Air-cooled hydrogen fuel cell based on single metal polar plate and electric pile

A metal plate, fuel cell technology, used in fuel cells, fuel cell additives, fuel cell heat exchange, etc., can solve the problems of complicated bipolar plate manufacturing, improve the effective contact area, simplify the complexity, structure and System compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

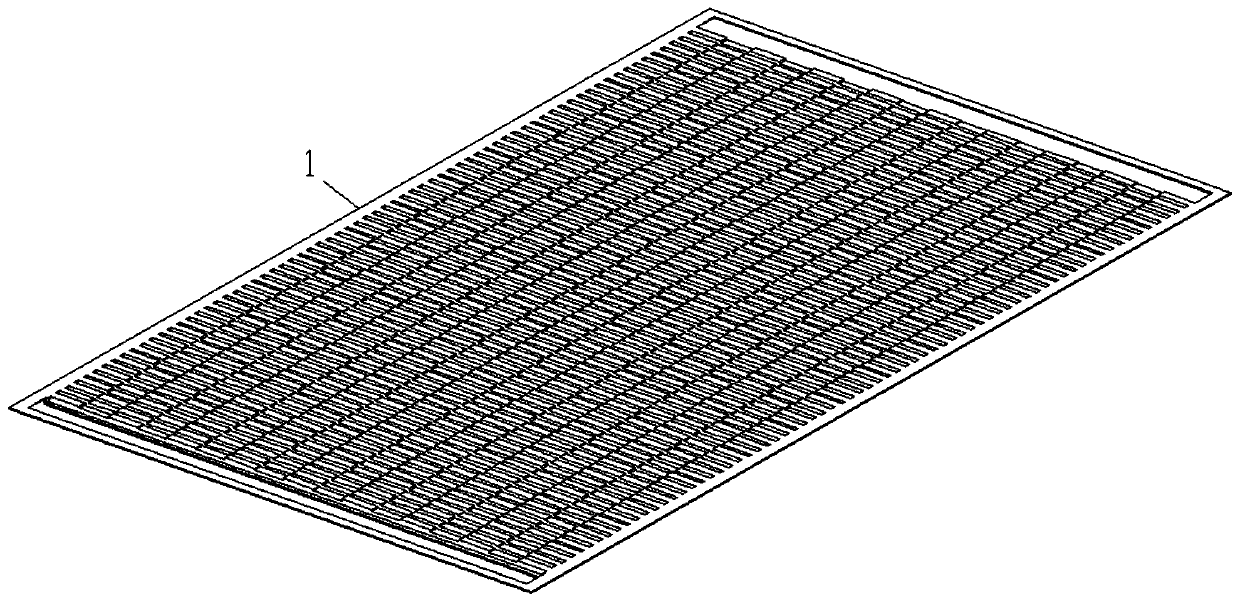

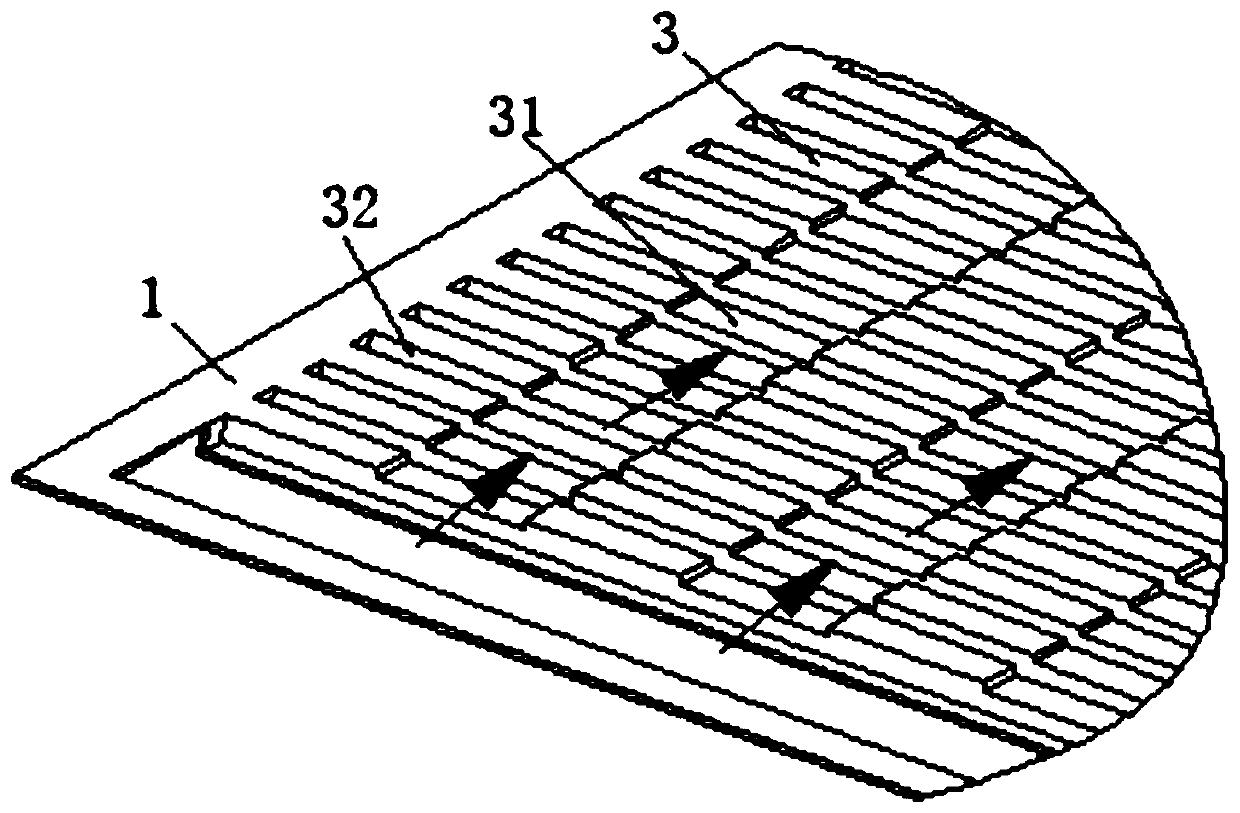

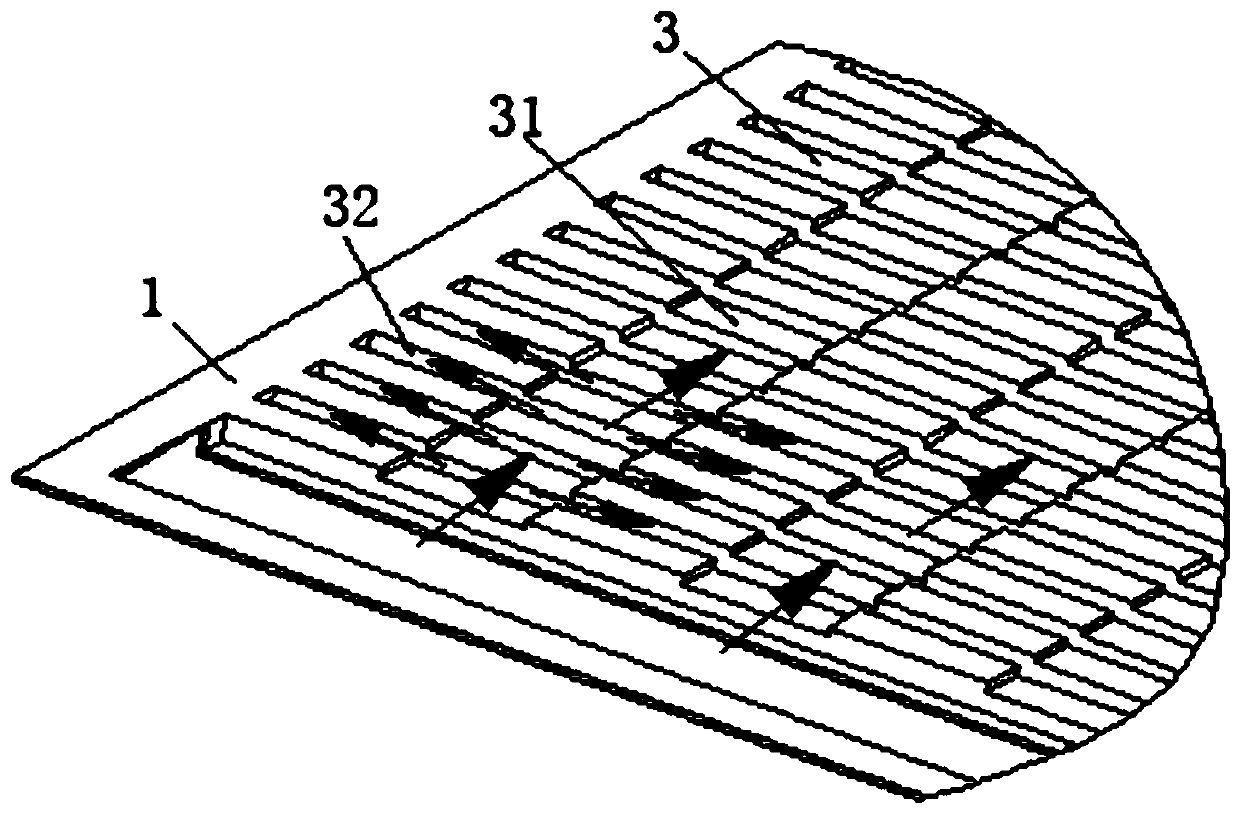

[0032] An air-cooled hydrogen fuel cell based on a single metal plate, such as Figure 1-Figure 4 As shown, it includes a metal pole plate 1 and a reaction flow channel. The metal pole plate 1 is a single-piece metal pole plate, and the single-piece metal pole plate is used as a separator for the reaction gas, which is used for collecting and transporting the reaction gas. Function; both sides of the metal pole plate 1 are flow spaces for air and hydrogen respectively; one side of the metal pole plate 1 is the cathode gas reaction flow channel 2 and the cooling medium flow channel, and the cathode gas reaction flow channel 2 and the cooling medium flow channel The medium flow channel is the same flow channel, which simplifies the structure of the fuel cell; the gas in the cooling medium device and the circulating air medium can not only provide the oxygen required for the reaction to the membrane electrode 4, but also can take the heat generated by the reaction out of the fuel ...

Embodiment 2

[0040] On the basis of Embodiment 1, there is also a stack, such as Figure 5 As shown, a single cell is included, and the single cell is the above-mentioned air-cooled hydrogen fuel cell based on a single metal plate.

[0041] The single cell also includes a membrane electrode 4, and the membrane electrode 4 is located between adjacent metal pole plates 1, and the metal pole plates 1 are stacked alternately, and after a plurality of metal pole plates 1 are stacked together , forming the inlet channel for hydrogen. The anode gas reaction channels 3 and the cathode gas reaction channels 2 are arranged alternately. The single cells are stacked together, and the widths of the hydrogen and oxygen sides are set differently to ensure that the two sides of the yellow membrane electrode are hydrogen and oxygen respectively, so that the reaction can proceed.

[0042] There are multiple single cells, and the multiple single cells are connected in series. The batteries are connected in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com