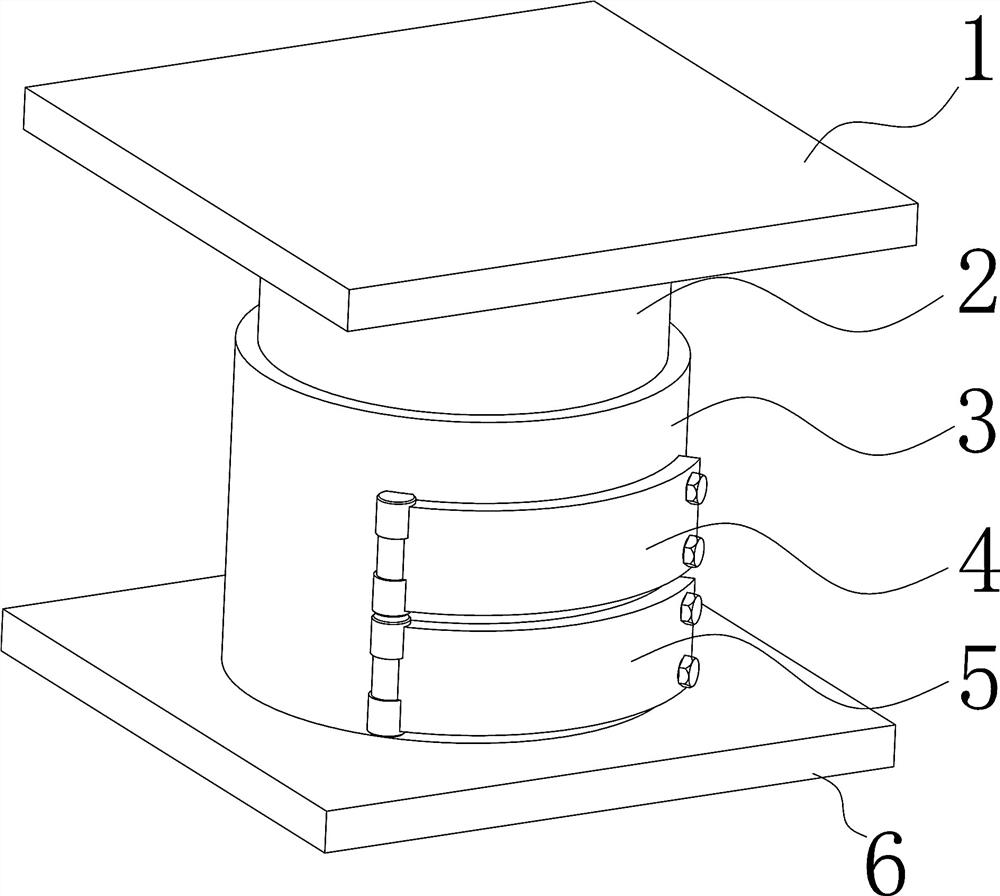

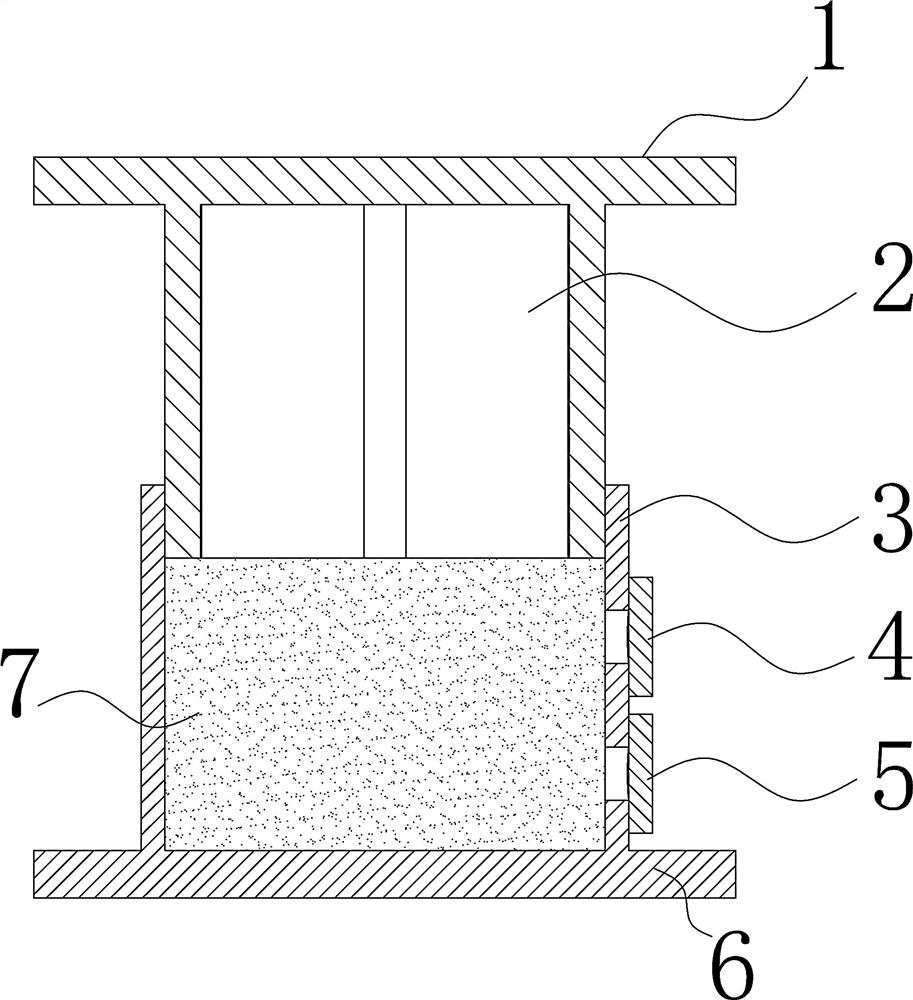

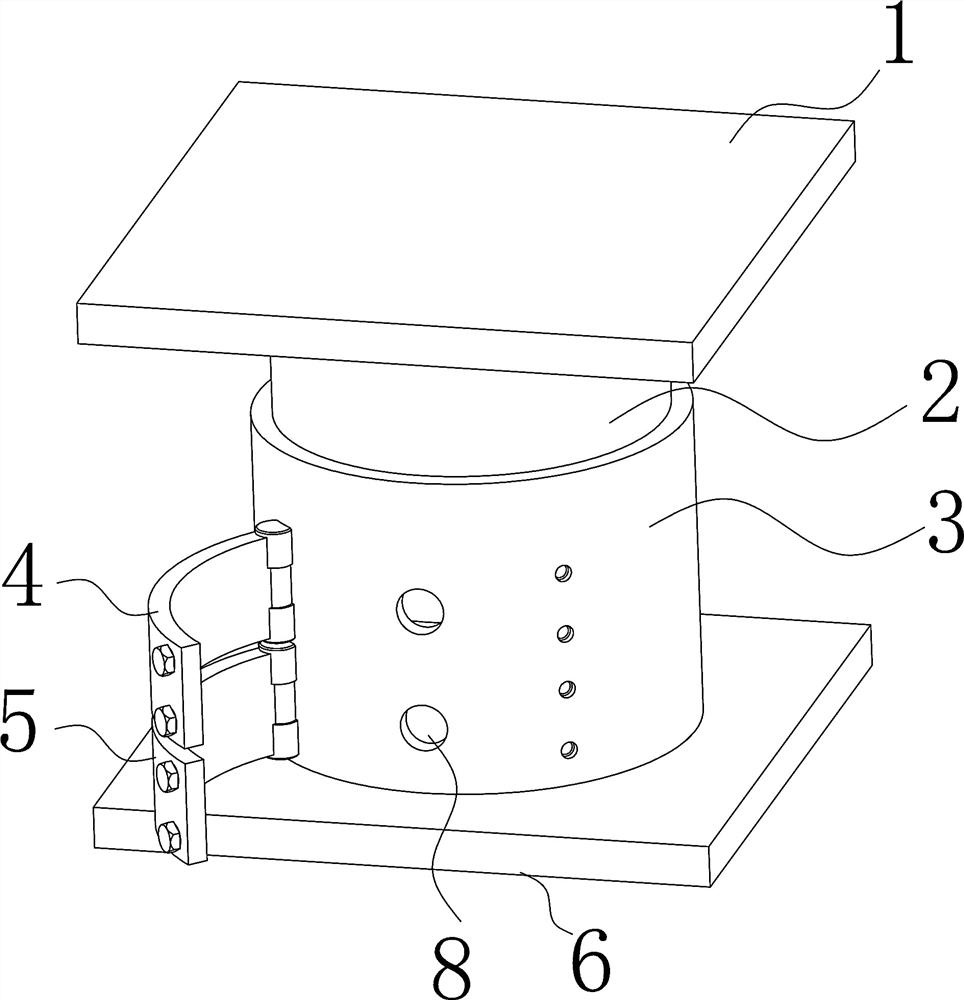

[0030] Such as Figure 1~9 As shown, a graded unloading sand box includes a top plate 1 and a bottom plate 6, the lower surface of the top plate 1 is provided with an inner vertical plate 2, the bottom plate 6 is provided with an outer vertical plate 3, and the inner vertical plate 2 is set on the outer vertical plate 3 Inside, a plurality of material leakage holes 8 are provided on the outer vertical plate 3, and a baffle plate is arranged outside the material leakage hole 8, one end of the baffle plate is hinged with the outer vertical plate 3, the other end is clamped with the outer vertical plate 3, and an auxiliary The discharge device 9, the auxiliary discharge device 9 is stuck on the leakage hole 8, the auxiliary discharge device 9 is provided with a screw shaft 902, the end of the screw shaft 902 is connected with the motor 904, and the rotation of the motor 904 drives the screw shaft 902 to rotate the inner Riser 2 internal material output. The lower outer vertical ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com