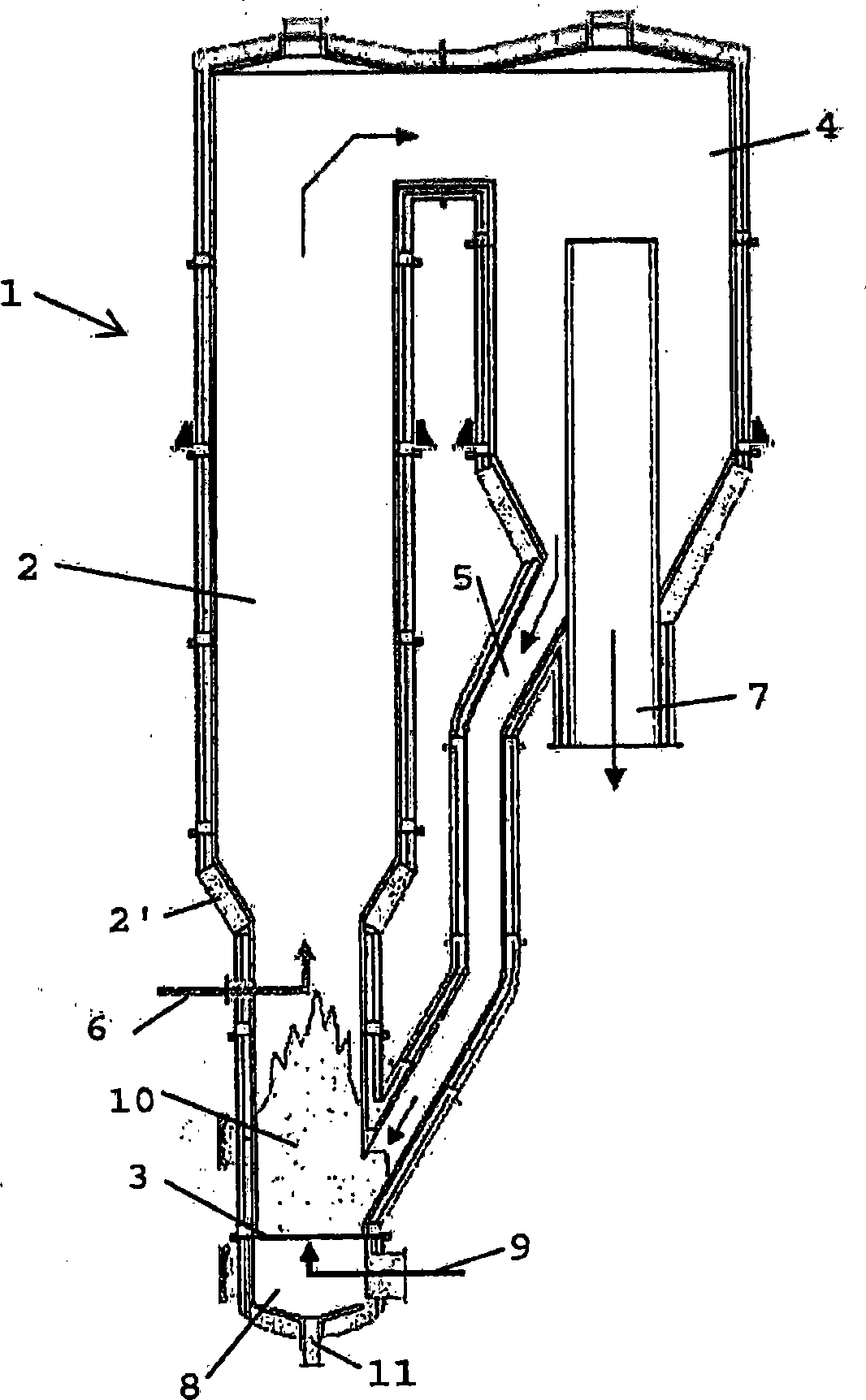

Grid for fluidized bed gasifier

A technology of gasifier and fluidized bed, which is applied in the field of grid structure of fluidized bed gasifier, can solve the problems of mechanical wear of grid structure, increase of manufacturing cost, complex structure, etc., and achieve the effect of eliminating downtime

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

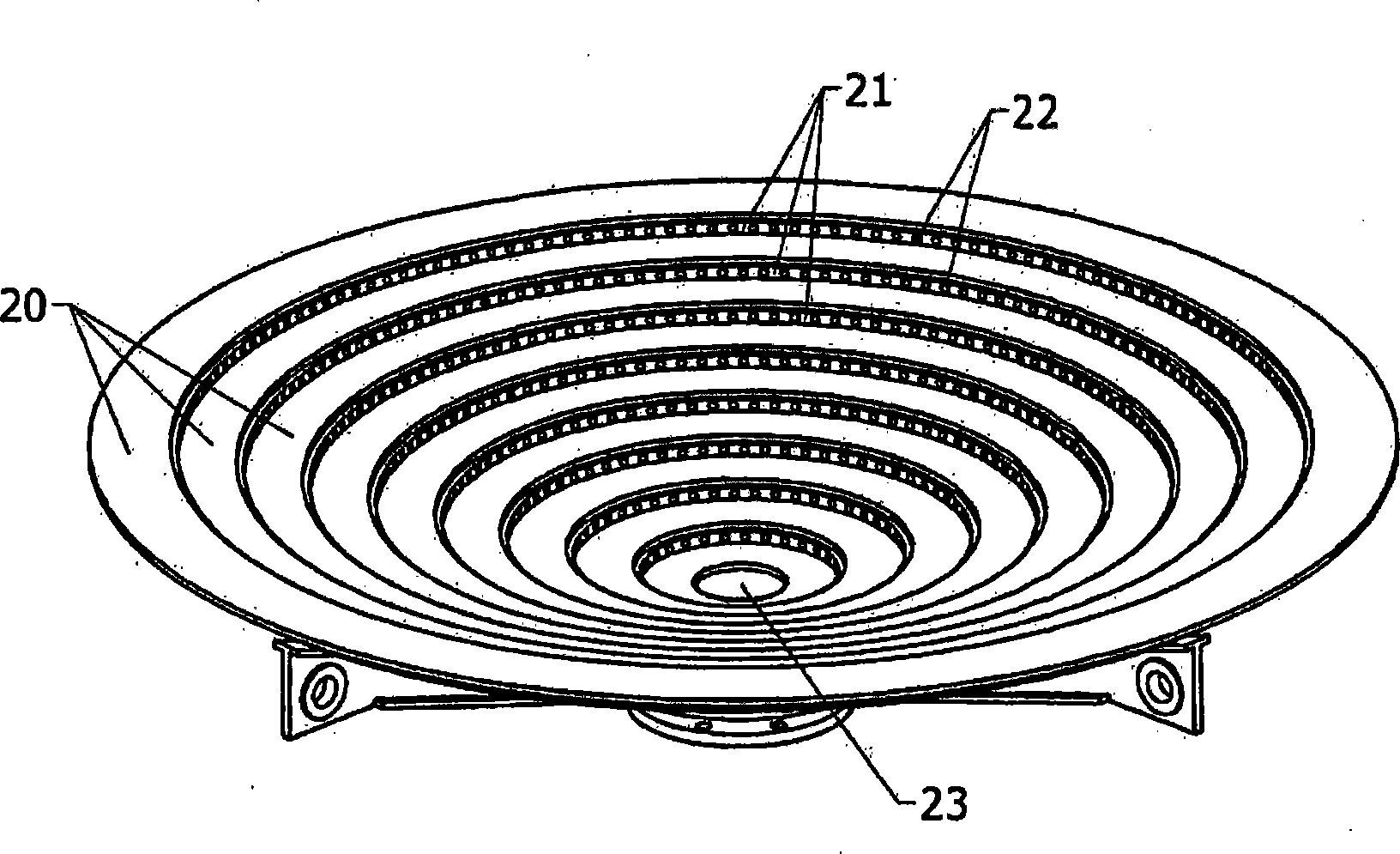

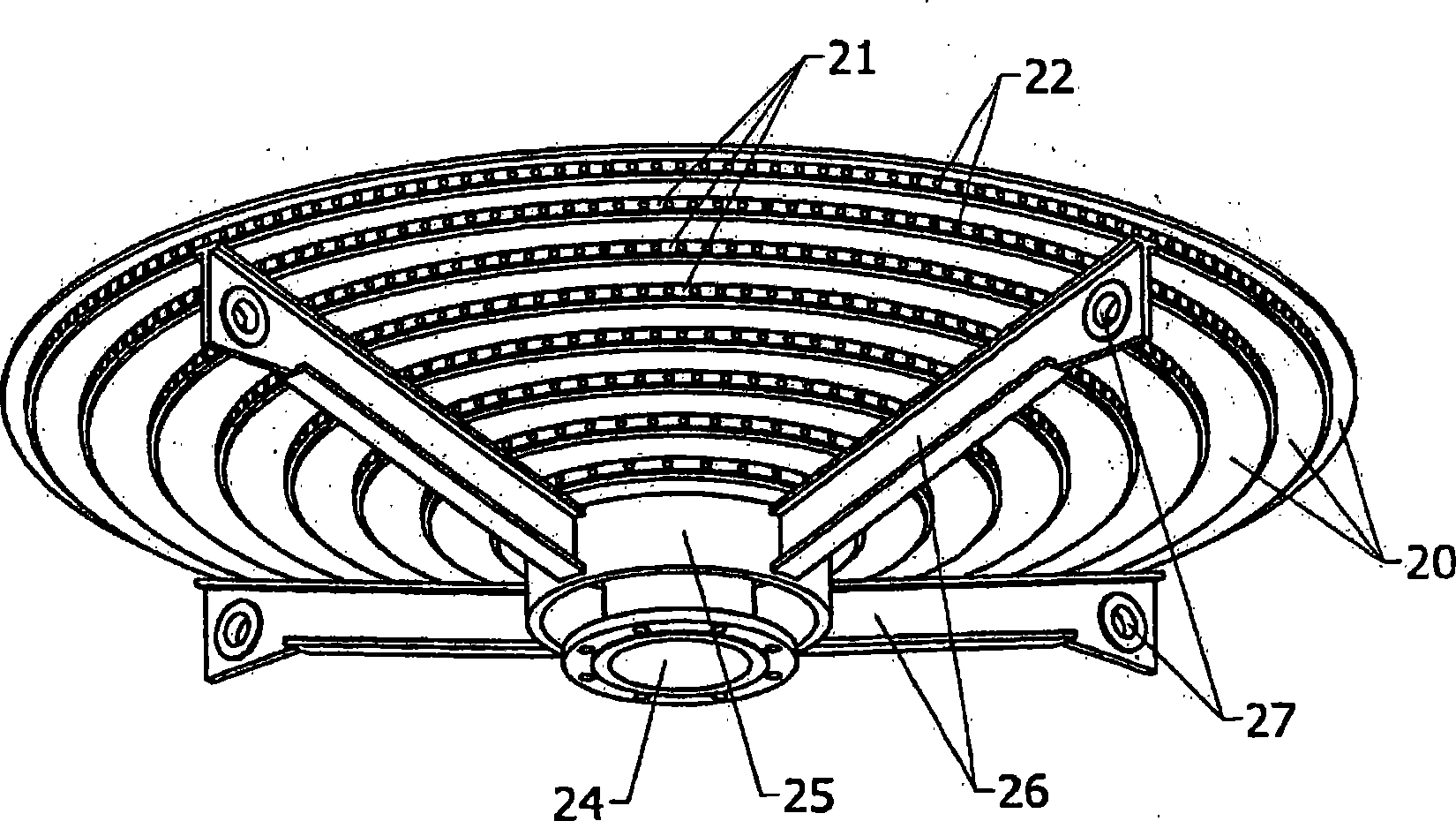

[0036] according to figure 2 and image 3 , the grating structure includes multiple layers of annular concentric plate rings arranged at different levels to form a downwardly tapering conical structure. The plate rings have different sized diameters. This structure includes two kinds of plate rings. The completely flat plate rings 20 are the first set of plate rings which form the basic structure of the grid. The first plate rings are most advantageously all horizontal. However, the grid structure also does not preclude the mounting of these plate rings in an oblique position. The slanted plate ring is then oriented towards the center of the cone of the structure.

[0037] The second ring 21 is the second set of rings which are located between the plate rings 20 which are completely flat. The thickness / height of the second ring generally corresponds to the mutual distance of the first plate rings from each other. The second plate ring has openings 22 to form horizontal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com