Pellet stove

a pellet stove and burner technology, applied in the field of pellet stoves, can solve the problems of reducing the ability to achieve complete and efficient combustion of fuel, requiring a considerable amount of effort to maintain and use, and reducing or at least substantially affecting the ability to allow the introduction of combustion air through the burning mass of fuel, so as to facilitate the cleaning of small amounts of ash

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

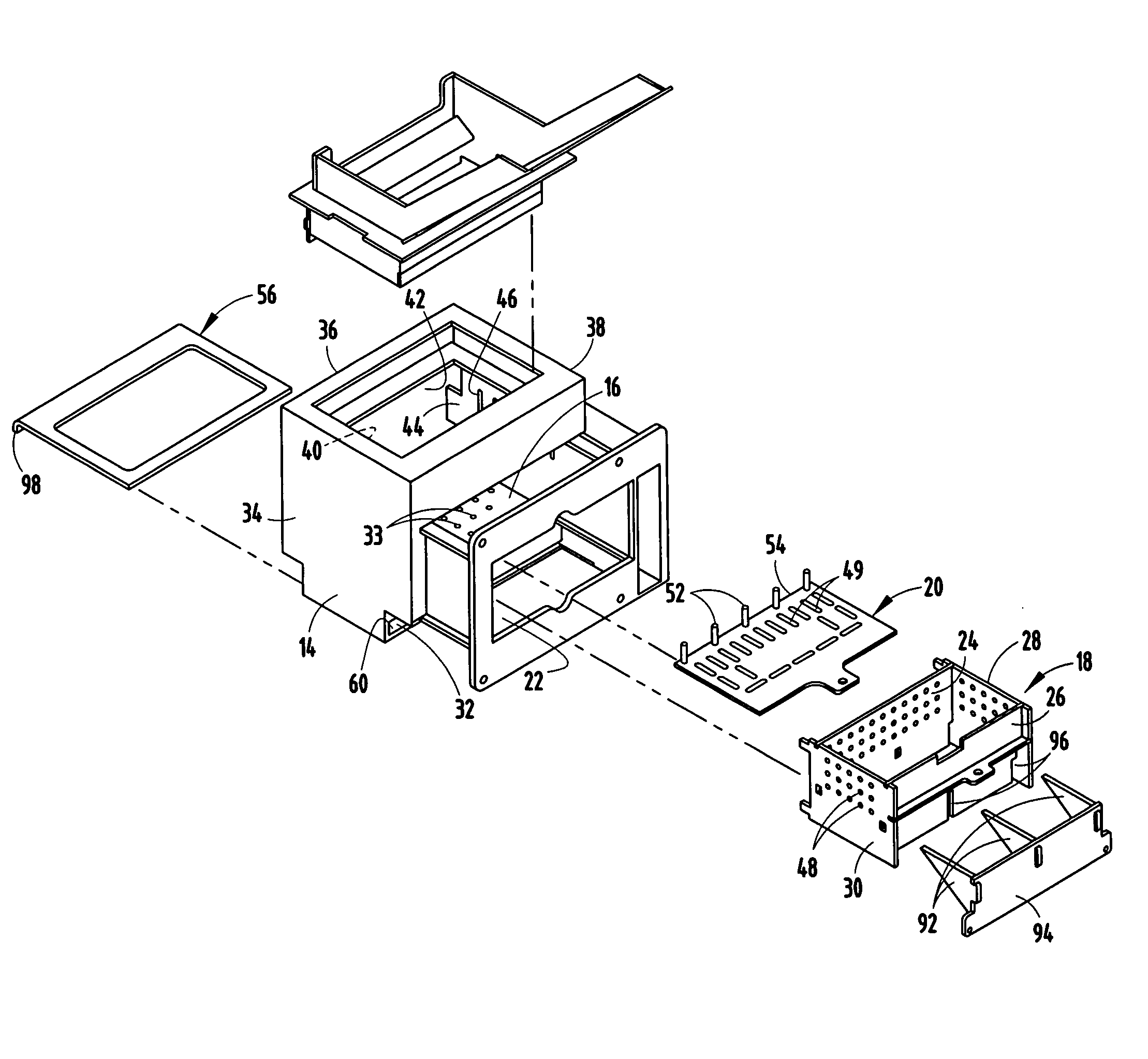

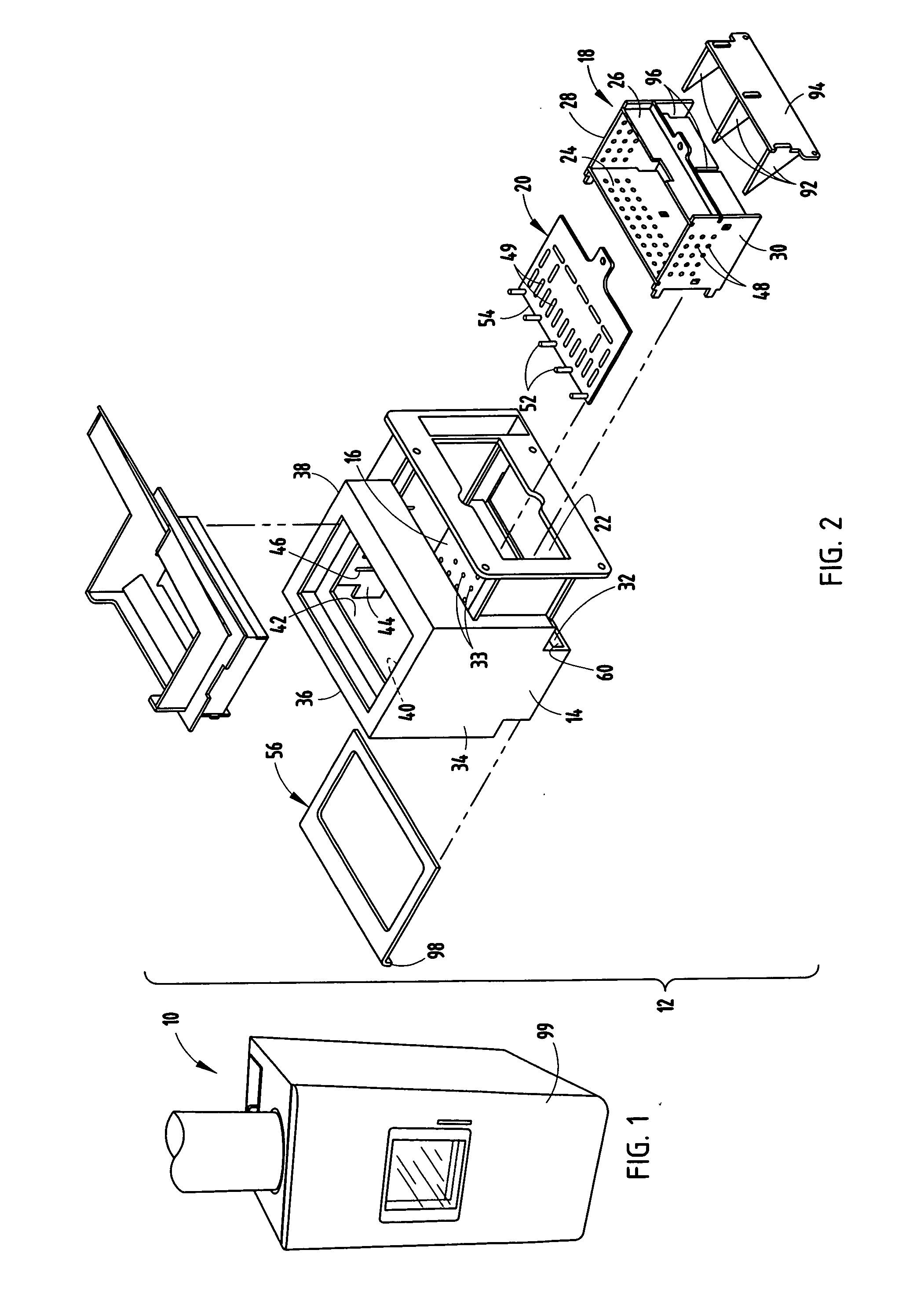

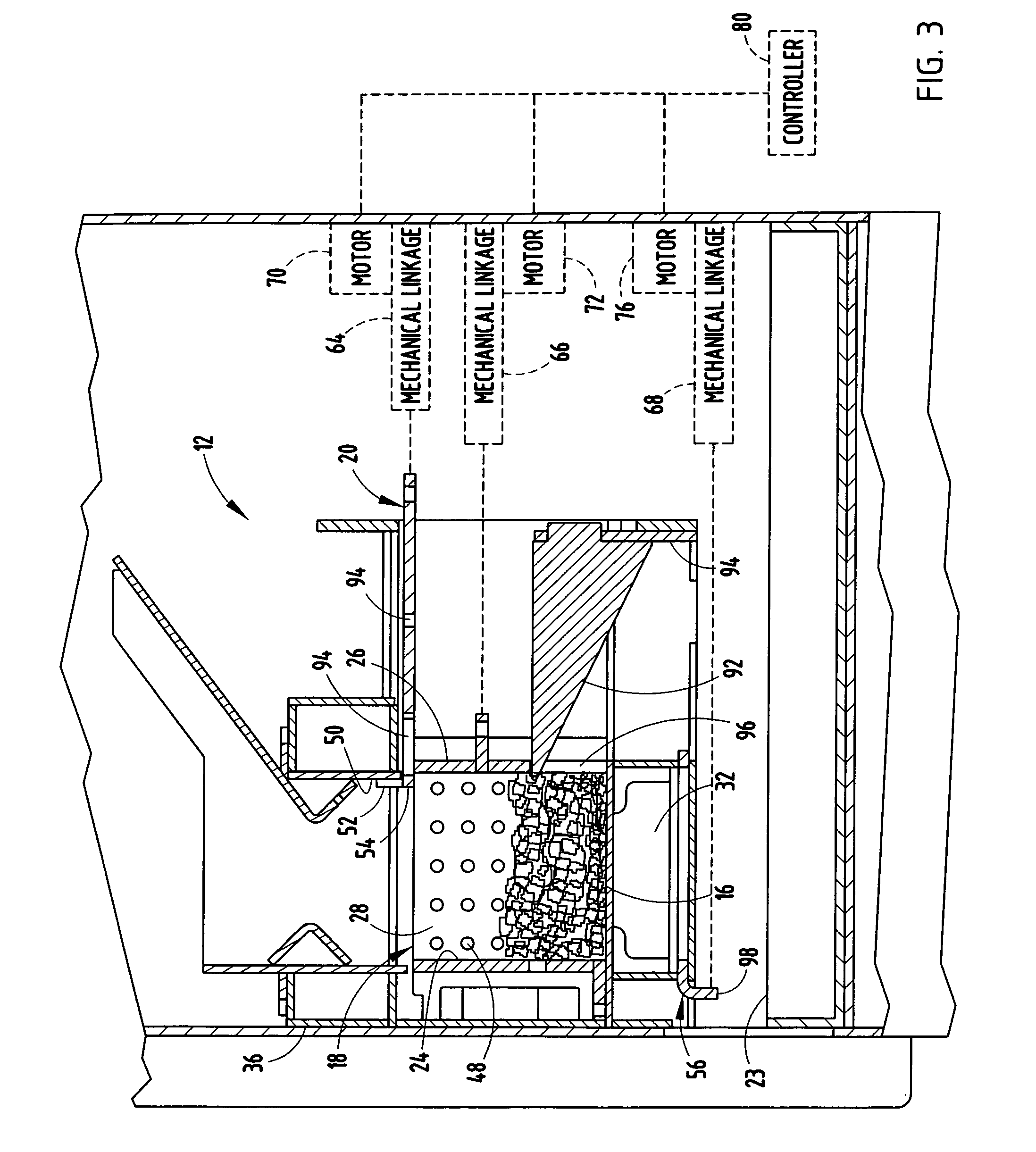

[0018]A pellet stove 10 (FIG. 1) in accordance with the invention includes a burnpot assembly 12 (FIG. 2) comprising a burnpot holder 14 having an immovable floor 16, a movable burnpot 18, and a combustible fuel retention plate 20. The burnpot 18 and burnpot holder 14 are configured to allow the burnpot to be moved from a normal fuel burning position to a clinker removal position in which the burnpot is located laterally adjacent the normal fuel burning position. Defined by burnpot holder 14, adjacent immovable burnpot floor 16, is an opening 22 that allows clinker and / or ash to drop through into clinker pan 23 located below opening 22.

[0019]While not constituting an essential part of the invention, pellet stove 10 will preferably include heat exchange means for extracting heat from the product gases of combustion and transferring the heat to air that is circulated in a building to heat living space within the building. Conventional furnace heat exchangers, fans, blowers and the lik...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com