Double-sided flow field for polar plate for improving material distribution uniformity of fuel cell

A technology with uniform distribution and fuel cells, applied in fuel cell components, fuel cells, circuits, etc., can solve the problems of low material concentration, large flow resistance, and difficulty in discharging water droplets, so as to improve mass transfer efficiency and improve consistency. , the effect of small flow resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0029] 1. The bipolar plate is made of stainless steel sheet, and the groove is formed on the front and back of the stainless steel plate by stamping process.

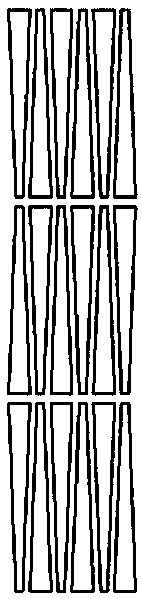

[0030] 2. The pole plate proves that the flow field is set with 3 sets of parallelogram grooves in the horizontal direction and 3 sets of parallelogram grooves in the vertical direction, arranged in a matrix, such as figure 2 , the longitudinal staggered spacing is 4.5mm; the isosceles trapezoidal groove, the waist length is 40mm, the short side is 1.5mm, the short side section depth is 0.5mm, the long side is 4.5mm, and the long side section depth is 0.5mm; the reverse flow field plane is a parallelogram groove The short side of the groove is 1.5mm, and the long side is 40mm.

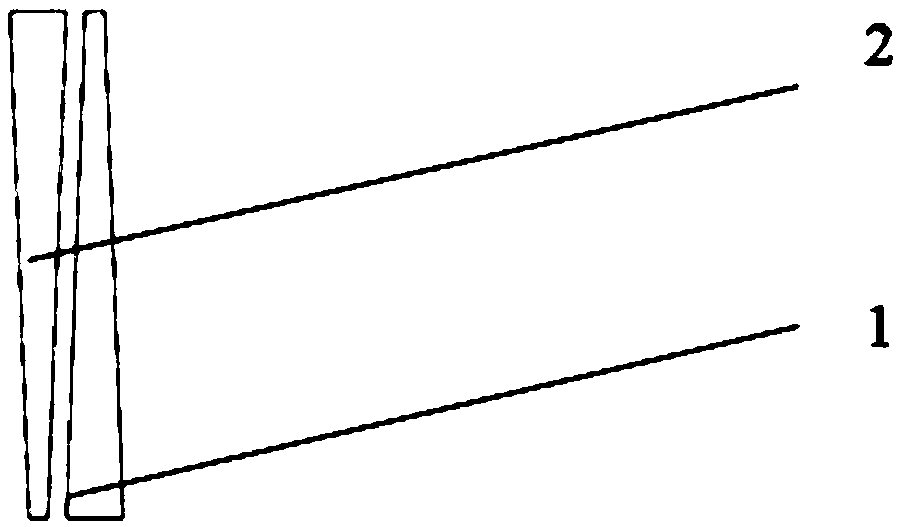

[0031] 3. The cross-sectional area of the channel on the long side of the trapezoid is larger than that on the short side of the trapezoid. The velocity of the fluid entering the channel on the short side of the trapezoid increases and the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com