Cigarette heating device

A heating device and cigarette technology, applied in tobacco, pipe, application, etc., can solve the problems of inability to guarantee air and smoke storage, inability to achieve better heat insulation effect, poor user experience, etc., to improve user experience, The effect of reducing heat transfer and reducing contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

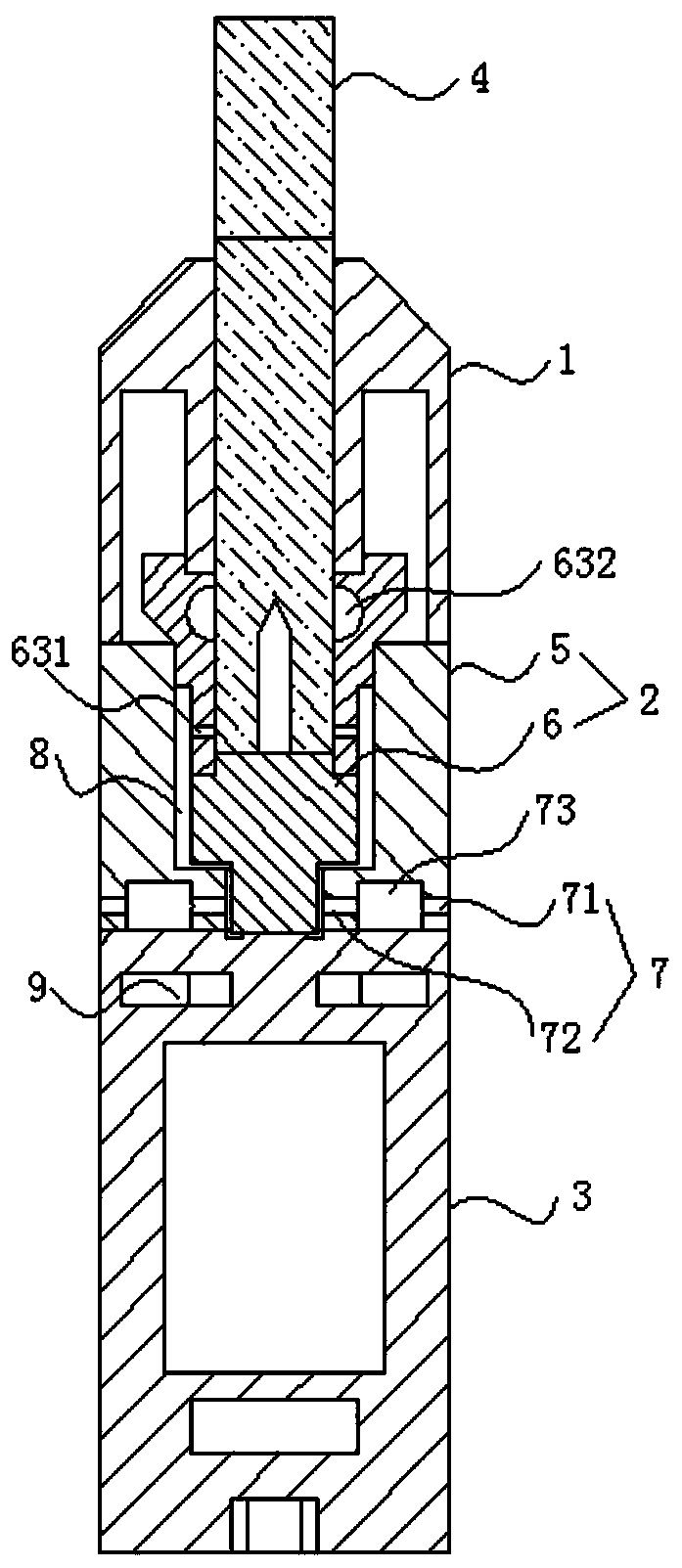

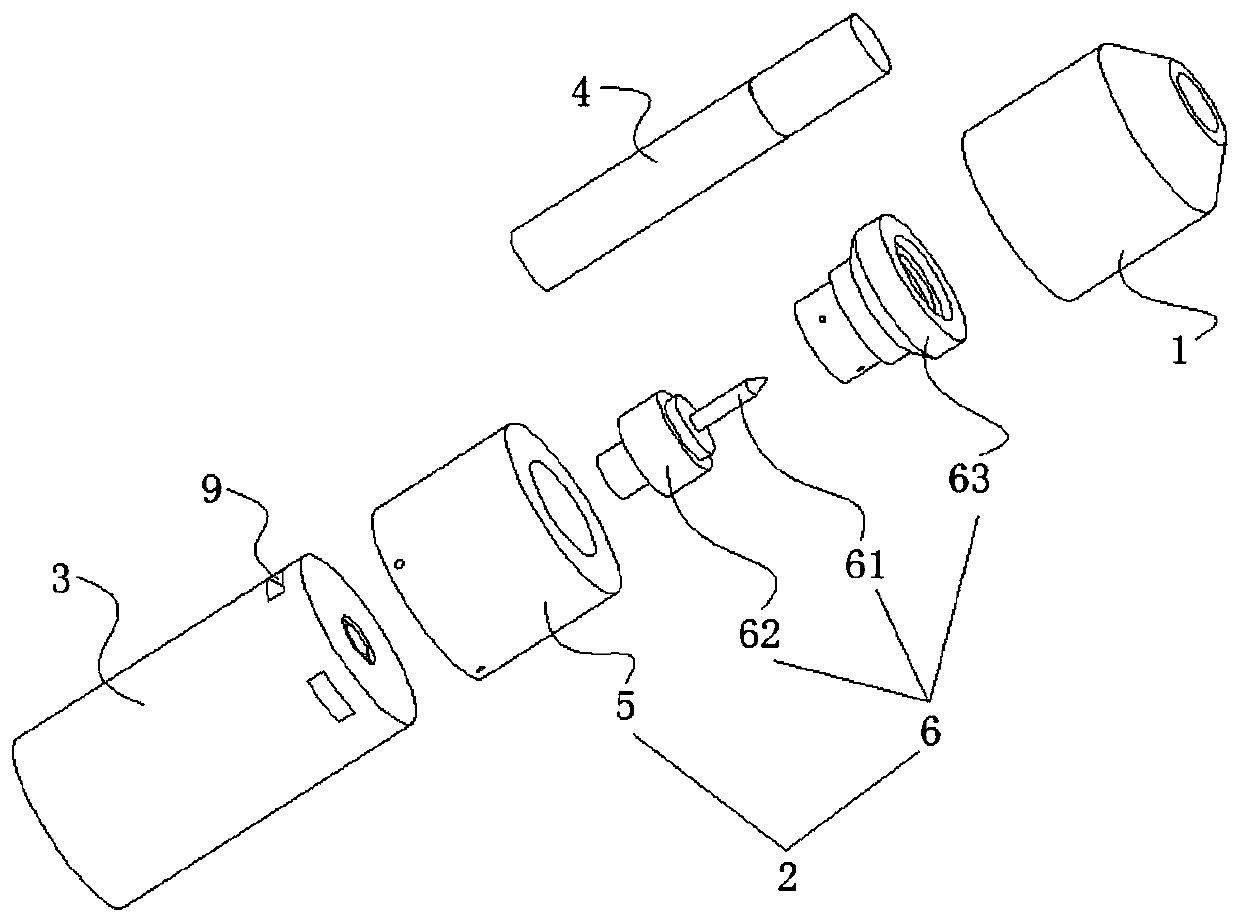

[0026] Such as Figure 1-2 As shown, this embodiment provides a cigarette heating device, which includes a cigarette holder 1, a heating chamber 2 and a base 3 connected in sequence, the top of the heating chamber 2 communicates with the cigarette holder 1, the heating chamber 2 is connected with a power supply device, and the power supply device is set on base 3. Specifically, the power supply device includes a rechargeable battery connected in series, a power adapter and a charging interface, the charging interface is a micro USB interface, and the charging interface can be arranged on the bottom surface of the base 3 .

[0027] Wherein, the heating chamber 2 includes a casing 5 and a heating assembly 6 for heating and roasting the cigarettes 4, and the heating assembly 6 is electrically connected with a power supply device.

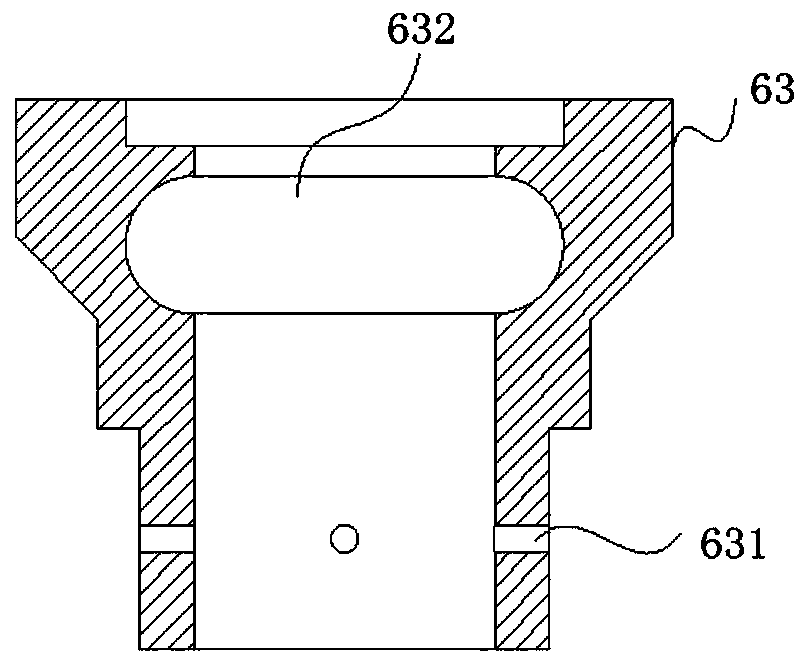

[0028] Specifically, as Figure 4 As shown, the housing 5 is a hollow structure, which is arranged around the outside of the heating component 6, le...

Embodiment 2

[0034] Such as Figure 5 As shown, this embodiment also provides a cigarette heating device. The structural principle is similar to that of Embodiment 1. The channel 7 directly connects the air gap 8 inside the heating chamber 2 with the external environment, and is used for air to enter and exit the heating chamber 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com