Patents

Literature

221results about "Grates" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

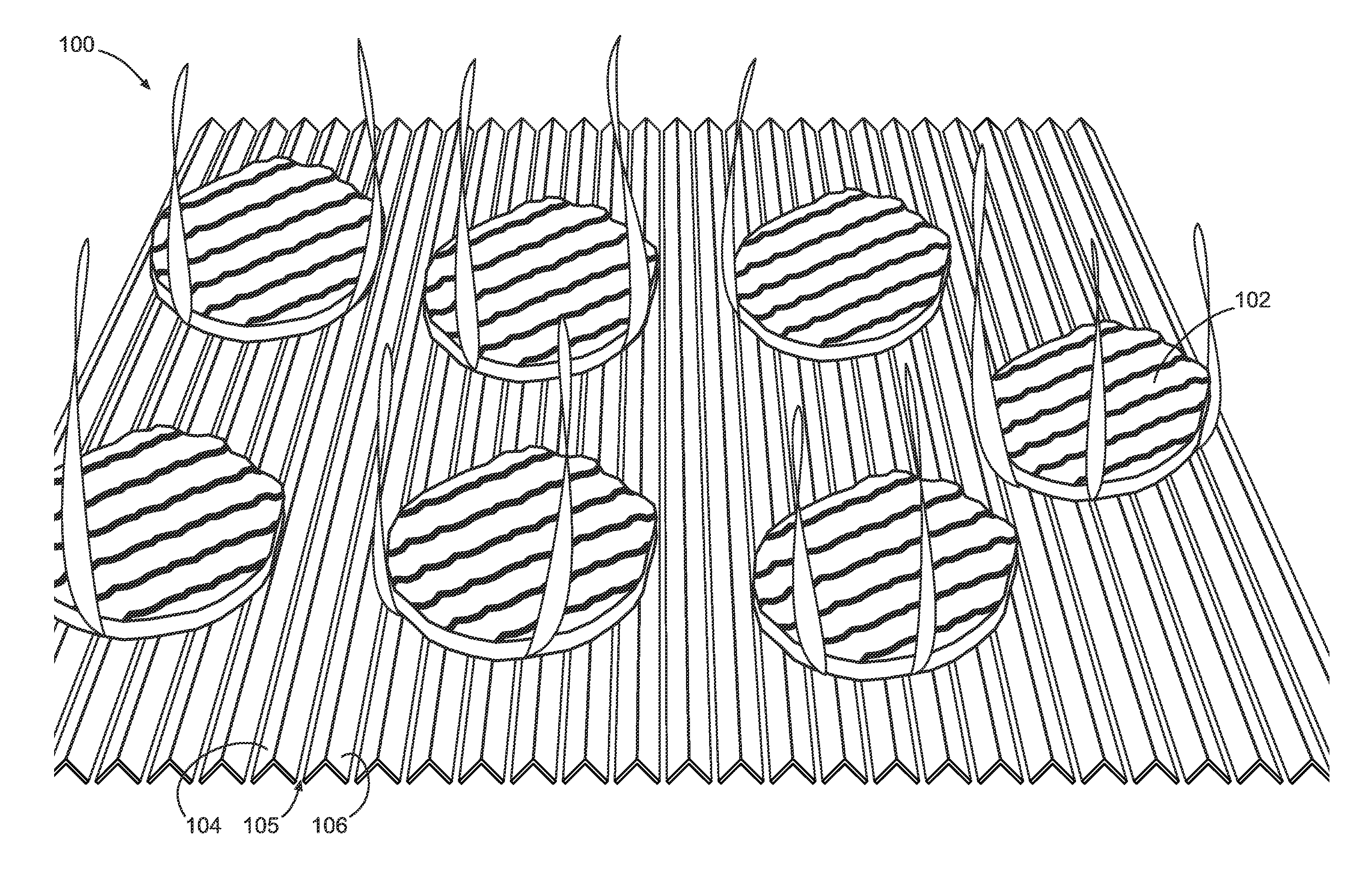

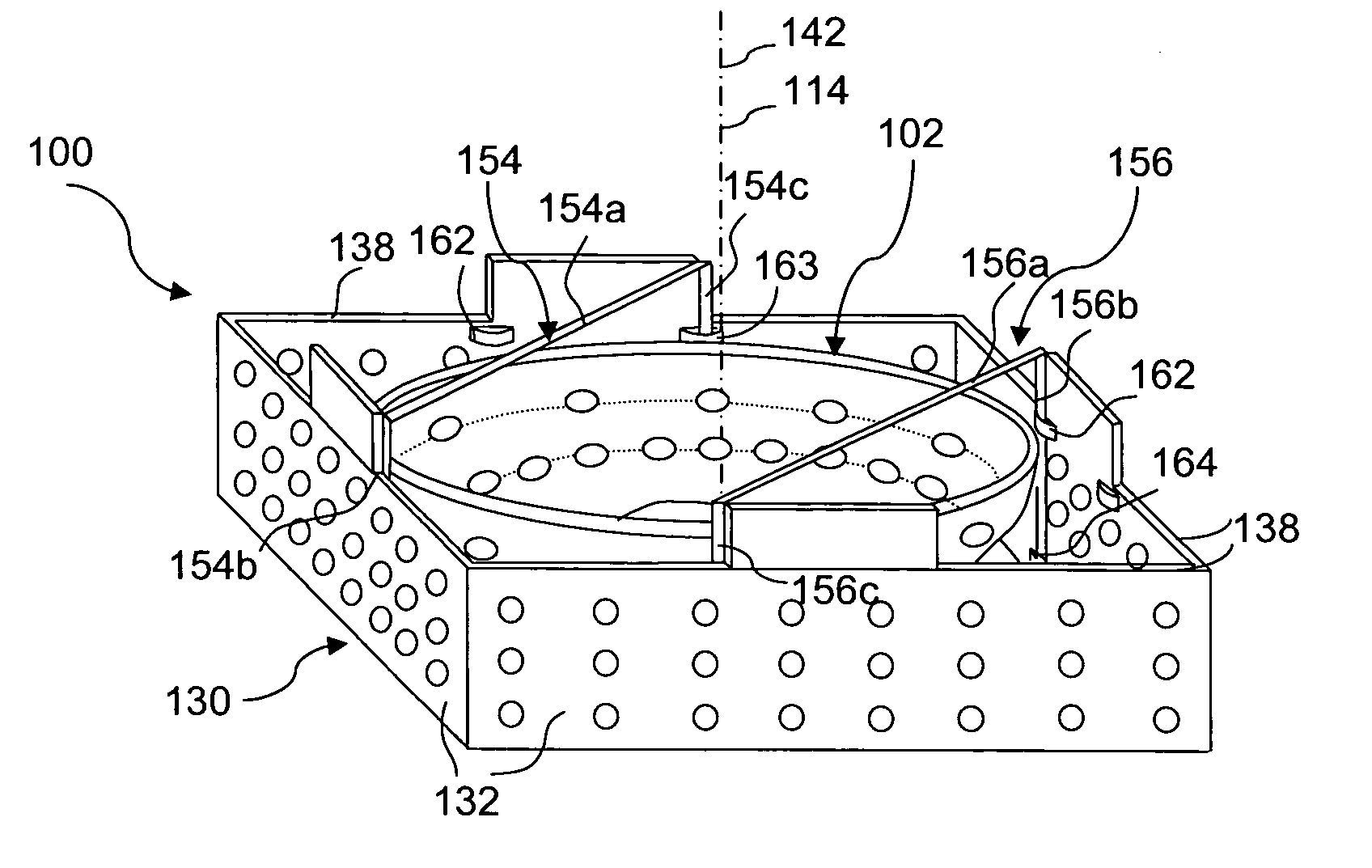

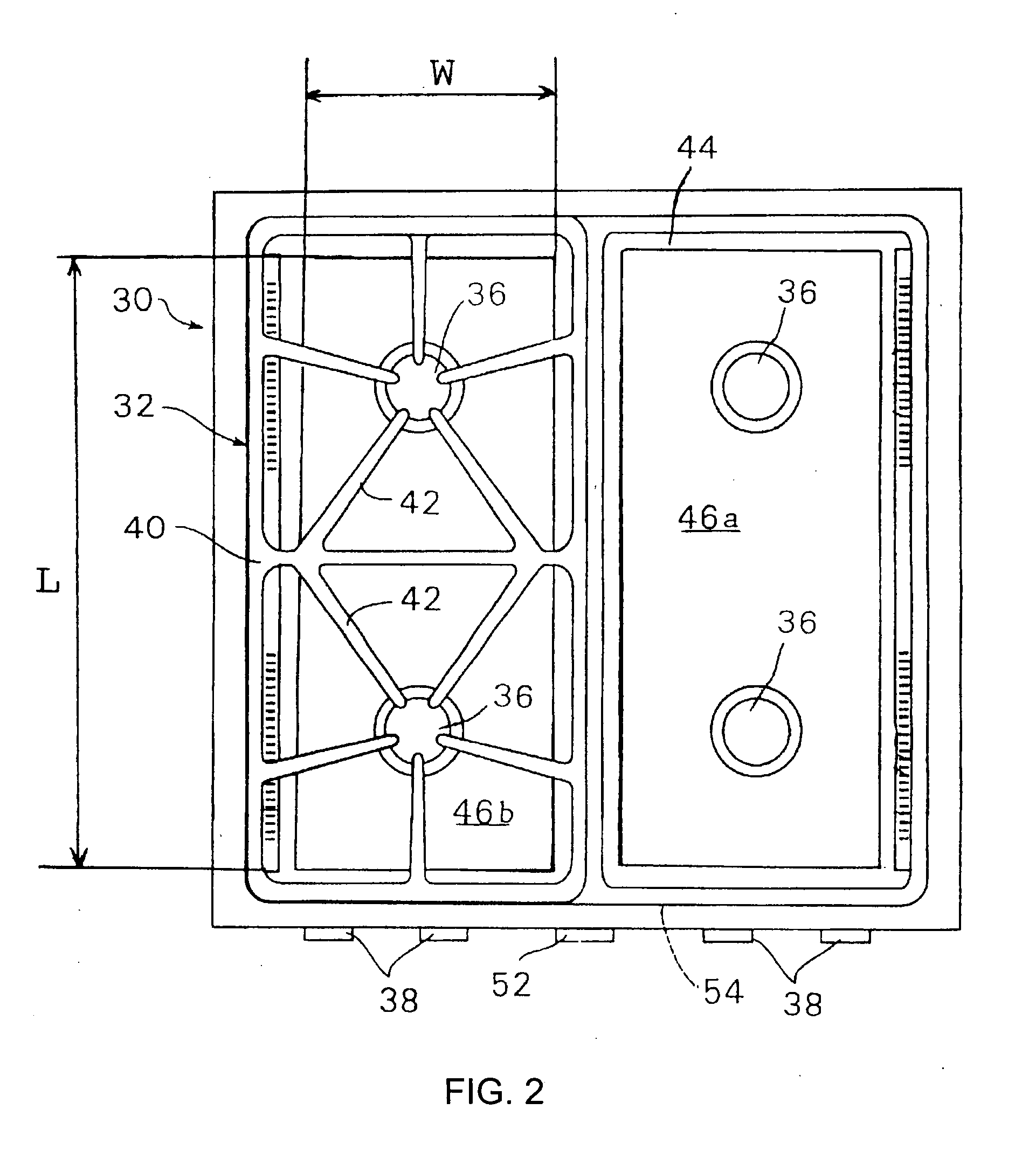

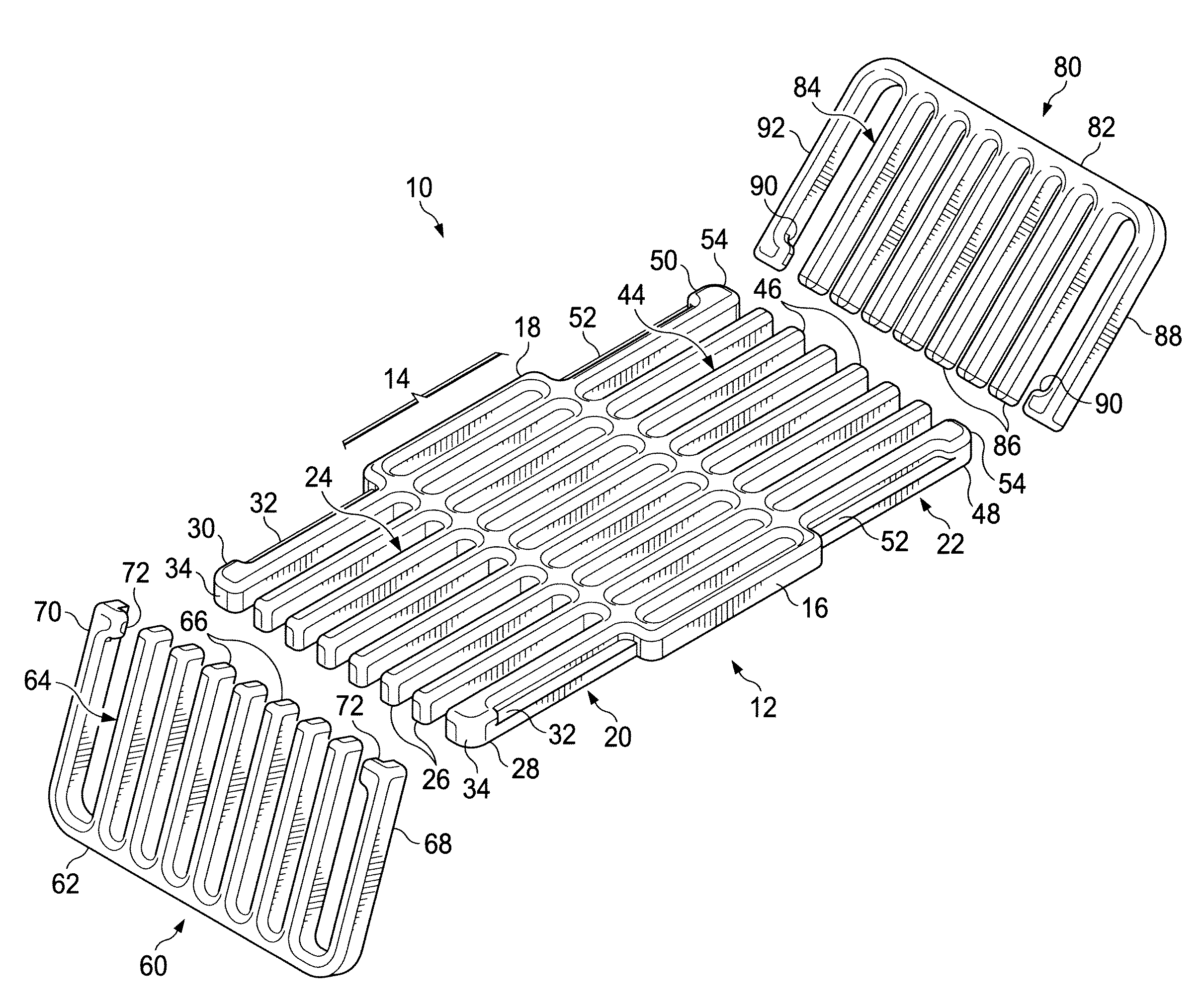

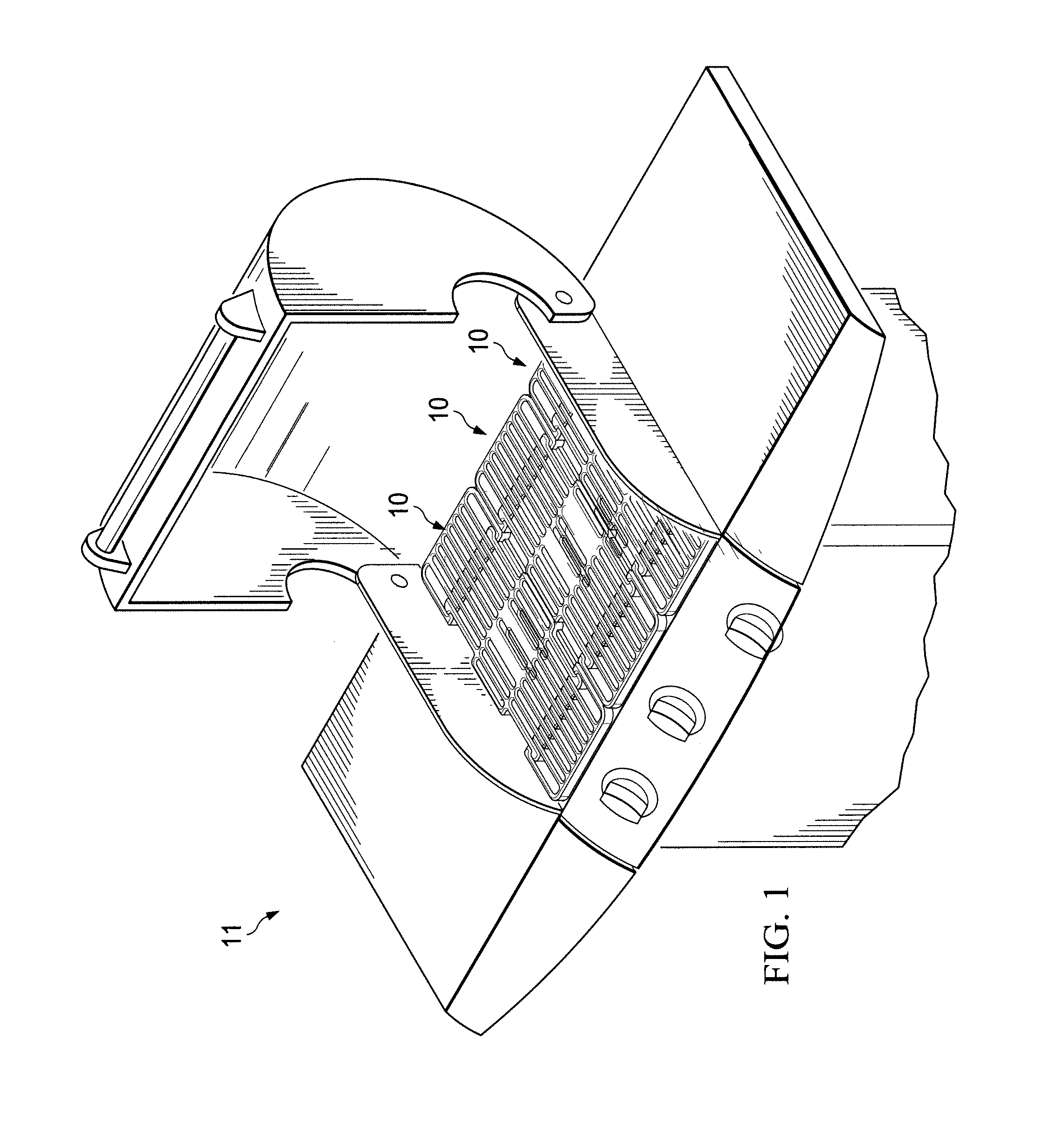

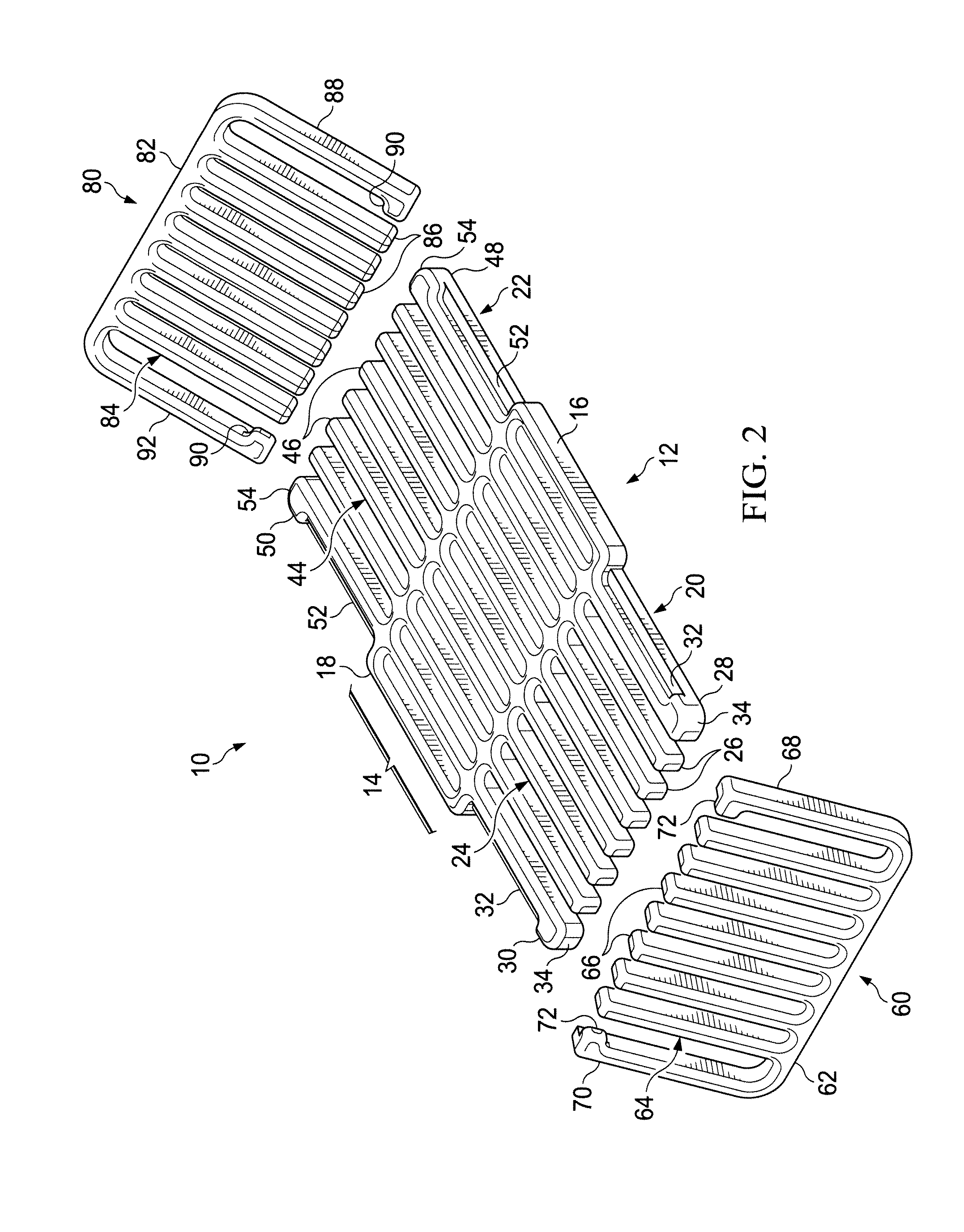

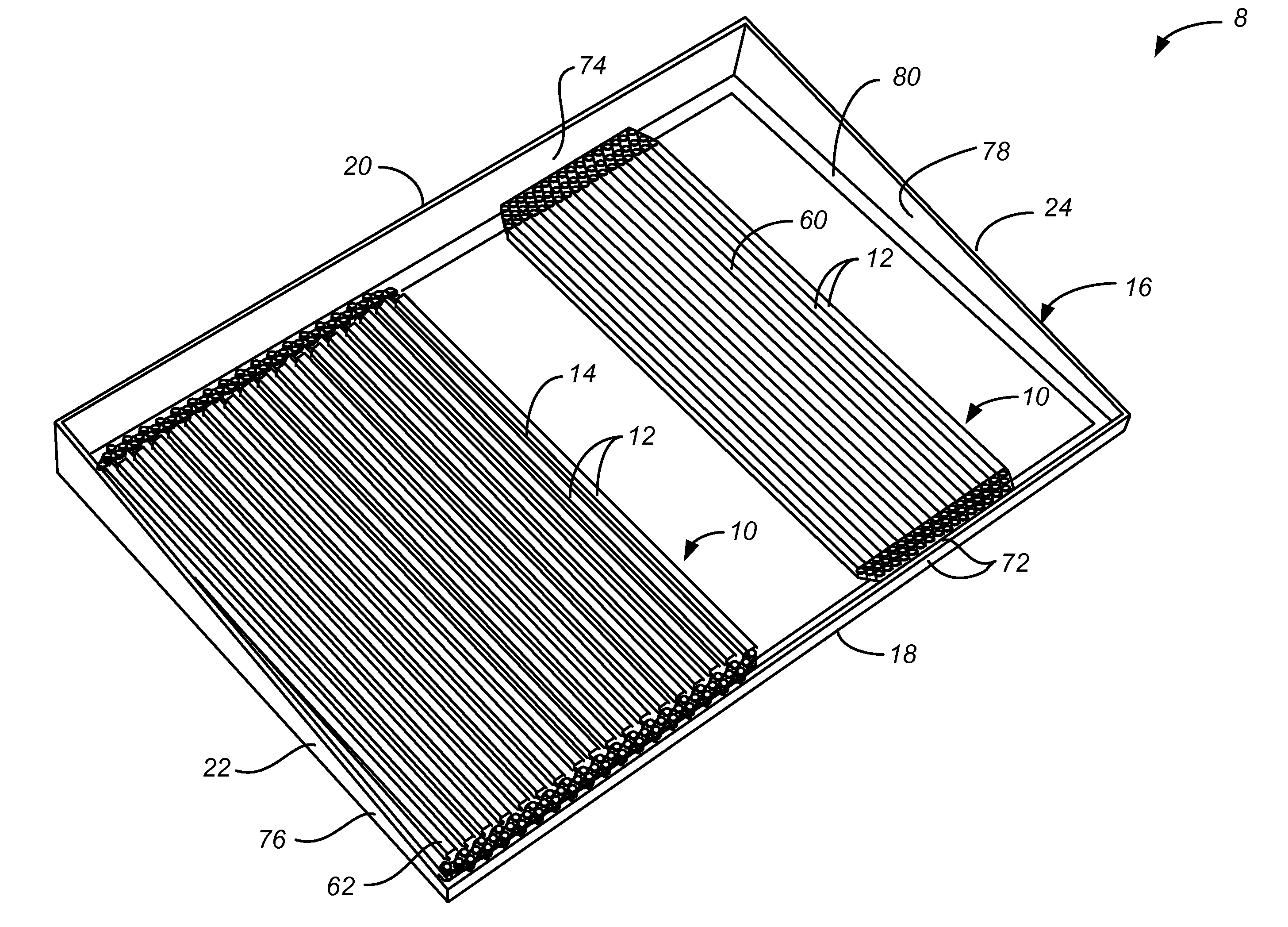

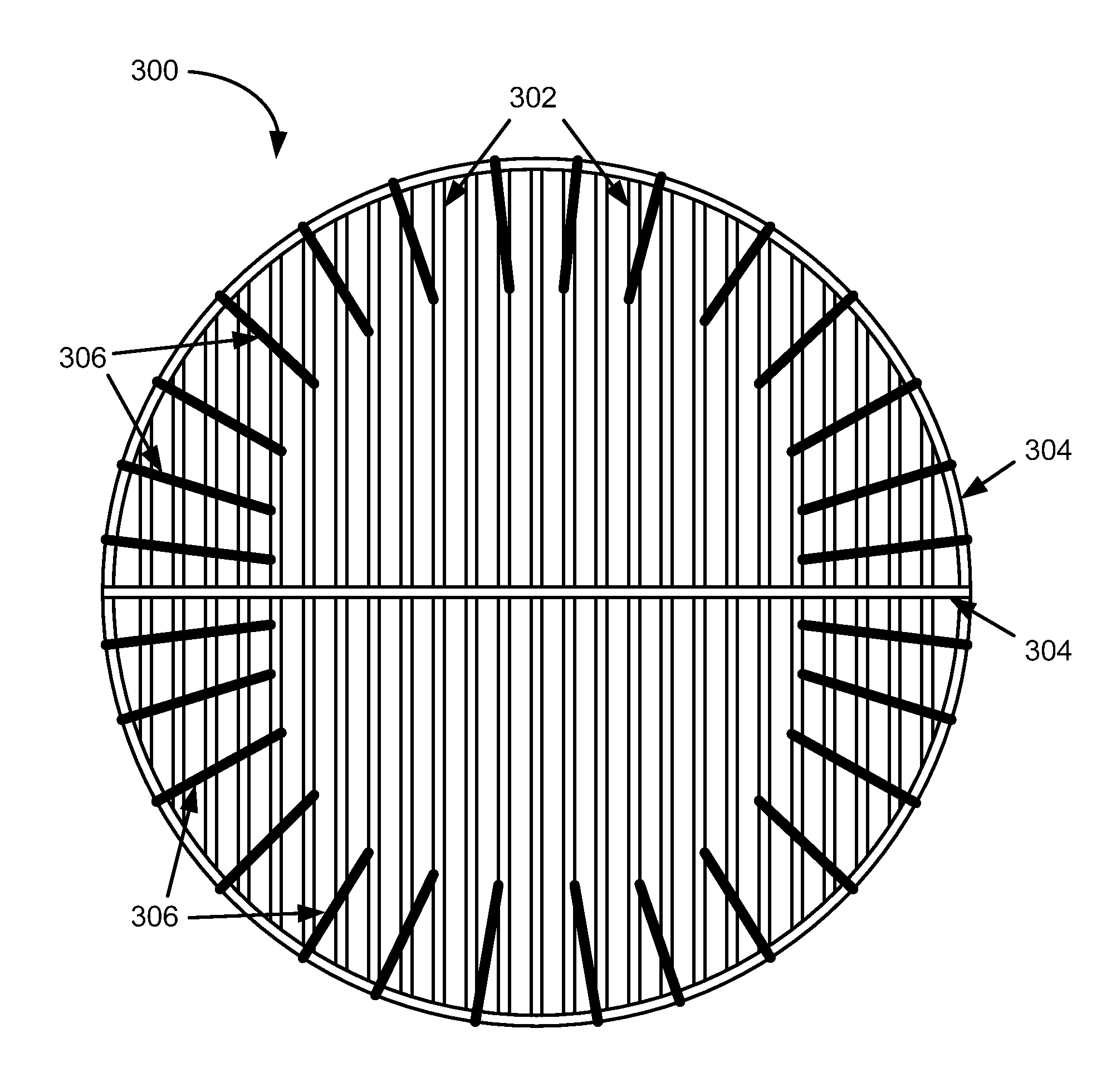

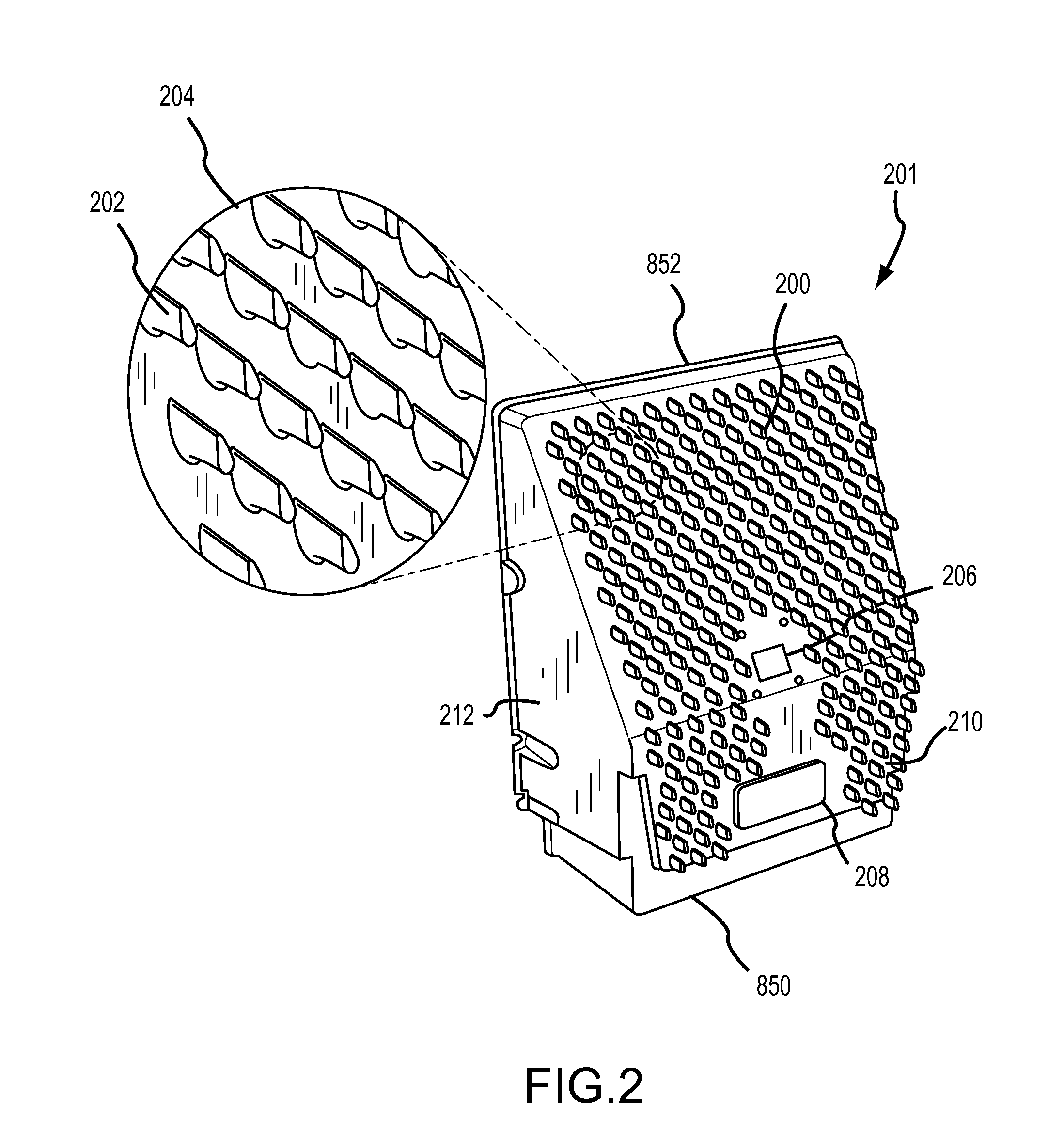

Cooking Grates and Grills Incorporating Such Grates

Cooking grates and grills incorporating such cooking grates are provided. A representative cooking grate includes: a plurality of elongate elements of heat resistant material, the elements being V-shaped in transverse cross-section, each of the elements having a first lower edge, a second lower edge and a vertex, the first lower edge and the second lower edge being spaced from each other with the vertex being located therebetween, the vertex being operative as a cooking surface to support food during cooking on the cooking grate; corresponding adjacent lower edges of adjacent ones of the elements being oriented to define gaps therebetween such that a first of the gaps, defined by a first lower edge of a first element and a second lower edge of a second element, exhibits a width of between approximately 5% and approximately 18% of a distance between the first lower edge and the second lower edge of the first element.

Owner:CHAR BROIL

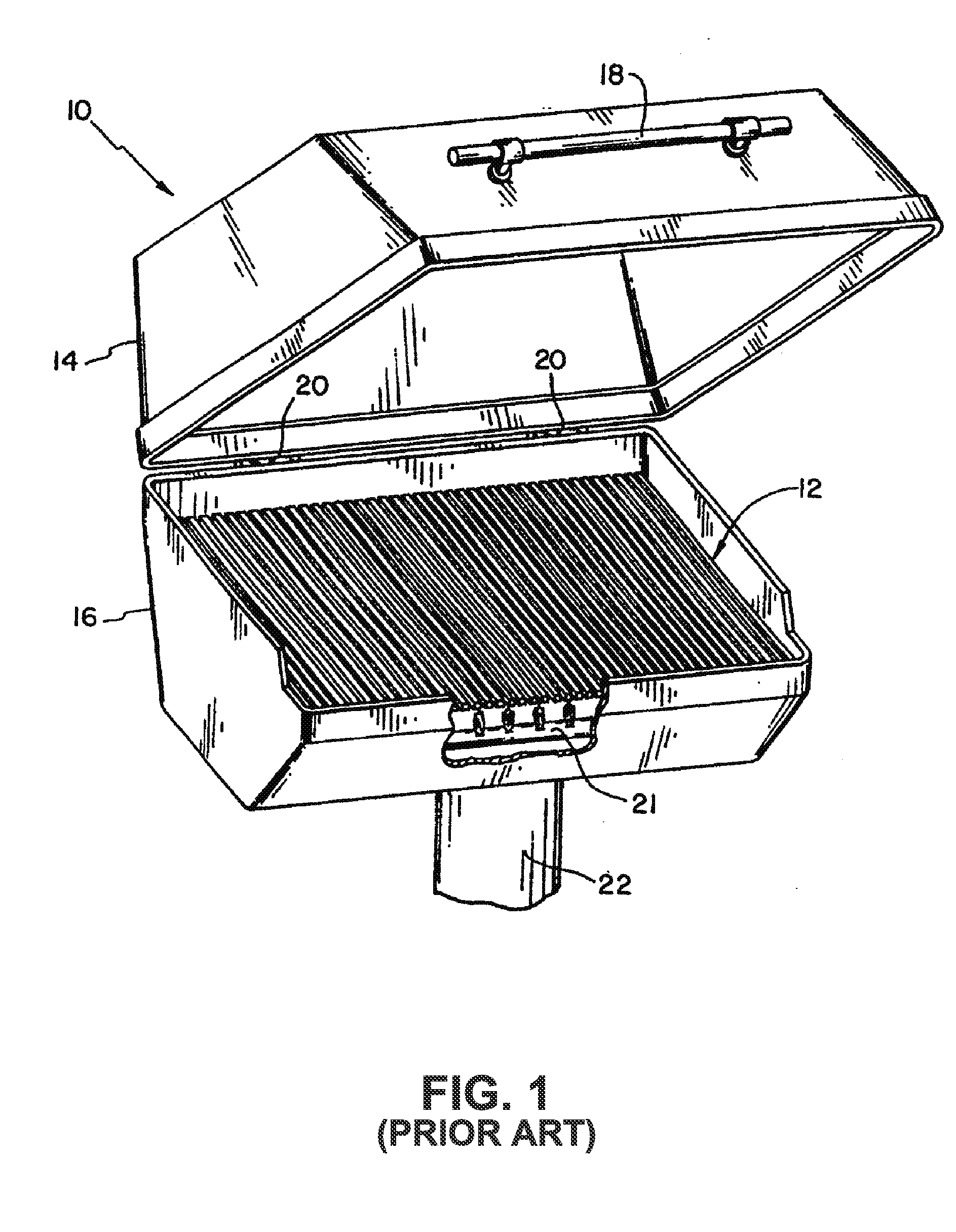

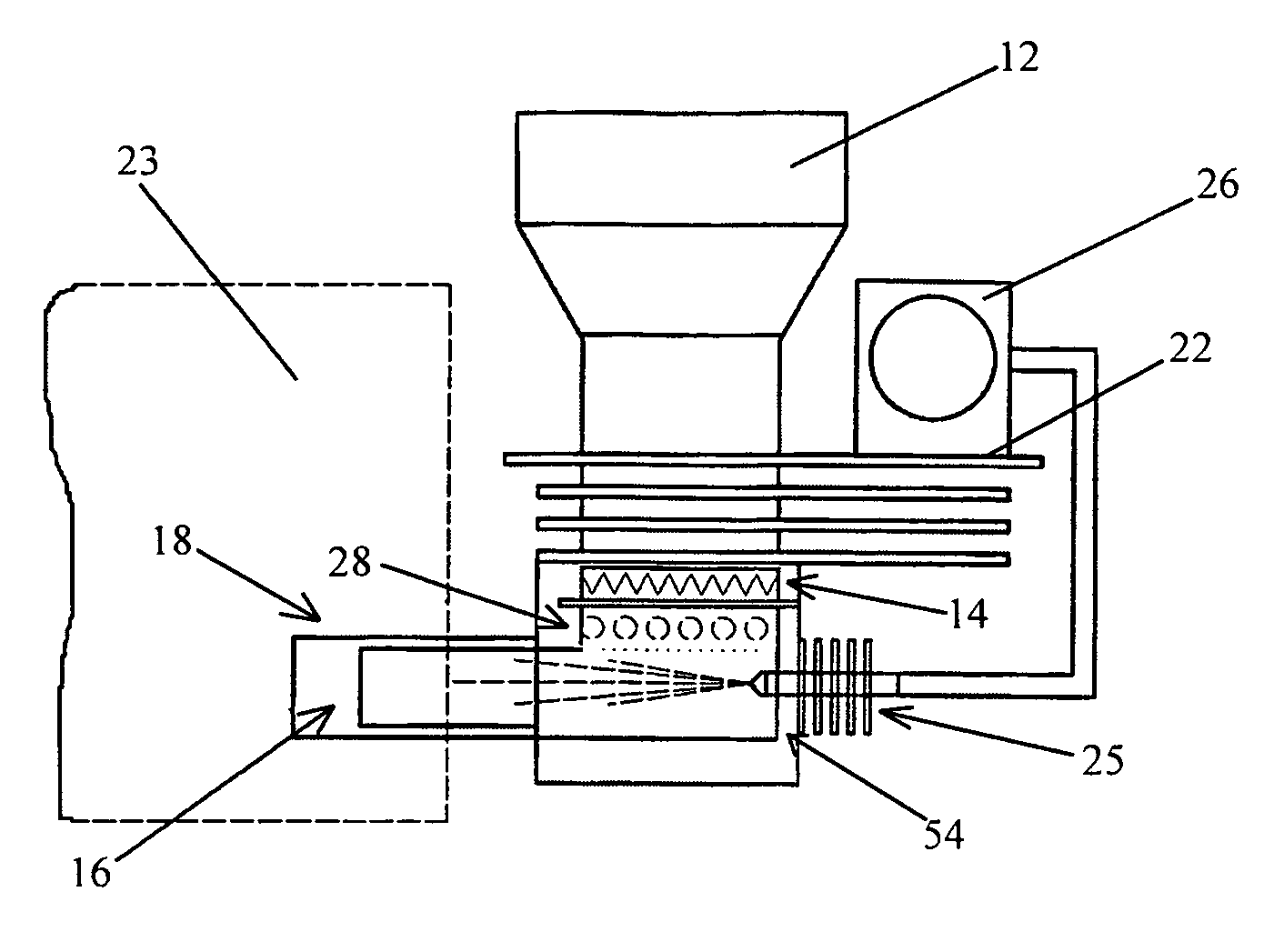

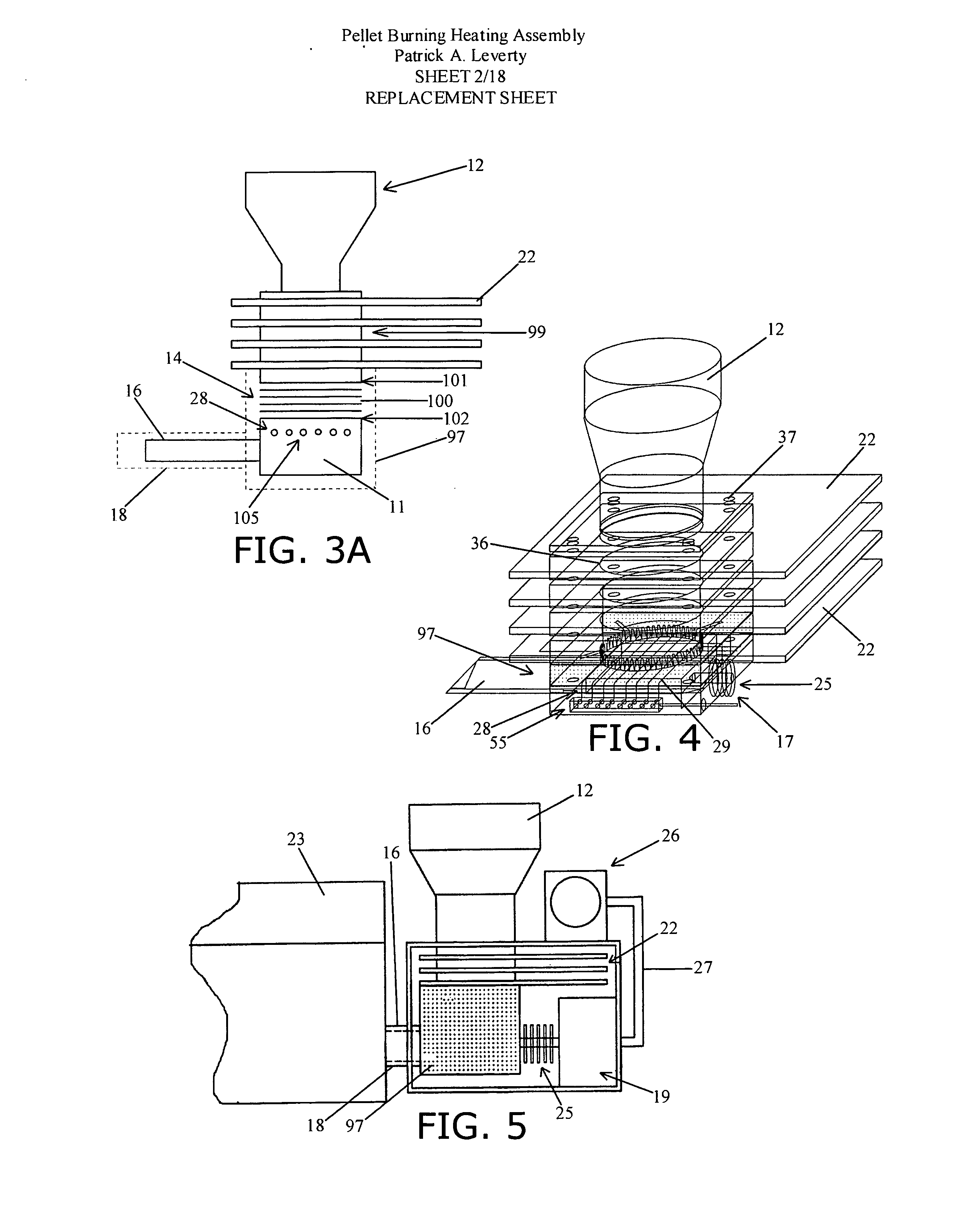

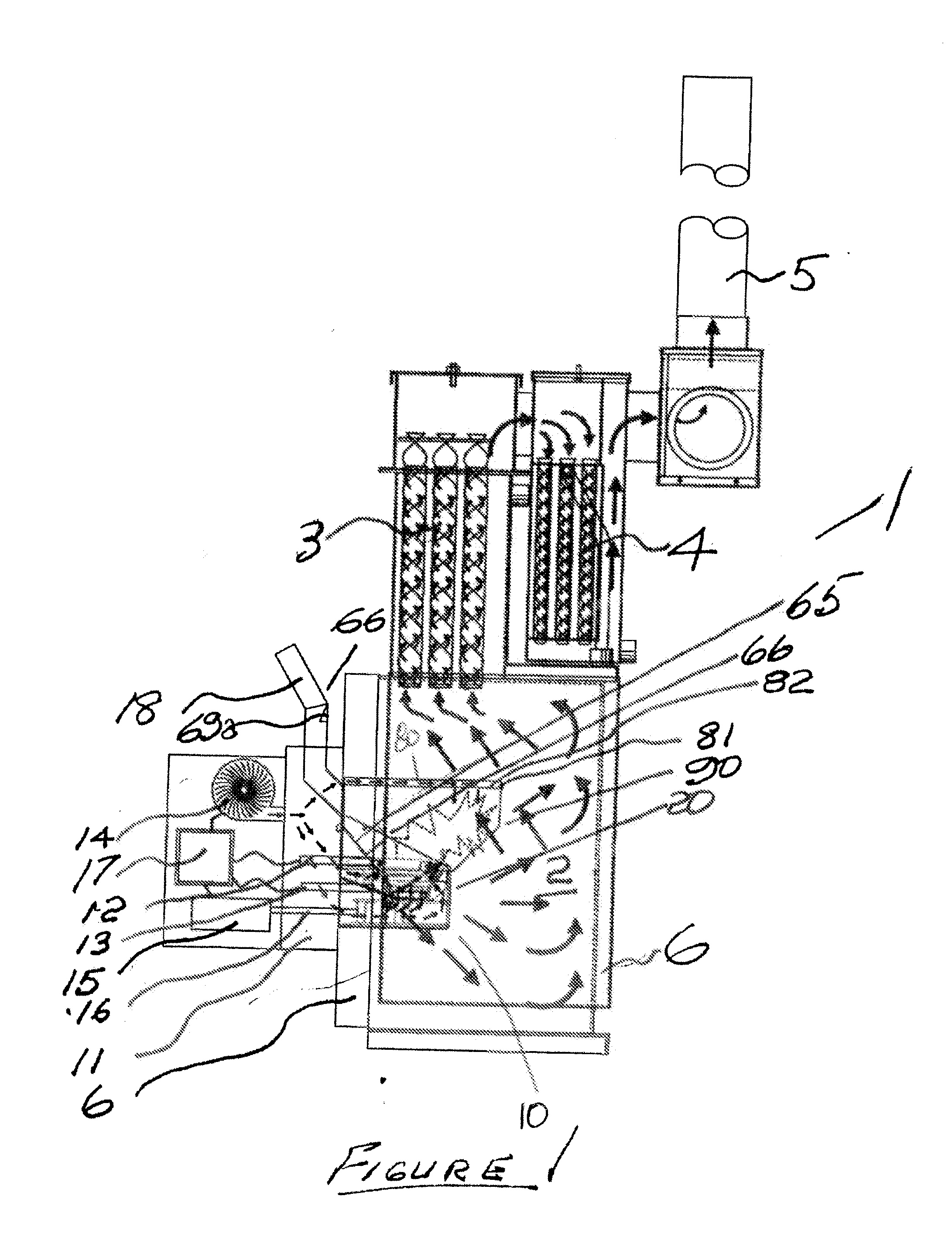

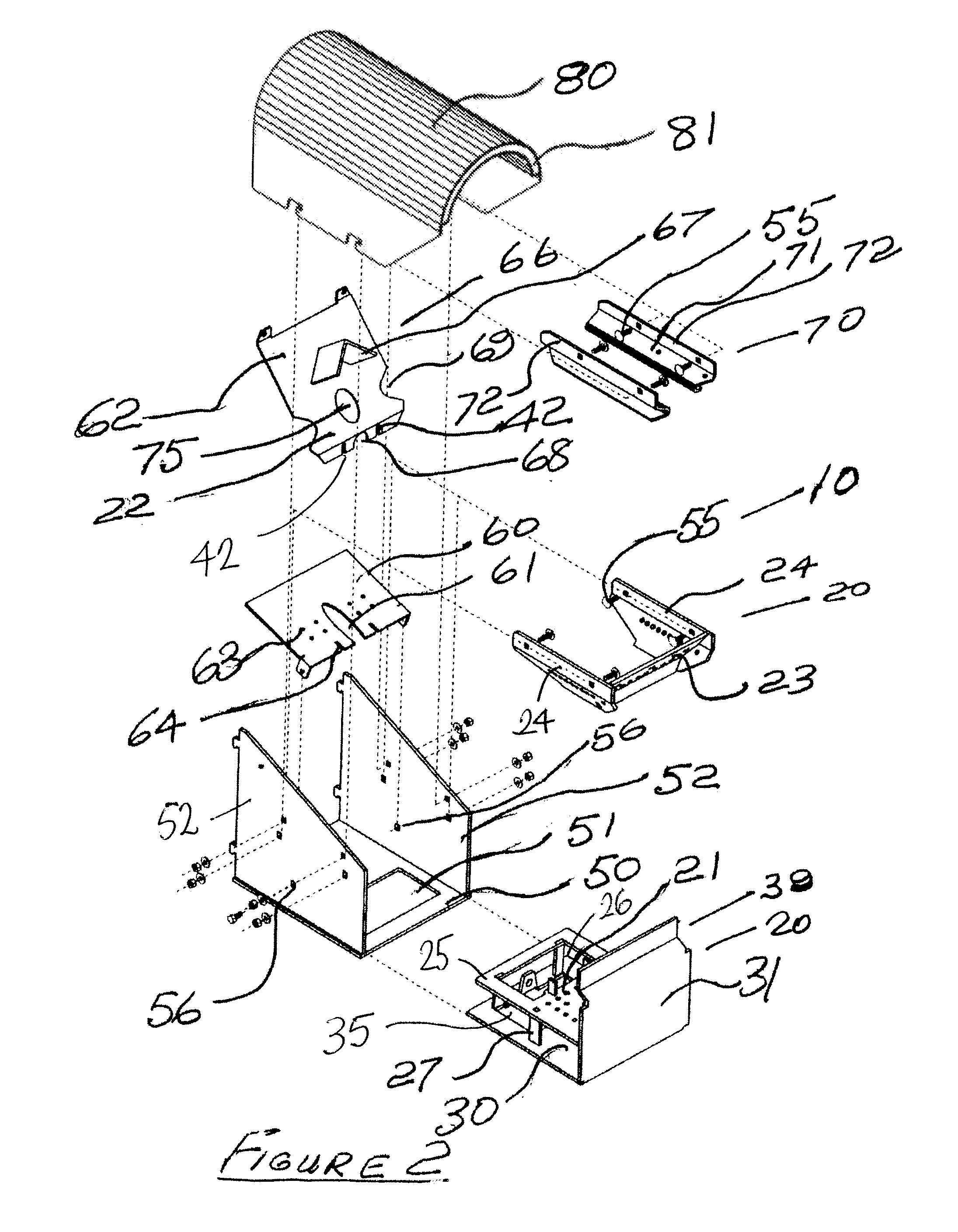

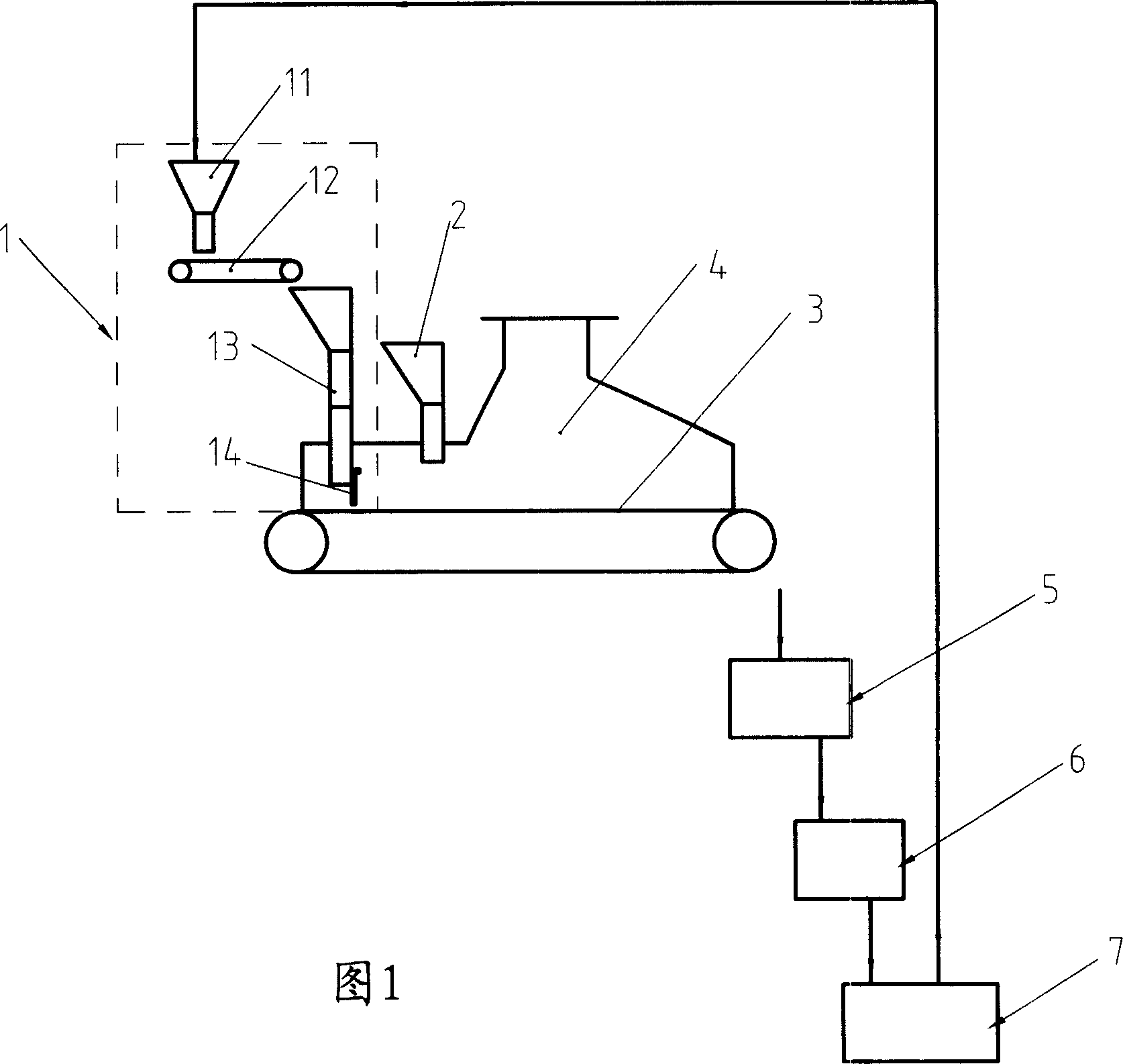

Pellet burning heating assembly

ActiveUS20080060632A1Low costShort cooking timeStoves/ranges with convection heatingCombustion-air/flue-gas circulation for stovesAtmospheric airWood gas

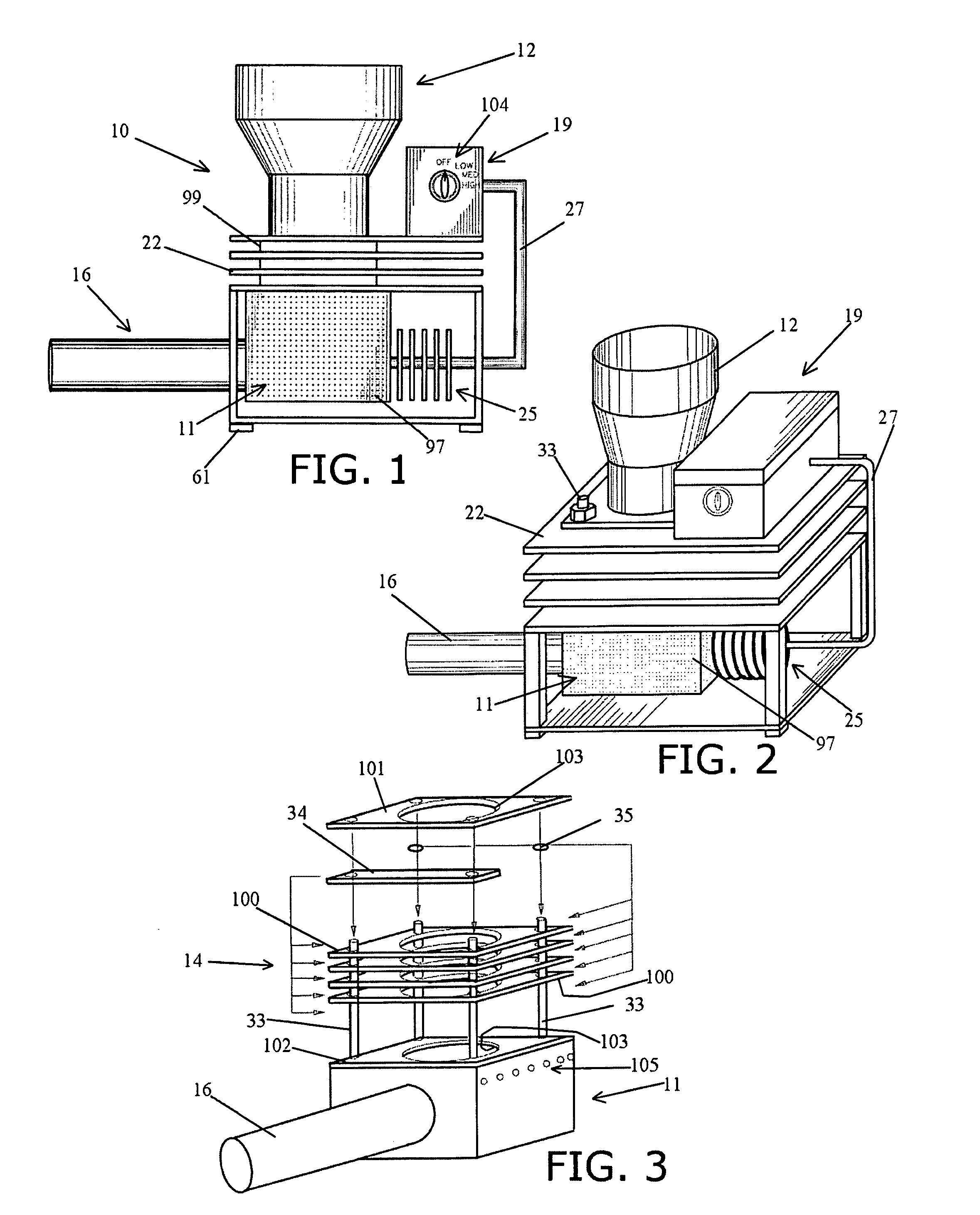

A portable pellet fired heating element for mounting to a grill or stove and comprising a gravity fed pellet holder, a unitary tubular structure having a burner, an air intake and an exhaust chute. Fuel may be supplied to the pellet holder by various supply means such as a conveyer, ramp, scooped, held in bulk in a hopper, and like pellet supply structures and methods. Fuel is fed to the air-cooled insulated burner area onto a decomposer grate, which defines the primary combustion area and which is partially open to the atmosphere for air intake. An adjustable high-pressure flow of gas or vapor is introduced to the primary exhaust chute below the decomposer grate to create a low pressure flow above the grate and which upon ignition, cause flames to be pulled into the pellet mass on the grate. In operation, air from the primary air intake maintains hot charcoal in the primary combustion area, and the secondary combustion area provides a steady flow of wood gas that mixes with a predetermined or adjustable amount of air supplied by the secondary air intake to maintain the flame. The super heated gasses and any ash are provided to the grill or stove by means of the exhaust chute. For cleaning purposes, an electrical / mechanical device may be provided to move the decomposer grate or to provide a sudden burst of high gas pressure.

Owner:GRILLSON

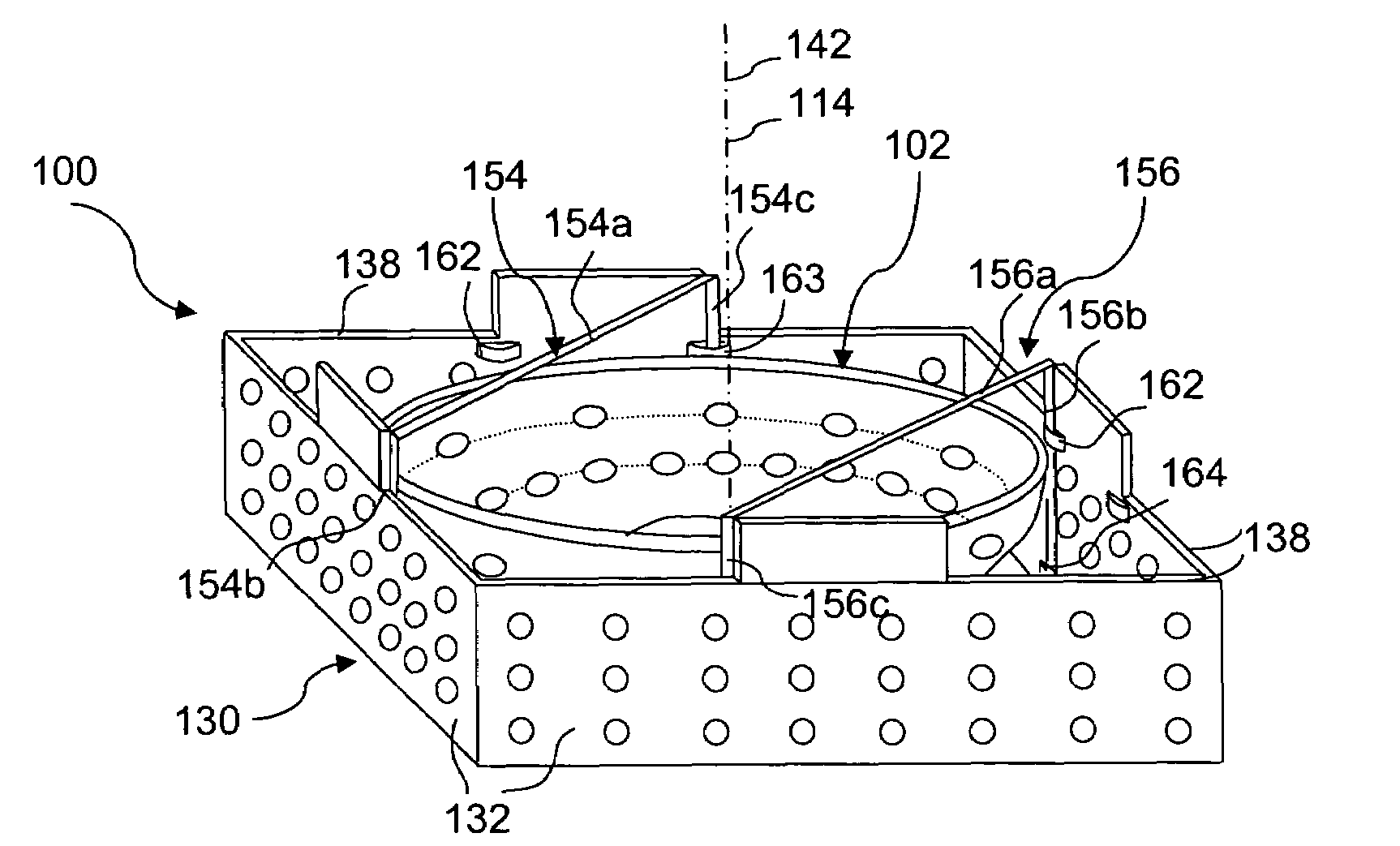

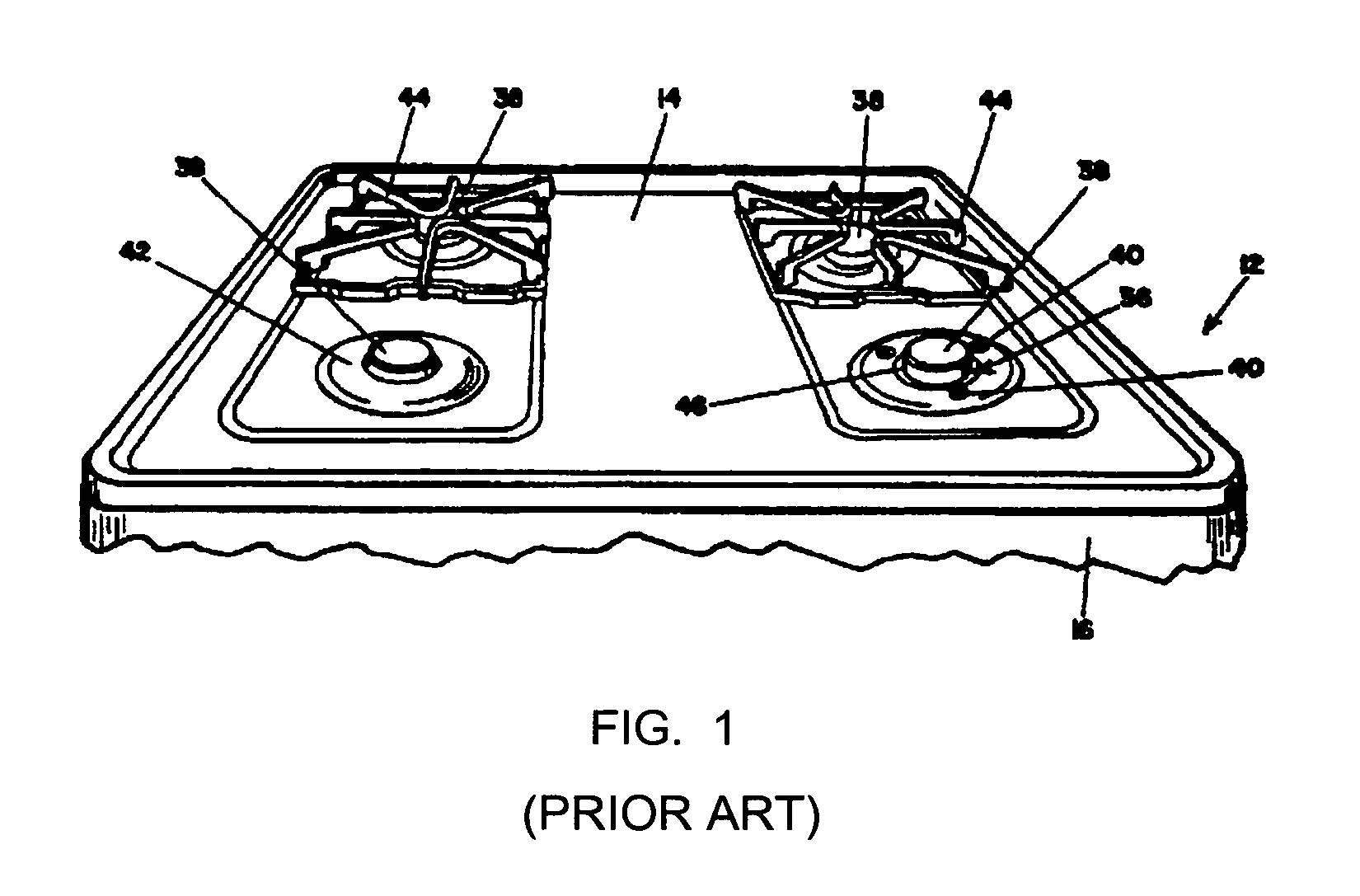

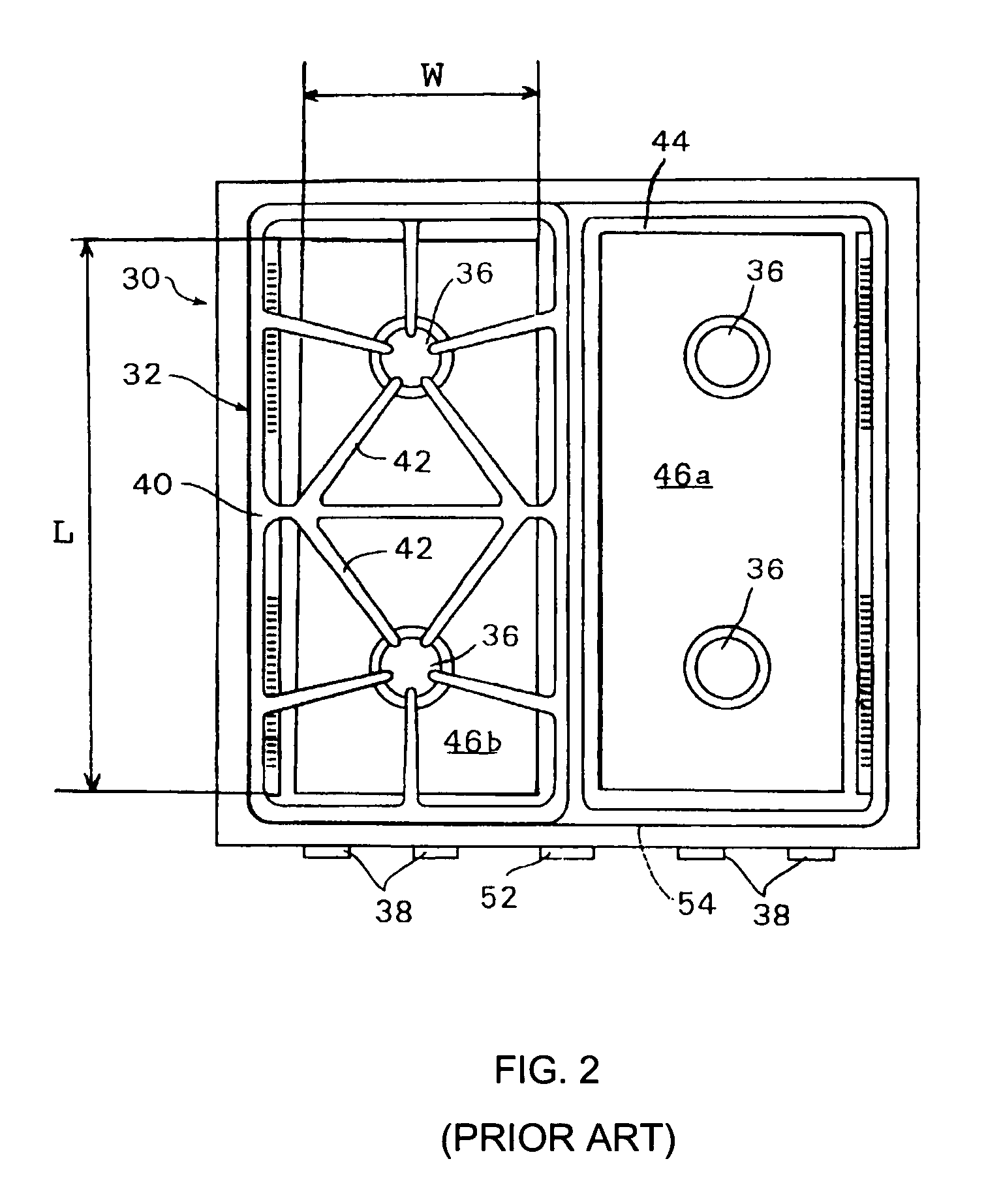

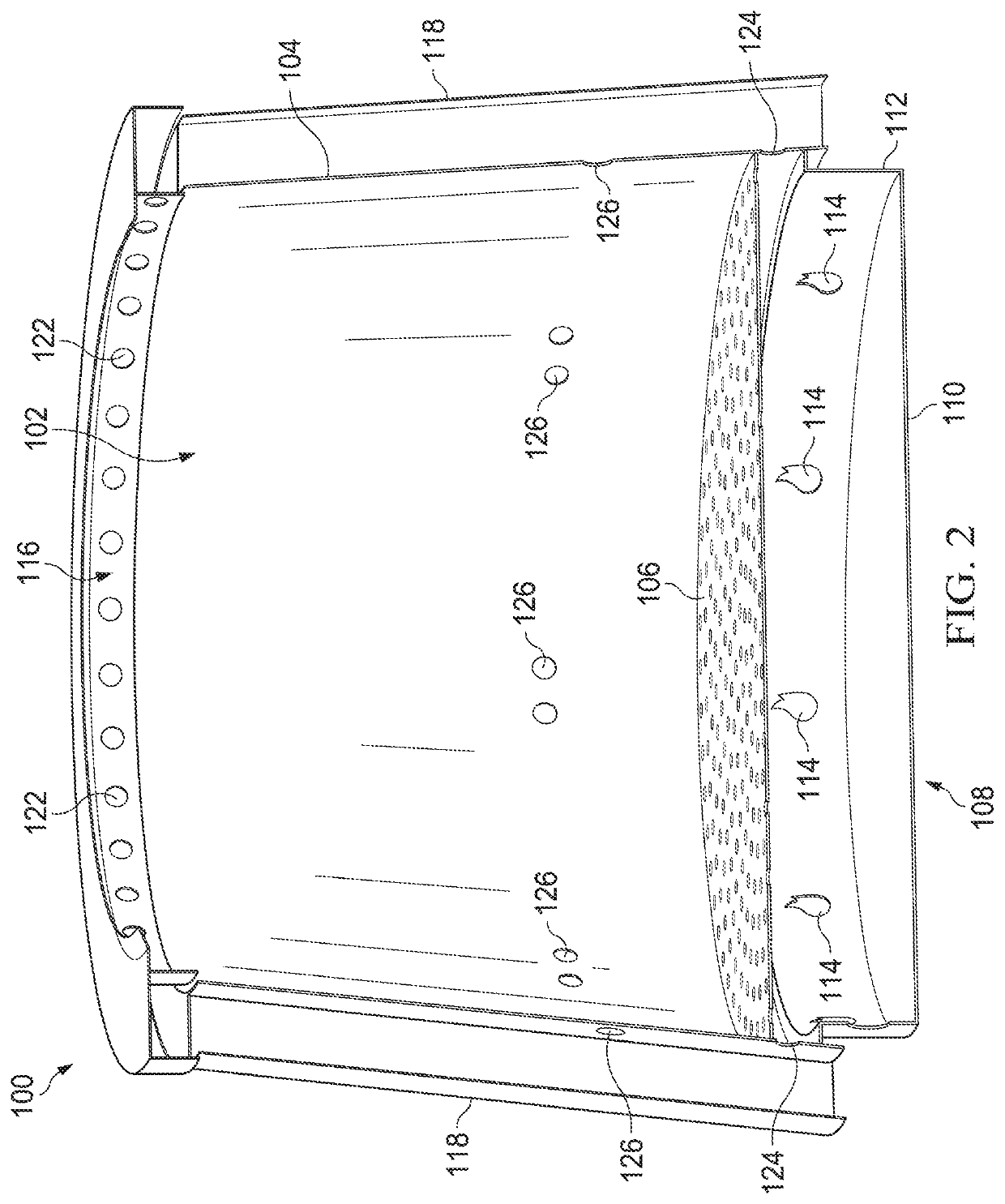

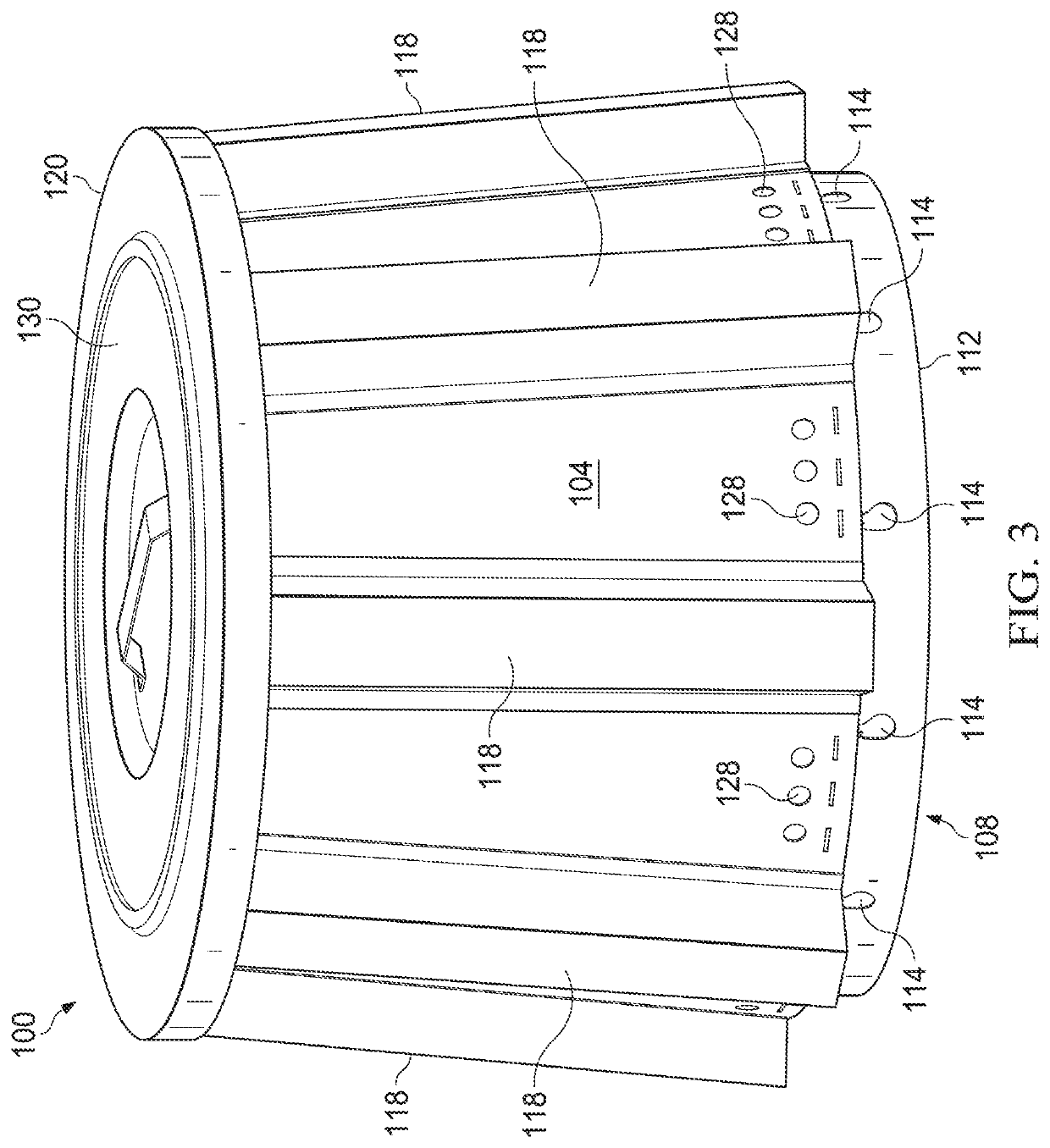

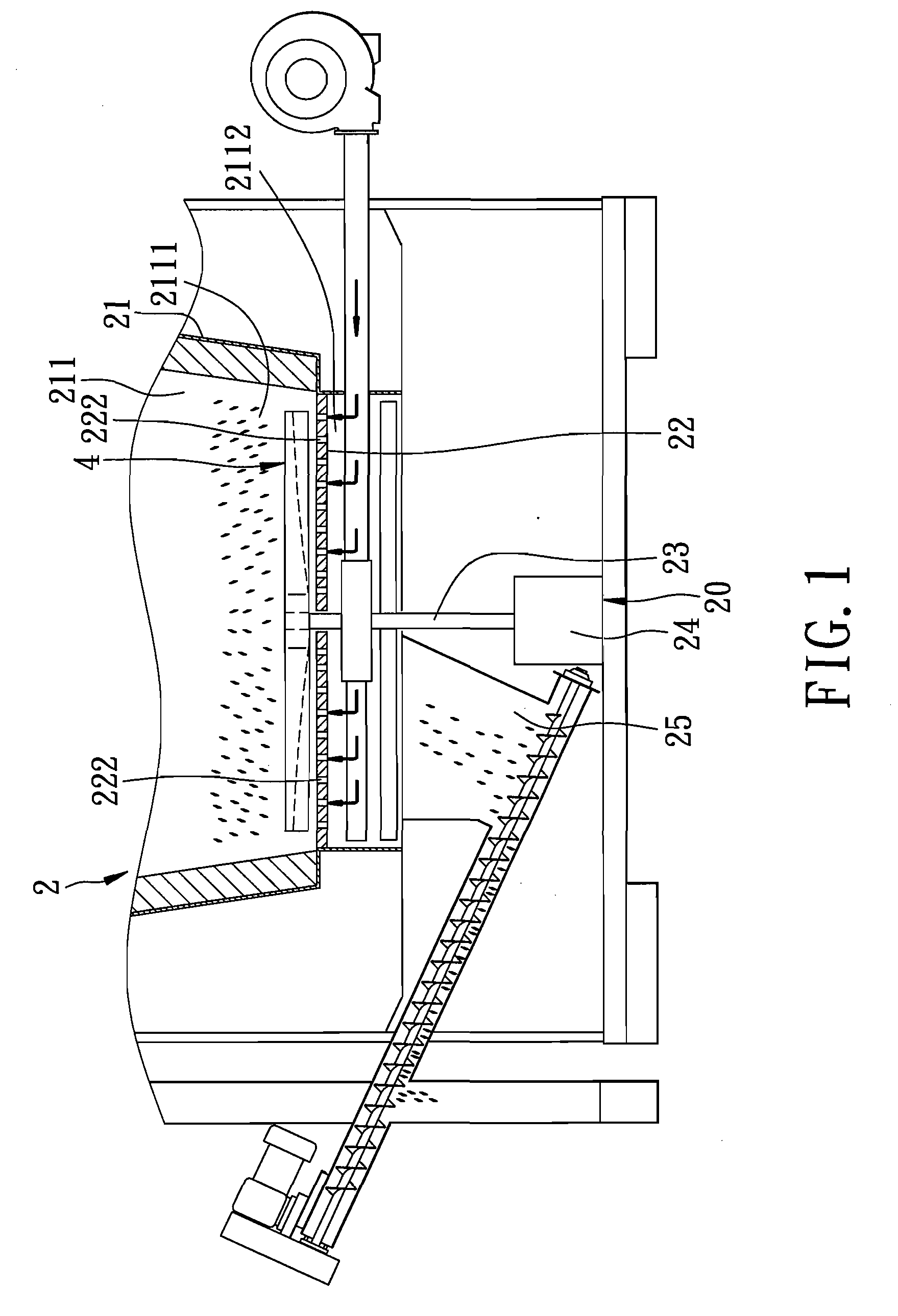

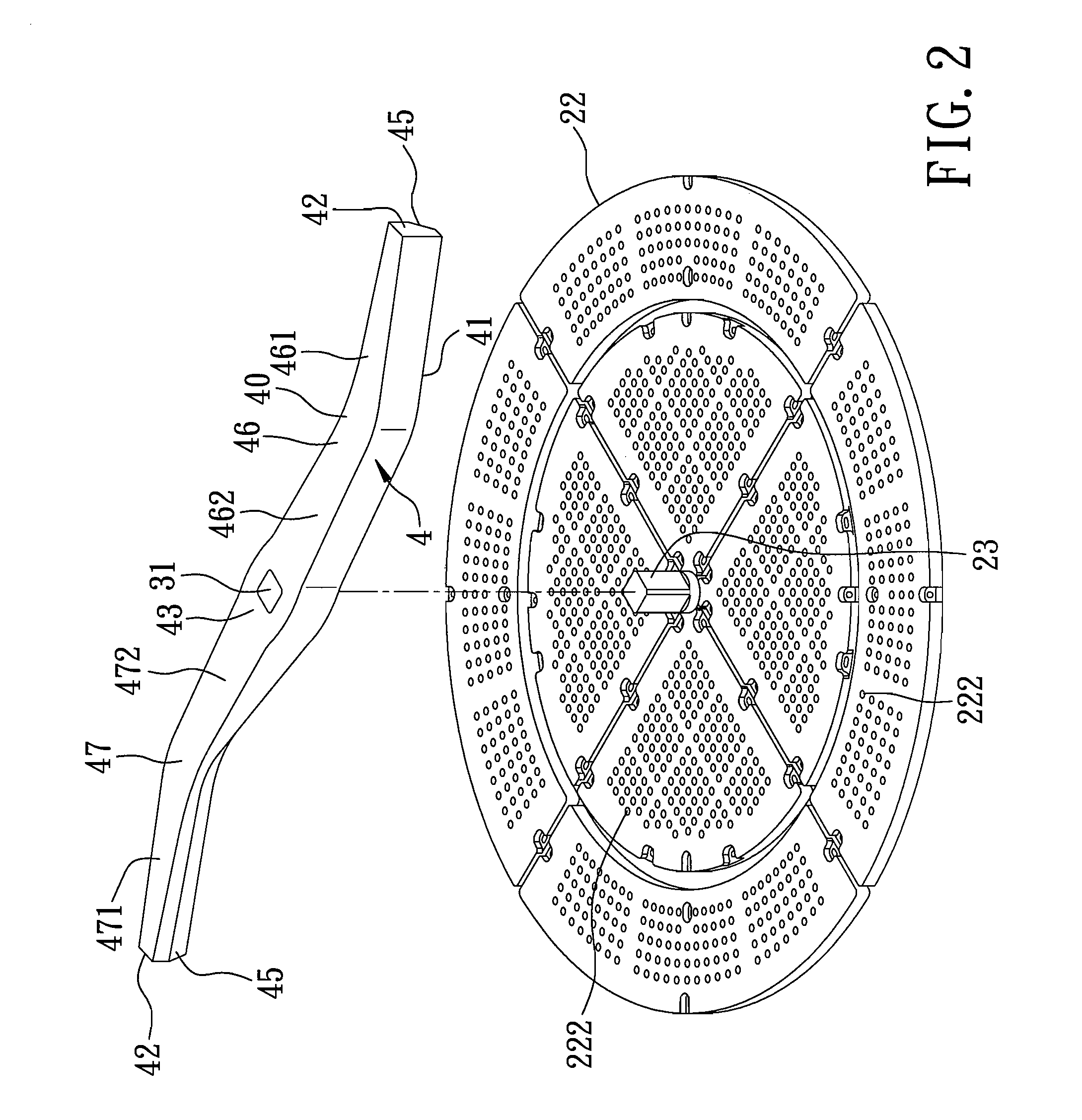

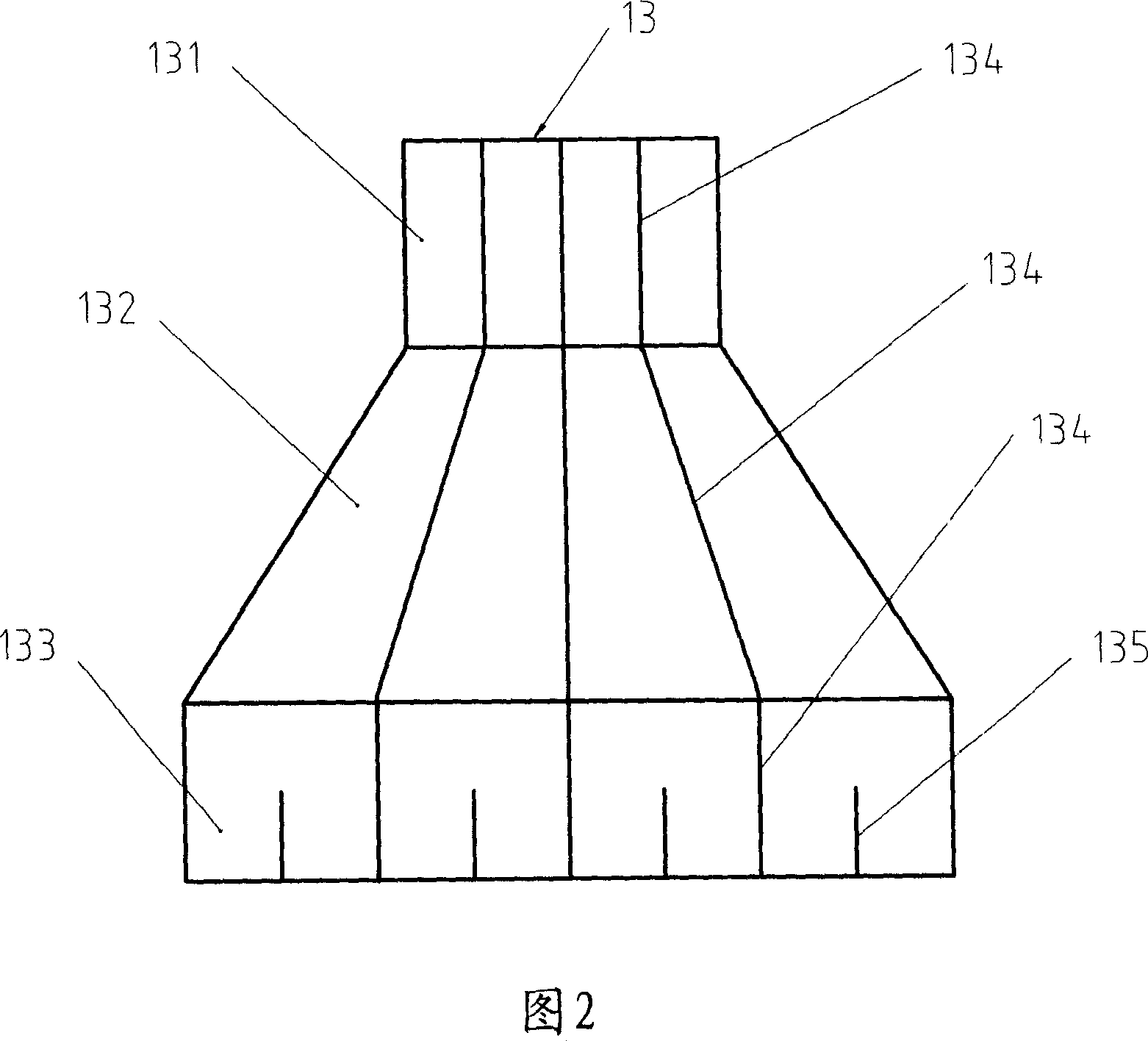

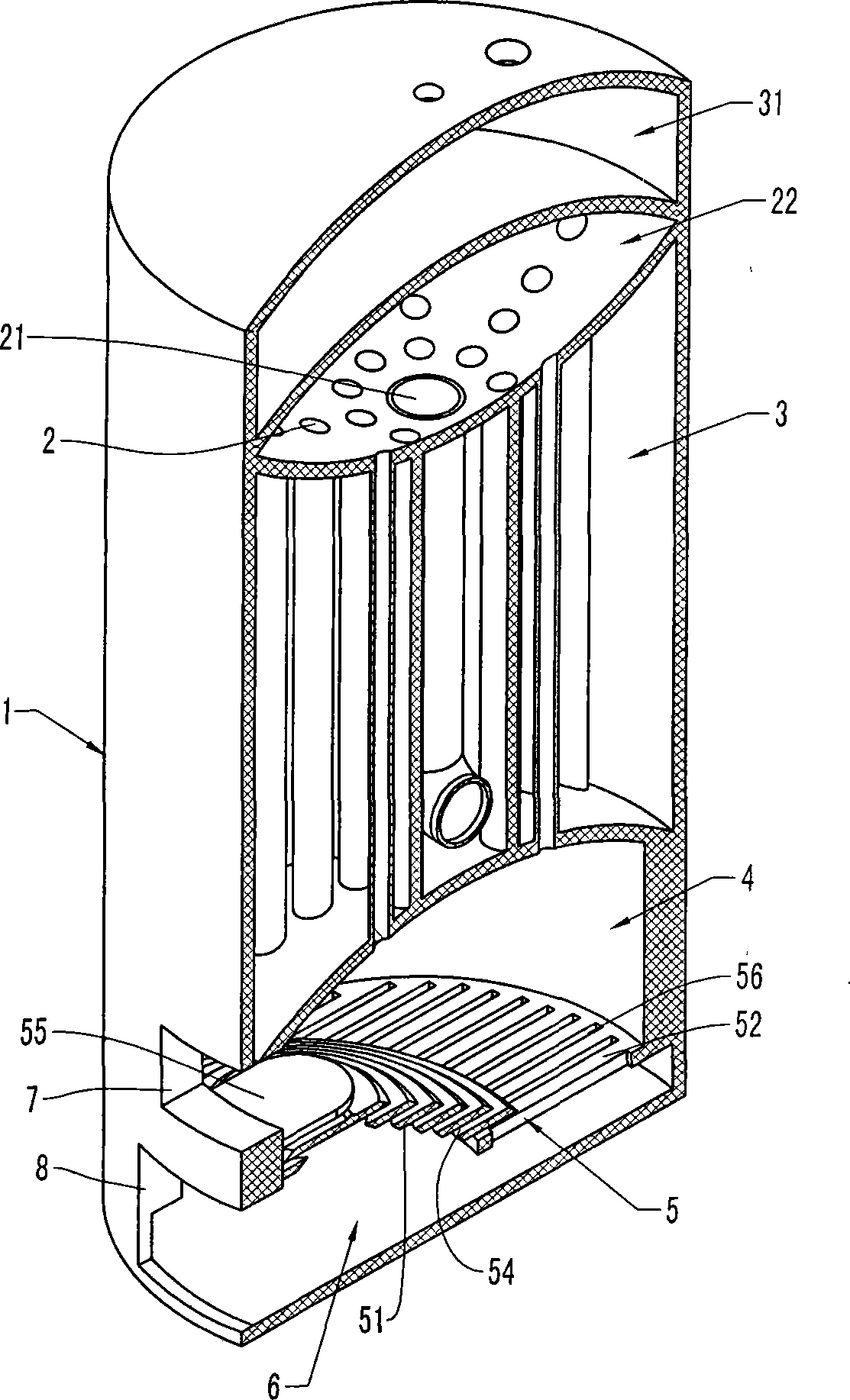

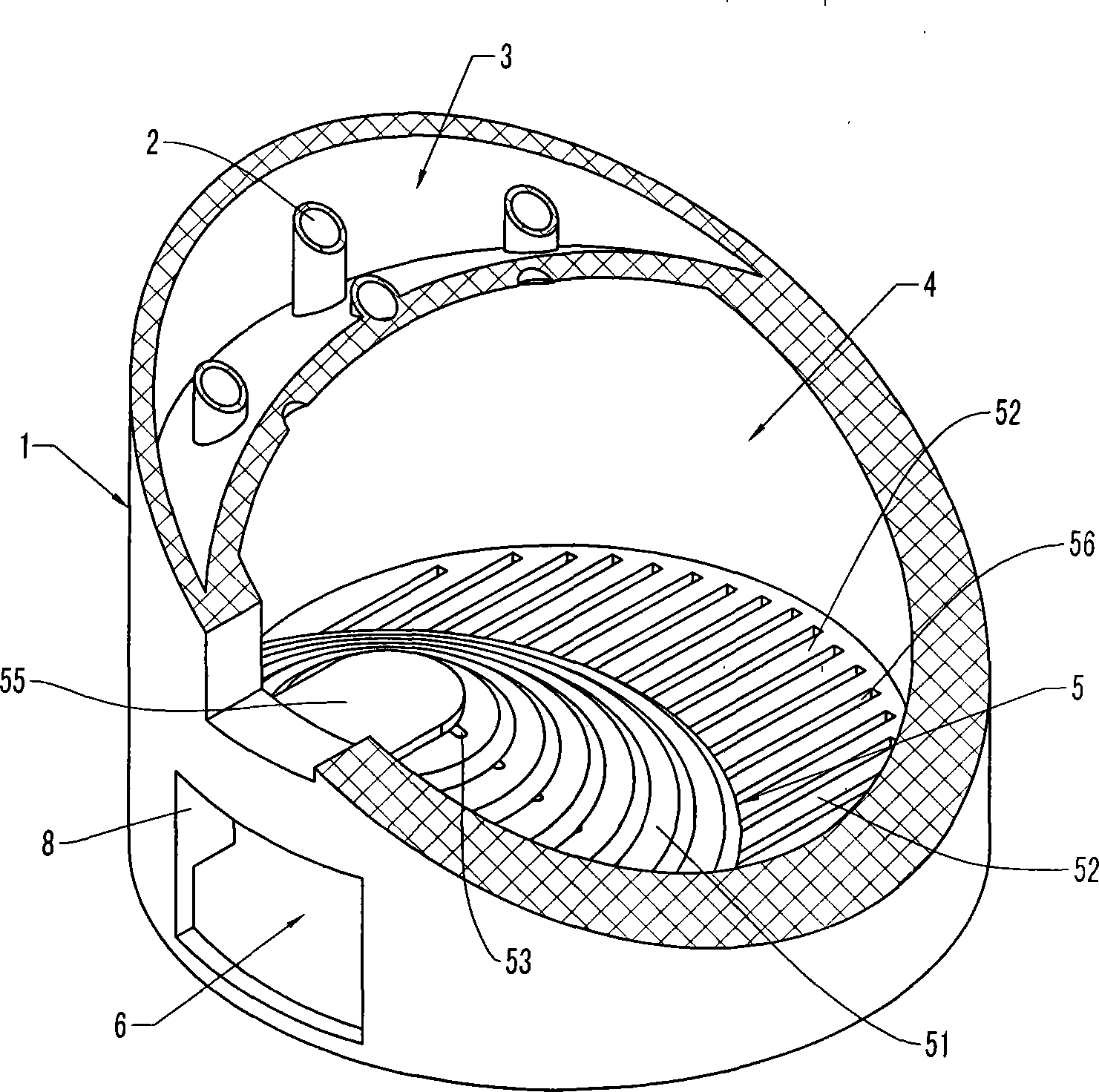

Removable flame heat regulating apparatus including an inner hollow shell and an outer wall for a burner of a gas stove

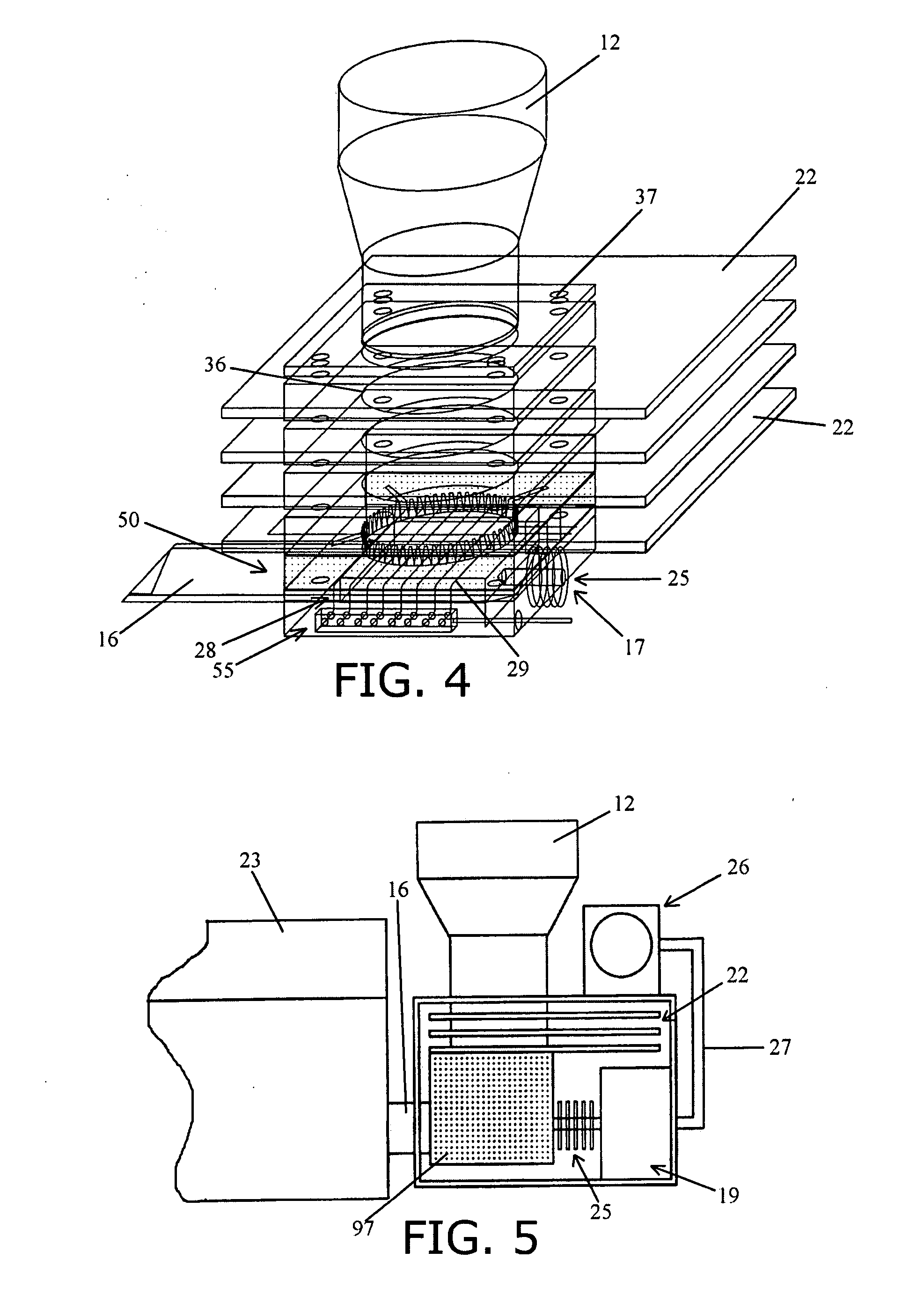

ActiveUS20080302353A1Easy maintenanceEasy to cleanStoves/ranges foundationsDomestic stoves or rangesCombustorEngineering

A flame heat regulating apparatus for a cooktop of a gas stove, comprising an inner hollow shell and an outer wall which are both placed onto the stove cooktop. The shell further positioned to surround a gas burner is arcuate in shape, having a smaller sized bottom side and a larger sized top side. A plurality of air passages are through the shell, wherein the air passages are more densely distributed onto a lower part of the shell, as compared with the air passages which are less densely distributed onto an upper part of the shell. The outer wall further positioned to surround the shell is comprised of a plurality of air passages which are evenly distributed therethrough. In addition, a plurality of extensions projecting upwardly are spaced on a top side of the wall to support a cookware. Application of the flame heat regulating apparatus enables increase of heating efficiency of the flame in cooking, and prevents undesirable heating of a handle of the cookware.

Owner:SUN YIZHONG

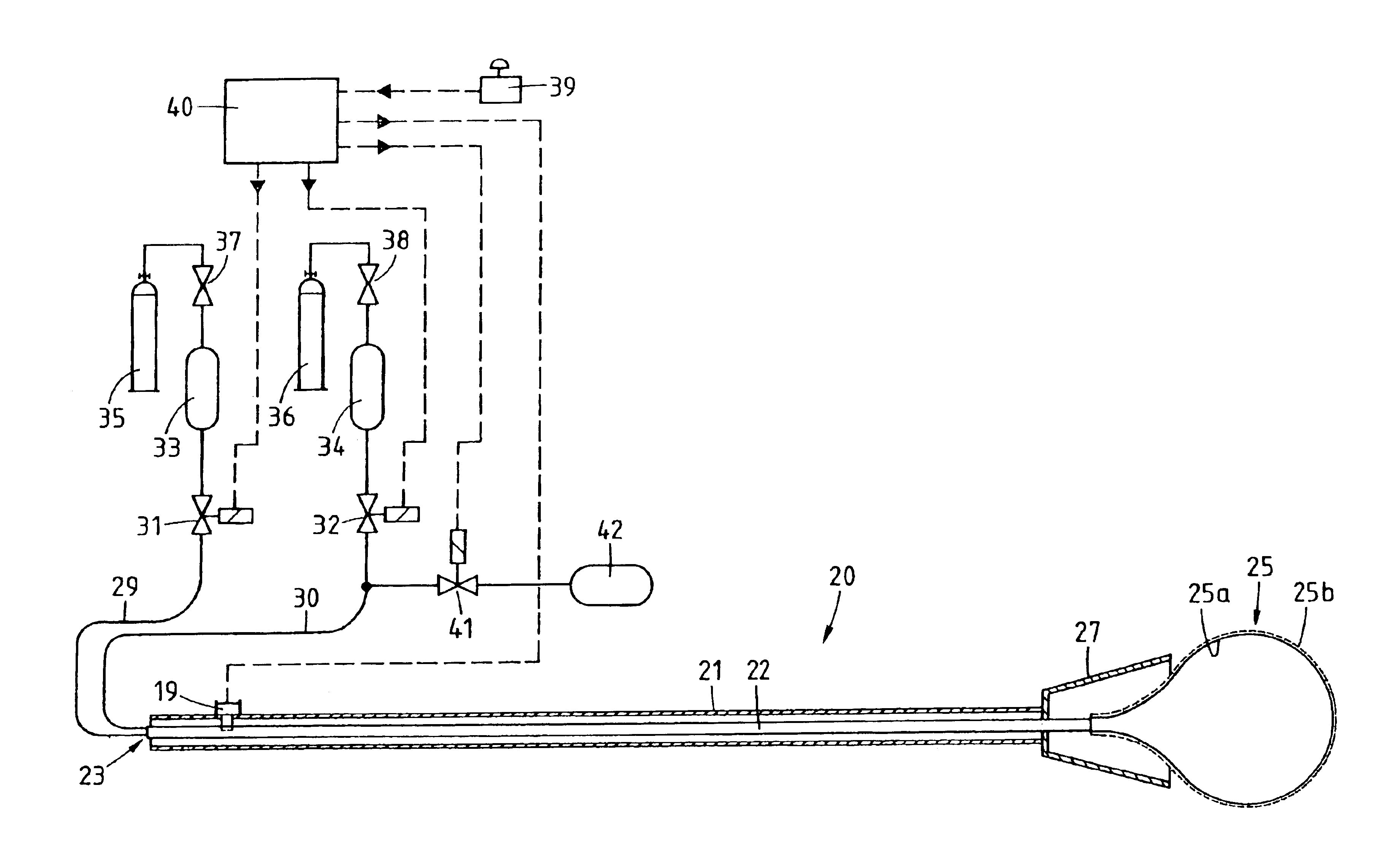

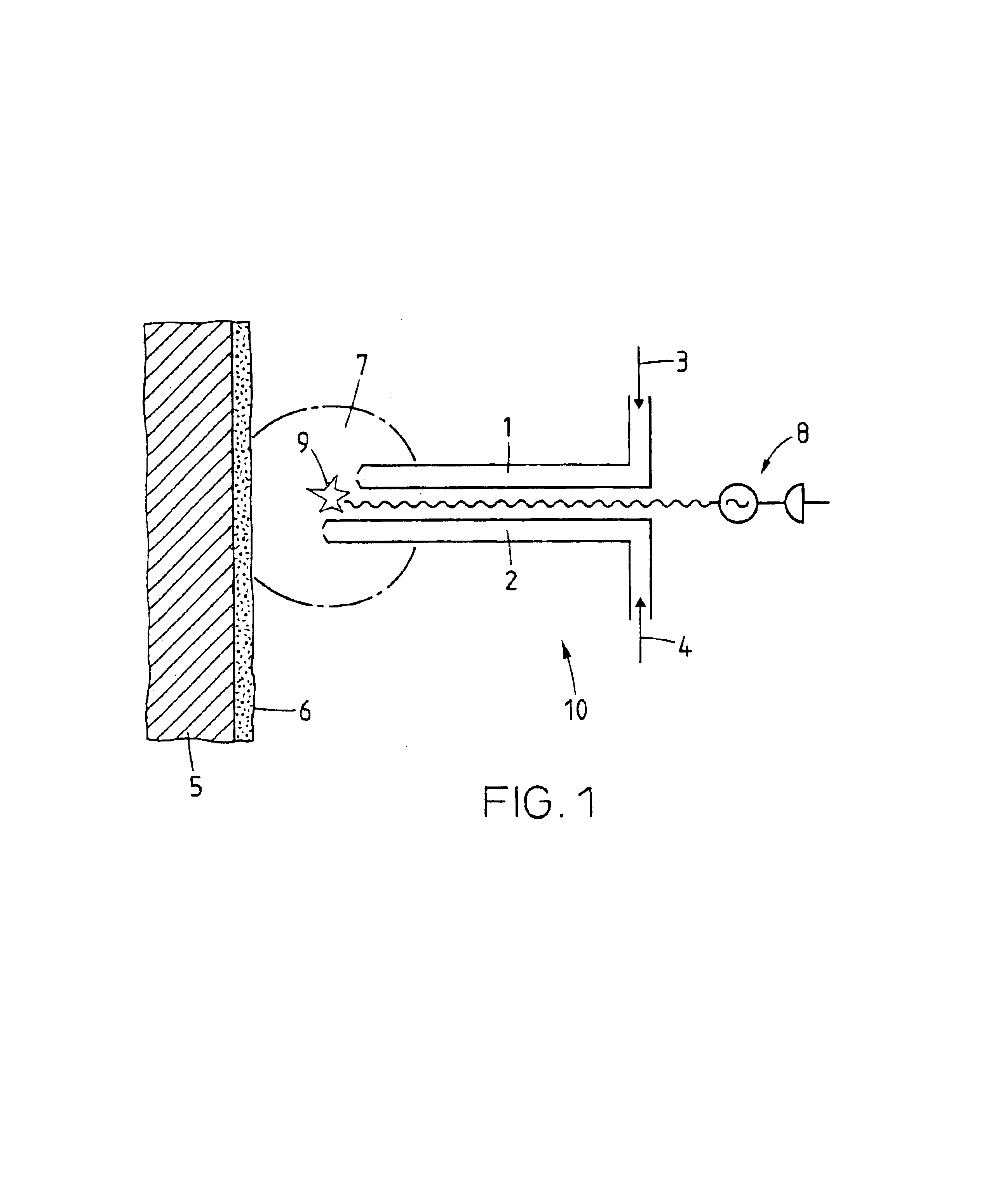

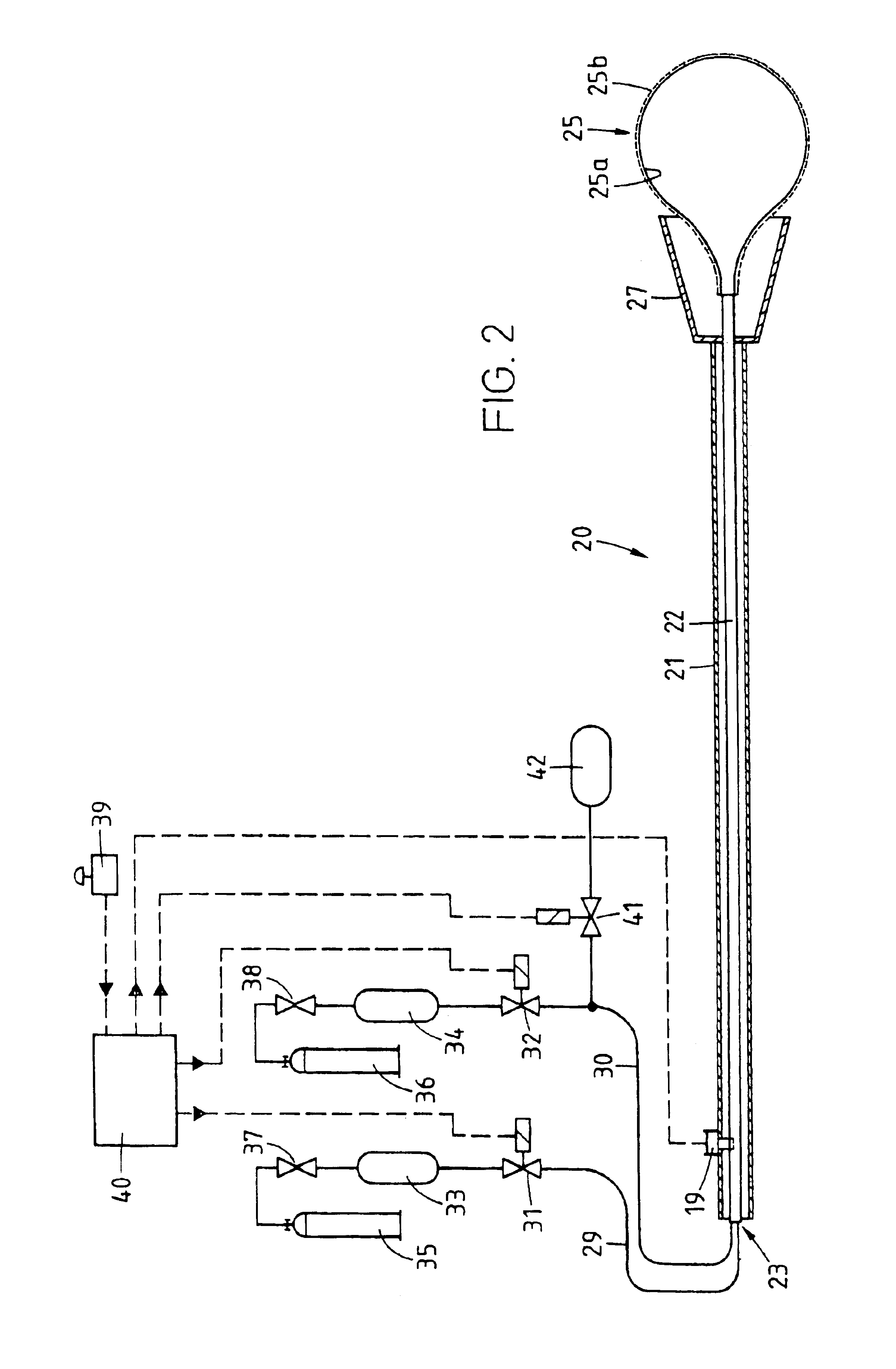

Method for cleaning combustion devices

InactiveUS6935281B2Short timeProcess can be minimizedLinings repairBoiler cleaning apparatusCombustionSlag

An on-line method and a device for cleaning of contamination such as caking or slag deposits from surfaces in vessels and combustion installations by means of blasting technology. An explosive gas mixture is made to detonate in the proximity of the deposits and thereby clean the deposits from the surfaces.

Owner:BANG & CLEAN

Removable flame heat regulating apparatus including an inner hollow shell and an outer wall for a burner of a gas stove

ActiveUS7708006B2Preventing undesirable heatingImprove versatilityStoves/ranges foundationsDomestic stoves or rangesFuel gasGas burner

A flame heat regulating apparatus for a cooktop of a gas stove, having an inner hollow shell and an outer wall which are both placed onto the stove cooktop. The shell further positioned to surround a gas burner is arcuate in shape, having a smaller sized bottom side and a larger sized top side. A plurality of air passages are through the shell, wherein the air passages are more densely distributed onto a lower part of the shell, as compared with the air passages which are less densely distributed onto an upper part of the shell. The outer wall further positioned to surround the shell has a plurality of air passages which are evenly distributed therethrough. In addition, a plurality of extensions projecting upwardly are spaced on a top side of the wall to support a cookware. The apparatus increases heating efficiency of the flame, and prevents undesirable heating of a handle of the cookware in cooking.

Owner:SUN YIZHONG

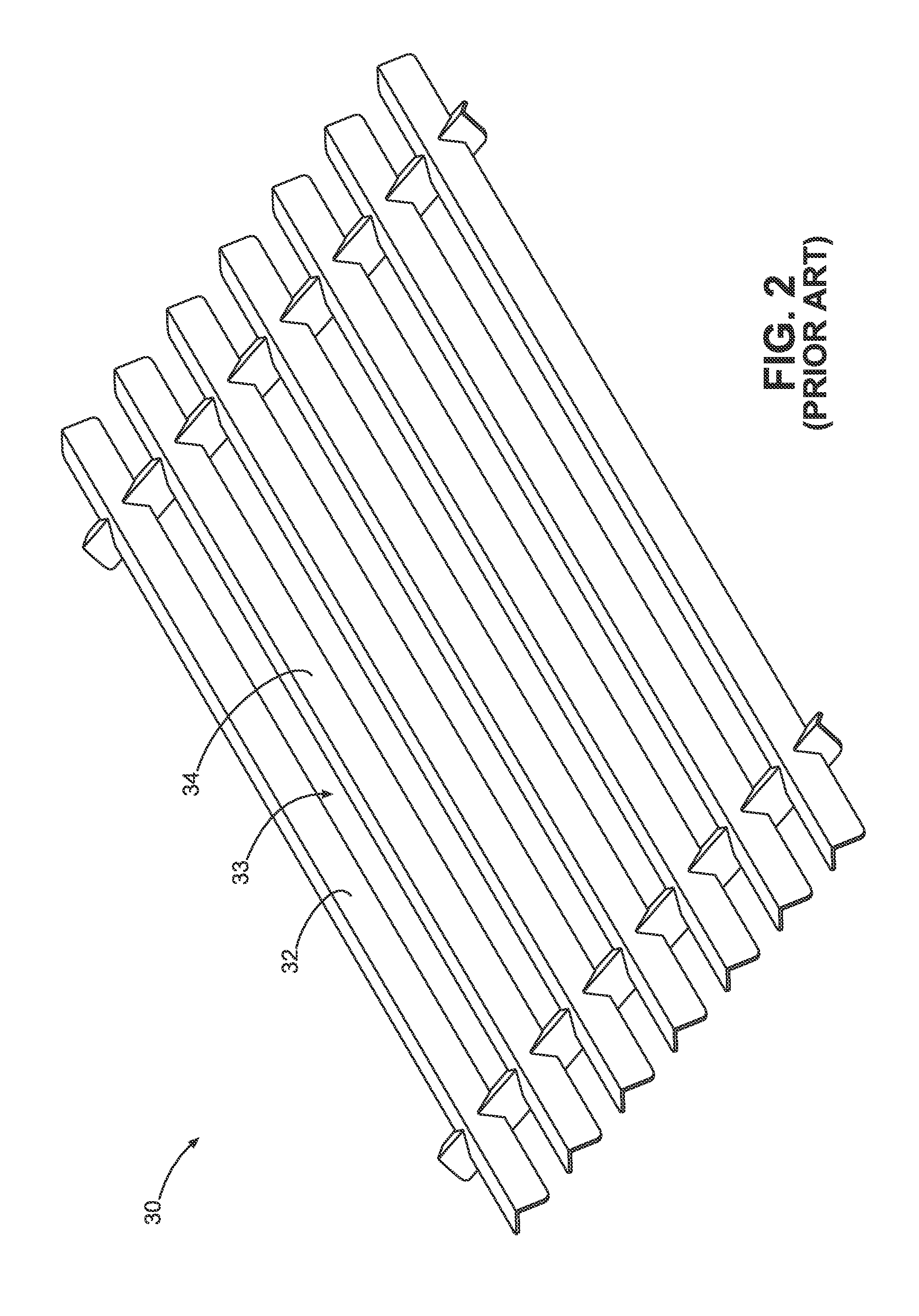

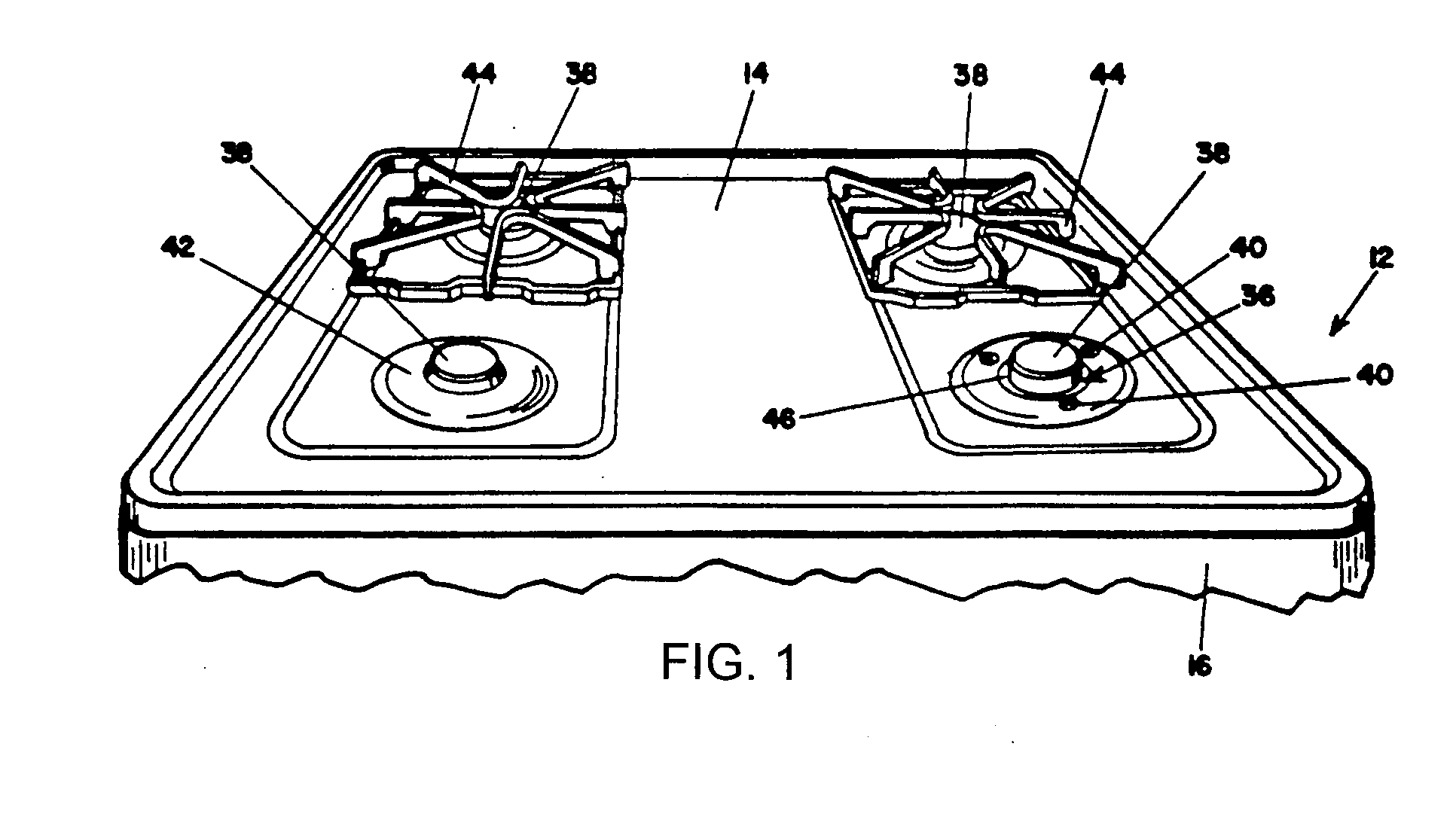

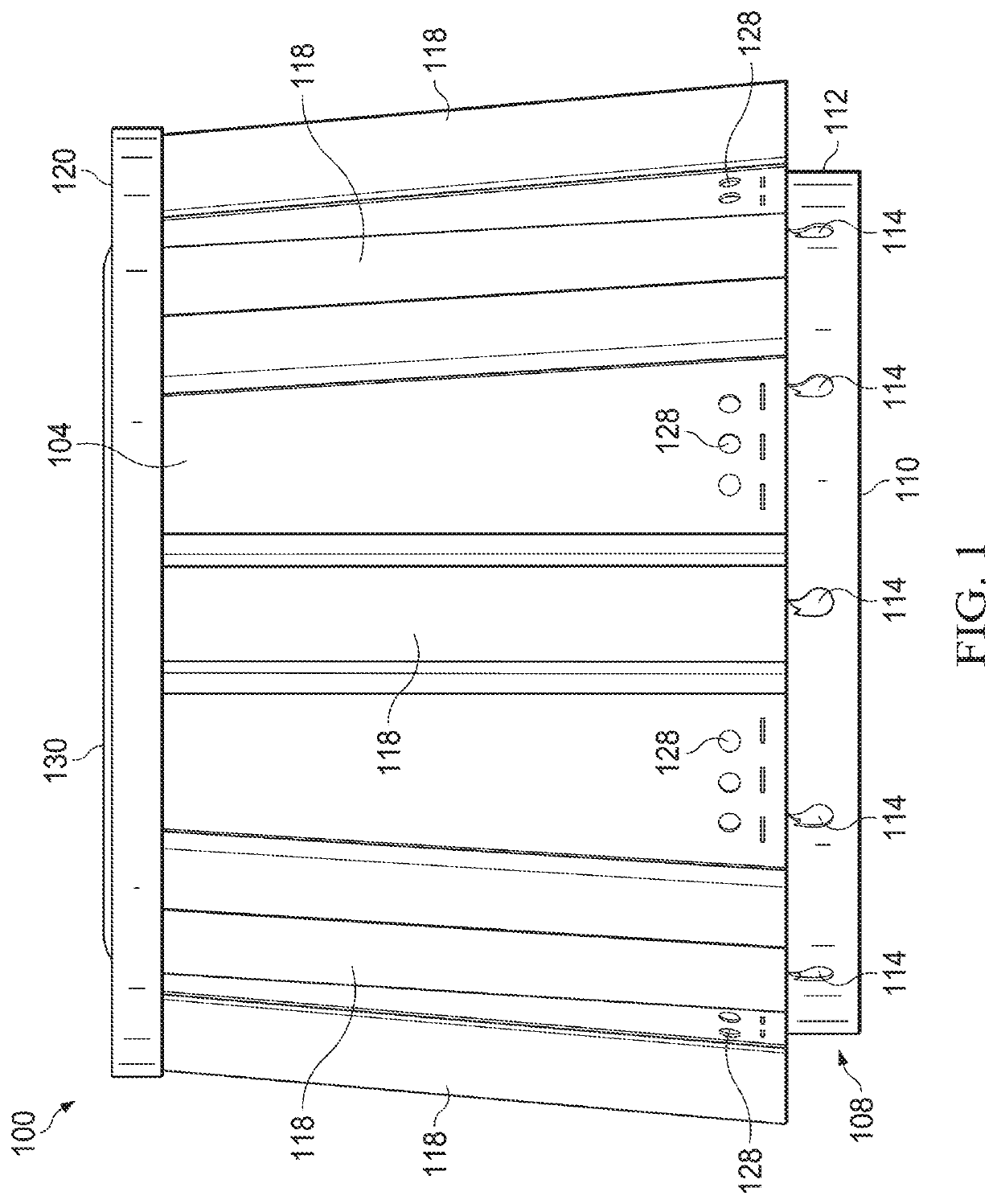

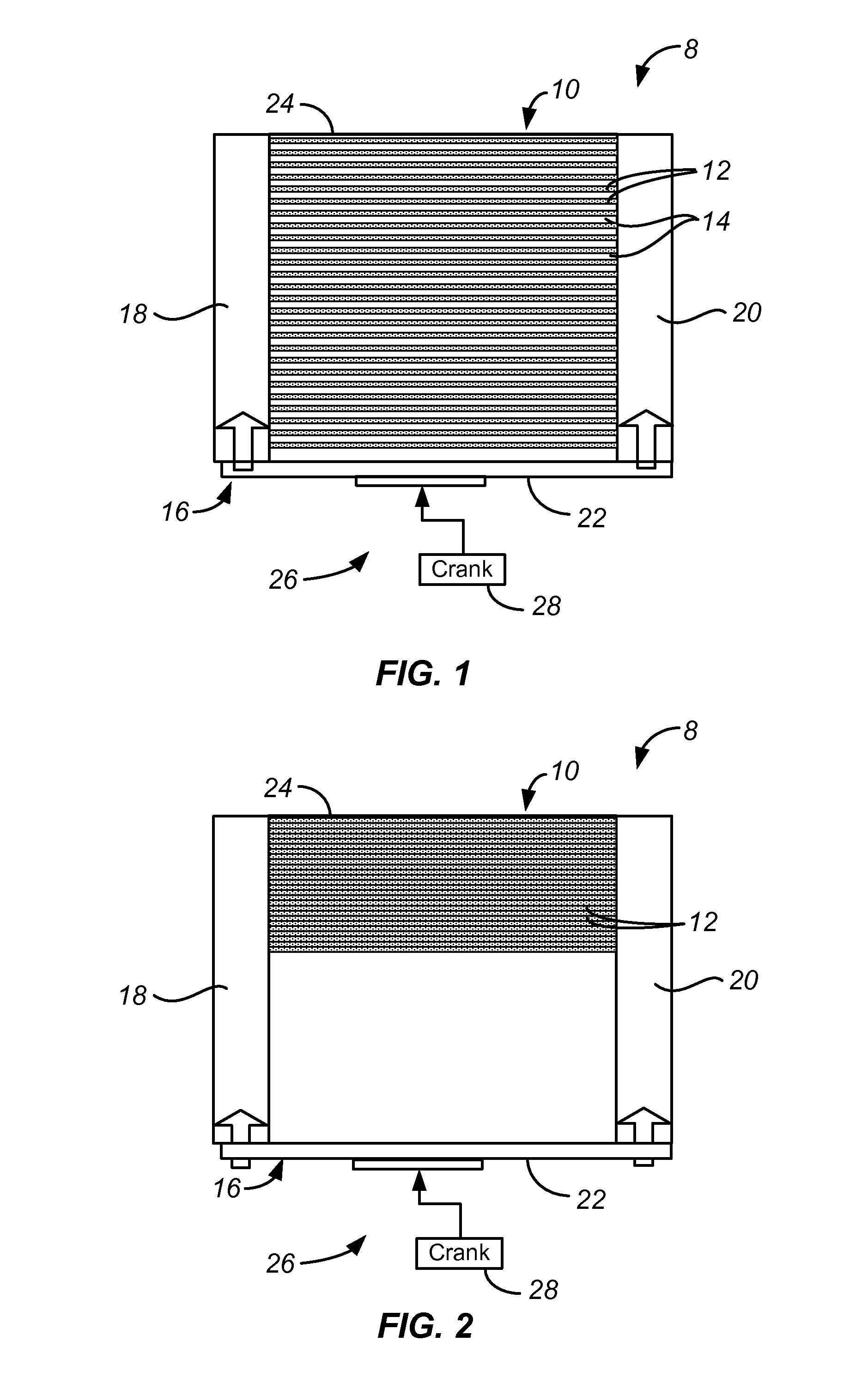

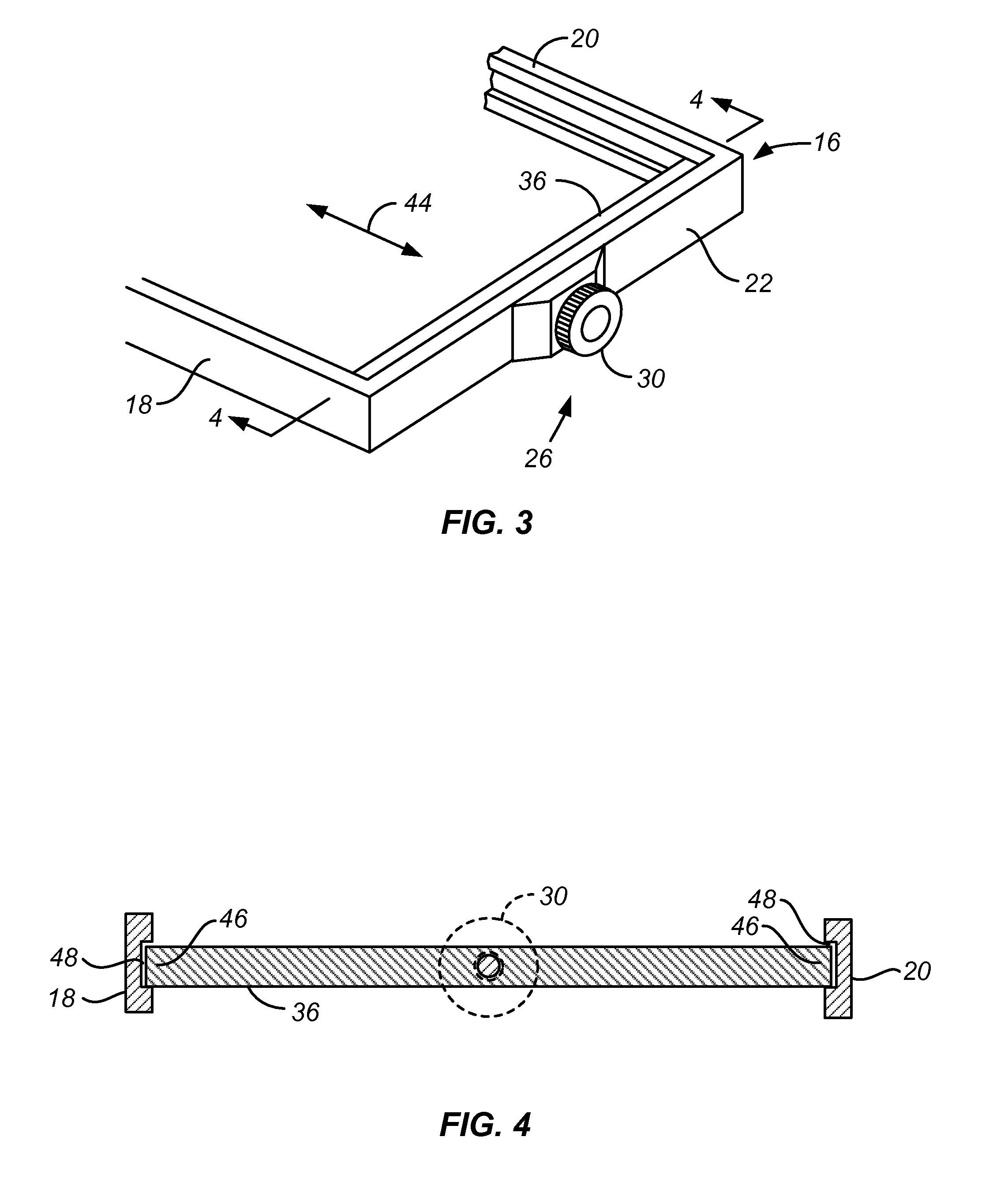

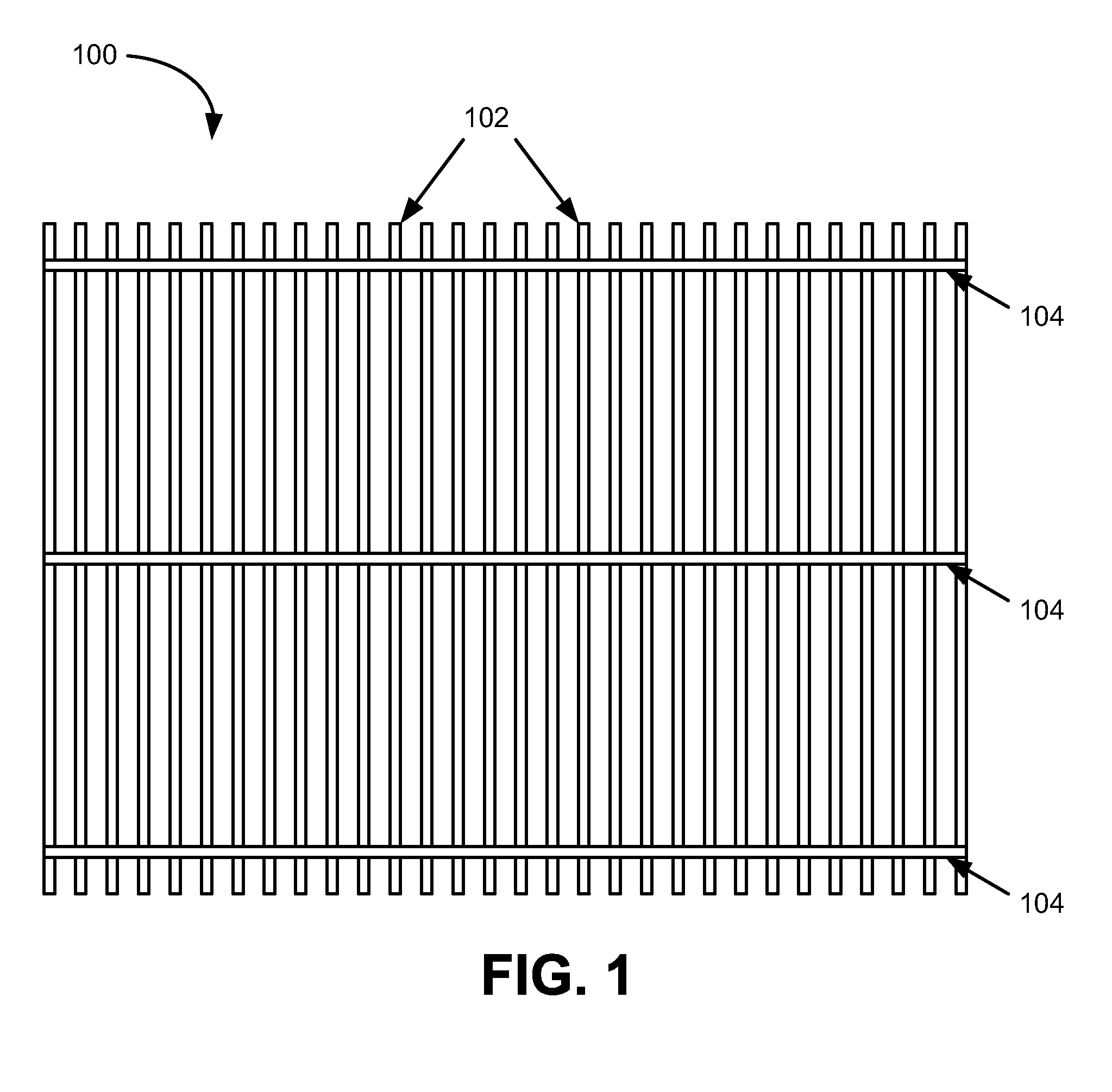

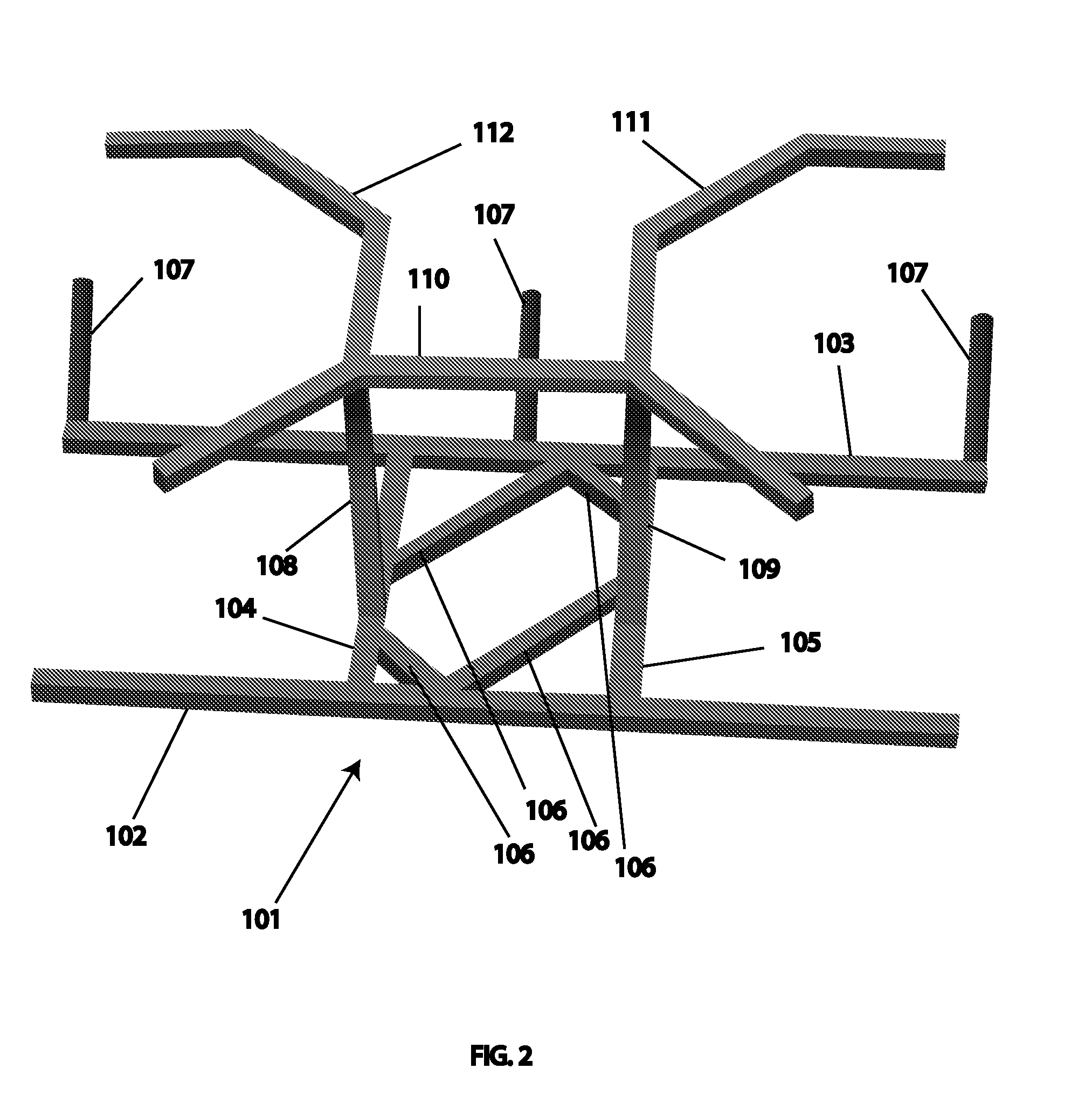

Adjustable cooking grate for barbeque grills

An adjustable grate is described herein that may be easily adjusted to fit within variously sized grills. The adjustable grate includes a main plate having a plurality of fingers extending from a front side and a rear side. A front slide plate has a plurality of fingers that slidably engage with the fingers on the front side of the main plate. A rear slide plate has a plurality of fingers that slidably engage with the fingers on the rear side of the main plate. The front slide plate, the rear slide plate and the main plate define a cooking surface. The front slide plate and the rear slide plate may be slidably adjusted with respect to the main plate to expand or contract the cooking surface.

Owner:W C BRADLEY CO

Pellet burning heating assembly

Owner:GRILLSON

Monitoring of fuel on a grate fired boiler

Owner:INT PAPER CO

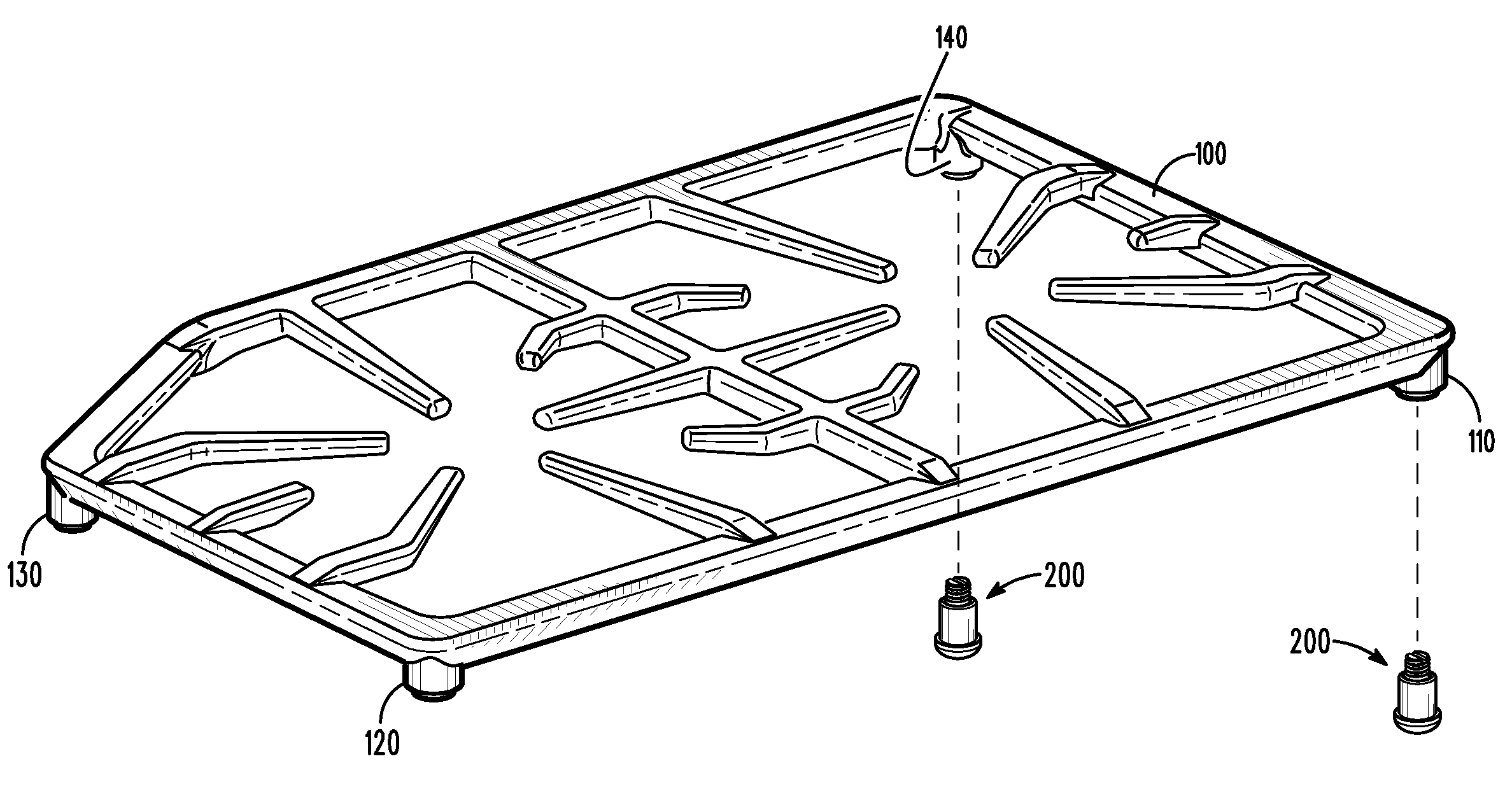

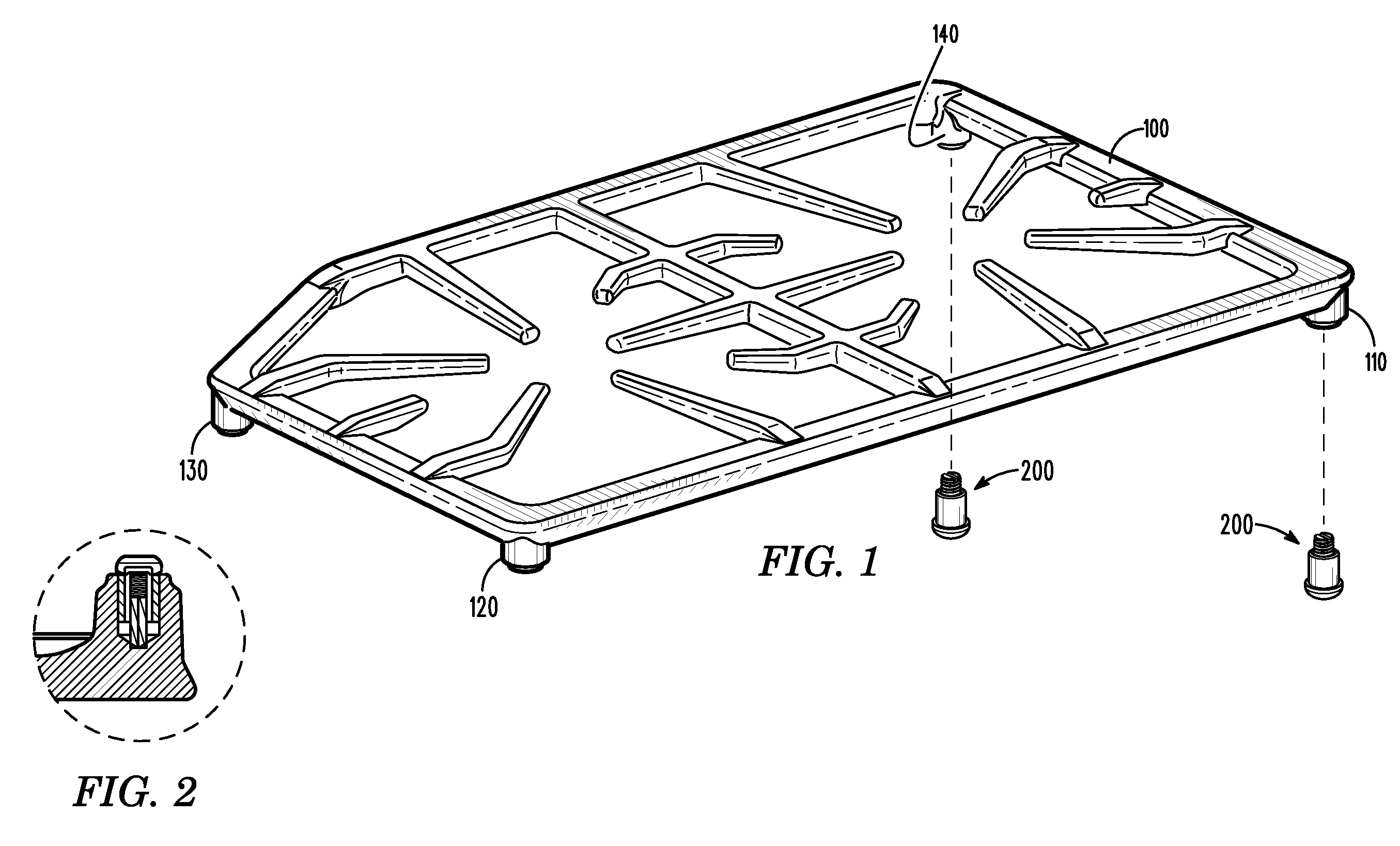

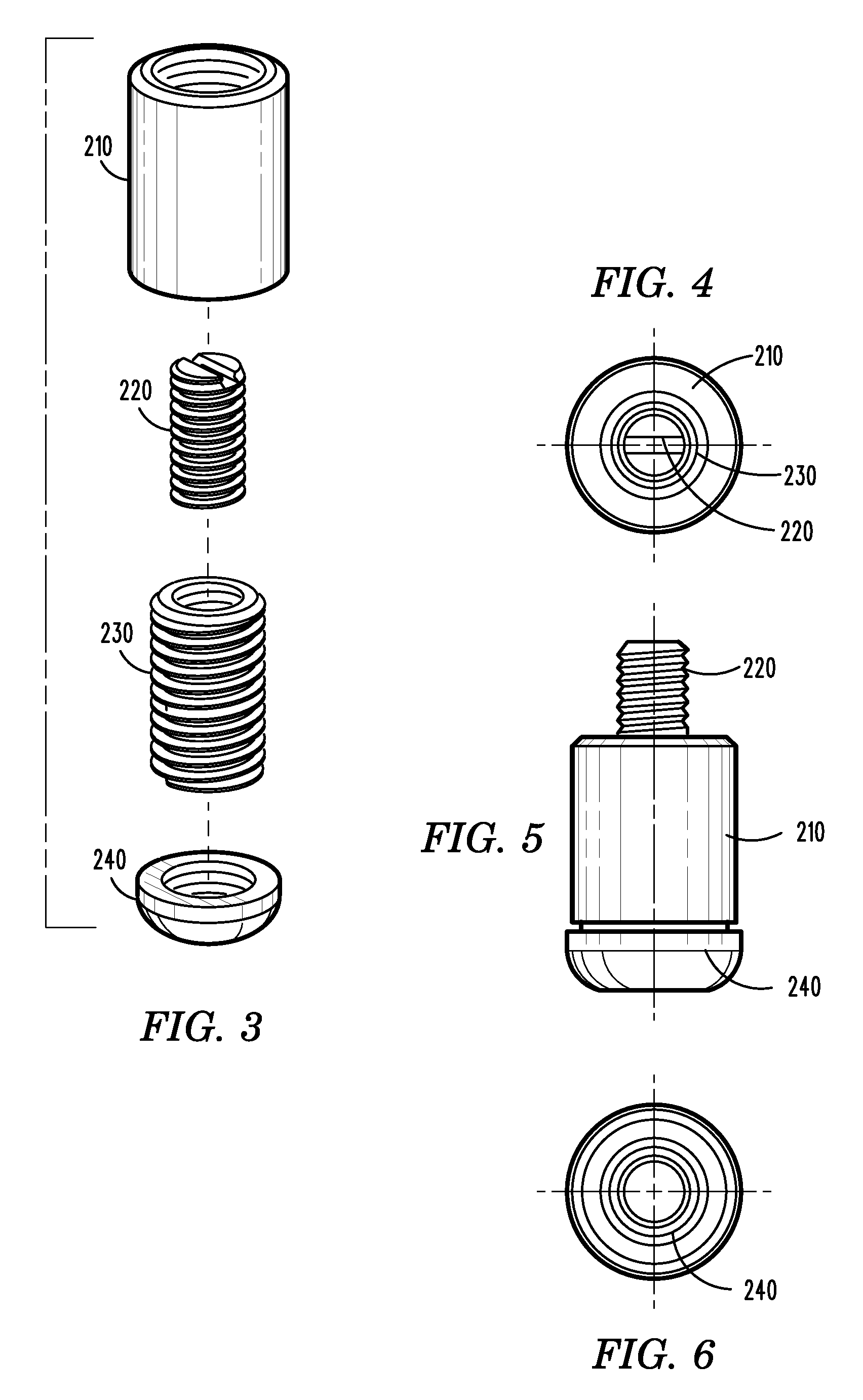

Adjustable grate foot for home appliance

An adjustable foot assembly for a pan support of a home appliance is provided. The assembly includes a first bushing having an inside threaded surface on an inner surface, and outside threaded surface on an outer surface; a set screw having an outside threaded surface on an outer surface, the outside threaded surface of the set screw engaging the inside threaded surface of the first bushing such that the set screw is movable relative to the first bushing along a first direction; and a contact foot attached to the first bushing. The first bushing and the set screw are adapted to allow the set screw to be moved relative to the first bushing as the set screw is moved into contact with the pan support, the relative movement being allowed by the outside threaded surface of the set screw moving relative to the inside threaded surface of the first bushing.

Owner:BSH HOME APPLIANCES CORP

Non-gas fire pit

PendingUS20210048188A1Increase the cross-sectional areaReduce the cross-sectional areaCombustion-air/flue-gas circulation for stovesGratesThermodynamicsEngineering

Owner:LAMPLIGHT FARMS

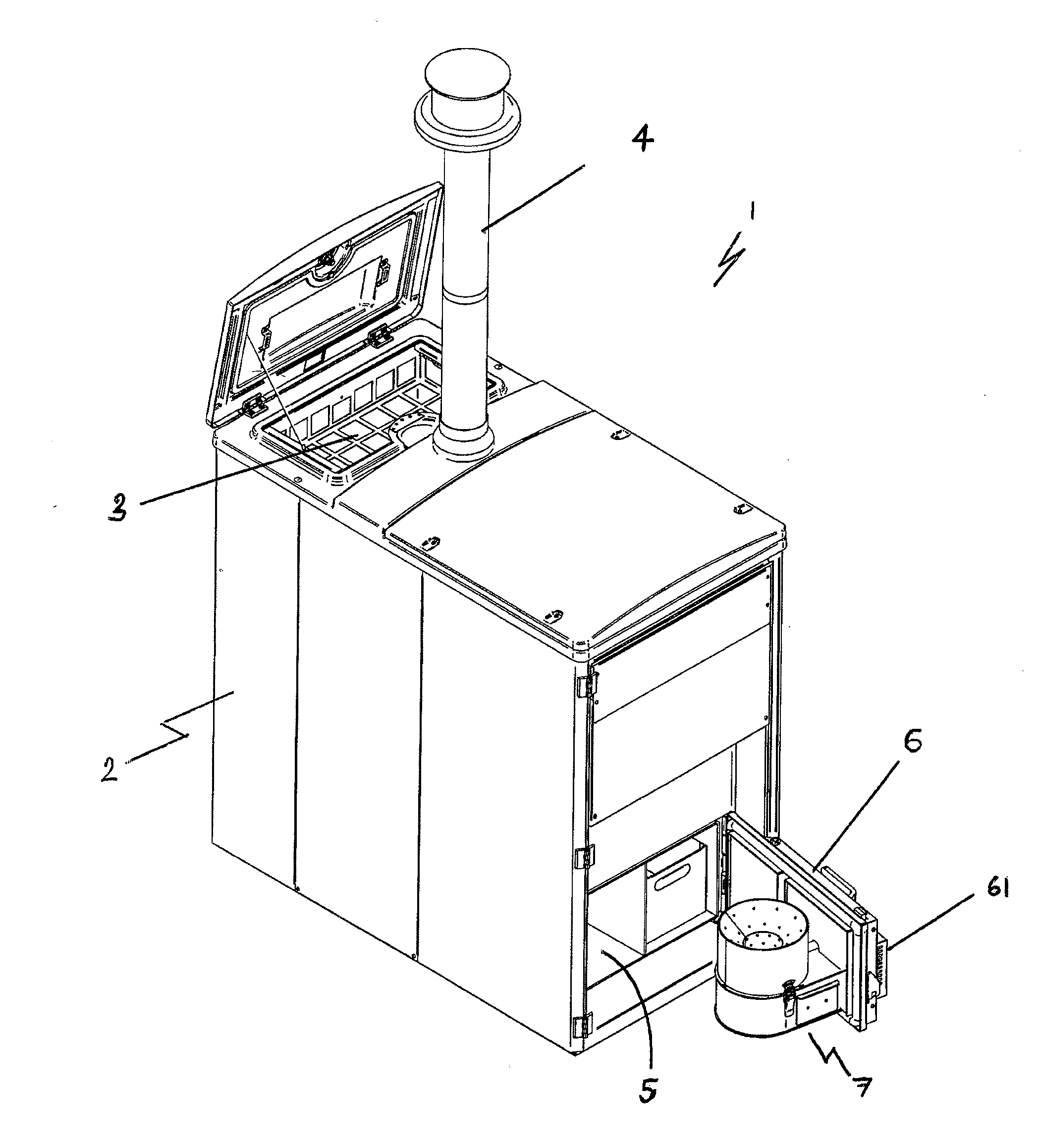

Pellet stove

InactiveUS20080156312A1Thorough removalEasy to cleanDomestic stoves or rangesGratesCombustorEngineering

Owner:FAHRENHEIT TECH

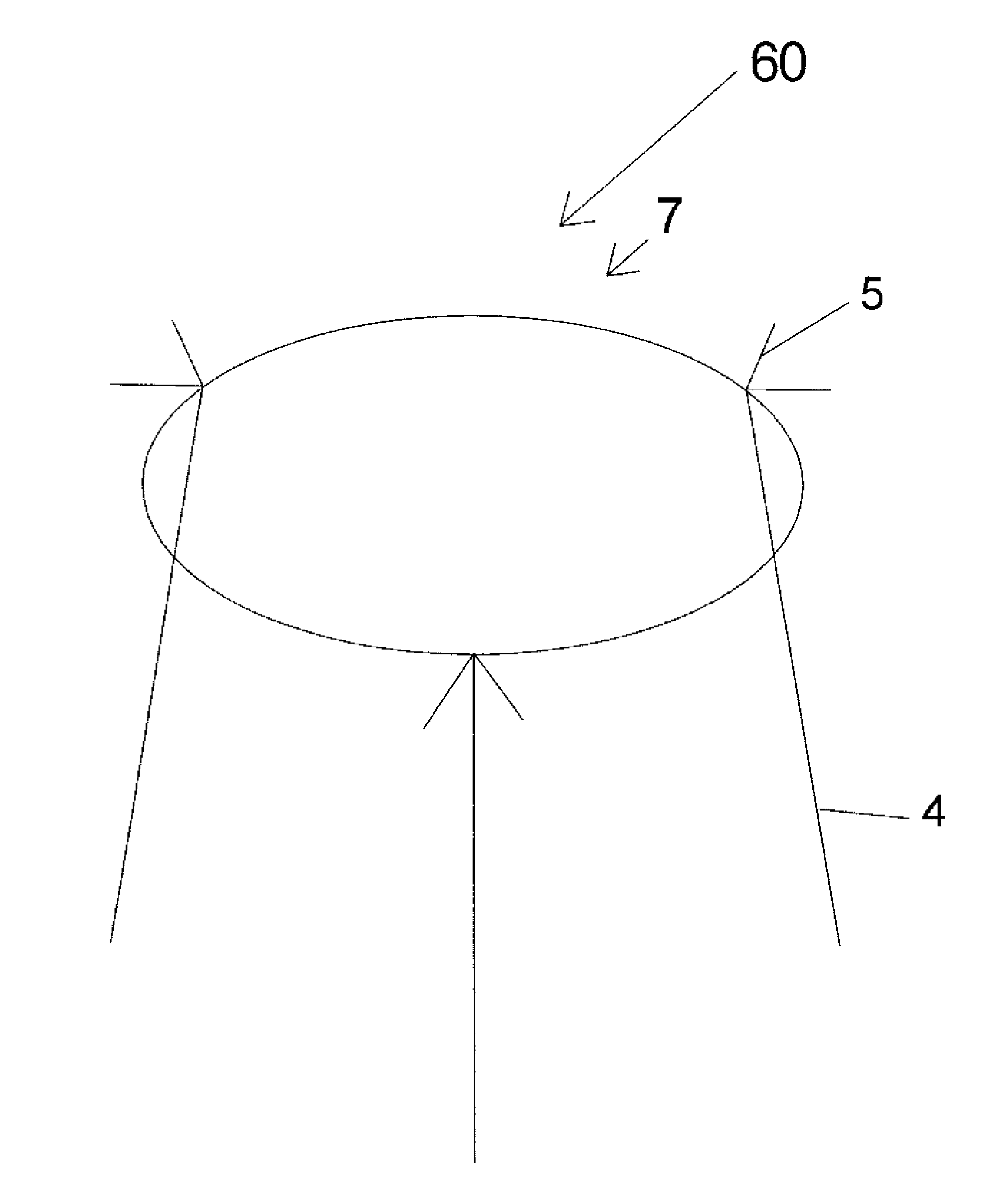

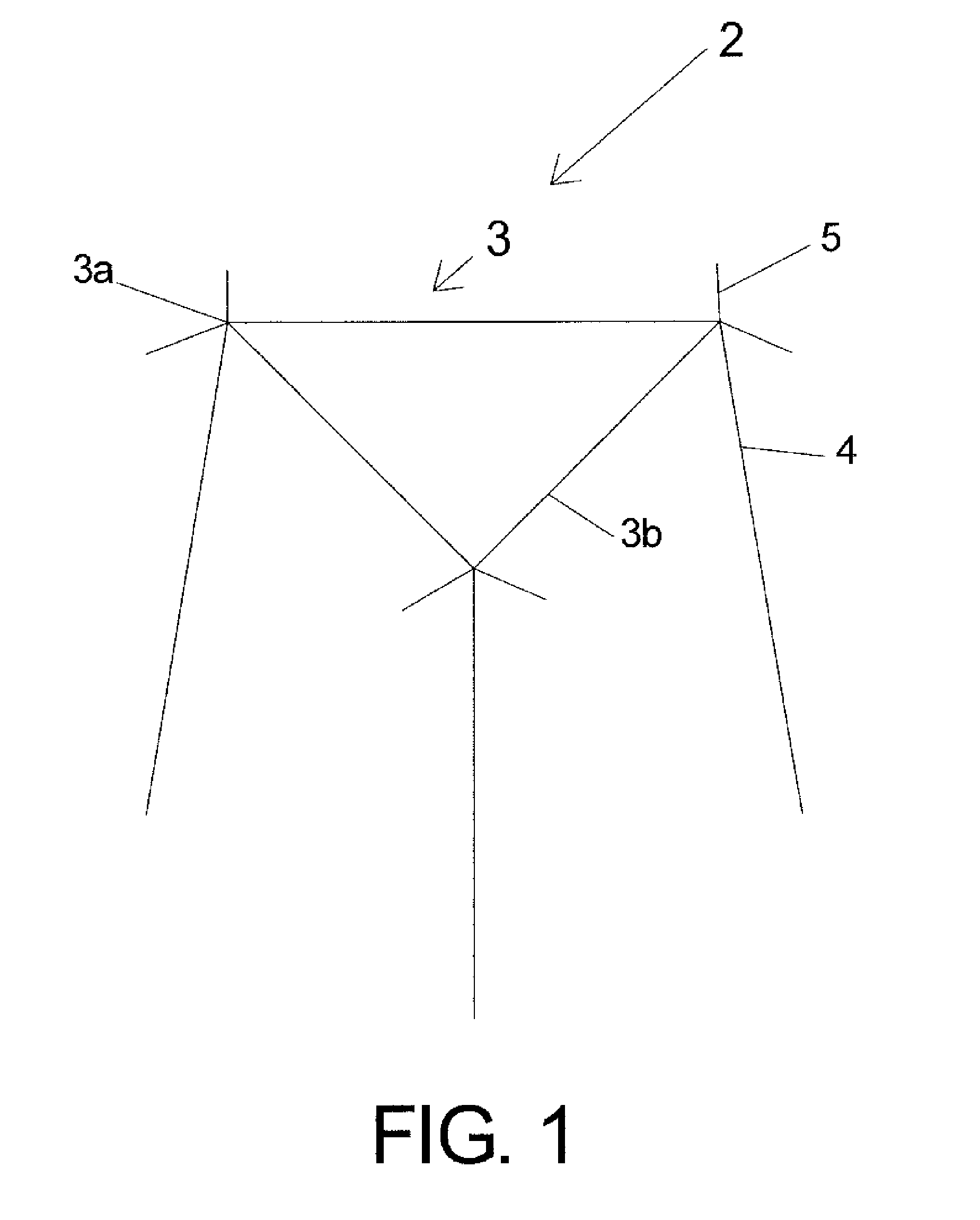

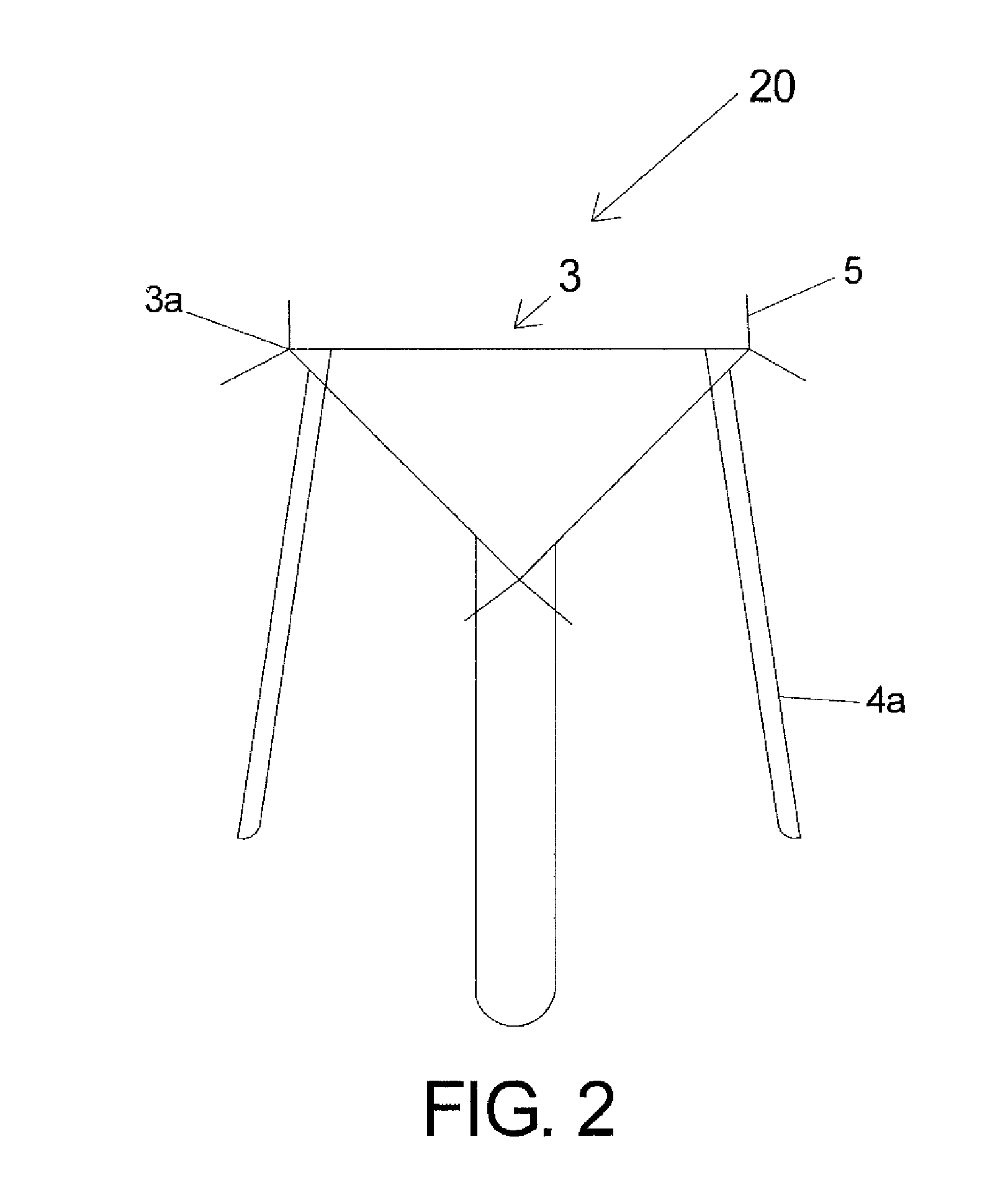

Campfire support unit

A campfire support unit for burning firewood. The unit has a metal frame that includes a metal support ring with metal tabs and support legs. The frame is made and arranged to support wood for a wood fire in a near-vertical ring position around a central core which contains wood supported in a near-vertical position. An internal core fire is started, using wood placed inside the metal ring. Then wood is leaned against the outer rim of the metal ring. The tabs support the wood leaned against the outer rim, preventing it from falling before, during, and after the outer wood is ignited by the internal core fire.

Owner:DUPONT DANIEL L

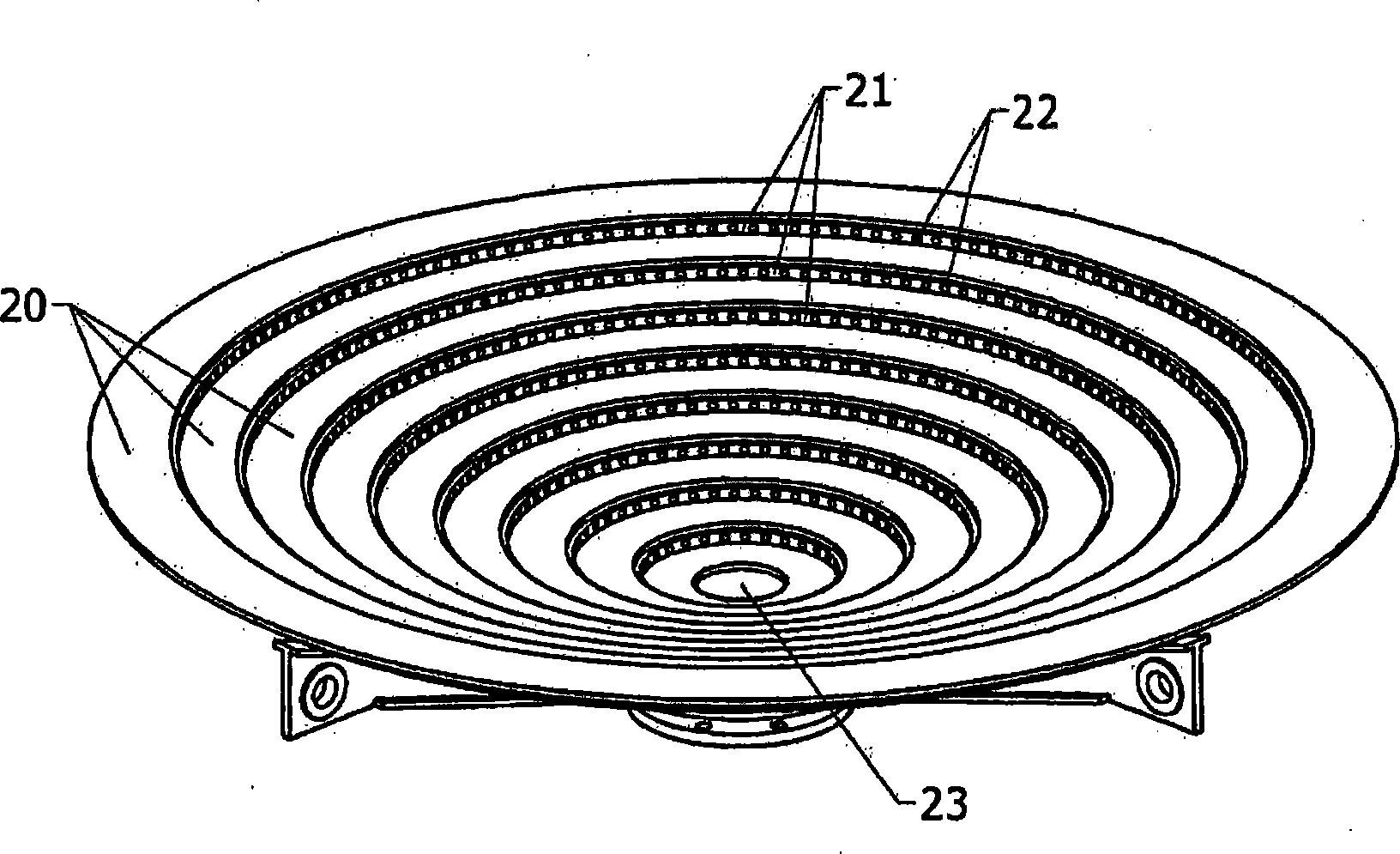

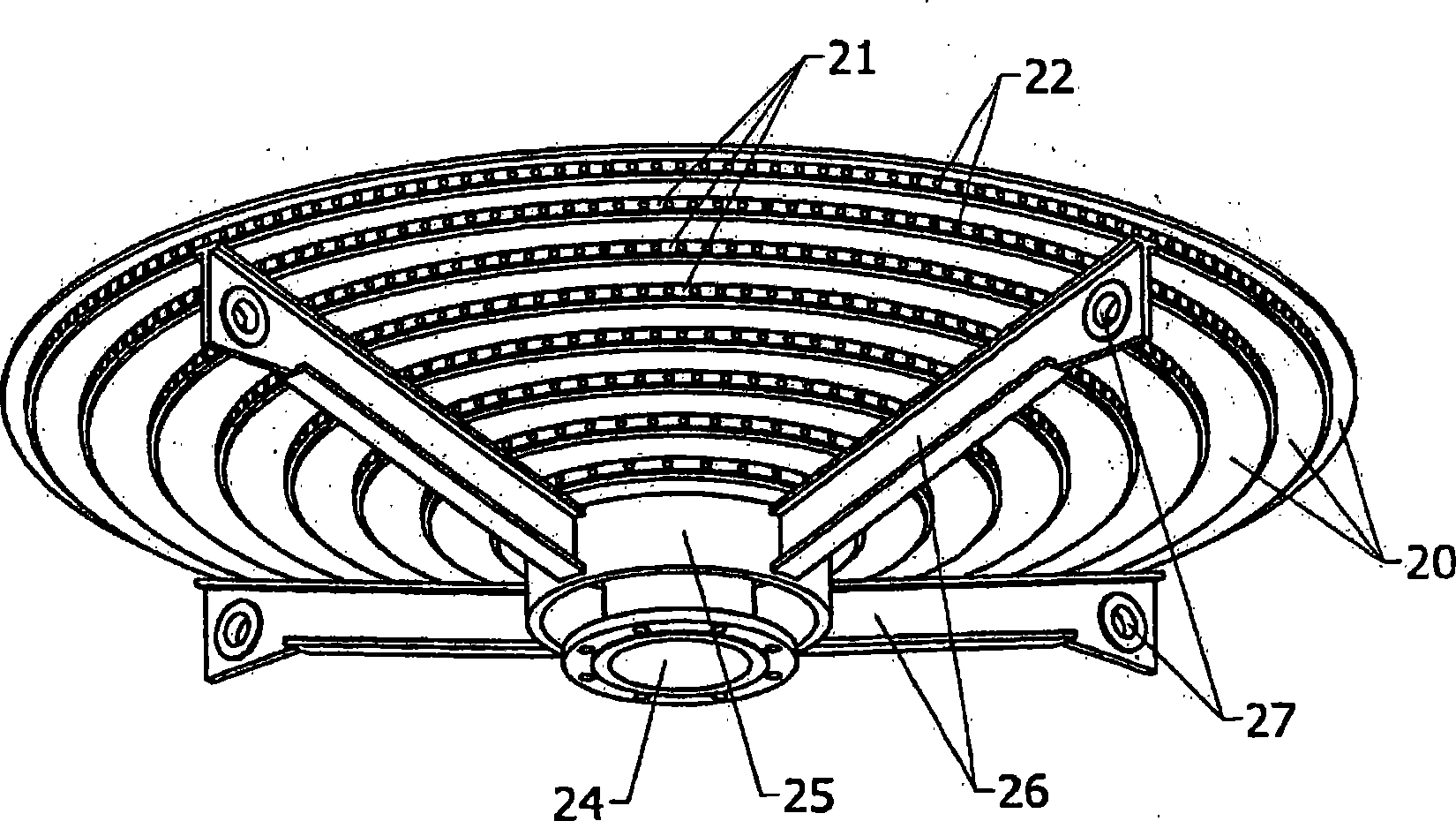

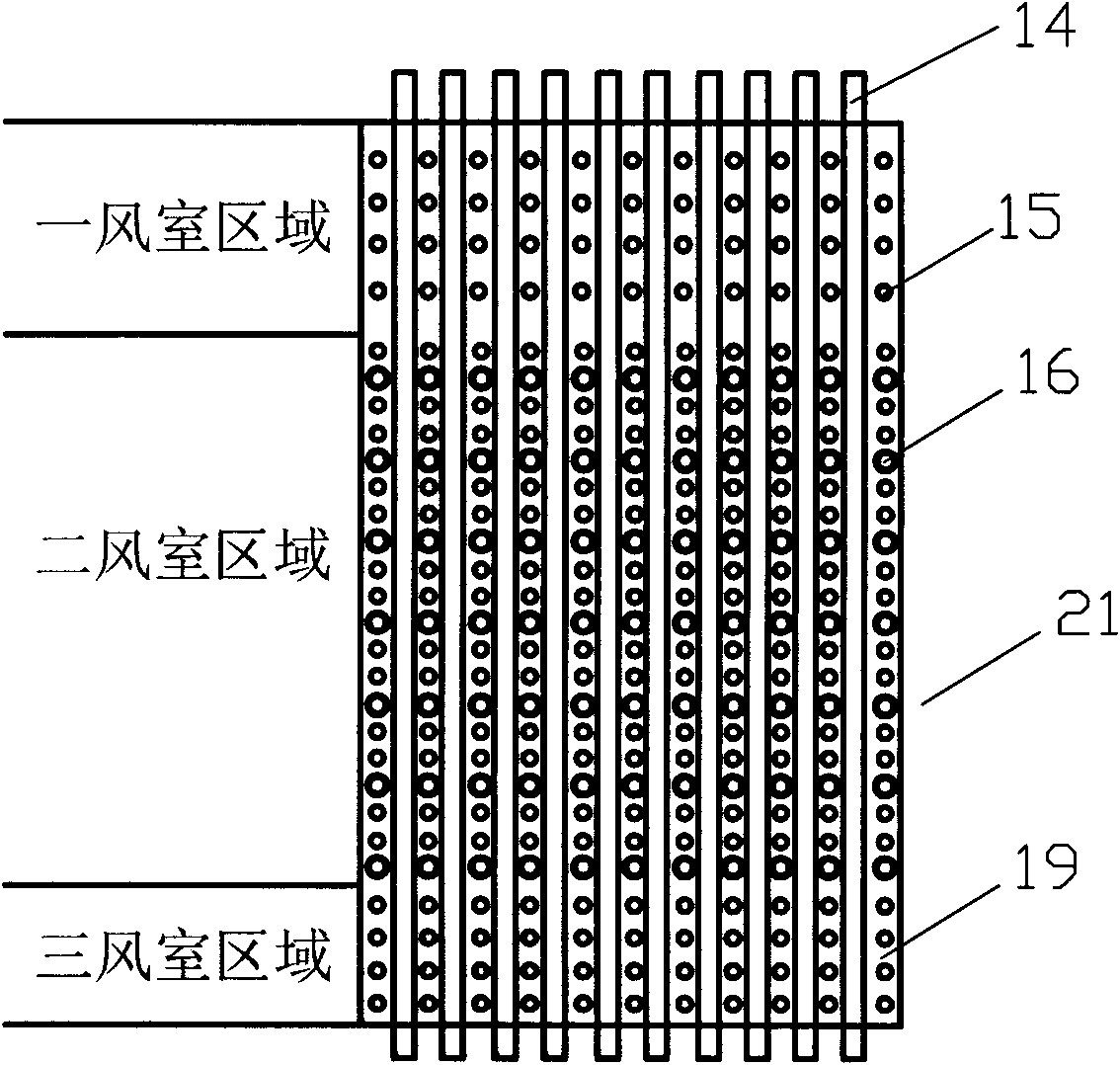

Grid for fluidized bed gasifier

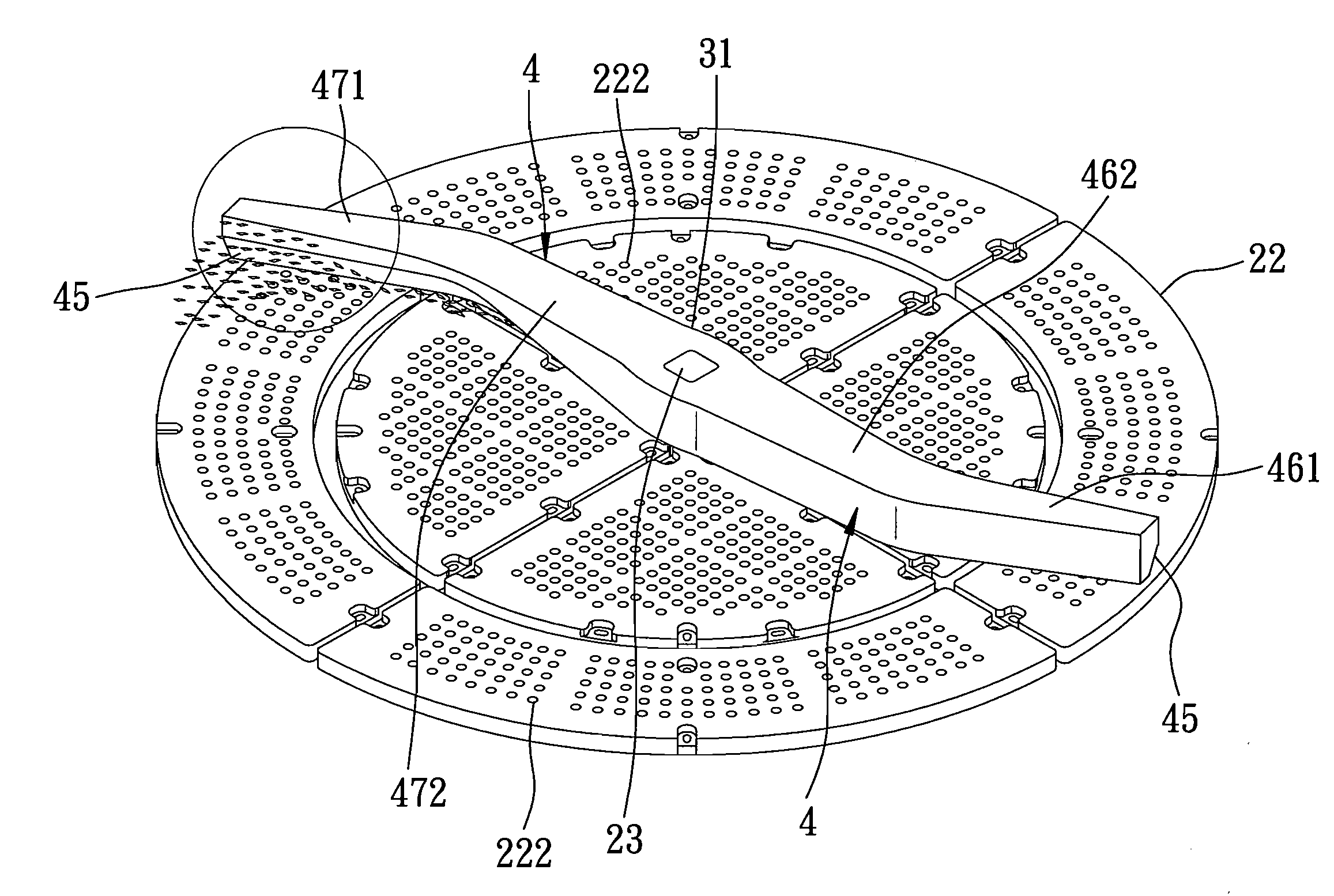

ActiveCN104093481ASimple and cheap to manufactureSimple structureFluidized bed combustionGratesFluidized bed gasifierFluidized bed

The present invention relates to a grid structure for a fluidized bed gasifier. The gasifier comprises an atmospheric or pressurized gasification reactor defined by vertical walls, wherein a fluidized bed is maintained in the reactor; a wind box located in the lower part of the gasifier below the reactor; and a grid that is arranged between the reactor and the wind box and comprises a number of substantially concentric plate rings. A first set of concentric plate rings are located at different levels to form a conical downwards tapering structure. The supporting structure of the first set of concentric plate rings comprises an annular supporting beam below the set of rings and radial supporting beams extending therefrom. The radial supporting beams are supported onto the walls of the wind box. The grid also comprises a second set of rings formed by plate rings arranged between the first rings. The second set of rings is provided with nozzle openings for leading air or other fluidizing gas from the wind box into the reactor.

Owner:ANDRITZ AG

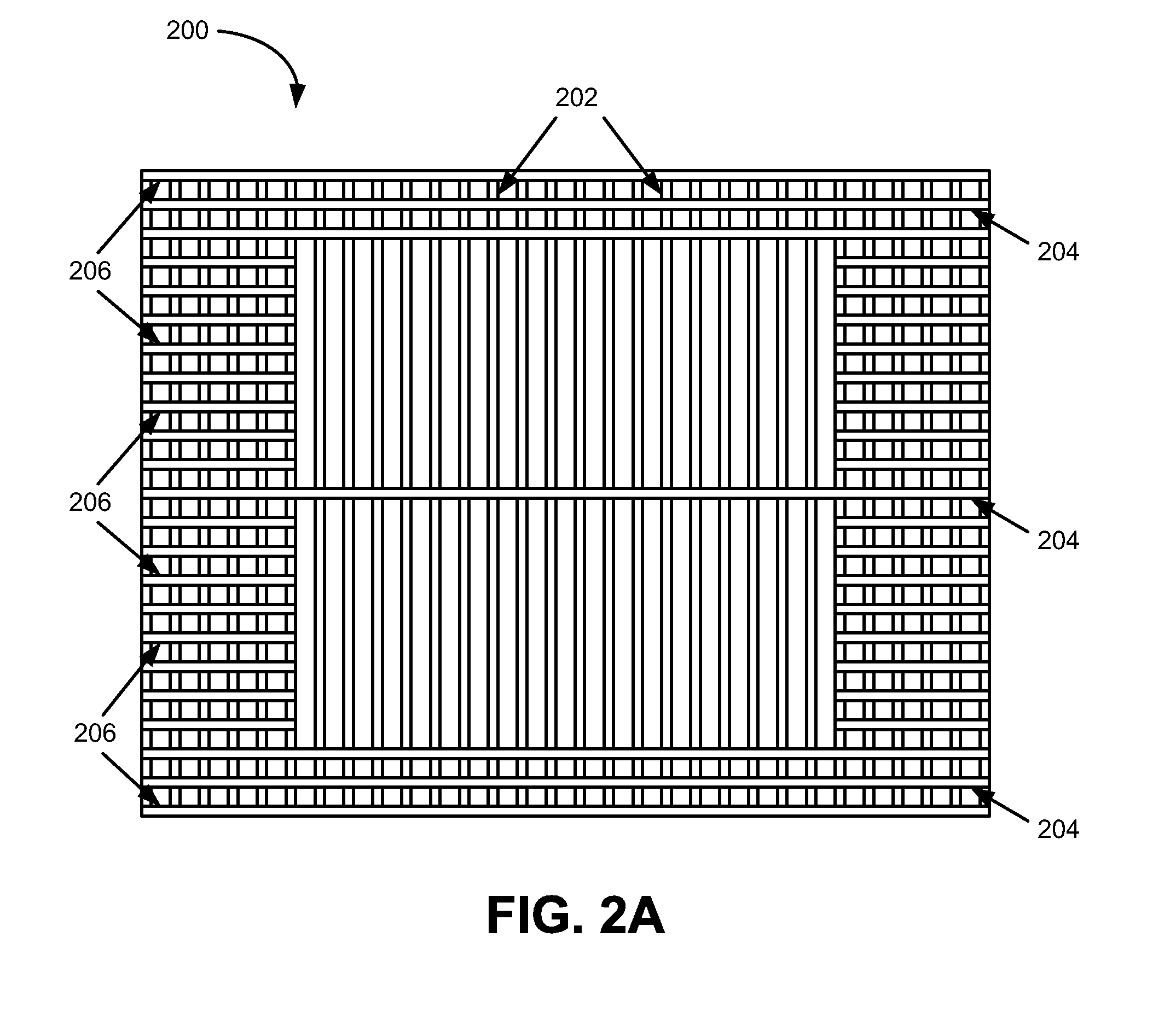

Adjustable pitch cooking grate

An adjustable pitch cooking grate includes generally parallel rods and means for changing the pitch of the rods by moving the rods between a closed configuration and a range of open configurations, with different width gaps therebetween. Scissors linkage at the rod ends can move the rods in unison between the open and close configurations. When the rods have flat upper surfaces the rods create a generally flat, smooth, continuous cooking surface when in the closed configuration and a plurality of generally flat coplanar cooking surfaces when in the different open configurations. The pitch changing means can include manual or motorized means for moving the rods between the open and close configurations. The spacing between the rods in a fully open configuration can be equal to about 1-3 times the lateral dimension of the rods. One or more cooking grates can be supported by the cooking grill frame.

Owner:ATLAW YOHANNES

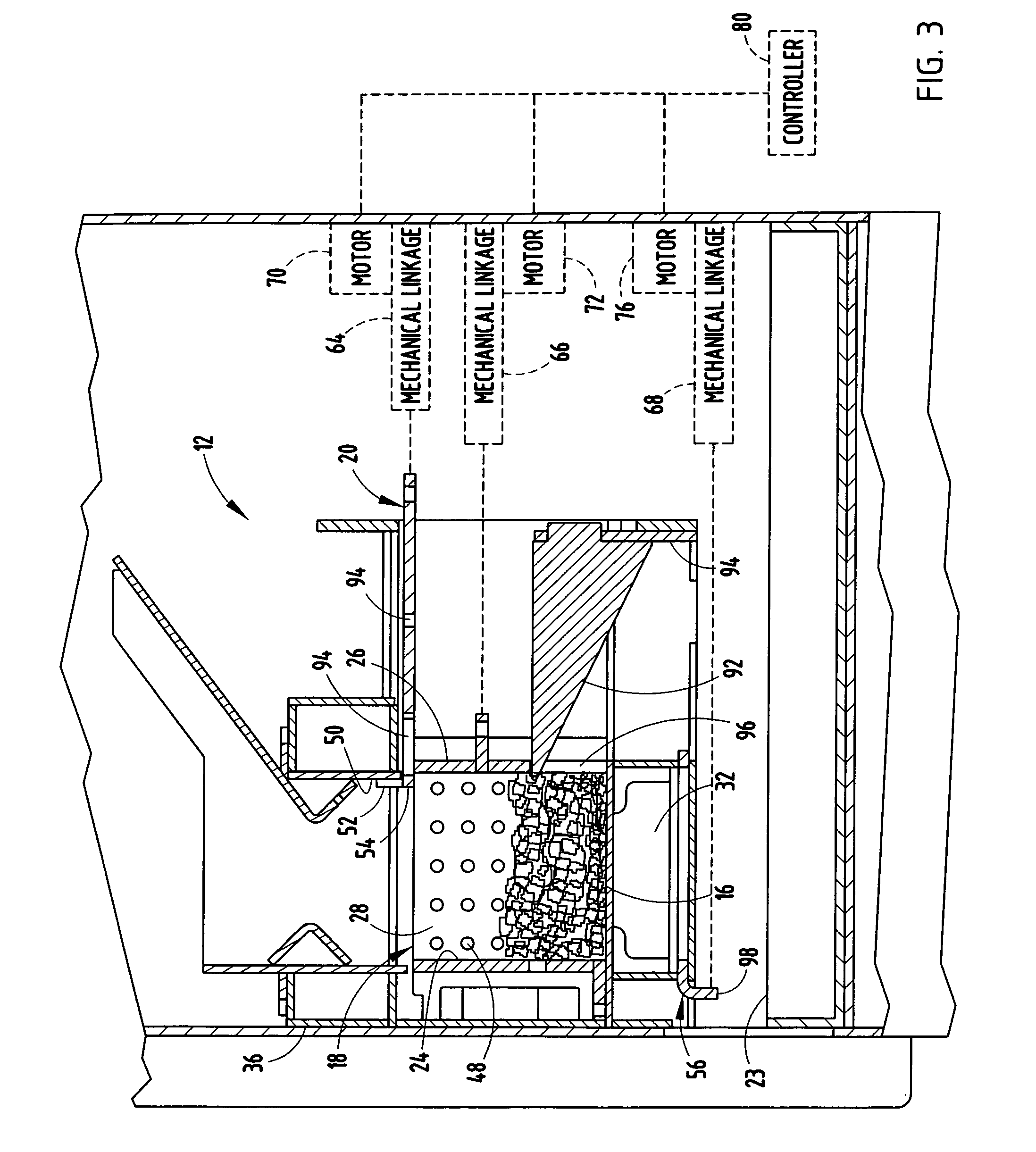

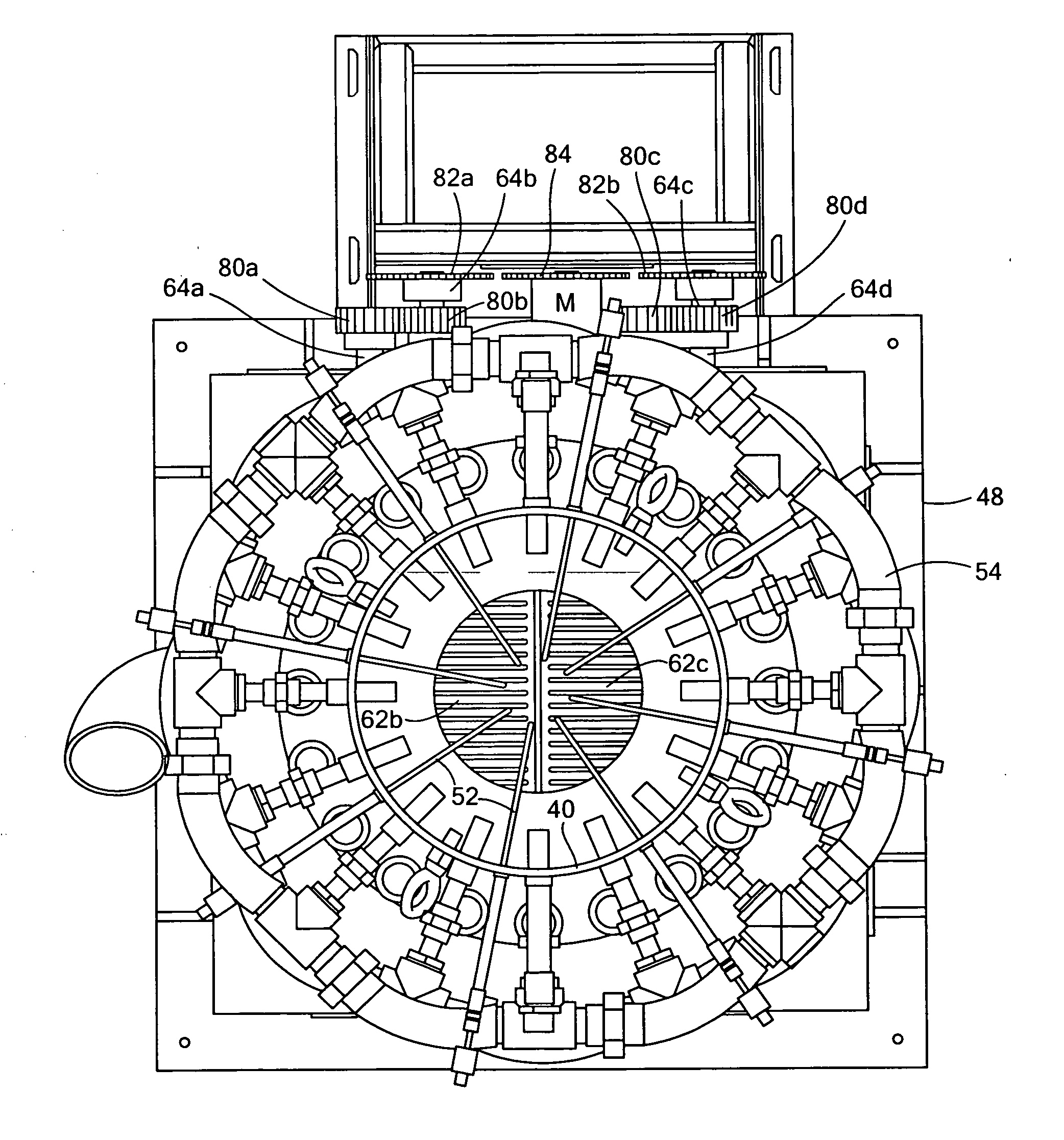

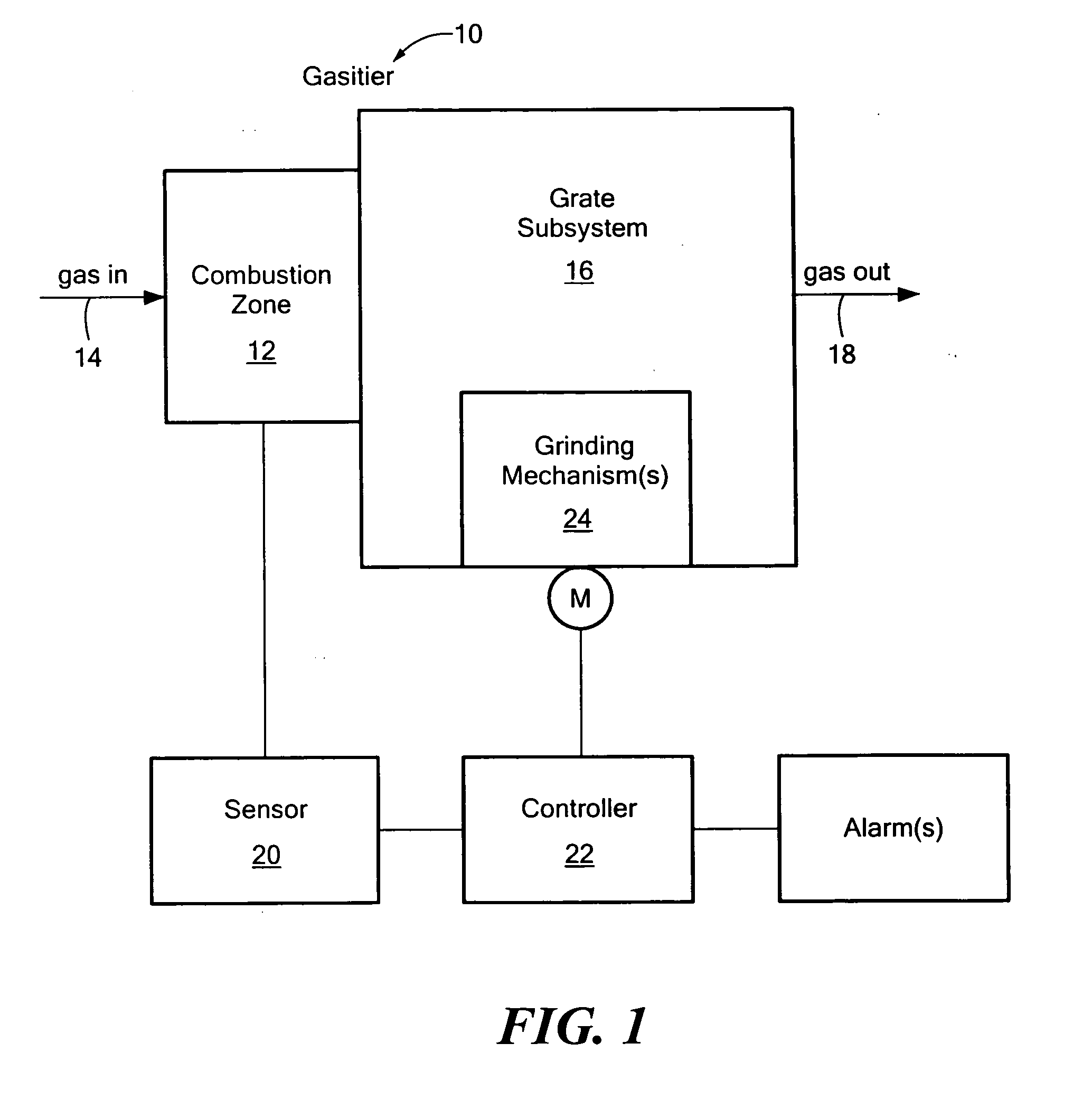

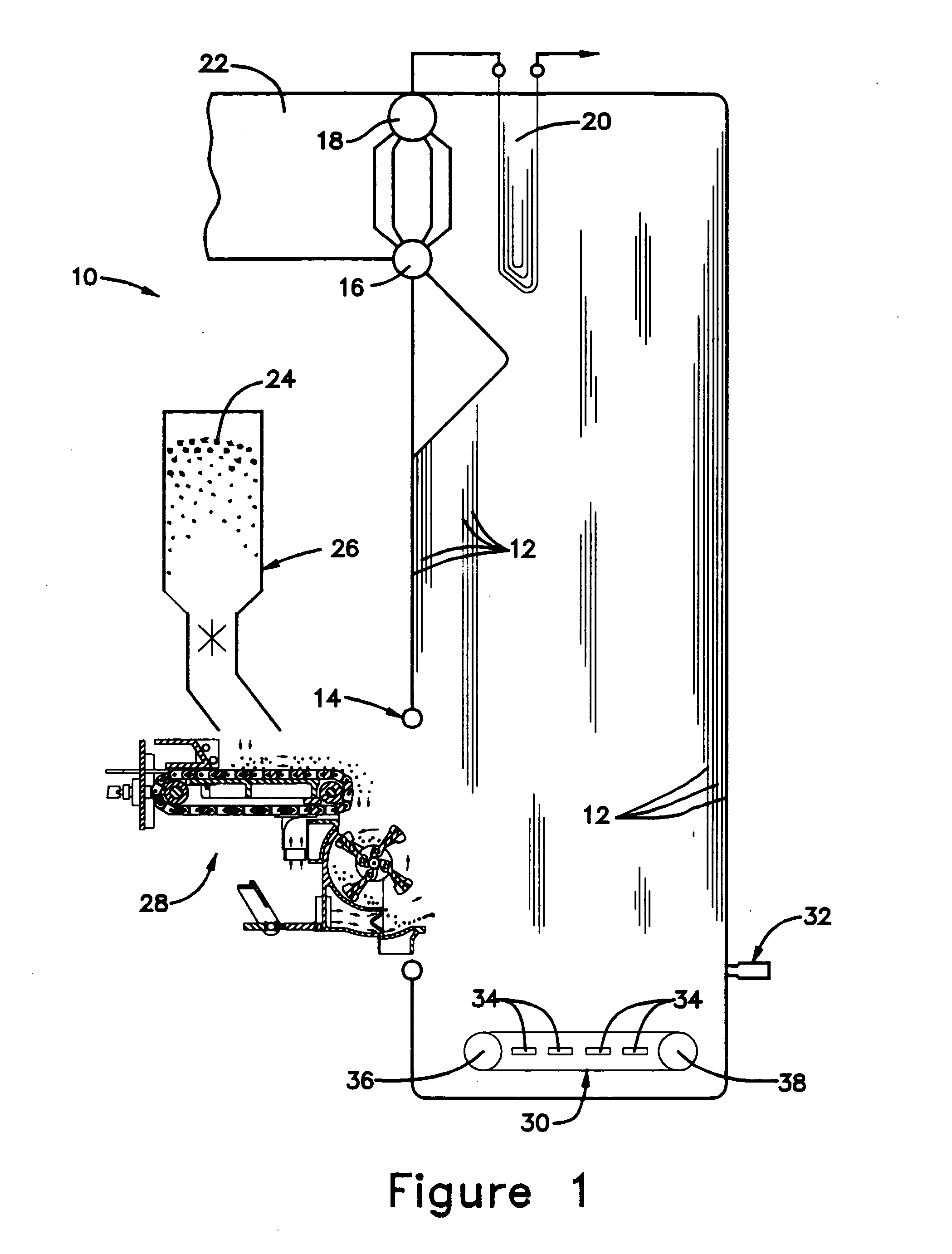

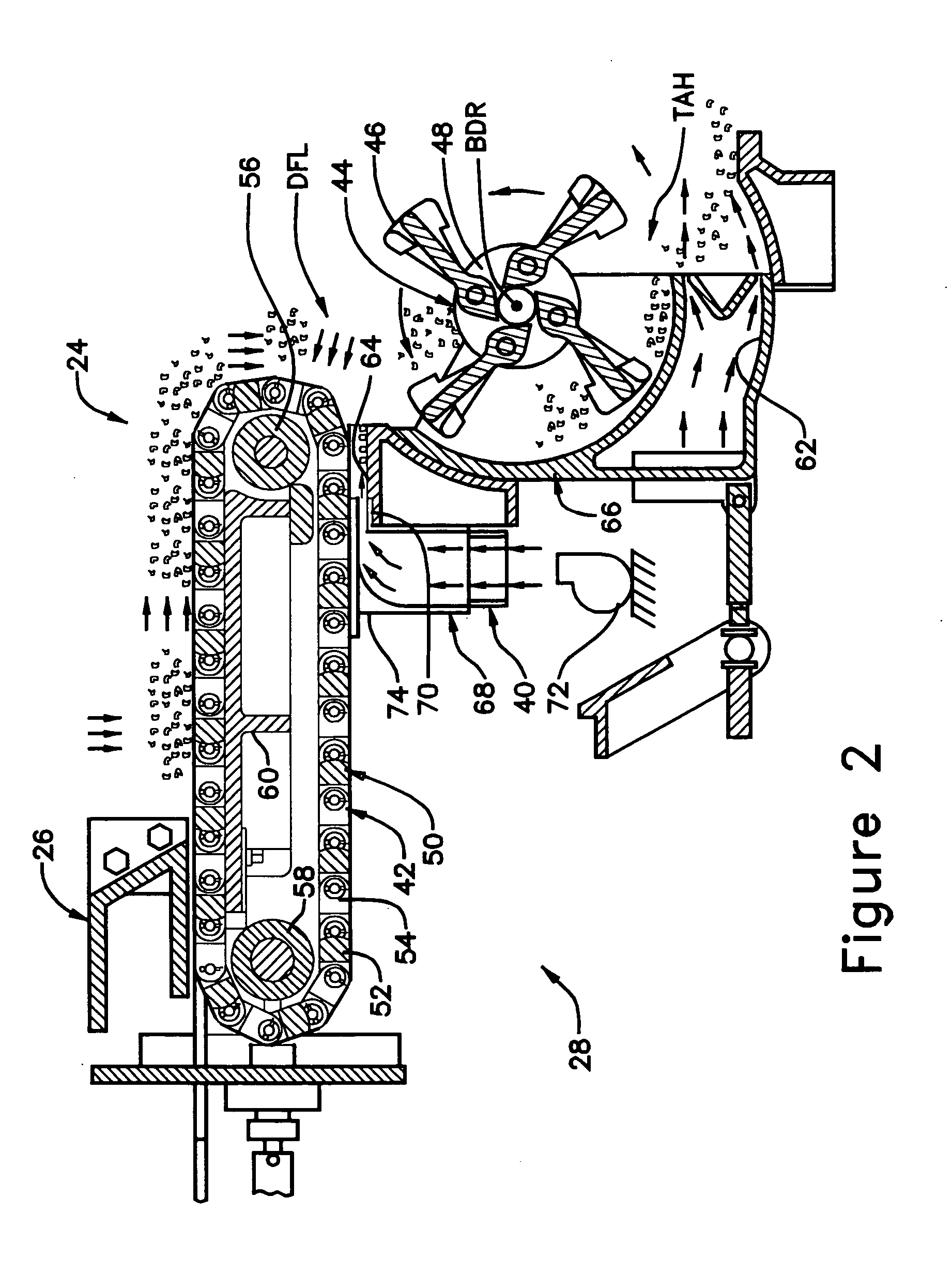

Gasifier ash processing subsystem

ActiveUS20110072722A1Reduce wasteReduce and eliminate clinkerBurnersGas modification by gas mixingCombustionEngineering

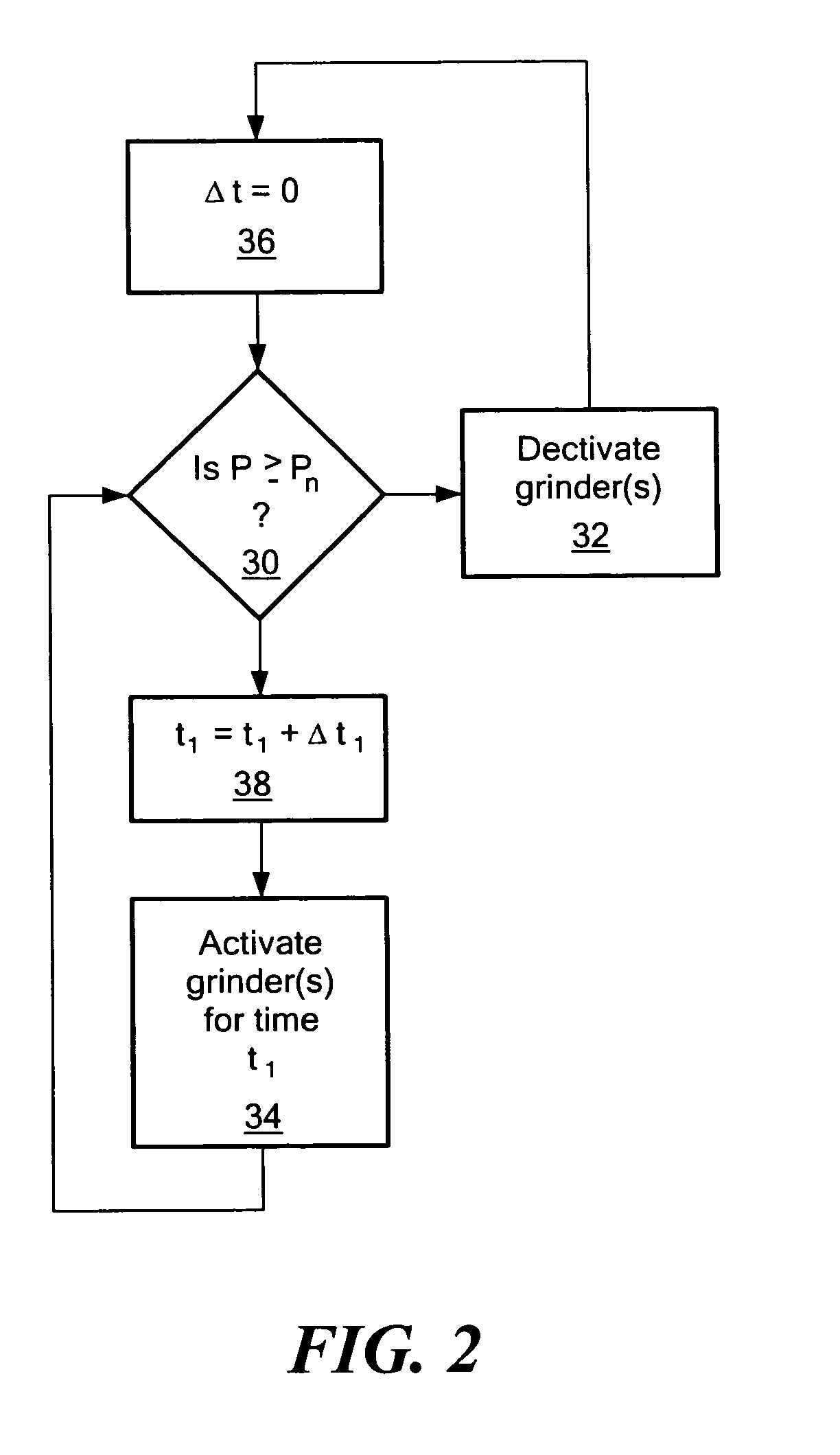

A gasifier includes a combustion zone where a gas is introduced and fuel is combusted and at least one sensor for measuring a predetermined condition in the gasifier. A grate subsystem contains the fuel and includes at least one grinding mechanism. A controller is responsive to the at least one sensor and controls the grinding mechanism by activating the grinding mechanism if the predetermined condition exists to reduce the collection of non-fuel products on the grate subsystem.

Owner:MSW POWER

Furnace

Owner:SUNCUE

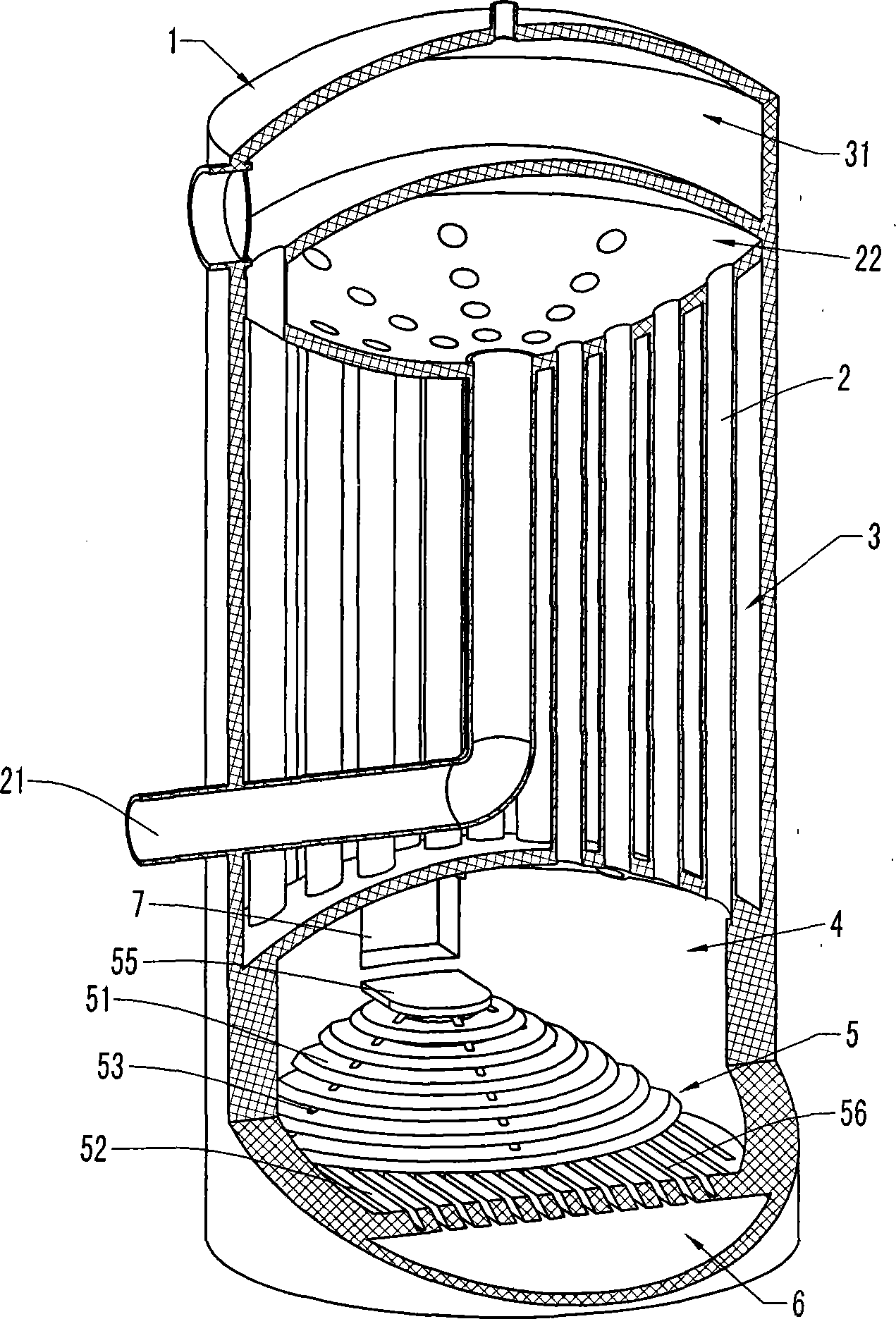

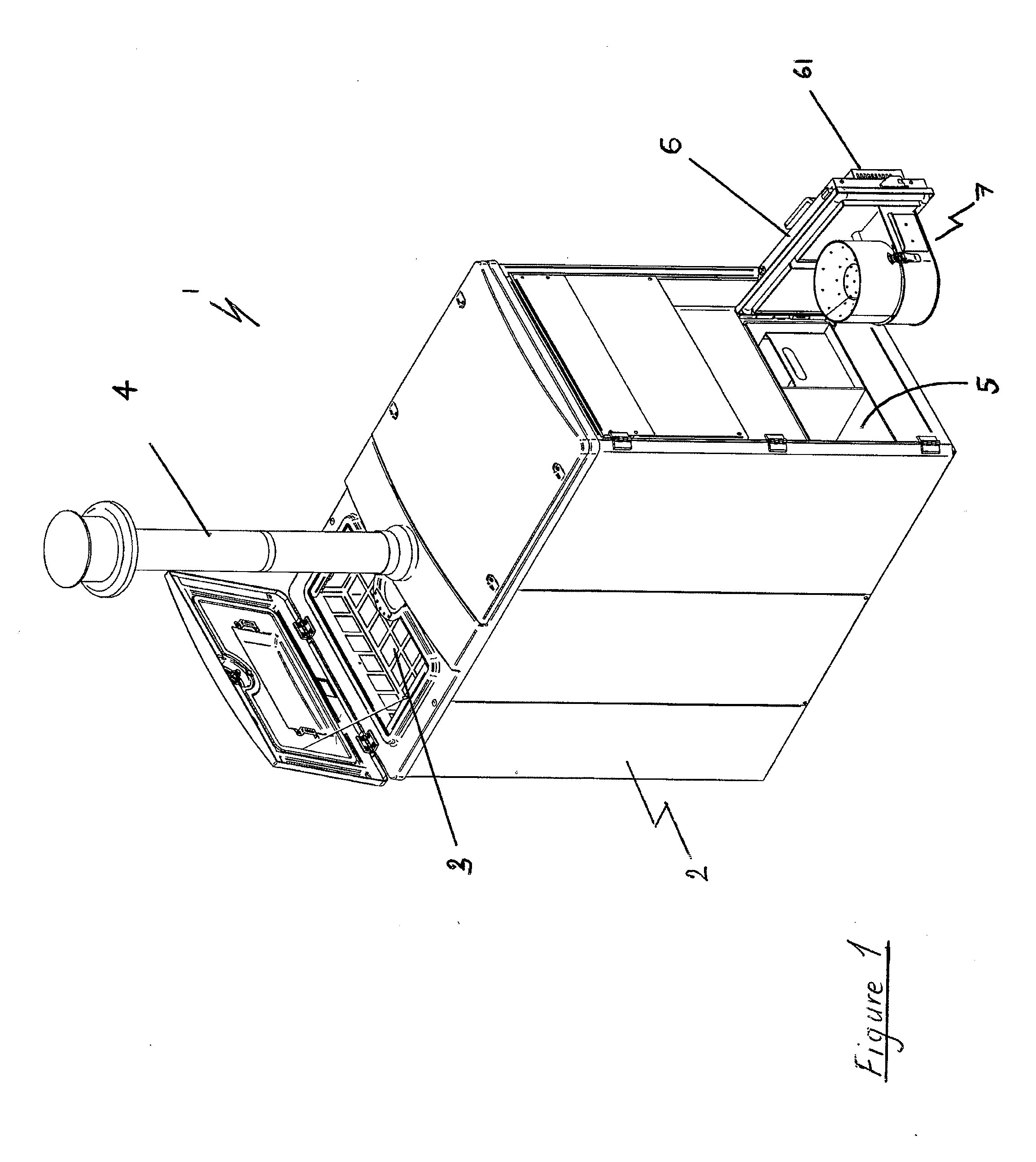

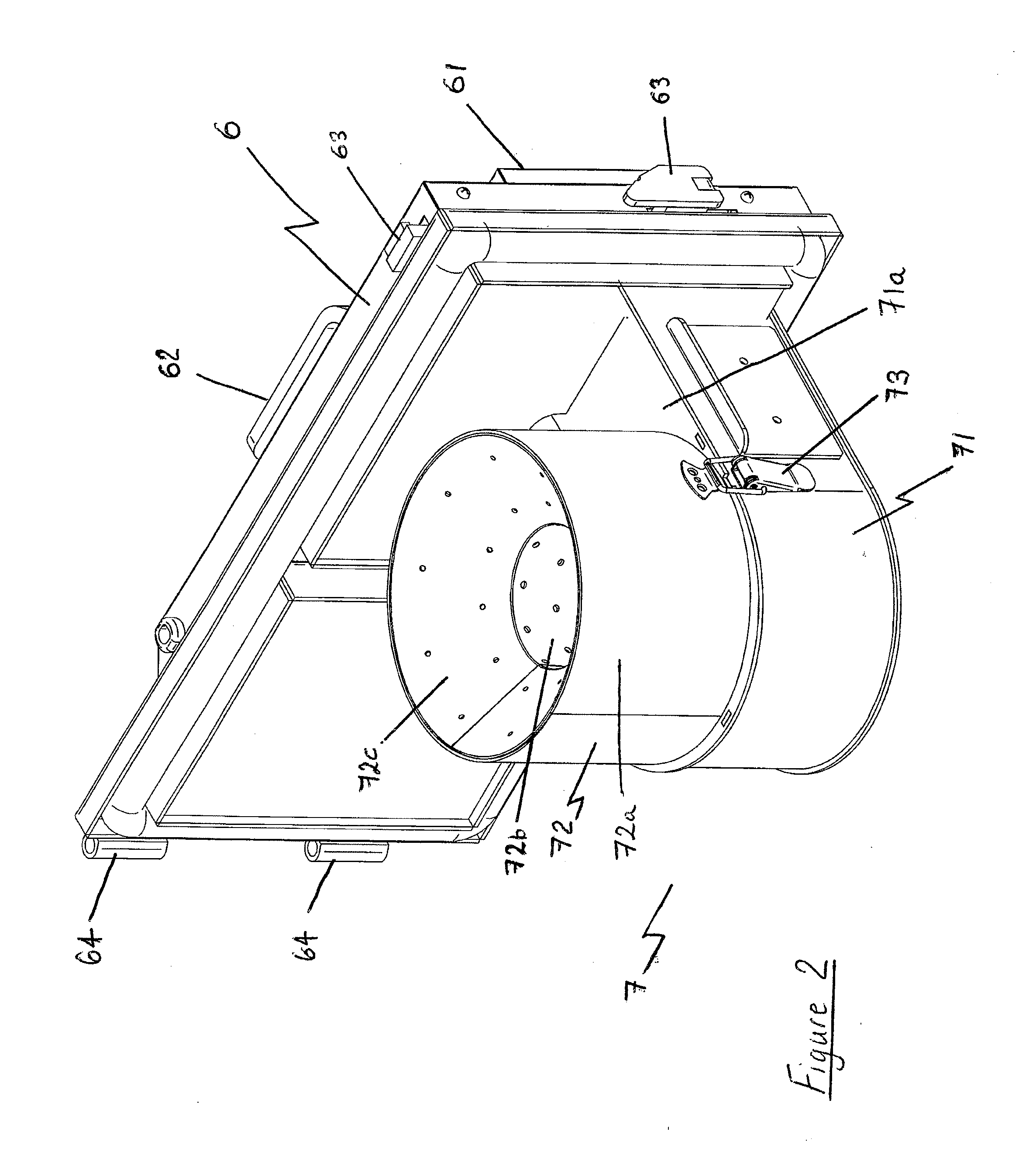

Wood pellet boiler

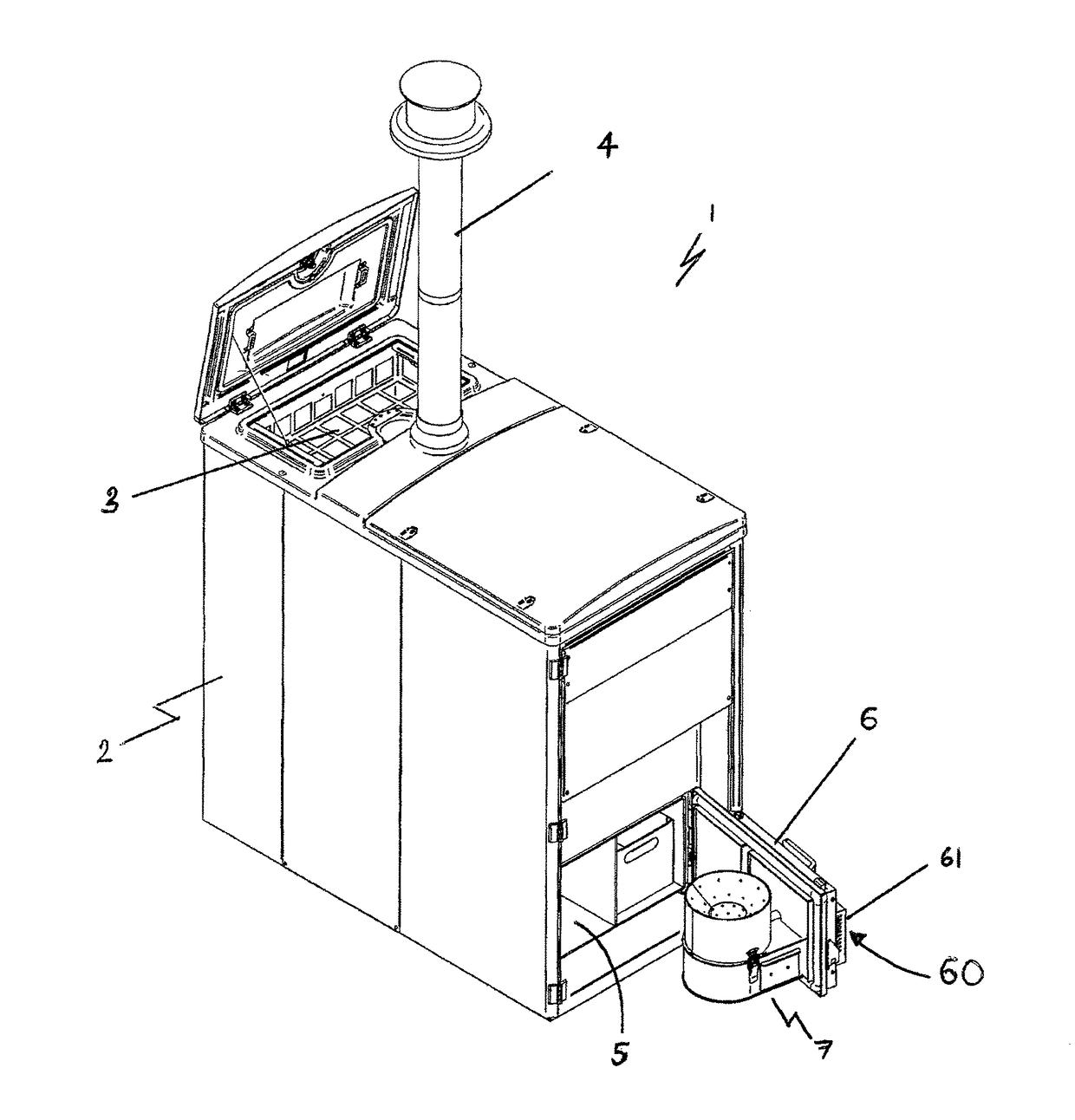

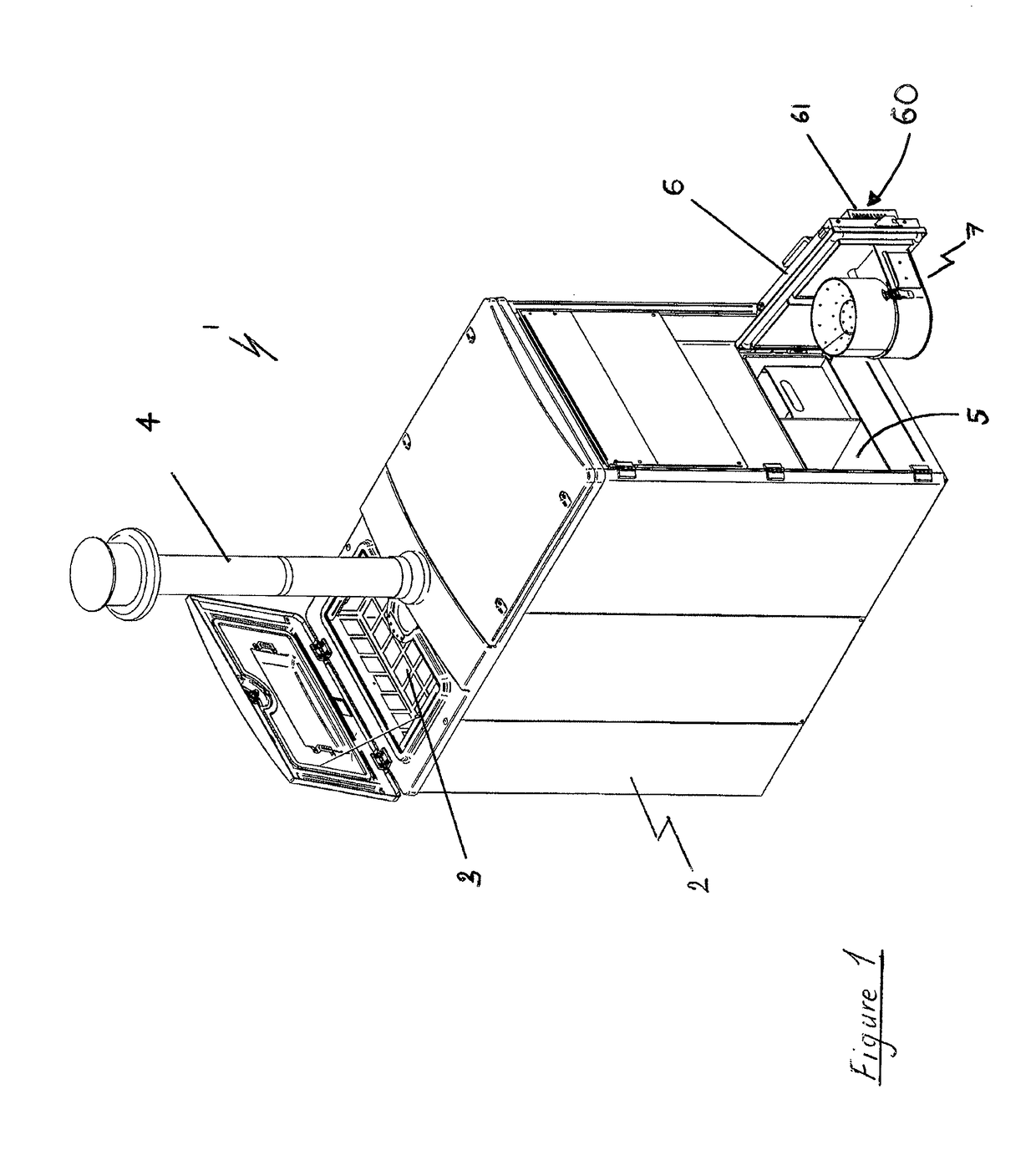

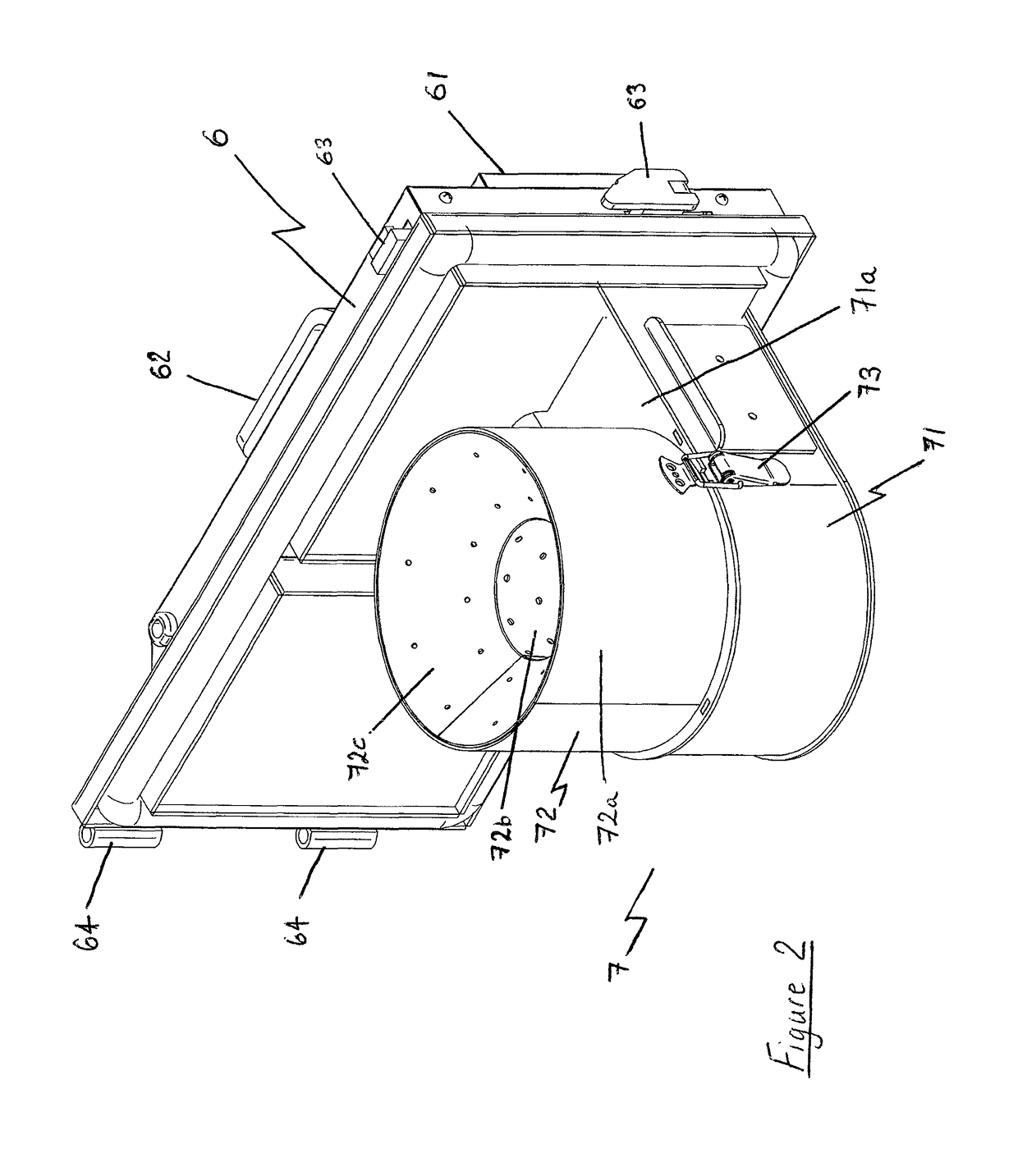

The present application relates to improvements to granular fuel burning boilers such as wood pellet boilers and burners therefor. In particular, there is disclosed a wood pellet boiler having a combustion chamber, wherein an access door for said combustion chamber comprises a wood pellet burner assembly mounted on the interior side thereof. In this way, the wood pellet burner assembly is movable from and into the combustion chamber of the wood pellet boiler when the access door is opened and closed, respectively.

Owner:WARMFLOW ENG

Heat distributing cooking grate

InactiveUS8544382B2Reduce, any “hot” or “cold” spotsEqually distributedGratesFrying pansProcess engineeringHeat distribution

Owner:WHIRLPOOL CORP

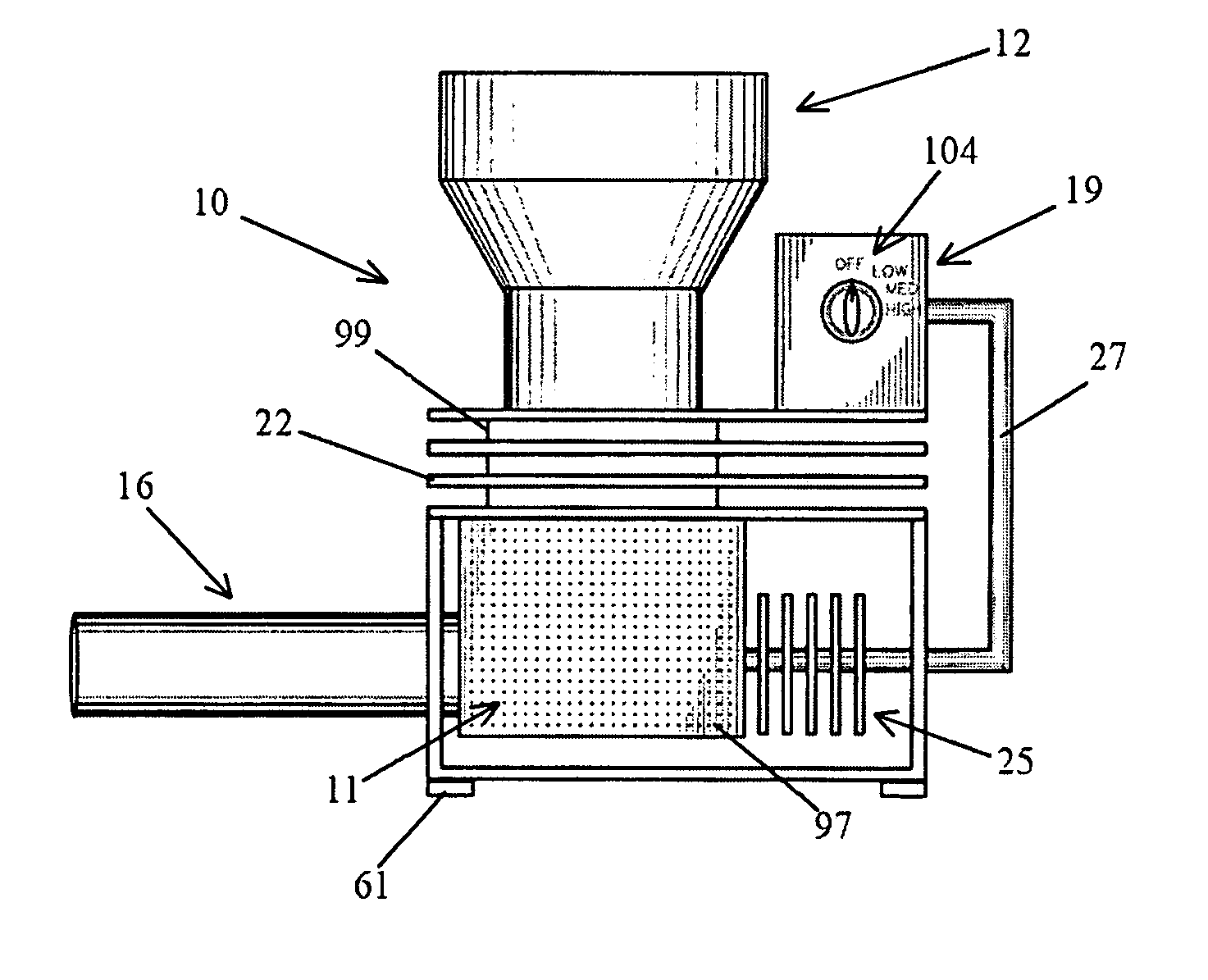

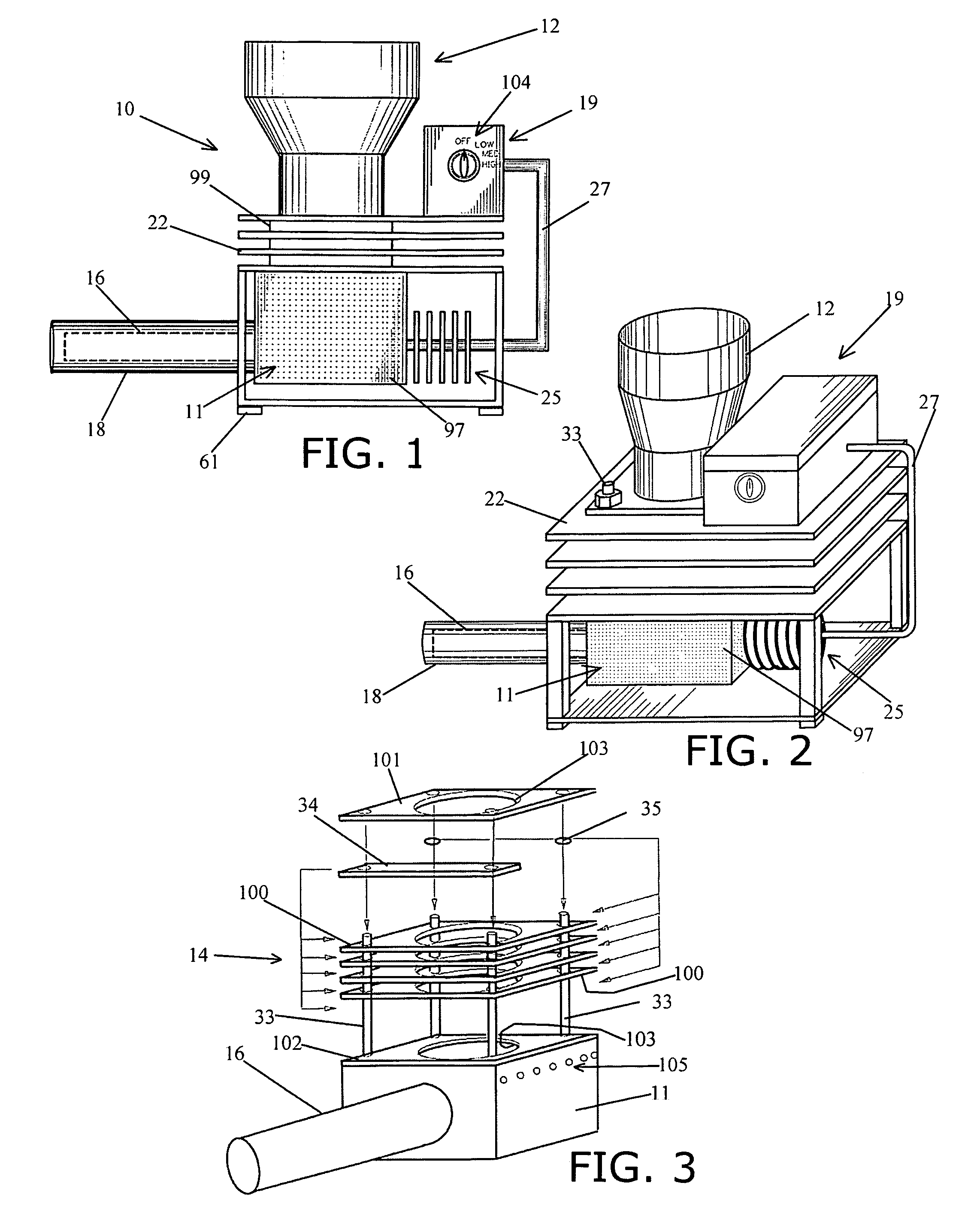

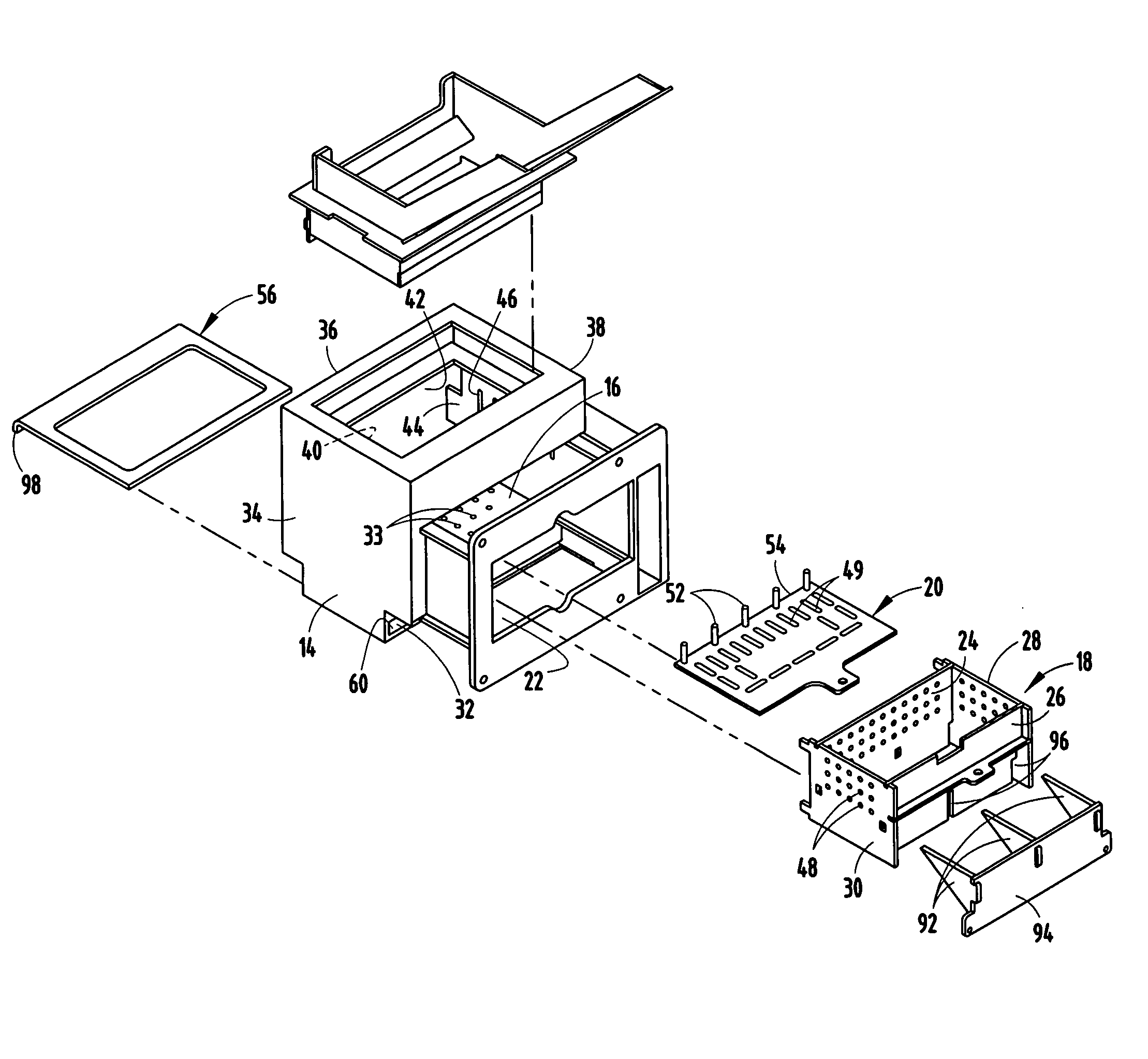

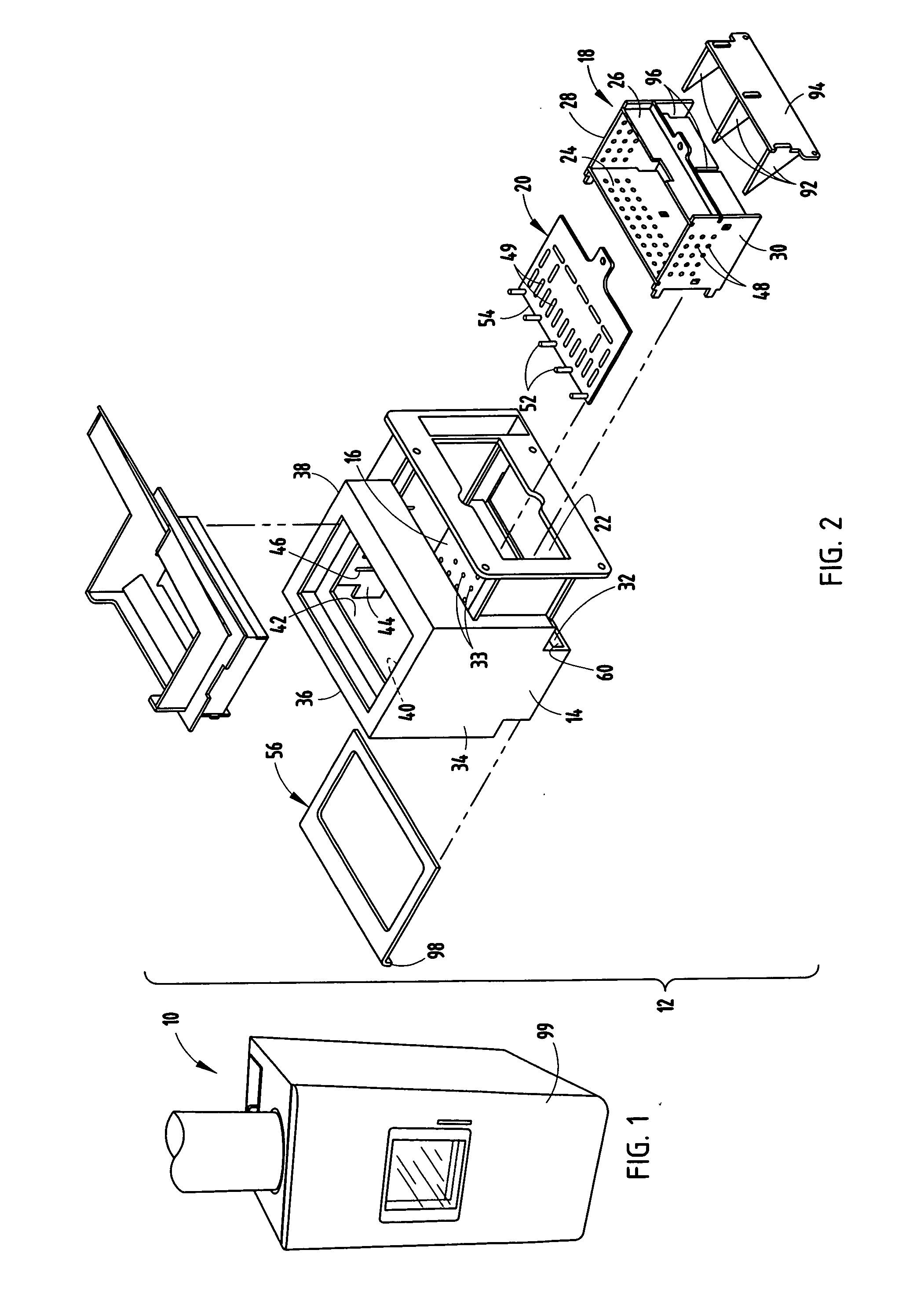

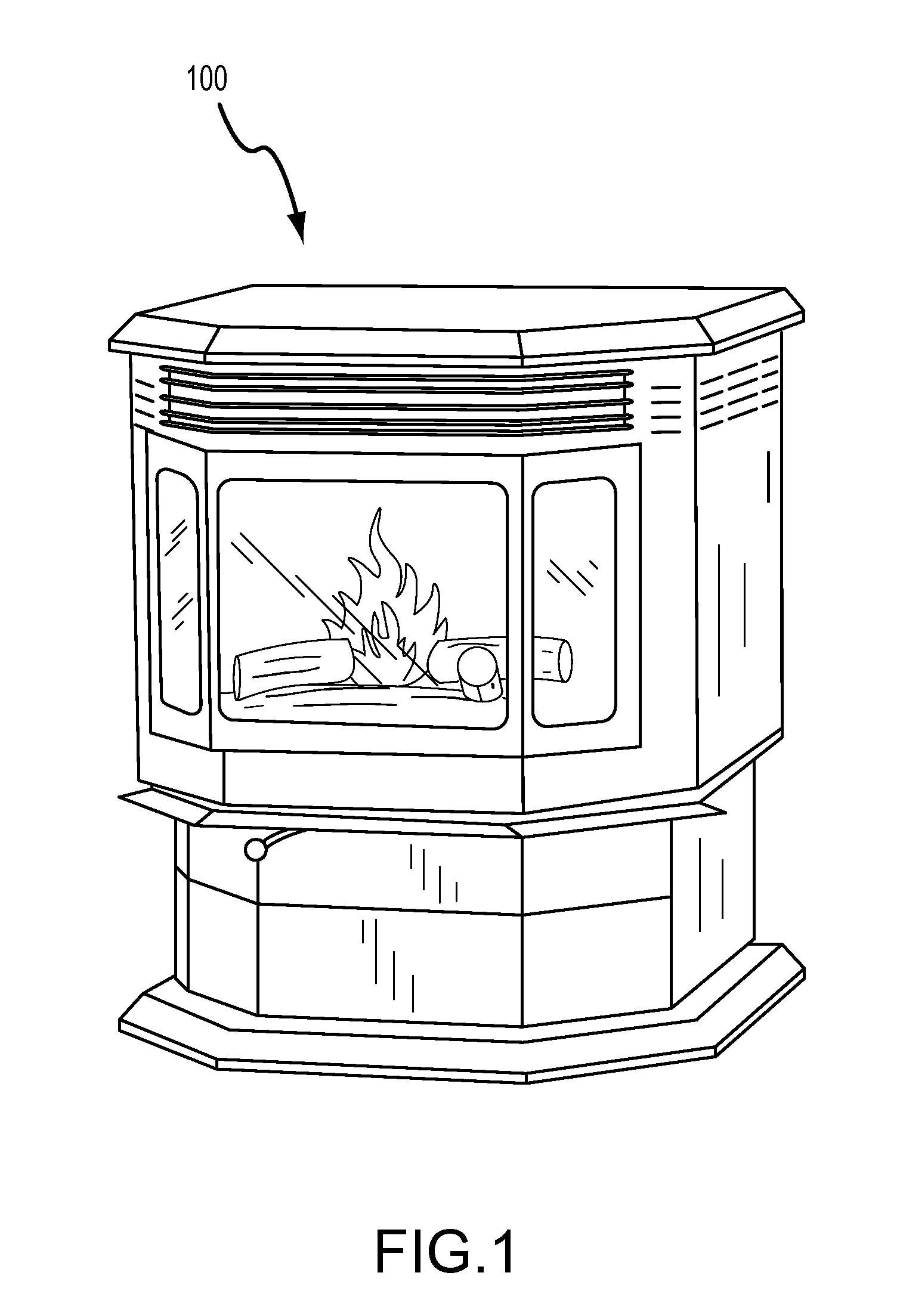

Pellet stove

According to embodiments of the present invention, a pellet stove includes a firepot assembly with a bottom plate slideable along rails to move between a closed position during combustion in the firepot and an open position during ash removal. According to other embodiments, a firebox or combustion enclosure includes a plurality of airfoils formed on the inner and outer surfaces of the enclosure to facilitate heat exchange between exhaust gases flowing across the inner surface of the enclosure and air blown across the outer surface of the enclosure. According to some embodiments, the airfoils and enclosure are of integral unibody construction. According to yet other embodiments, a user sets parameters via a wall control unit, and a stove control unit receives the parameters and automatically controls fuel feed rate, ignition, convection blower, combustion blower, and / or firepot cleaning based on the one or more parameters.

Owner:HNI TECH INC

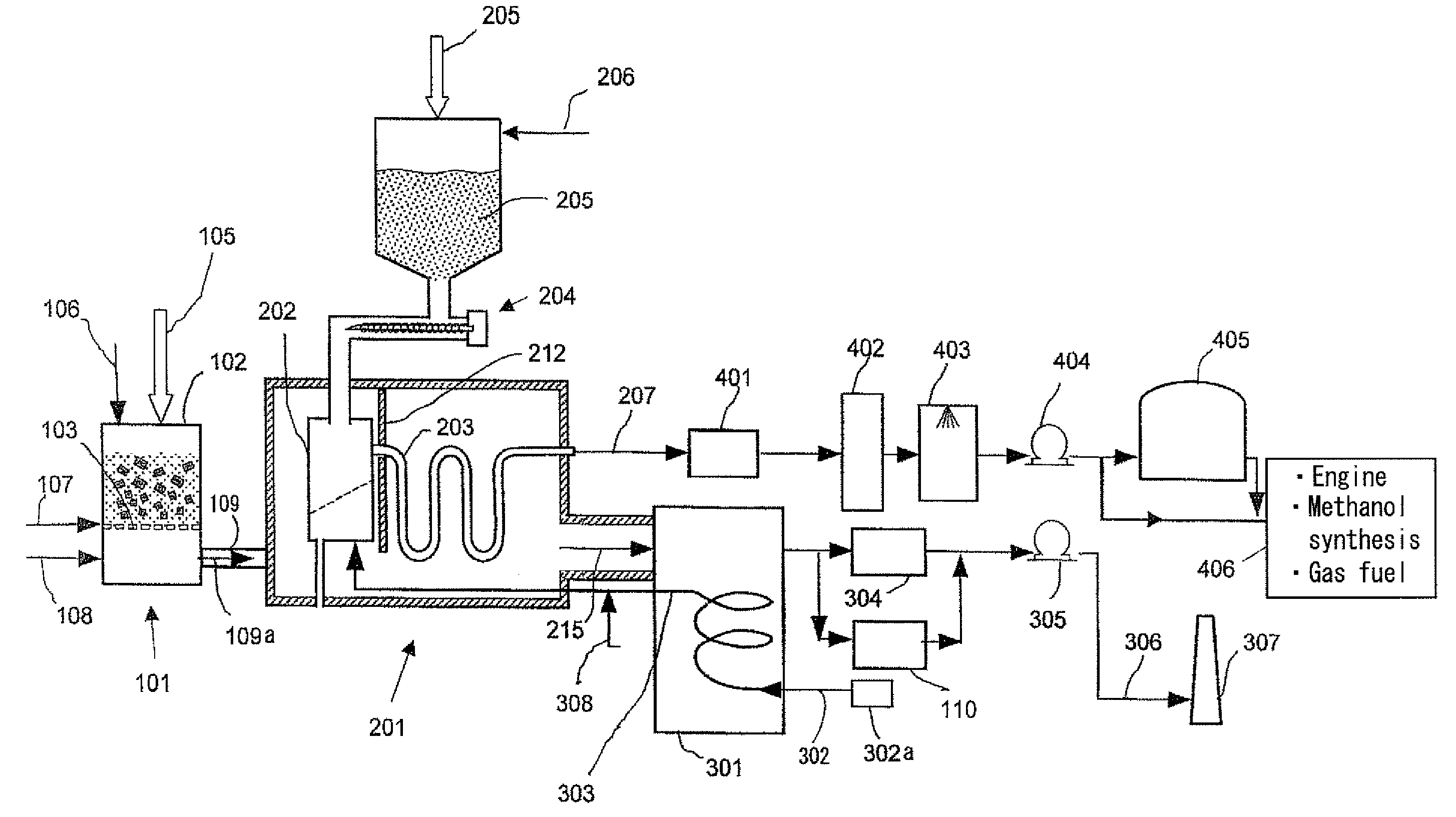

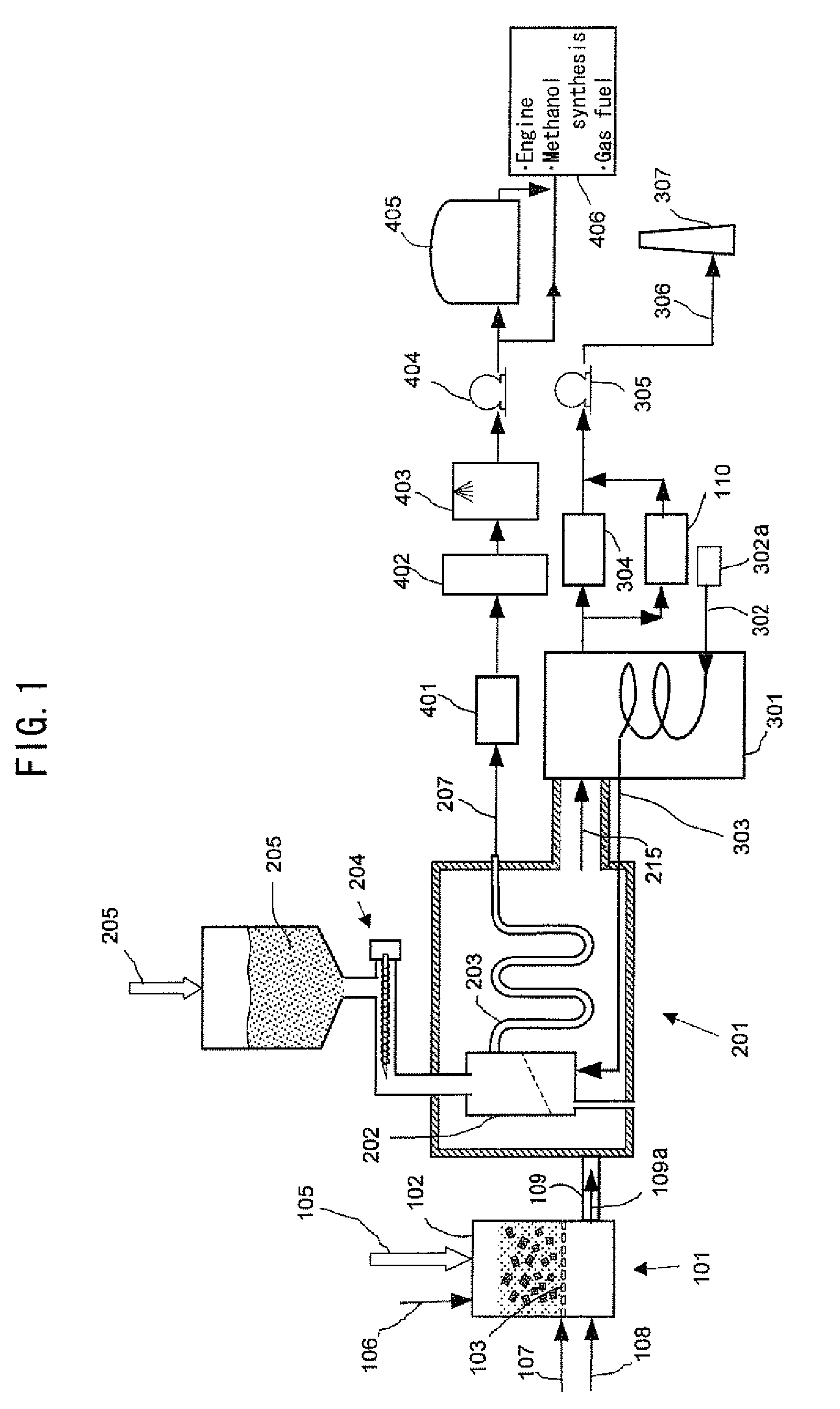

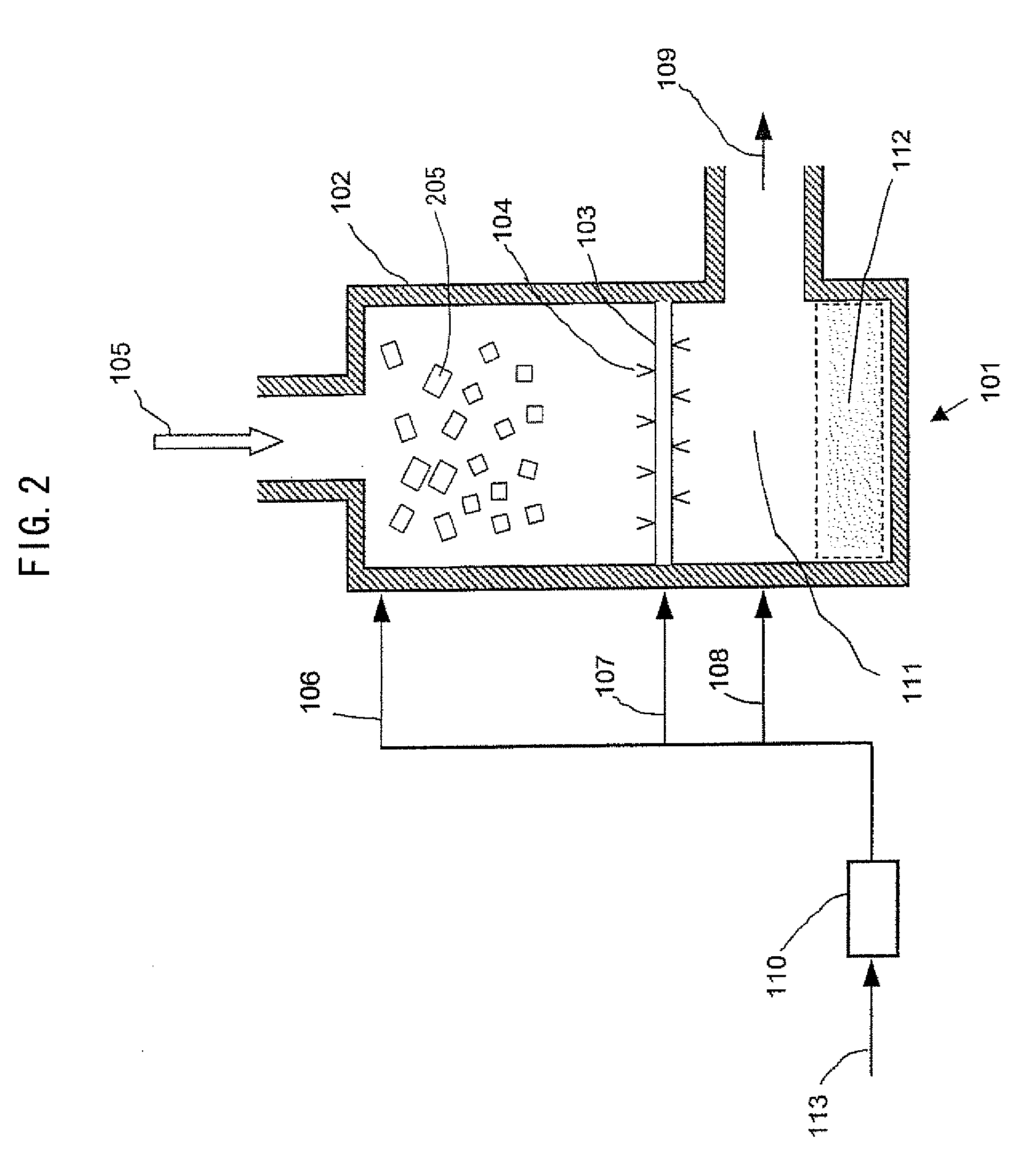

Biomass gasification apparatus

ActiveUS20100299995A1Increase temperatureImprove efficiencyThermal non-catalytic crackingBurnersProduct gasProcess engineering

A biomass thermochemical gasification apparatus is provided that can manufacture high-quality fuel gas out of solid biomass in an industrial manner. This fuel gas can be used as fuel for a gas engine and a gas turbine for example and also can be used as synthesis gas for methanol synthesis.A high-temperature combustion gas generation apparatus (101) for biomass operates entirely by biomass and the heat source thereof does not depend on fossil fuel. A coarsely-ground powder biomass (205) subjected to gasification and gasification agent (303) are introduced to a primary gasification reaction room (202) and generate gasification reaction by, as reaction heat, radiation heat from a wall face of the primary gasification reaction room (202) heated by combustion gas (109a) generated in the high-temperature combustion gas generation apparatus (101) and are dissolved. Consequently, the biomass (205) is converted to clean and high-quality generated gas.

Owner:NAGASAKI INSTITUTE OF APPLIED SCIENCE

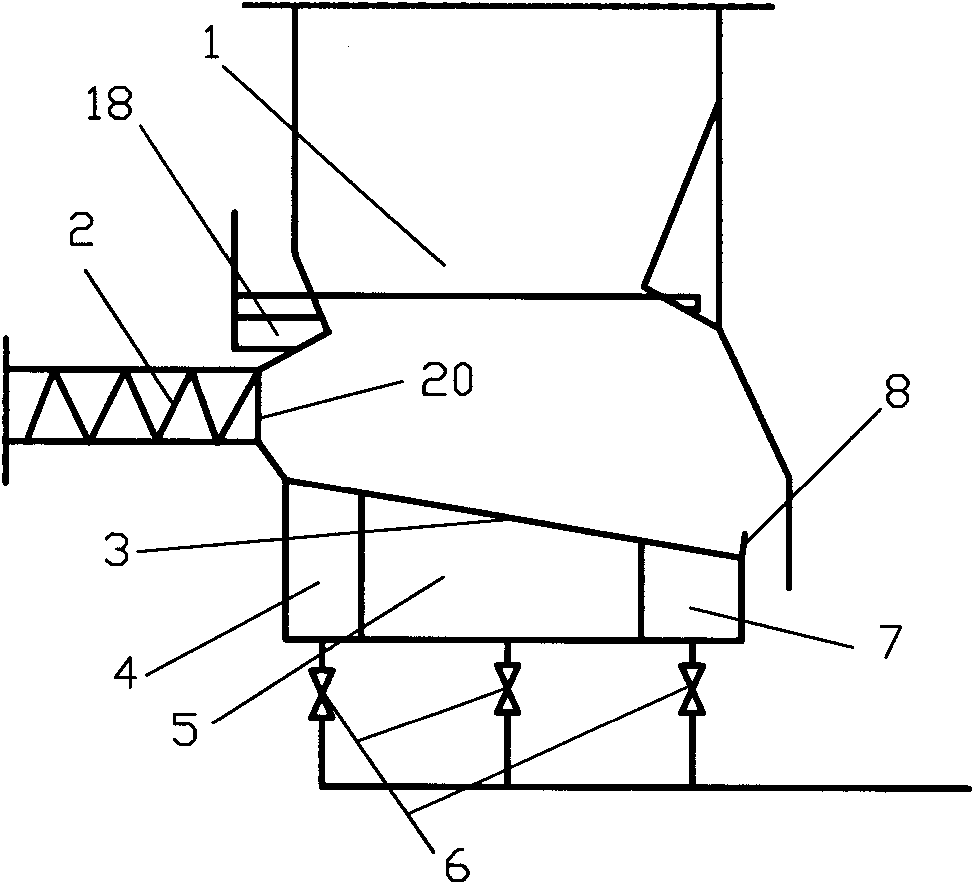

Grate for biomass boiler

InactiveCN101776275AIncreased oxidation areaImprove combustion efficiencyGratesEngineeringBiomass boiler

The invention provides a grate for a biomass boiler, which can supply air distinctively and is provided with an oxygenation area structure; the grate comprises a grate body for supporting and ventilation, and is characterized by comprising a plurality of rib plates and a plurality of water-cooled wall pipes; the rib plates and the water-cooled wall pipes are sequentially lined at intervals, and the rib plates are provided with vent holes; the density of the vent holes of the rib plates which are close to a feed opening and are far from the feed opening is smaller than the density of the vent holes in the middle part of the rib plates; the middle part of each rib plate is also provided with a plurality of hoods with cavities inside which protrude out of the surface of the rib plate; and the inside cavities of the hoods are communicated with the upper side and the lower side of the rib plate. The grate of the invention can increase an oxidation area but reduce a reduction area when the biomass on the grate is burned, and effectively improve the burning efficiency of the biomass.

Owner:SHANDONG ELECTRIC POWER RES INST

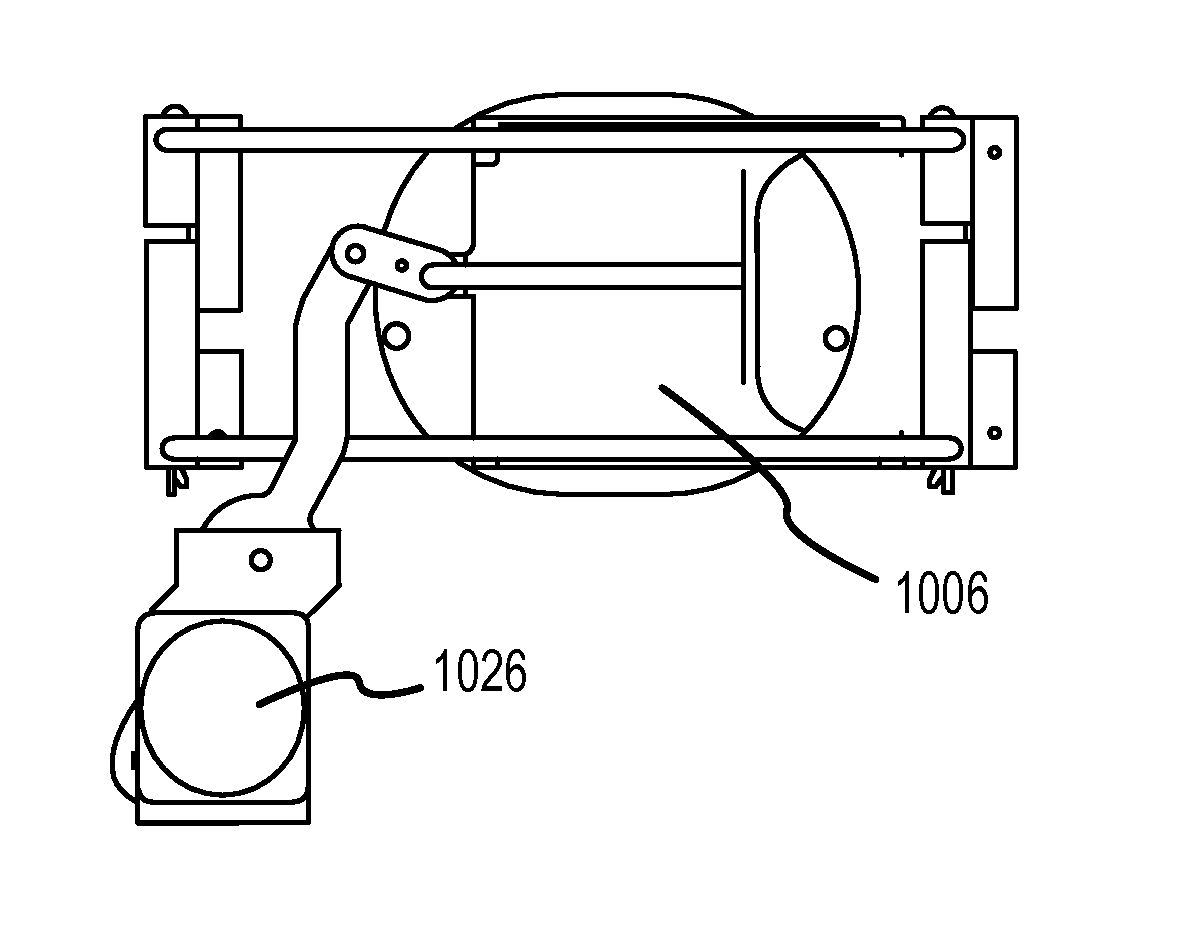

Enclosed granular fuel burning boiler

There is illustrated a fuel fired brazier for an enclosed granular fuel burning boiler. The brazier has an apertured grate-like brazier base. The brazier base is moved by an actuator from an operative position, retaining fuel in the brazier to a discharge position where ash can fall through a hole. At the same time, fragmentation means, formed by crushing teeth, move across the brazier to trap, for example, a large piece of clinker, between it and the opposed distal wall of the brazier.

Owner:ALLEY ENTERPRISES UNLIMITED CO

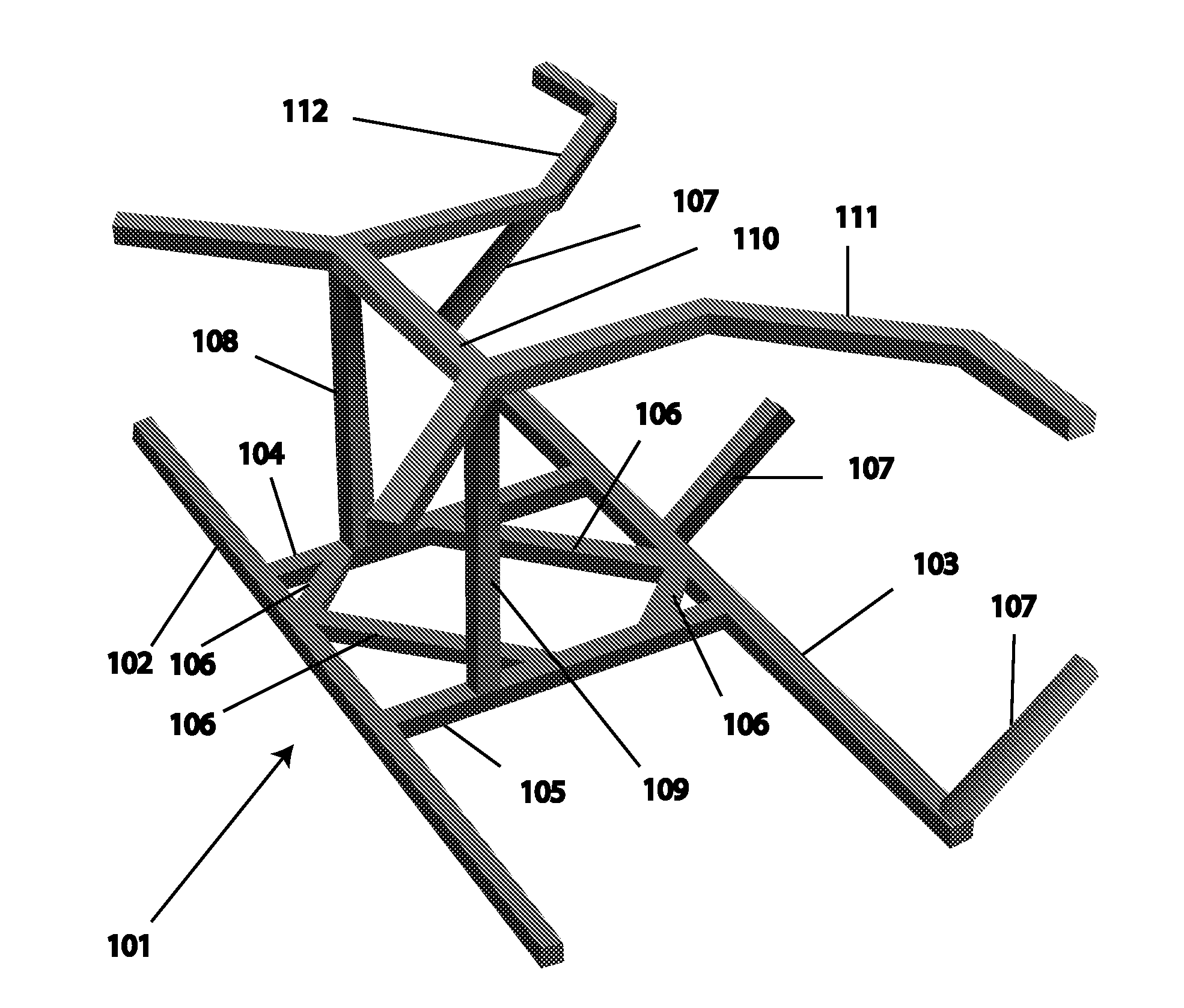

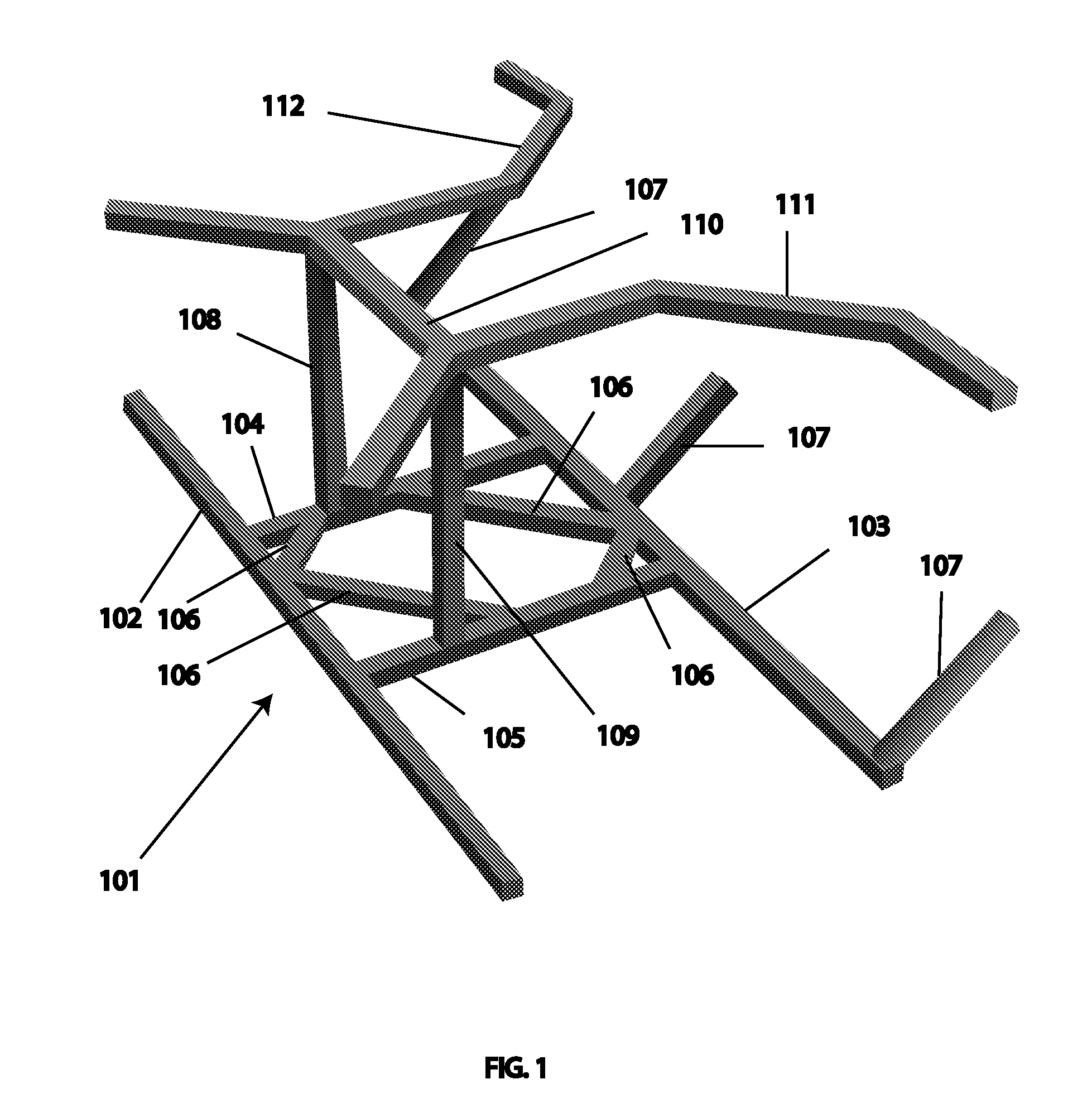

Log supporting and guiding apparatus for improved burning

InactiveUS20110000476A1Space maximizationHigh strengthDomestic stoves or rangesGratesC sectionsEngineering

A log supporting and guiding apparatus for improved burning, the apparatus comprising: a base which rests on a fireplace floor or fireplace grate, the base comprising a front bar, back bar, a left connecting bar, a right connecting bar, and a plurality of strength reinforcing bars; a plurality of log retaining bars which are functionally attached to the base and angled off of the fireplace floor or fireplace grate; a left upright bar which is perpendicular, functionally attached to the left connecting bar at the bottom of the left upright bar, and closer to the front bar than the back bar; a right upright bar which is perpendicular, functionally attached to the right connecting bar at the bottom of the right upright bar, and closer to the front bar than the back bar; a cross bar which functionally connects the top of the left upright bar with the top of the right upright bar; a c-section bar for holding a log upright, which is functionally attached to the top of the right upright bar; and an inverted c-section bar for holding a log upright, which is functionally attached to the top of the left upright bar.

Owner:KLEVE ROBERT B +1

Chain furnace grate protecting method for incinerating biomass fuel and its special device

InactiveCN1975255AAvoid corrosionBarrier contactGratesIncinerator apparatusChemical reactionAlkaline earth metal

The invention discloses the guard method of the fire grate of grate-fired furnace used to burn the biological materials, before laying the biological materials on the chain grate by the hopper, first lay a stable substance bed that can not generate chemical reaction with the alkali metals or its oxide in the burnt ash of biological materials through the hopper at the foreside of biological materials hopper, then lay the biological fuel on the narrated stable substance by the hopper. Therefore, using the method of the present invention, the fire grate made by relative low price of the ordinary material can be used, it can effectively protect against corrosion of the grate, avoid burning-out on the high temperature, improve the layout of the wind and combustion conditions of the grate at the same time and greatly reduce the cost of the grate. The specialized devices comprise stable material transportation equipment, cooling equipment, screening equipment and sending-back equipment. Thus the device can make the stable material repeatedly recycled, and lower overall operating costs.

Owner:BEIJING CHINA SCI GENERAL ENERGY & ENVIRONMENT CO LTD

Apparatus for controlling the deposition of feed material on a deposition build-up surface

An apparatus 40 for controlling the deposition of feed material, such as coal 24, on a deposition build-up surface 64 subjected to deposition loading of feed material is provided for use in a feeder arrangement having an endless conveyor 42 for conveying feed material to the rotating blades 46 of a distribution rotor 44 for further conveyance of the feed material. The deposition control apparatus 40 controls the deposition on the deposition build-up surface 64 of feed material that has exited the endless conveyor 42 yet has not been conveyed beyond the distribution rotor 44. The deposition control apparatus 40 includes a device for influencing the movement of feed material relative to the deposition build-up surface 64 such that the deposition of feed material on the deposition build-up surface 64 is hindered.

Owner:ASPEN ACQUISITION CORP +1

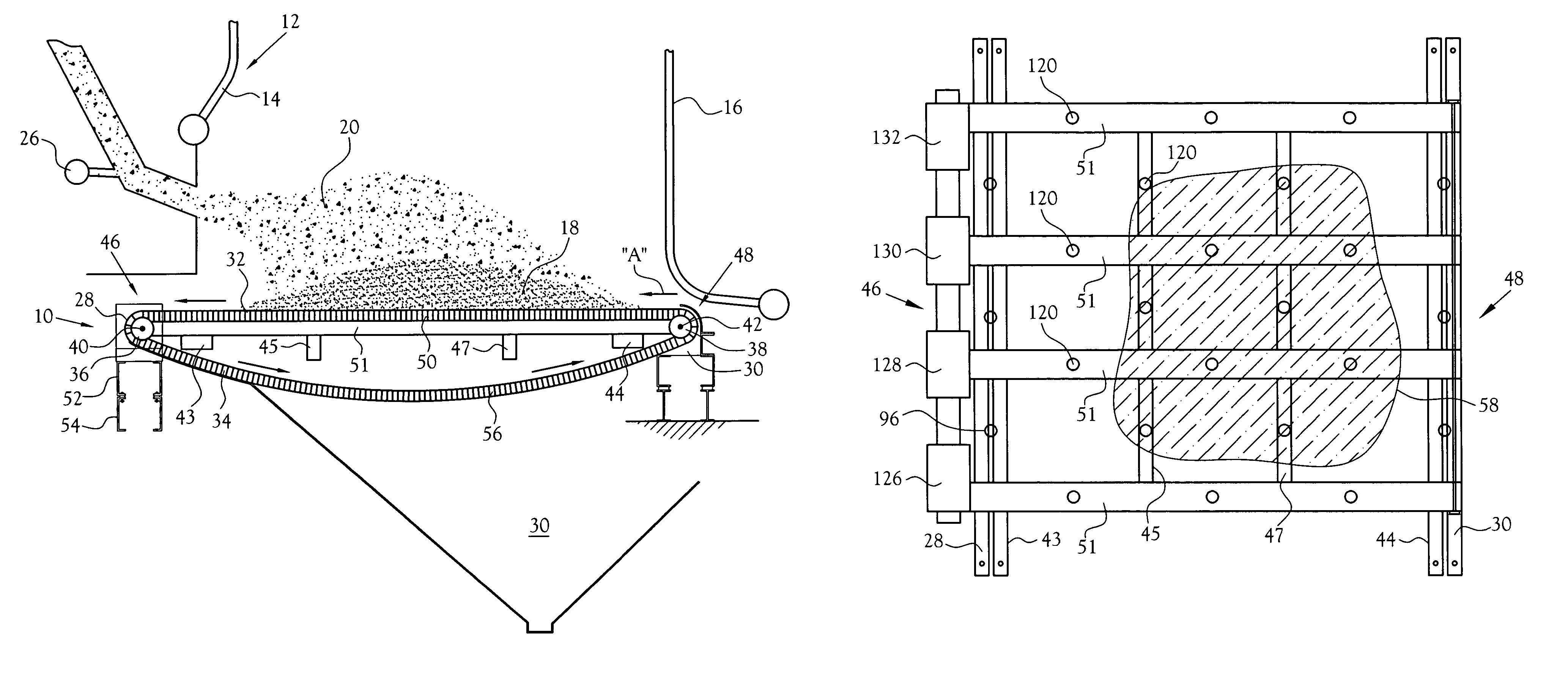

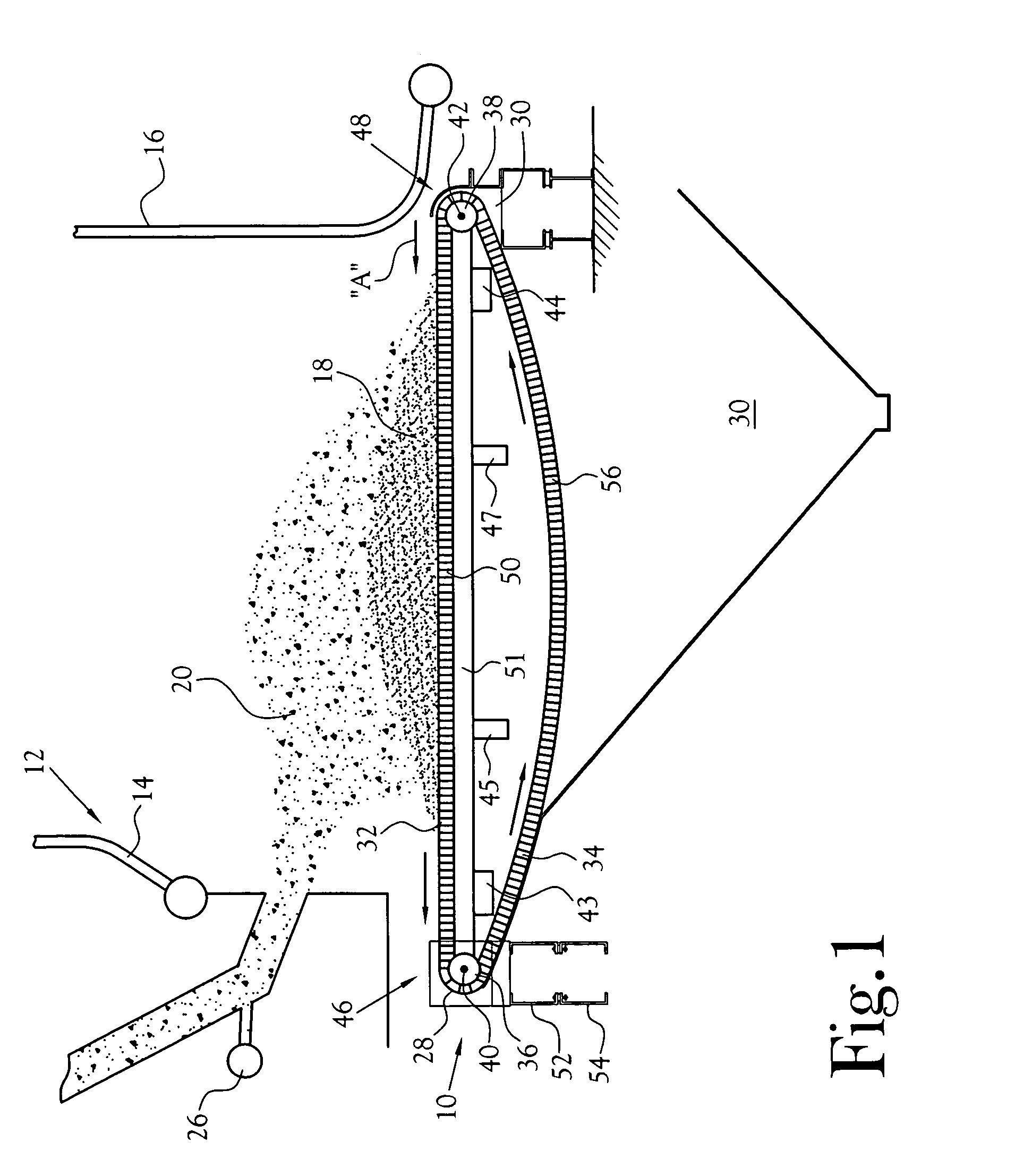

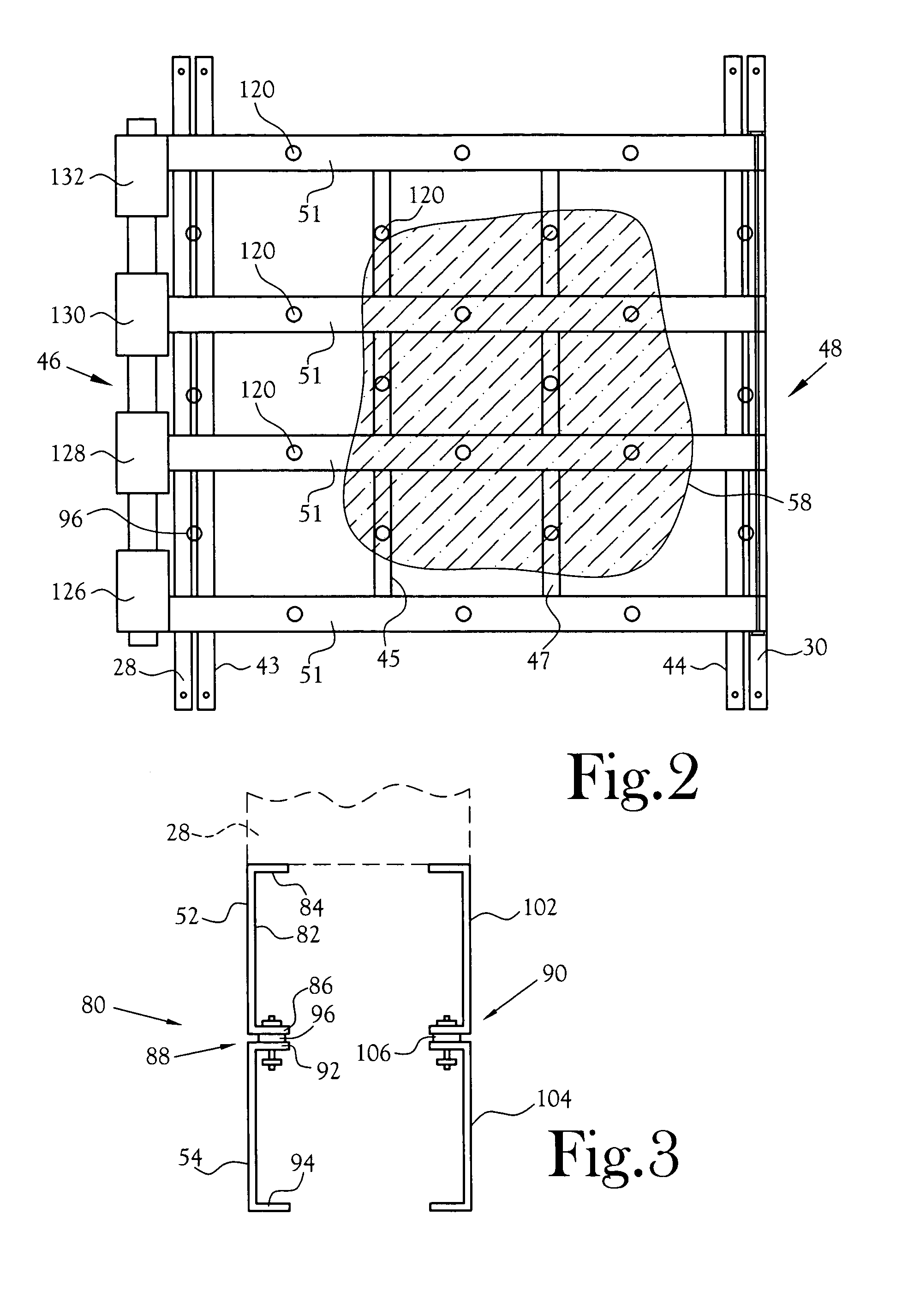

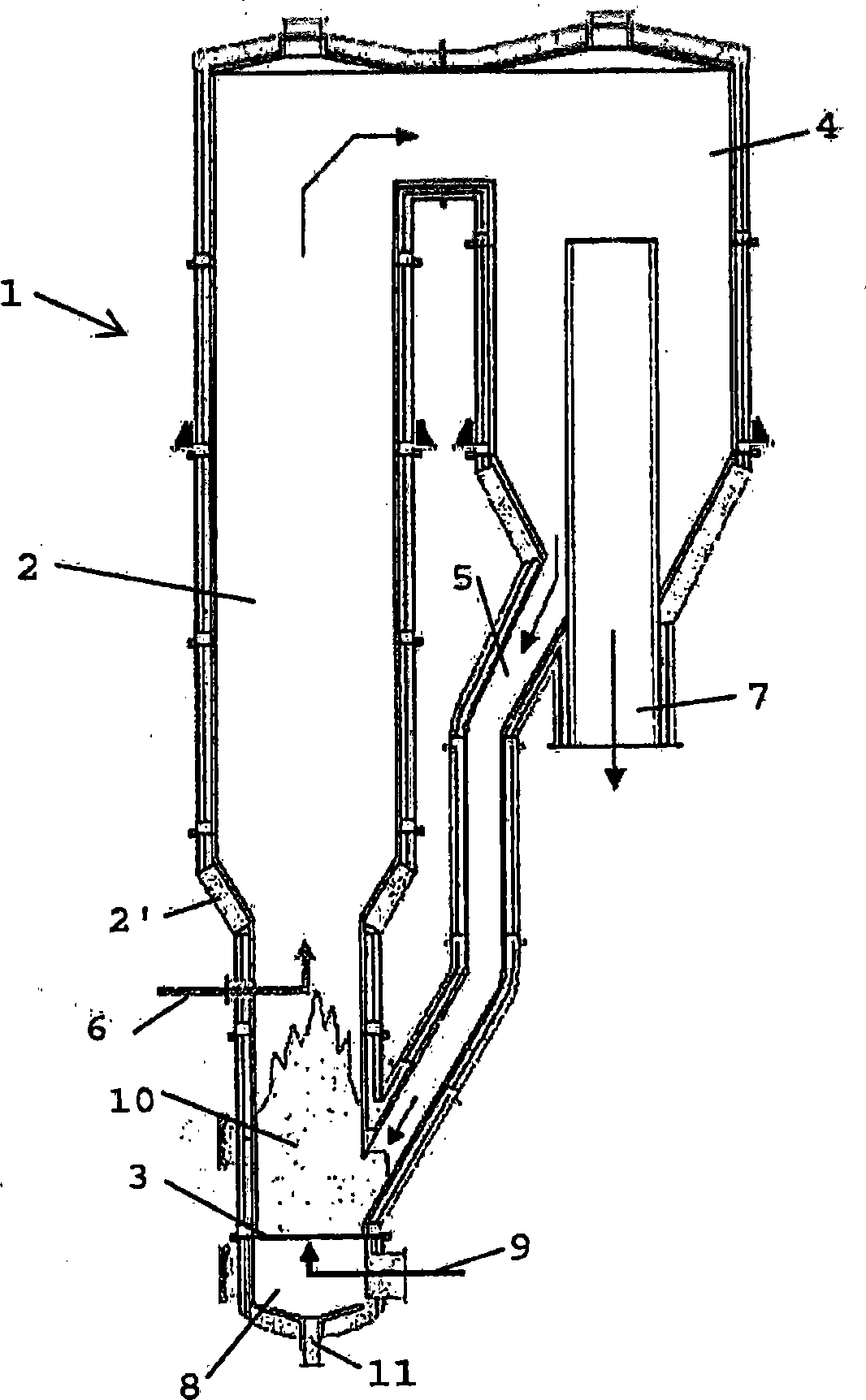

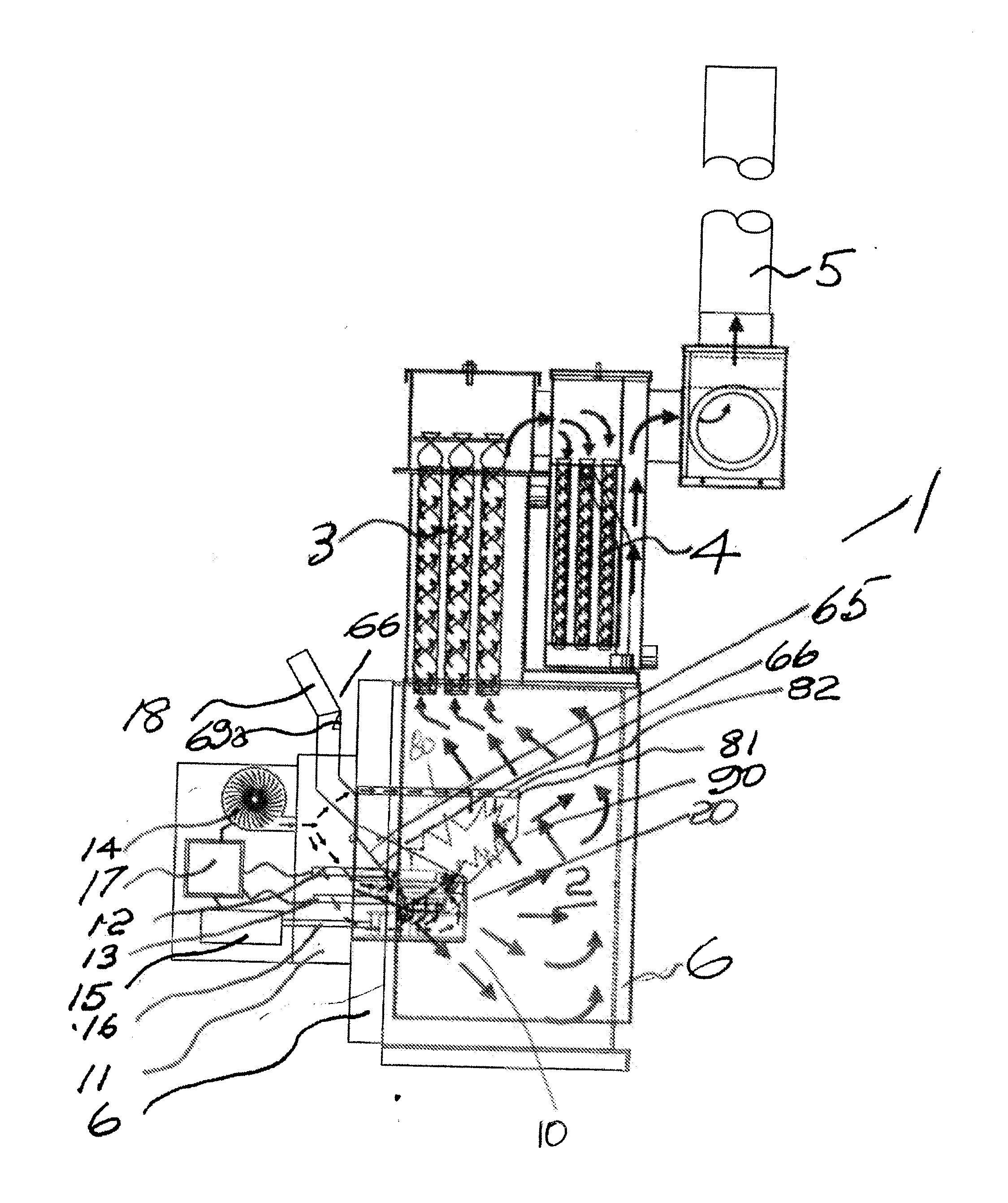

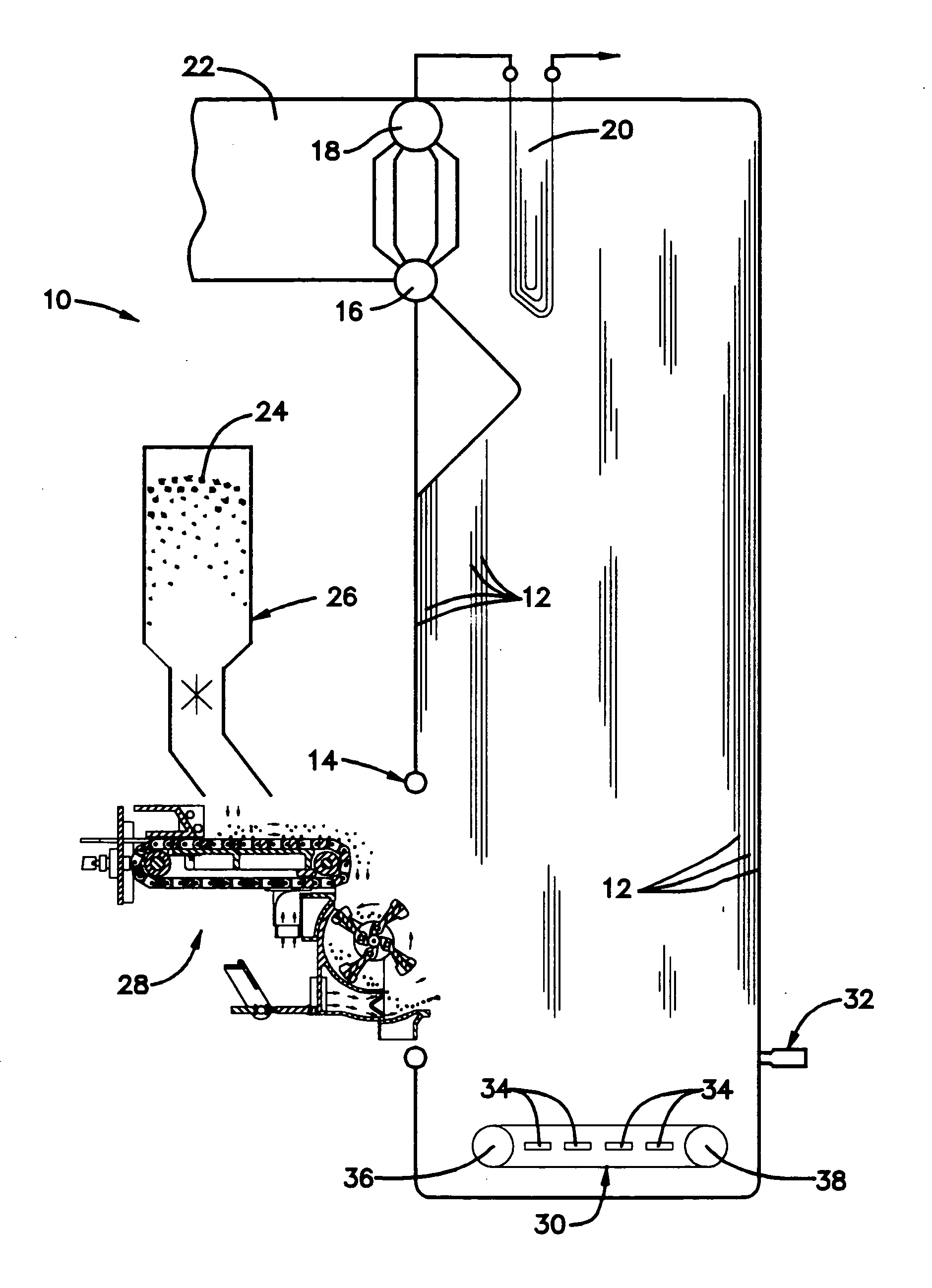

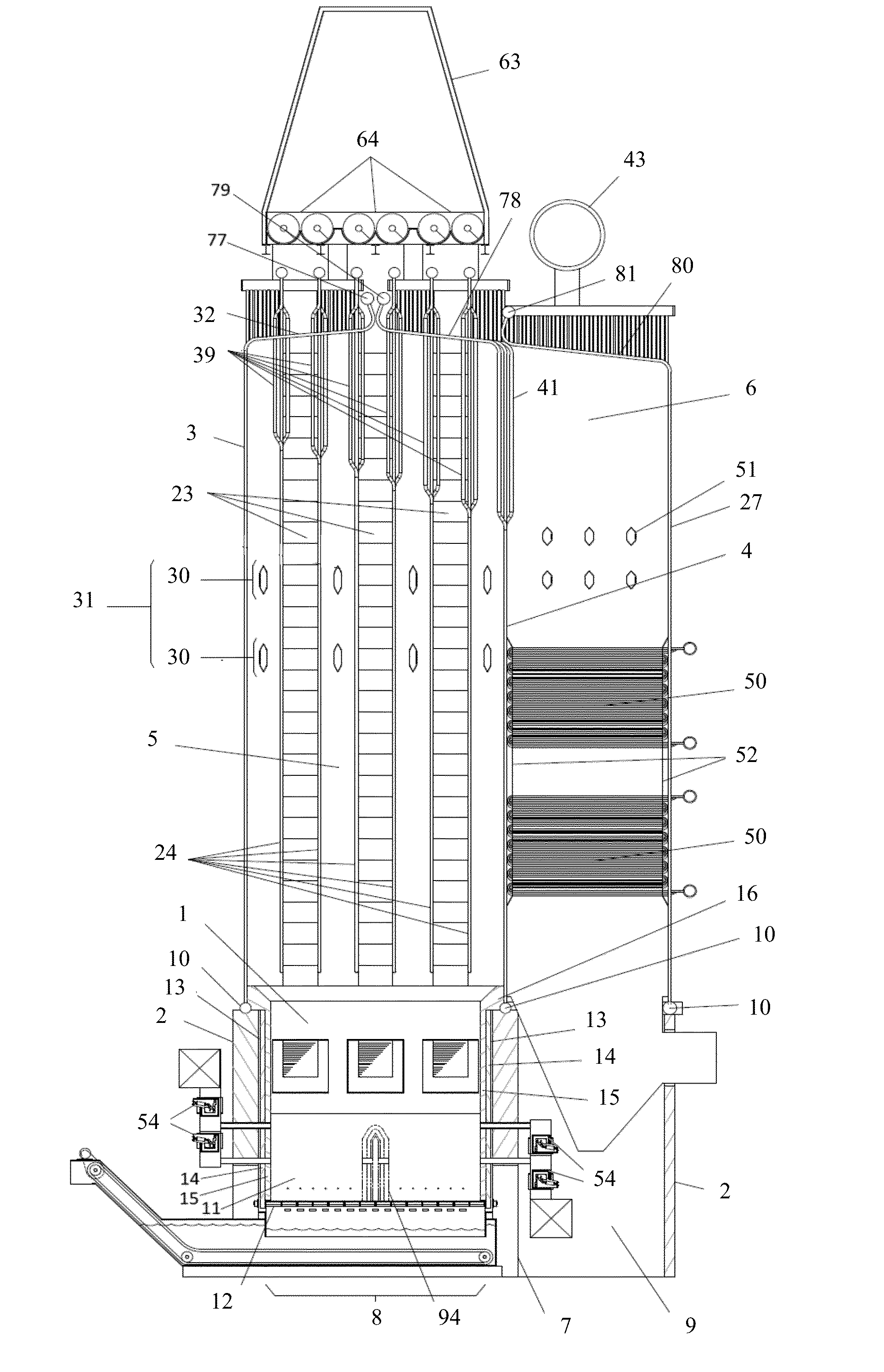

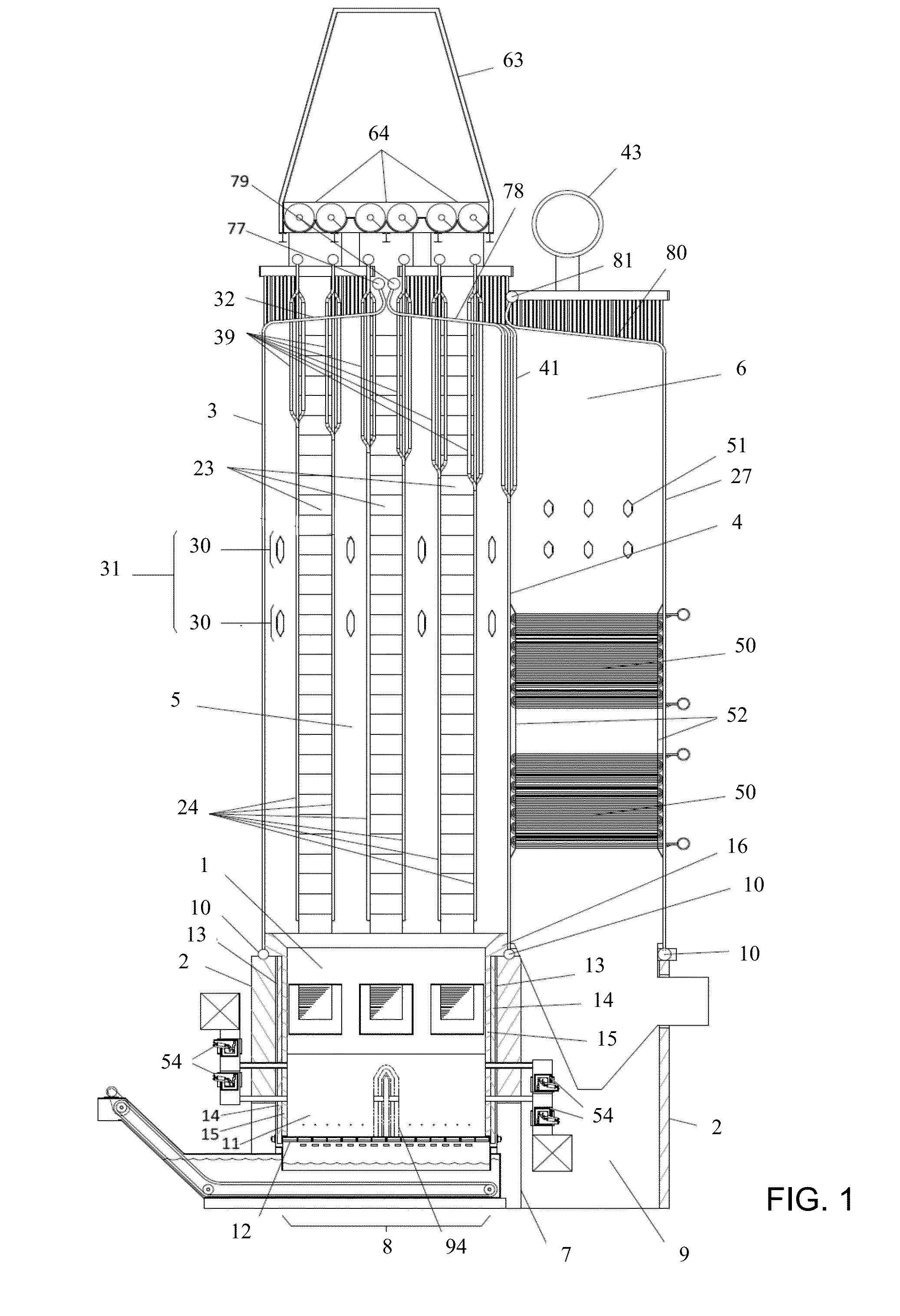

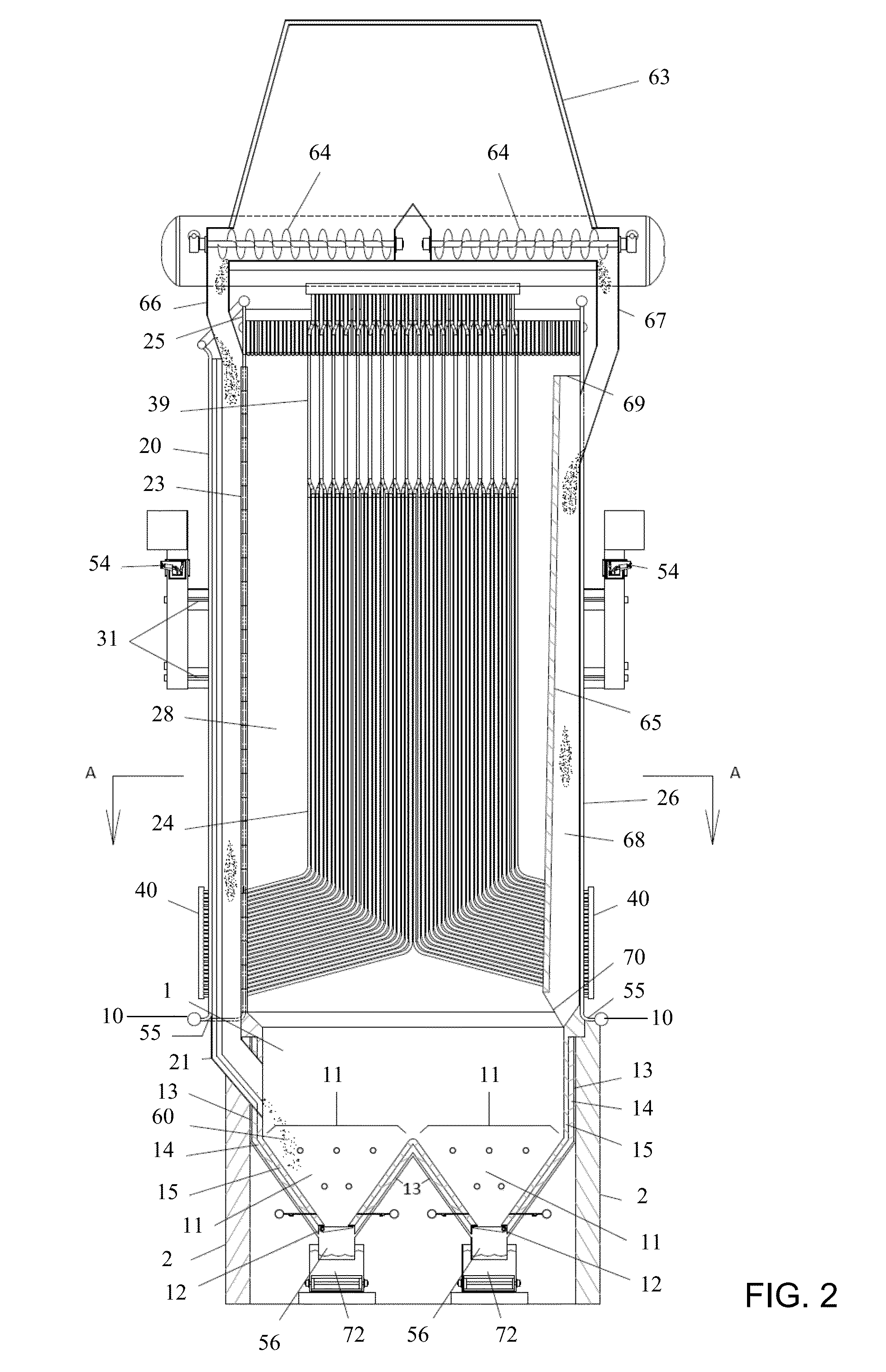

Method and Apparatus for Improved Firing of Biomass and Other Solid Fuels for Steam Production and Gasification

InactiveUS20130276723A1Reduce temperature changesRapid and preferably independent controlBoiler water tubesWater-tube boilersCombustorCombustion chamber

A ground supported single drum power boiler is described combining a refractory lined and insulated V-Cell floor; refractory lined and insulated combustion chamber; integrated fuel chutes configured to pre-dry wet solid fuel; top mounted fuel bin; internal chamber walls; configurable combustion air systems; and a back pass with after-burner ports and cross flow superheaters. The boiler can be configured in pre-assembled modules to minimize the field construction time and cost. An alternative embodiment is adaptable as a gasifier.

Owner:SULLIVAN HIGGINS & BRION PPE LLC

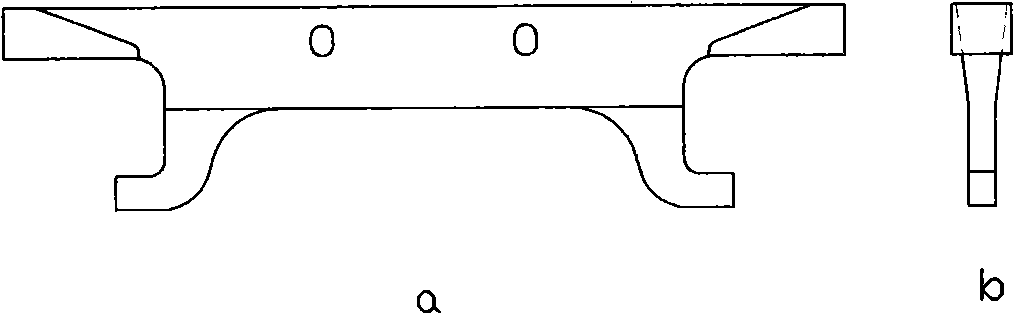

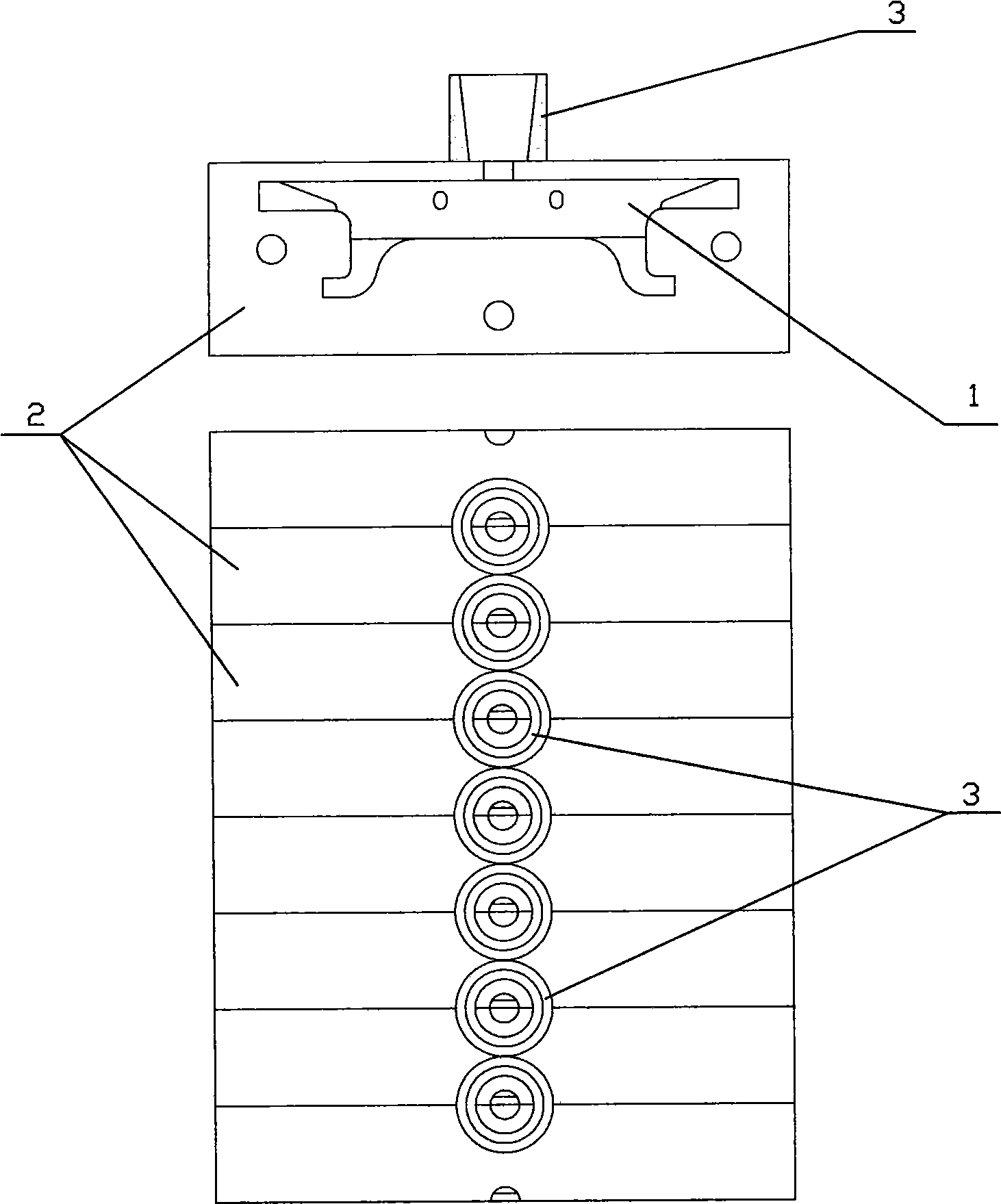

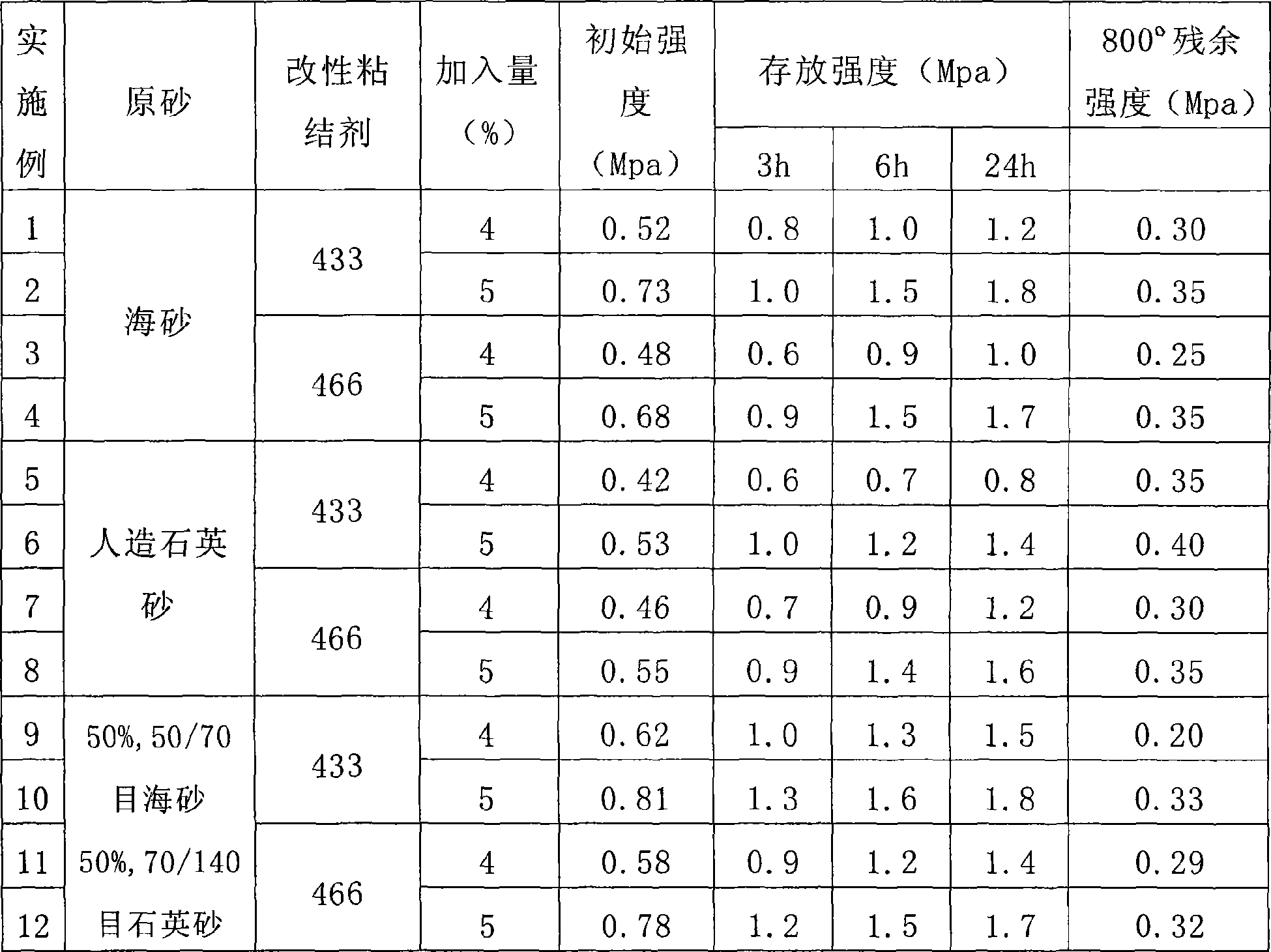

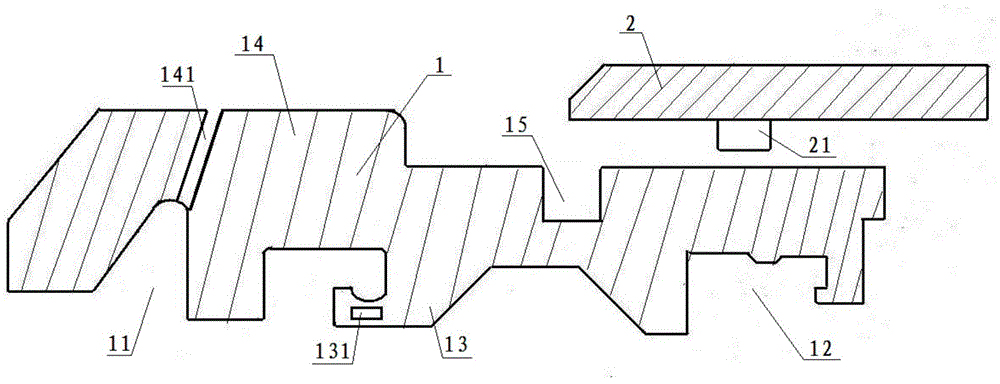

Grate production process for steel mill sintering apparatus

The invention discloses a production process of a grate bar used for sintering equipment of steelworks. The production process comprises the following steps of: mixing molding sand, namely, adding 4-5% of modified water glass to 50% of base sand (50 / 70 meshes) and 50% of base sand (70 / 140 meshes) so as to prepare the molding sand; modeling, namely, adopting a vertical molding process, injecting CO2 and then carrying out the patter drawing; coating, namely, coating the quick-dry alcohol-based coating in a curtain coating way; molding integration, namely, vertically molding the sand mold in series correspondingly; finally, preparing corresponding risers and runners for pouring-forming. The production process completely meets the special quality requirement of the grate, the production cost can be reduced by more than 10%, furthermore, the production efficiency can be improved, especially the environmental pollution can be reduced, the utilization ratio of the resource can be improved and the energy resource consumption can be reduced.

Owner:上海市机械制造工艺研究所有限公司

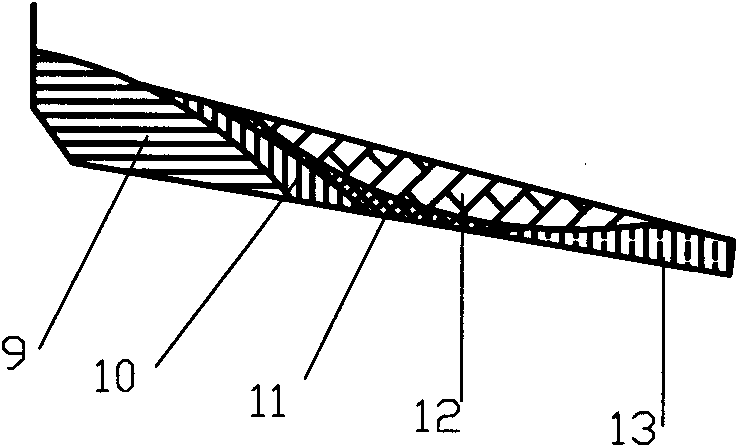

Energy-saving type boiler

InactiveCN101251249ABurn fullyExtended combustion strokeGratesFire-tube steam boilersSlagProcess engineering

The invention relates to an energy-saving type boiler, comprising a heat exchange chamber arranged on the upper part of a boiler body and a furnace hearth arranged on the lower part of the boiler body, wherein the heat exchange chamber consists of a water-storing cavity, a smoke exhaust pipe and a main smoke pipe; the furnace hearth consists of a furnace gate, a furnace slag chamber, a furnace door and a clearing slag port; the furnace gate is divided into a pyramidal part and a plane part; the furnace gate close to one side of the furnace door is the pyramidal part which radially extends into a furnace hearth from the furnace door in descending order. The furnace gate is divided into a pyramidal feed zone and a plane zone, which can ensure that: the fuels are gradually heated and burned along the pyramidal zone, rolled to the plane zone for continuous burning and then discharged from the plane zone. The energy-saving type boiler has the characteristics of ingenious design, reasonable structure and sufficient air supply as well as fuel burning; moreover, the long burning travel of fuels in the boiler ensures that the fuels are difficult to directly drop in the furnace slag chamber and discharge out, thereby saving energy and fuels. At the same time, as the energy-saving type boiler changes the direct discharging type into the backward-flow type for discharging smoke, the high-temperature fuel gas forms reheating, so as to ensure more sufficient heat exchange, larger gas producing quantity and quicker gas producing speed.

Owner:黄传柳

Abrasion resisting fire grate segment

InactiveCN104534488AEasy to installEasy to install and maintainGratesCremation furnacesStructural engineeringMechanical engineering

Owner:辽宁省兴城市特种铸钢有限公司

Wood pellet boiler

The present application relates to improvements to granular fuel burning boilers such as wood pellet boilers and burners therefor. In particular, there is disclosed a wood pellet boiler having a combustion chamber, wherein an access door for said combustion chamber comprises a wood pellet burner assembly mounted on the interior side thereof. In this way, the wood pellet burner assembly is movable from and into the combustion chamber of the wood pellet boiler when the access door is opened and closed, respectively.

Owner:WARMFLOW ENG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com