Efficient and safe low-calorific-value waste gas burner

A technology of waste gas combustion and low calorific value, which is applied in the direction of gas fuel burners, combustion chambers, burners, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

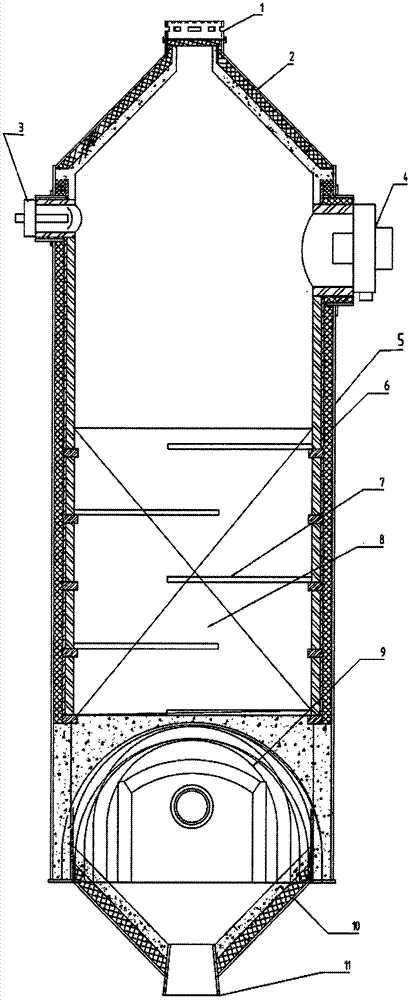

[0009] An efficient and safe low calorific value waste gas combustion furnace of the present invention is mainly composed of (2) upper cone, (3) high calorific value burner, (4) low calorific value burner, (5) furnace body, (6) insulation layer, ( 7) baffle plate, (8) lattice brick, (9) arch ring, (10) lower cone form.

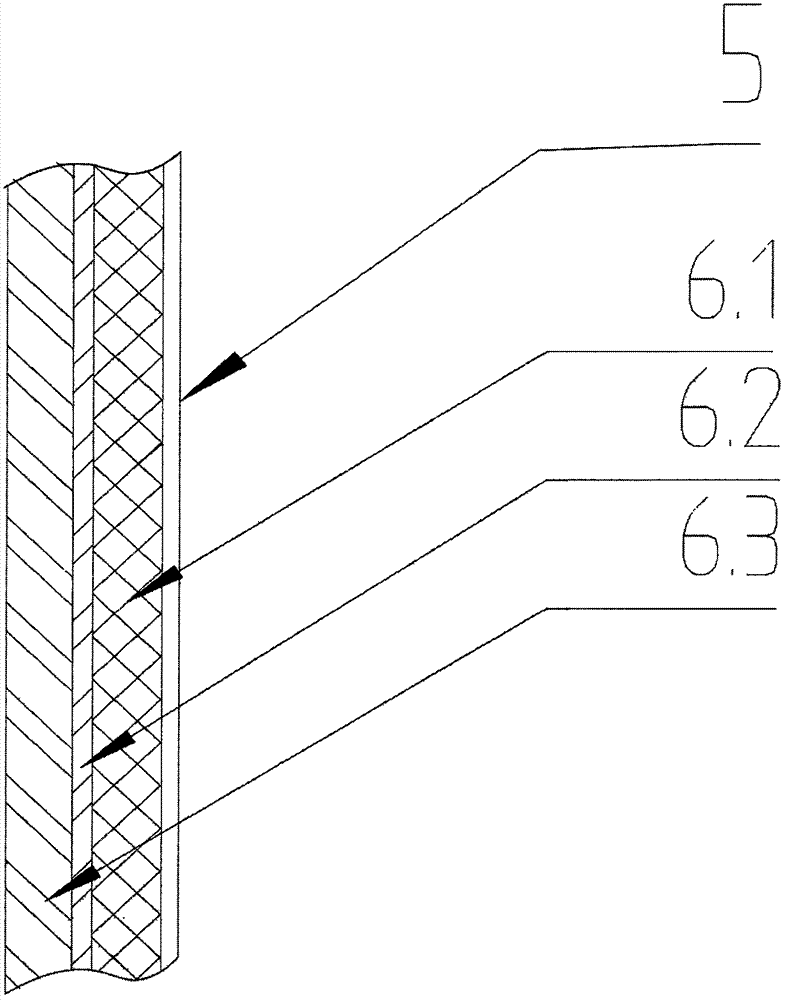

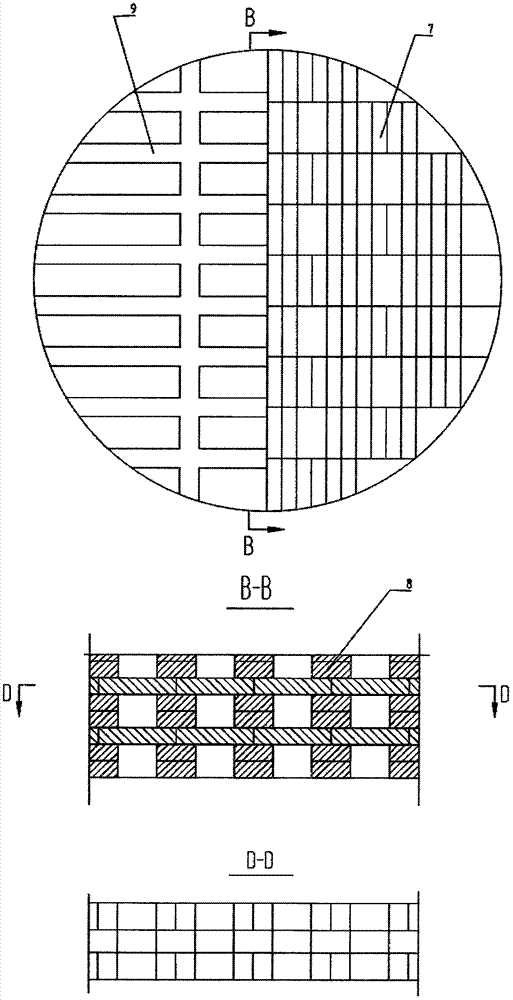

[0010] A specific embodiment of the present invention is: a high-efficiency and safe low calorific value waste gas combustion furnace is a three-dimensional tower structure composed of (10) lower cone, cylindrical (5) body of furnace and (2) upper cone, (2) ) the upper cone, (10) the lower cone and (5) the interior of the furnace body (6) insulation layer, (6) insulation layer is a composite structure consisting of (6.1) heat-resistant high-alumina bricks, (6.2) heat-insulating bricks, (6.3) Composed of aluminum silicate insulation cotton, which can minimize heat loss. The heat storage layer is composed of (7) baffles, (8) checker bricks, (9) arch rings, and (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com