Oxygen enriching and magnetizing device of air duct of internal combustion engine

A technology of magnetization device and air intake channel, which is applied in the direction of internal combustion piston engine, combustion air/combustion-air treatment, combustion engine, etc., can solve the problem of insufficient combustion of the mixture gas of internal combustion engine, and achieve the problem of sluggish start and increase the combustion rate , the effect of particle reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

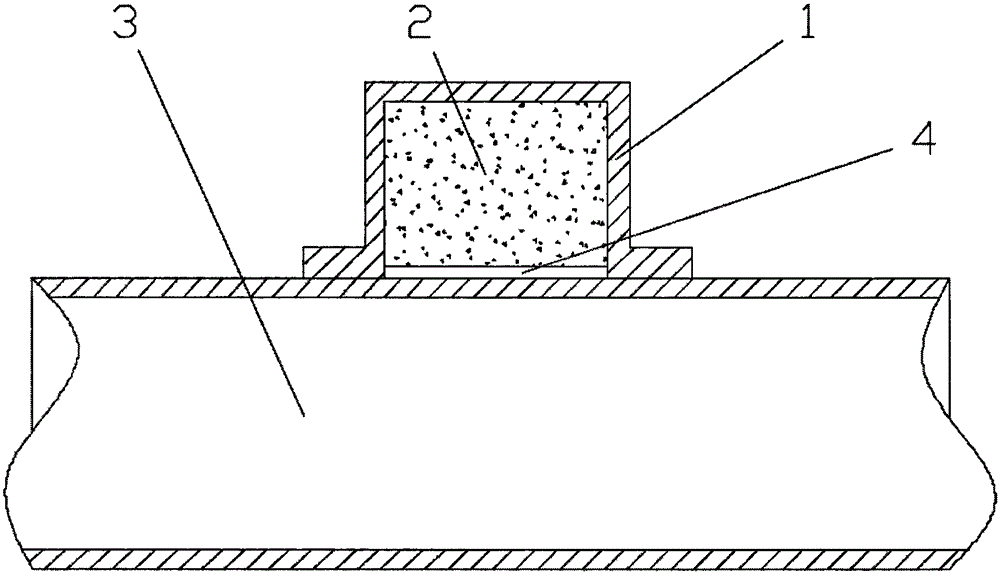

[0028] Embodiment one: if figure 1 Shown:

[0029] The device can be installed outside the pipeline 3 through an external installation method. The device includes a permanent magnetic material 2 and a magnetic isolation cover 1. The permanent magnetic material 2 is wrapped in the magnetic isolation cover 1. There is a side surface on the magnetic isolation cover 1. The magnetic force acting surface 4 formed by the gap.

[0030] The permanent magnet material 2 can be samarium cobalt, neodymium iron boron, samarium iron nitrogen or electromagnet, but not limited to these materials.

[0031] The magnetic field strength of the permanent magnet material 2 is 10MT to 1500MT.

[0032] The operating temperature of the device is -40°C to 250°C.

[0033] The magnetic isolation cover 1 can affect the magnetic field distribution of the permanent magnet material, isolate the magnetic fields in other directions, and strengthen the magnetic field strength on the opening acting surface lef...

Embodiment 2

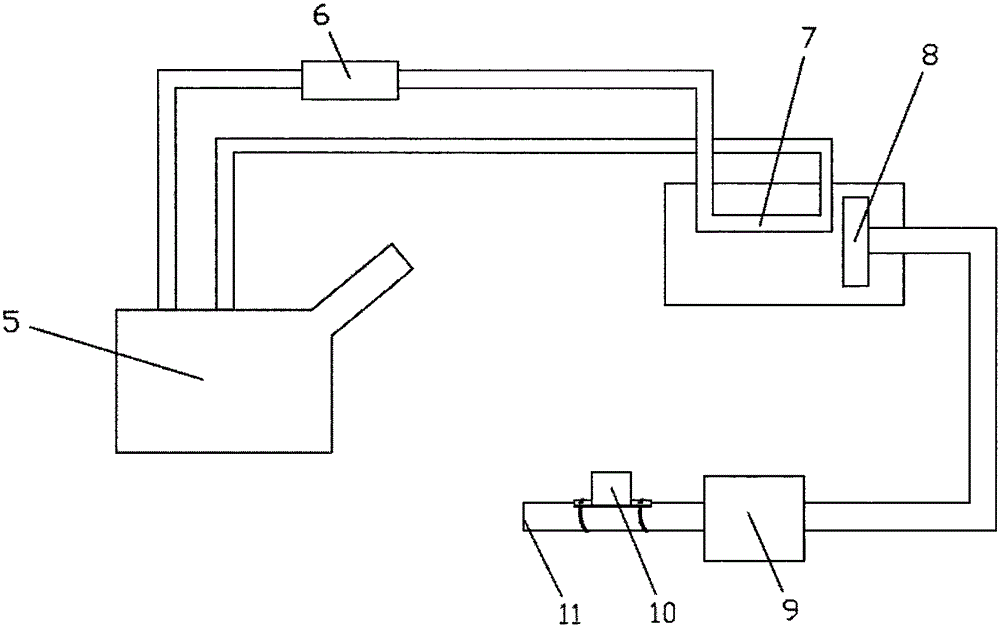

[0036] Embodiment two: if Figure 4 Shown:

[0037] The device includes a permanent magnetic material 2 and a magnetic isolation cover 1. The permanent magnetic material 2 is wrapped in the magnetic isolation cover 1. The magnetic isolation cover 1 is provided with a magnetic force acting surface 4 formed by a gap. The device can pass through a semi-embedded The installation method is that one part is installed inside the pipeline 3 and the other part is installed outside the pipeline 3 . The rest of the structure of the device is the same as in Embodiment 1.

Embodiment 3

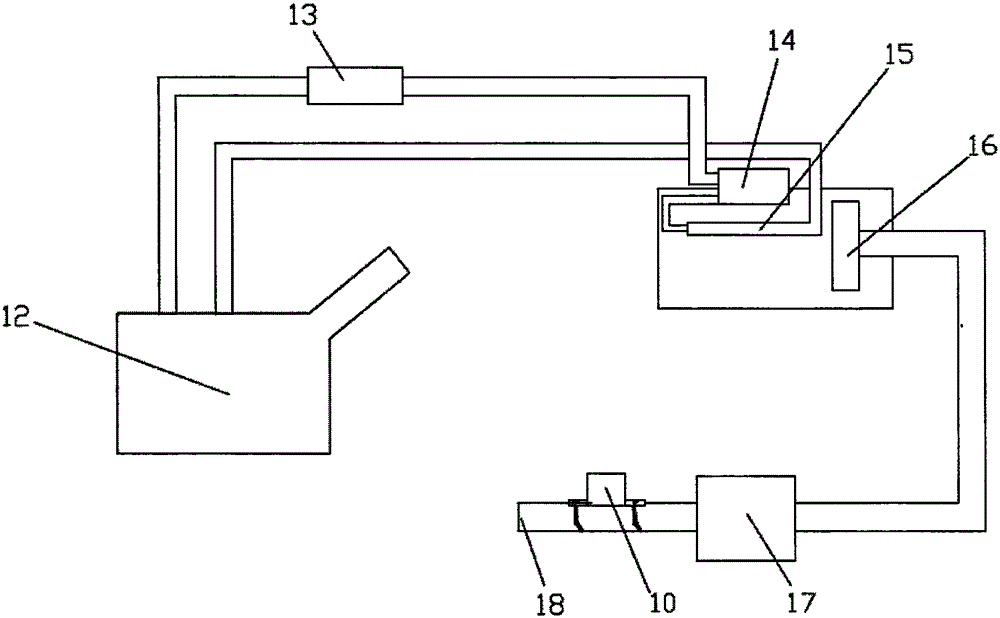

[0038] Embodiment three: as Figure 5 Shown:

[0039] The device includes a permanent magnetic material 2 and a magnetic isolation cover 1, the permanent magnetic material 2 is wrapped in the magnetic isolation cover 1, and the magnetic isolation cover 1 is provided with a magnetic force acting surface 4 formed by a gap. The device can be installed inside the pipeline 3 through a built-in installation method, and the rest of the structure of the device is the same as that of the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com