Electric-motor-driven liquid pump

一种流体泵、电动机的技术,应用在电动组件、径向流动泵、机器/发动机等方向,能够解决限制等问题,达到容易输送的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

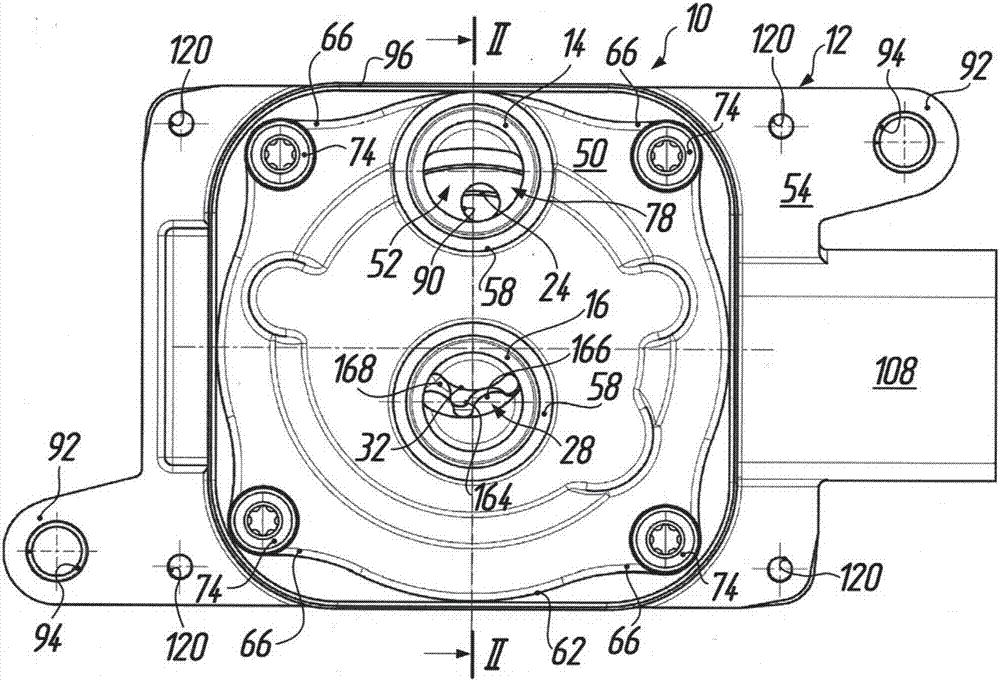

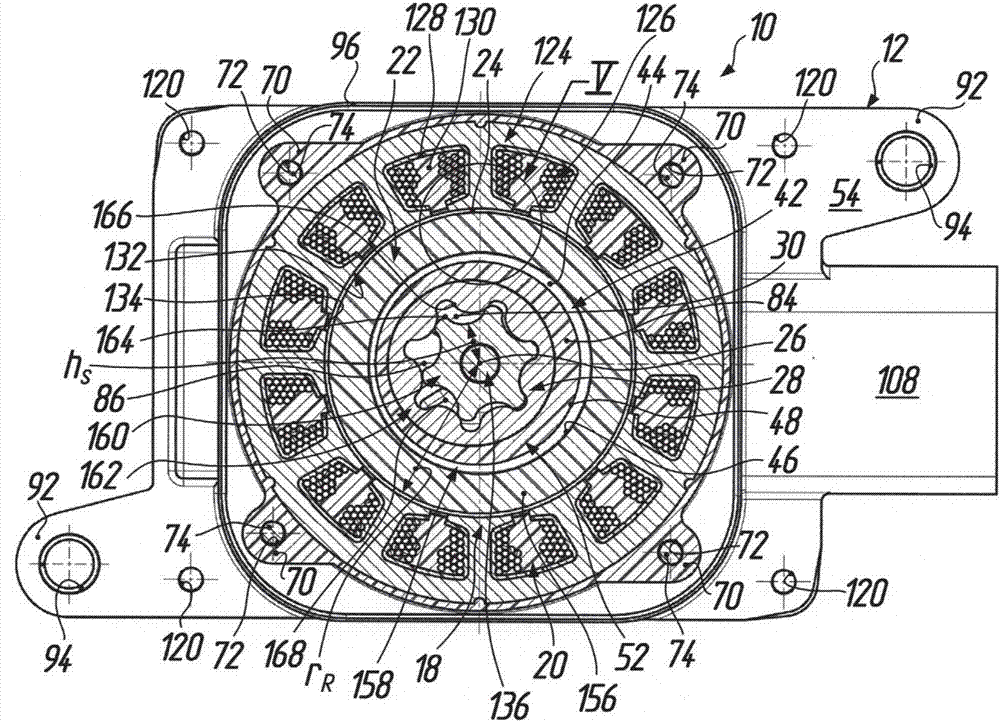

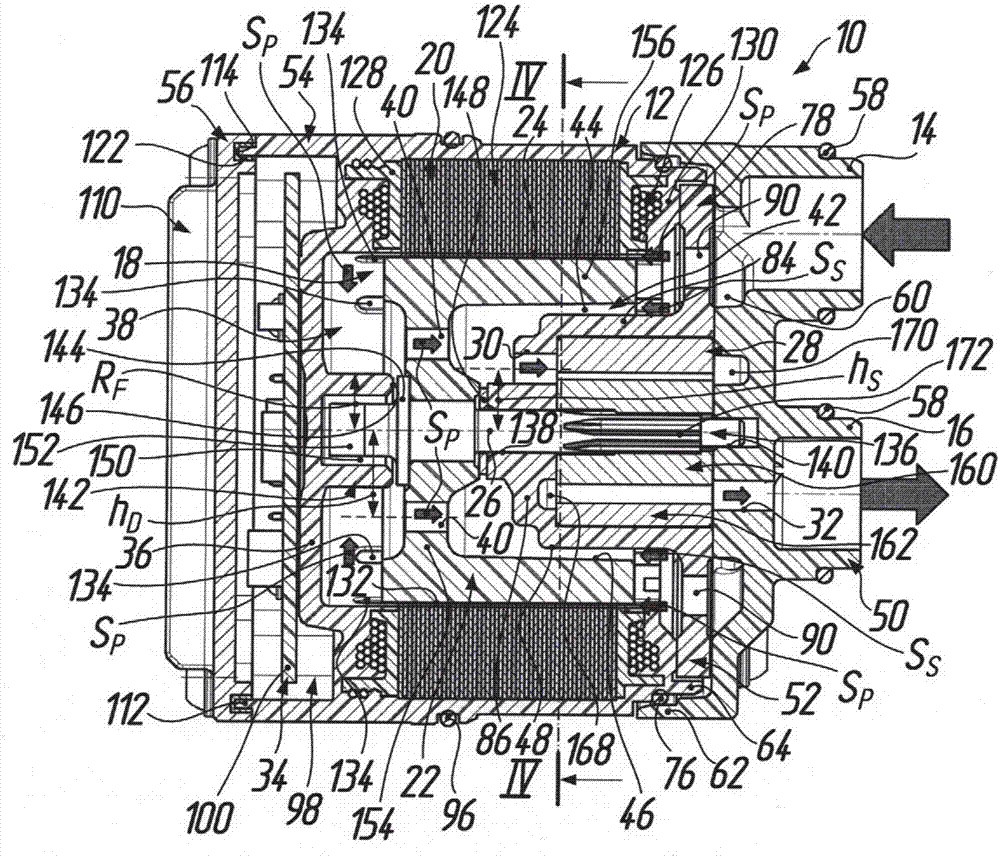

[0035] In the figures, reference numeral 10 generally designates an electric motor-driven fluid pump usable in or at a transmission of a motor vehicle, in particular as an oil pump for cooling and / or lubrication. The fluid pump 10 includes a housing generally designated by reference numeral 12 having a suction connection 14 and a pressure connection 16 . Specifically, as figure 2 As shown, an electric motor 18 is disposed within a housing 12 and includes a stator 20 and an inner rotor 22 located at the housing. A rotor 22 is accommodated within the stator 20 with an annular gap 24 therebetween and is driven in rotation about an axis of rotation 26 . exist figure 2 with Figure 4 28, the delivery device is generally designated by reference numeral 28, said delivery device 28 has a suction port 30 fluidly connected to the suction connection 14 of the housing 12 and a pressure outlet 32 fluidly connected to the pressure connection 16 of the housing 12, The conveying devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com