Vertical flashback type coal burning boiler

A technology for burning coal and boilers, which is applied in the field of vertical reverse combustion coal-fired boilers, can solve the problems of polluting the environment, low fuel utilization rate, and a large amount of black smoke, and achieves the effect of reducing the use cost and improving the fuel utilization rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

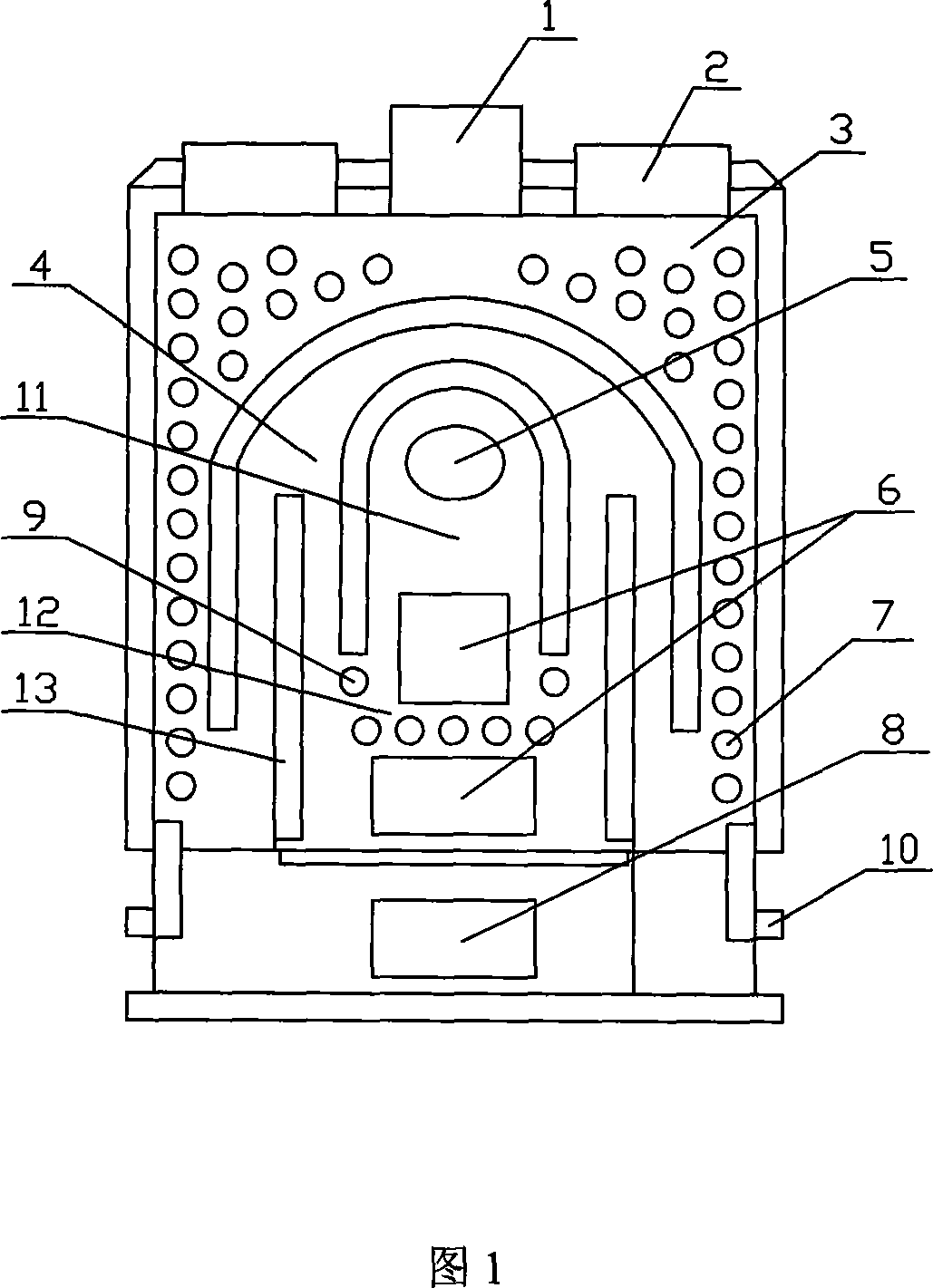

[0011] A vertical reverse combustion coal-fired boiler, the furnace body includes a gas generating chamber 11, a combustion chamber 4 and a burnout chamber 3, adopts the reverse combustion coal combustion method, the boiler furnace body is vertical, and the upper part of the furnace body is provided with a chimney 1 and two A dust removal door 2, the chimney 1 is located in the middle of the upper part of the furnace roof, and the dust removal door 2 is located on both sides of the upper chimney 1 of the furnace roof; the lower part is provided with a return pipe 10; the gas generating room 11 is provided with a coal storage bin 12 and a coal filling port 5 , two air inlets 6 and a slag removal outlet 8, the coal inlet 5 is in the middle of the front of the gas generating chamber 11; Above the coal bunker 12, the wind is directed downward to form rev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com