Ignition and low-load stable combustion burner for fluidized bed boiler

A fluidized-bed boiler and burner technology, applied in the field of combustion, can solve the problems of cold-state ignition and low-load stable combustion of fluidized-bed boilers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention provides a burner for ignition and low-load stable combustion of a fluidized bed boiler. The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

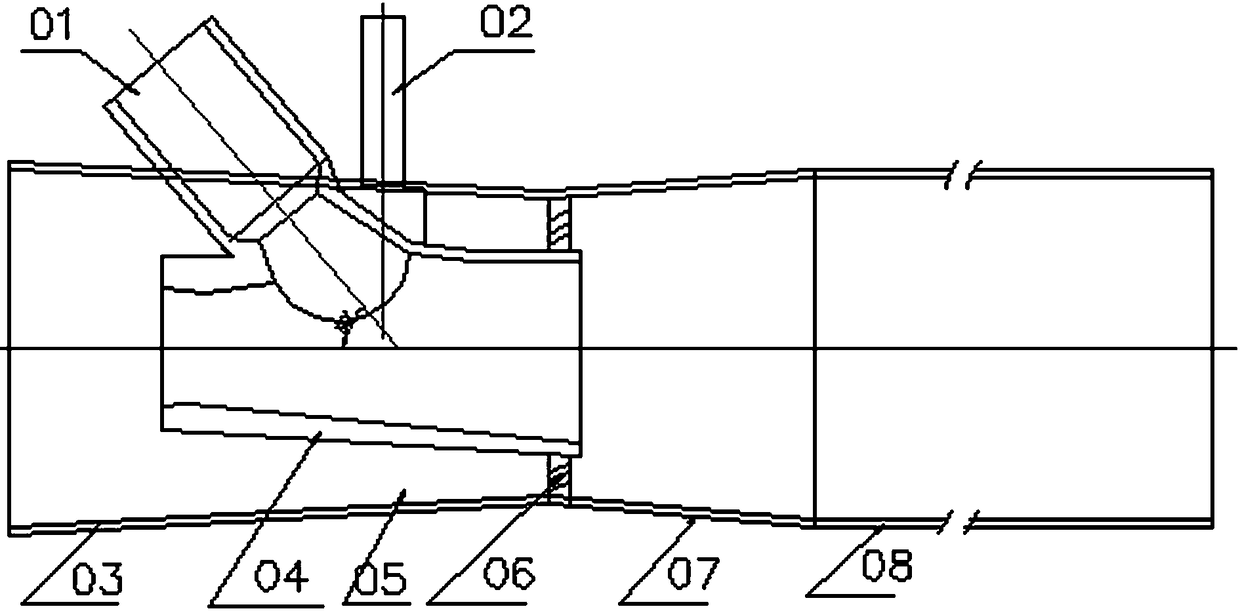

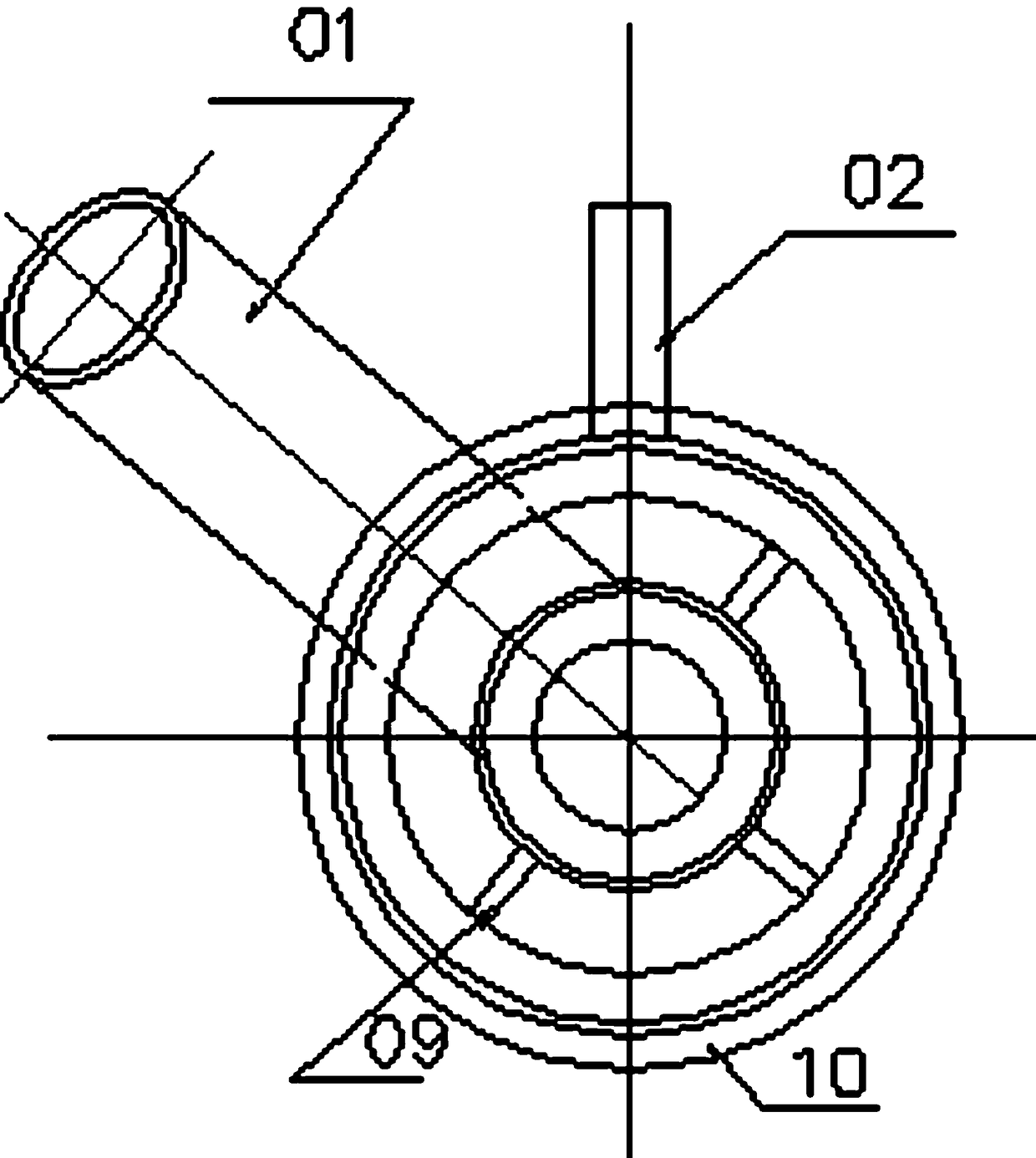

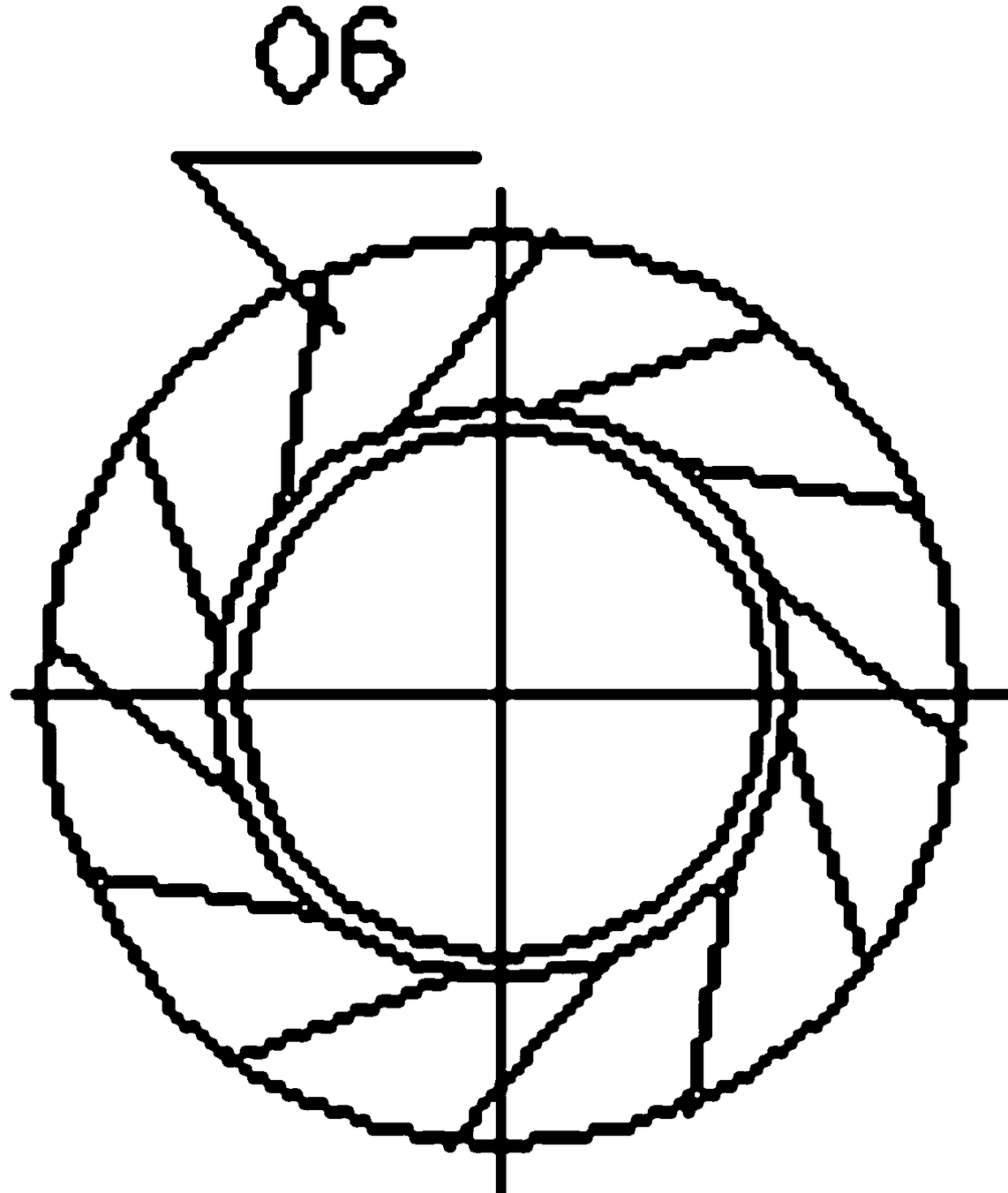

[0021] figure 1 It is a schematic diagram of the principle structure of the burner, and the burner is mainly composed of 10 parts. The ignition device and the oil combustion chamber 01 are designed as one body. The oil combustion chamber 01 and the secondary oil combustion chamber 04 are connected through 40-55º. The secondary oil combustion chamber 04 and the tapered section 03 are arranged coaxially and horizontally. A fire detection device 02 is installed at the connection with the secondary oil combustion chamber 04 to detect flame ignition and serve as a control signal for fuel oil, cold air flow rate control and fire protection protection. Design swirl blades 06 at the outlet end of the secondary oil combustion chamber...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com