Patents

Literature

50results about How to "Get on the horse fast" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

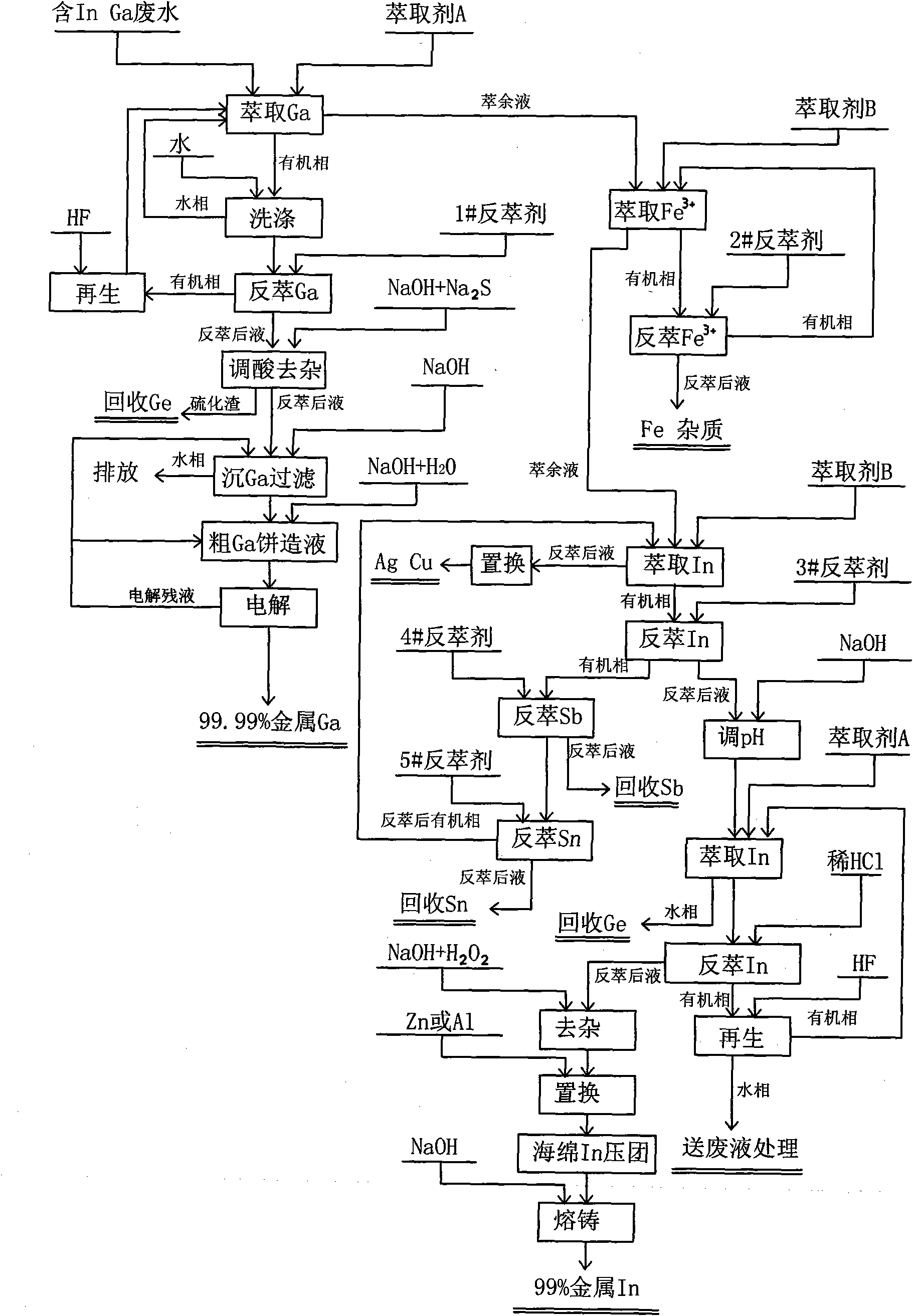

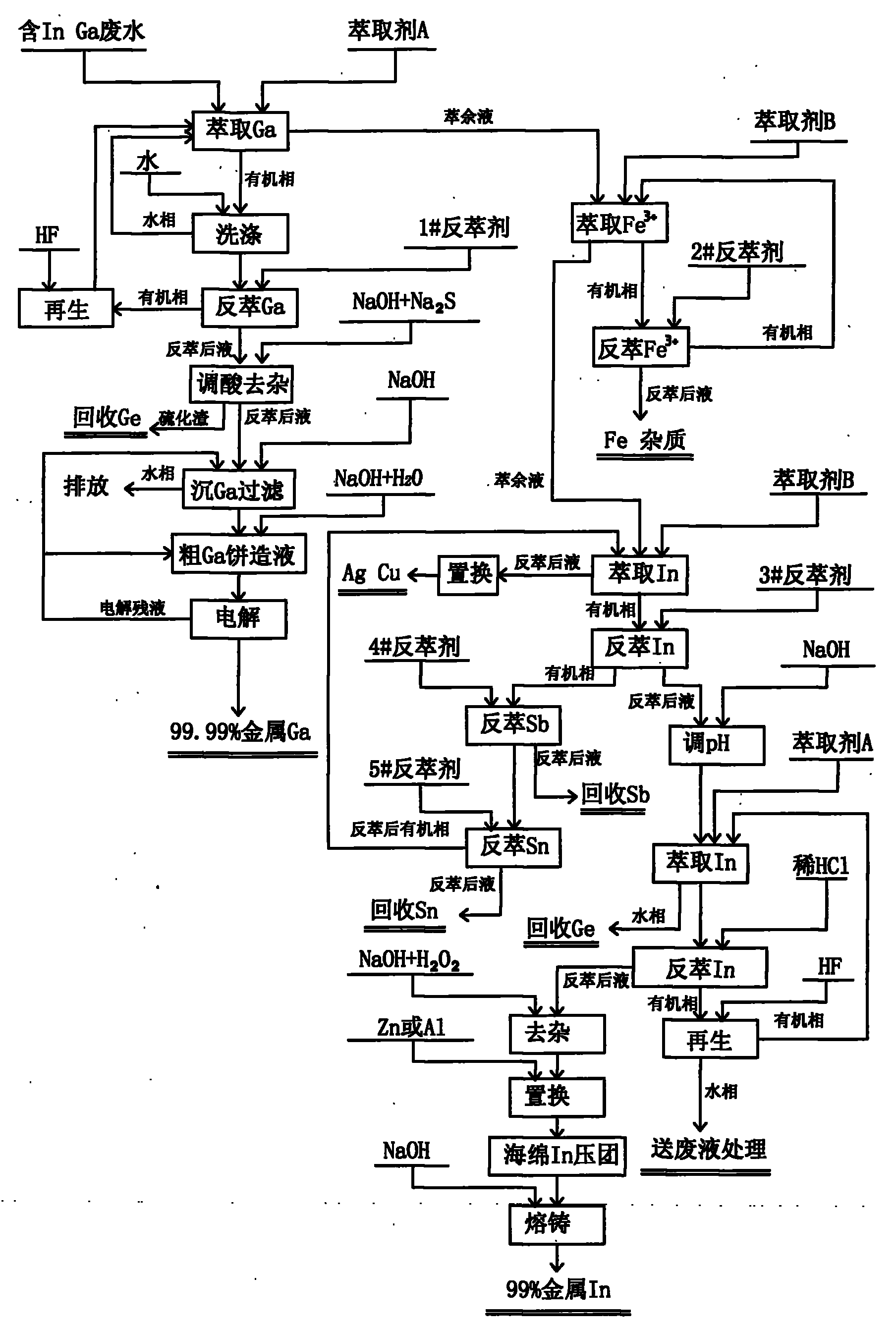

Multi-metal recovery processing technique of waste liquid generated in germanium producing process

InactiveCN101671777AReduce corrosionLow pricePhotography auxillary processesProcess efficiency improvementLiquid wasteIndium

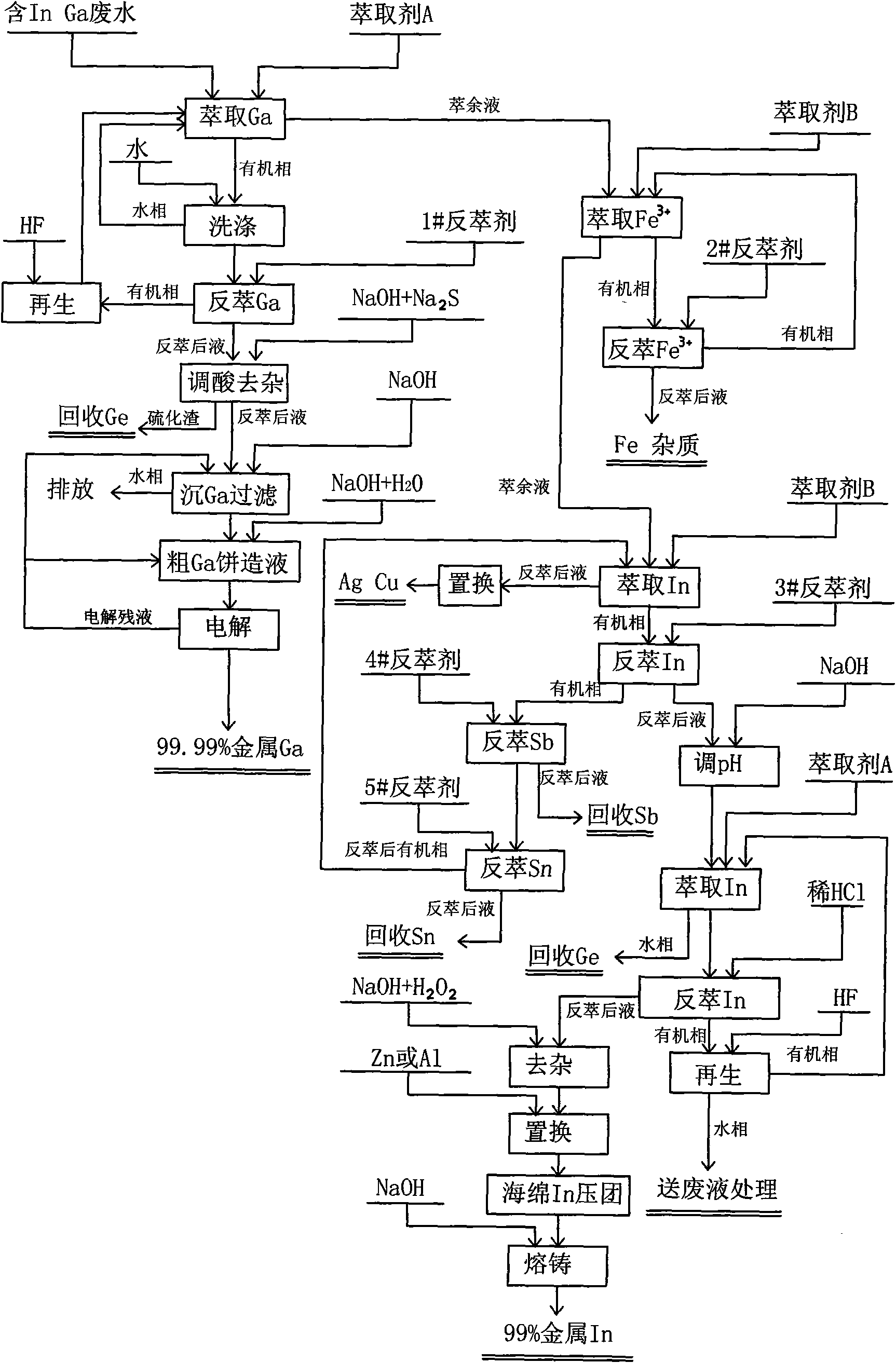

The invention relates to a multi-metal recovery processing technique of waste liquid generated in a germanium producing process, belonging to the technical field of non-ferrous metal wet method metallurgy. The multi-metal recovery processing technique comprises the following steps: extracting germanium from the waste liquid generated in the germanium producing process by an extractant A and a kerose diluent, washing, carrying out back-extraction, removing impurities, purifying, depositing the germanium and electrolyzing to obtain the metal germanium with the purity of 99.99%; firstly extracting iron and partial impurities from the residual waste liquid after extracting the germanium by an extractant B and the kerose diluent, and extracting indium from the residual waste liquid after extracting the iron by the same organic extractant B, adjusting the pH, extracting the indium by the extractant A, carrying out the back-extraction, neutralizing, oxidizing, removing the impurities and replacing to obtain spongy indium, and then briquetting and casting to obtain 99% metal indium. The invention has the advantages of short process flow, small occupied area, few investment, fast implementation and good working conditions, solves the problems that the valuable metal in the waste acid solution can not be recovered and has higher value of the resource comprehensive utilization. Furthermore, the metal recovery rate is larger than 92%; the purity of the obtained product, metal germanium, is 99.99%, and the purity of the metal indium is 99%.

Owner:湖南福欣锗业科技有限公司

Production method of vegetable stem made pot

InactiveCN1557128AReduce energy consumptionRelieve pressureCultivating equipmentsReceptacle cultivationSeedlingRoot system

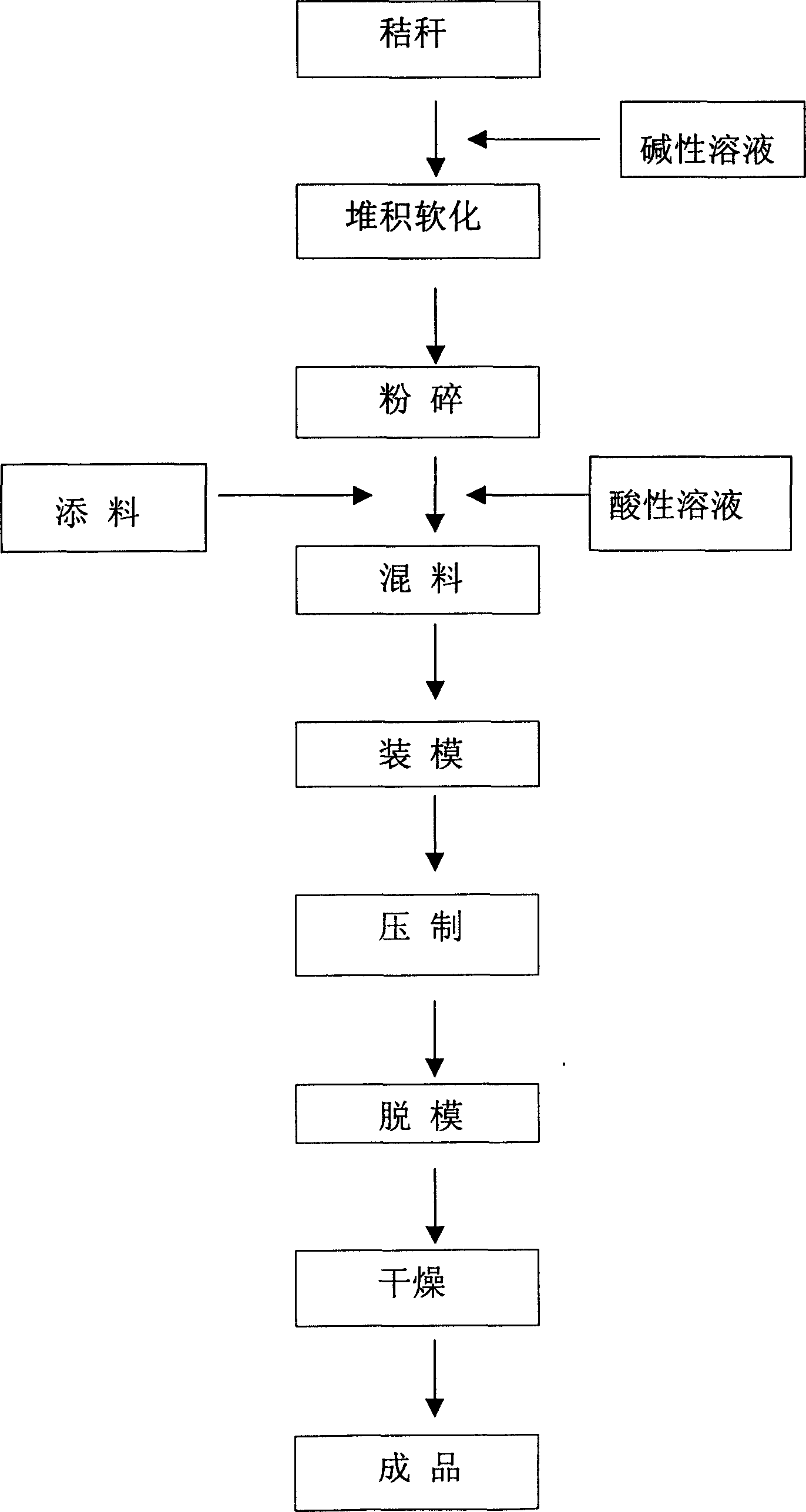

The plant stalk pot making process has simple apparatus used, less investment and low cost, and the plant stalk pot is used in cultivating and transplanting seedling and becomes fertilizer for the plant after degradation. The making process includes adopting plant stalk as main material, adding alkali solution to raise pH value to over 9, stocking for softening, crushing, adding acid solution to regulate pH to neutral, mixing with additive, molding, demolding, and drying. The weight ratio among plant stalk, alkali solution, acid solution and additive is 1 to 0.2-0.6 to 0.06-0.2 to 0.02-0.08. The present invention is suitable for cultivating seedling and pot cultivation.

Owner:JIANGSU ACADEMY OF AGRICULTURAL SCIENCES

Heat-insulating light sandwich wall board

InactiveCN1362563ADoes not affect strengthLight weightSolid waste managementLayered productsWhitening AgentsPolystyrene

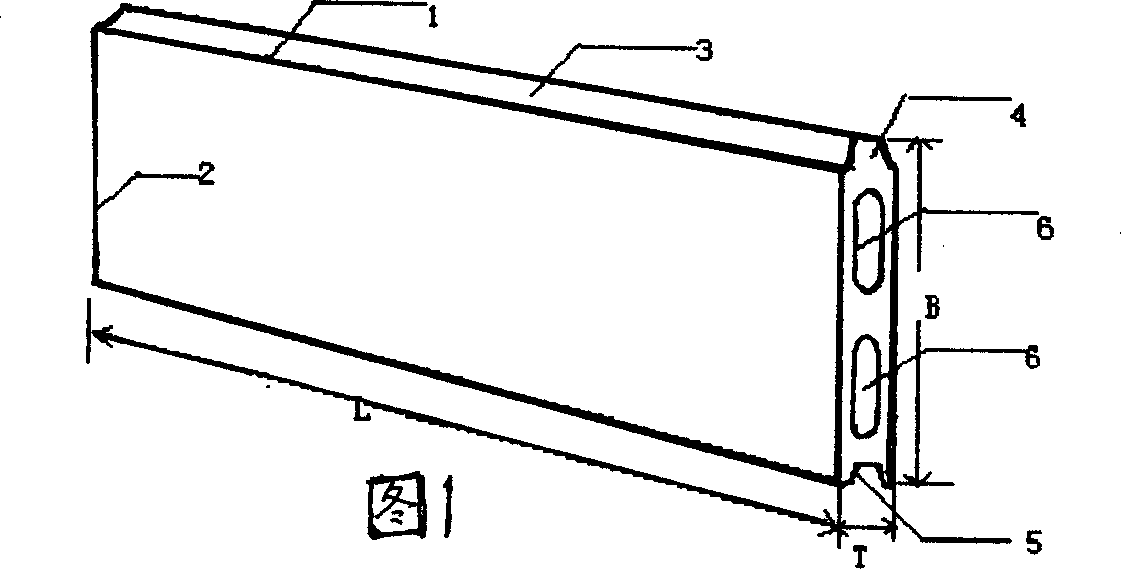

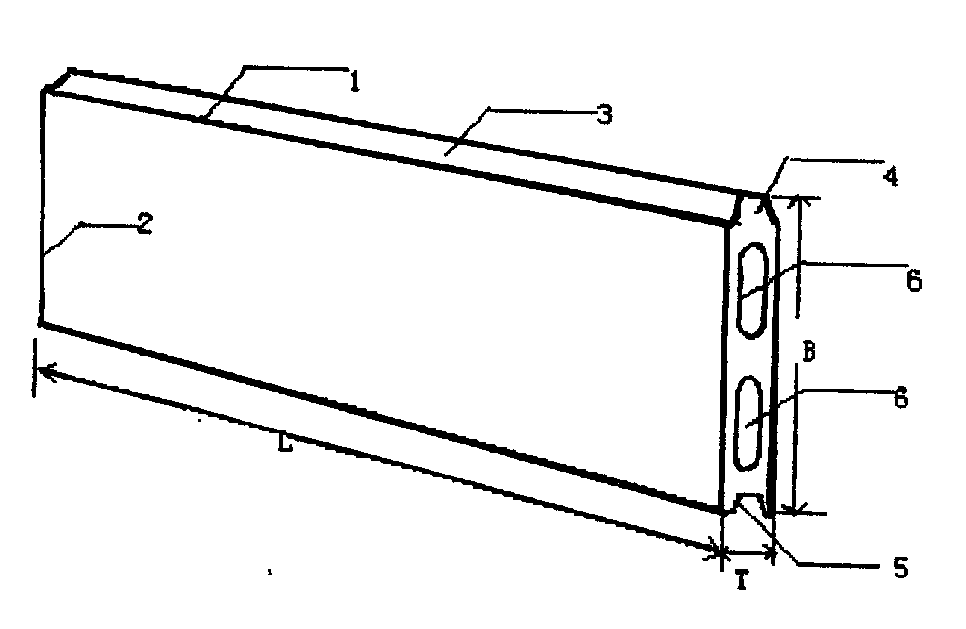

The sandwich heat-insulating light wall panel is made up by using crop straw and stalk as main raw material, matching with light ore powder, gelling agent and other components and sandwiching polystyrene foam plate and utilizing special-purpose equipment through one-step process. Its composition comprises straw and stalk powder 48-50%, light ore powder 35-42%, flyash 4-8%, halide powder 10-12%, glass fibre 1-2%, gelling agent 0.2-1%, fiore-resisting agent 0.5-0.8%, whitening agent 0.05-0.1% and solidifying agent 0.01-0.09%, and its internal core is polystyrene foam plate, its thickness is 30-100 mm.

Owner:范广俭

Method for removing phosphorus impurities in silicon by vacuum induction melting

The invention relates to a silicon-extracting method, in particular provides a method for removing phosphorus impurities in silicon by vacuum induction melting. The silicon-extracting method comprises the following steps: putting polysilicon into a crucible; vacuumizing and preheating the crucible; closing a roughing valve; starting a diffuser pump valve to be vacuumized; switching on a mid-frequency induction heating power supply so that crucible heat is heated by induction; preheating silicon raw materials in the crucible at a low temperature so that silicon is self heated by induction when the temperature rises to 600 DEG C; increasing mid-frequency heating power to 50-200kW so that the silicon starts to melt when the temperature reaches over 1415 DEG C; adjusting the mid-frequency heating power after the silicon is melted so that the temperature of silicon liquid is controlled at 1550-1850 DEG C; controlling a vacuum degree to 1.2*10<-2>-1.0*10<-1> Pa after the temperature is stabilized; starting timing while holding time is 45-120 min; adding circulating water in a water-cooled copper tray; and pouring the melt silicon liquid in a die to rapidly solidify.

Owner:XIAMEN UNIV

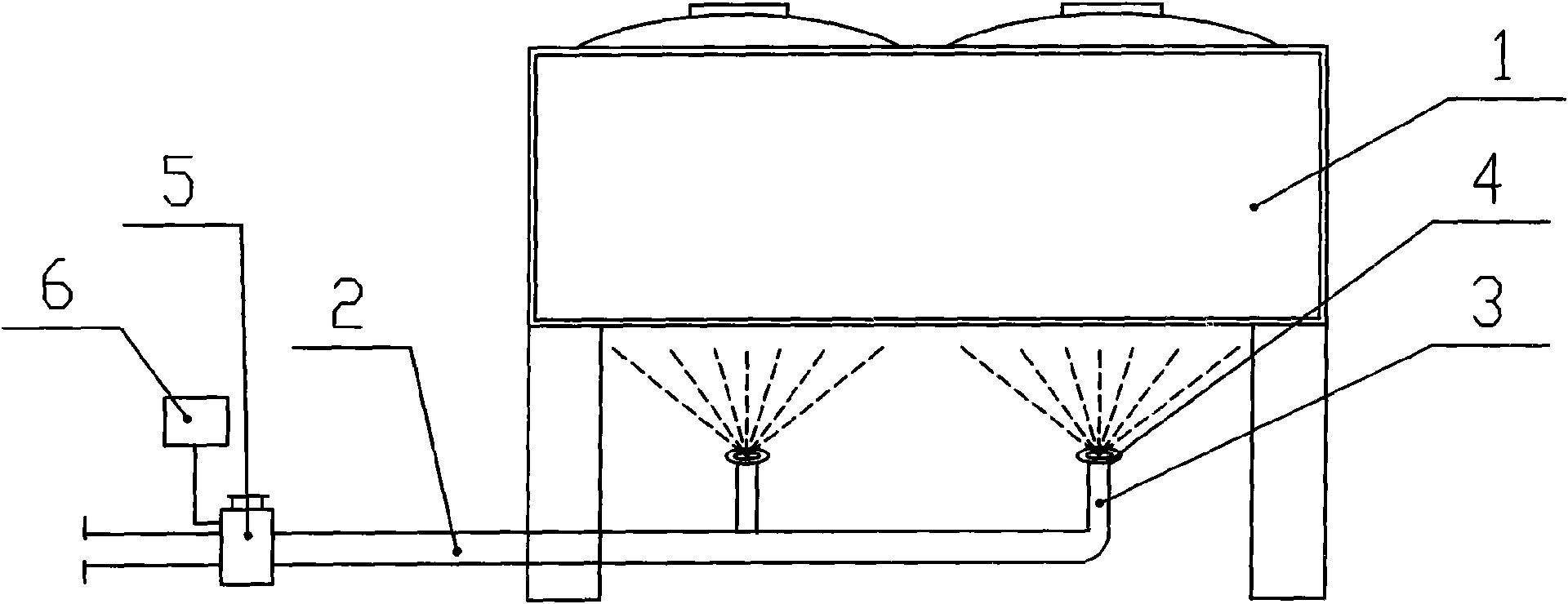

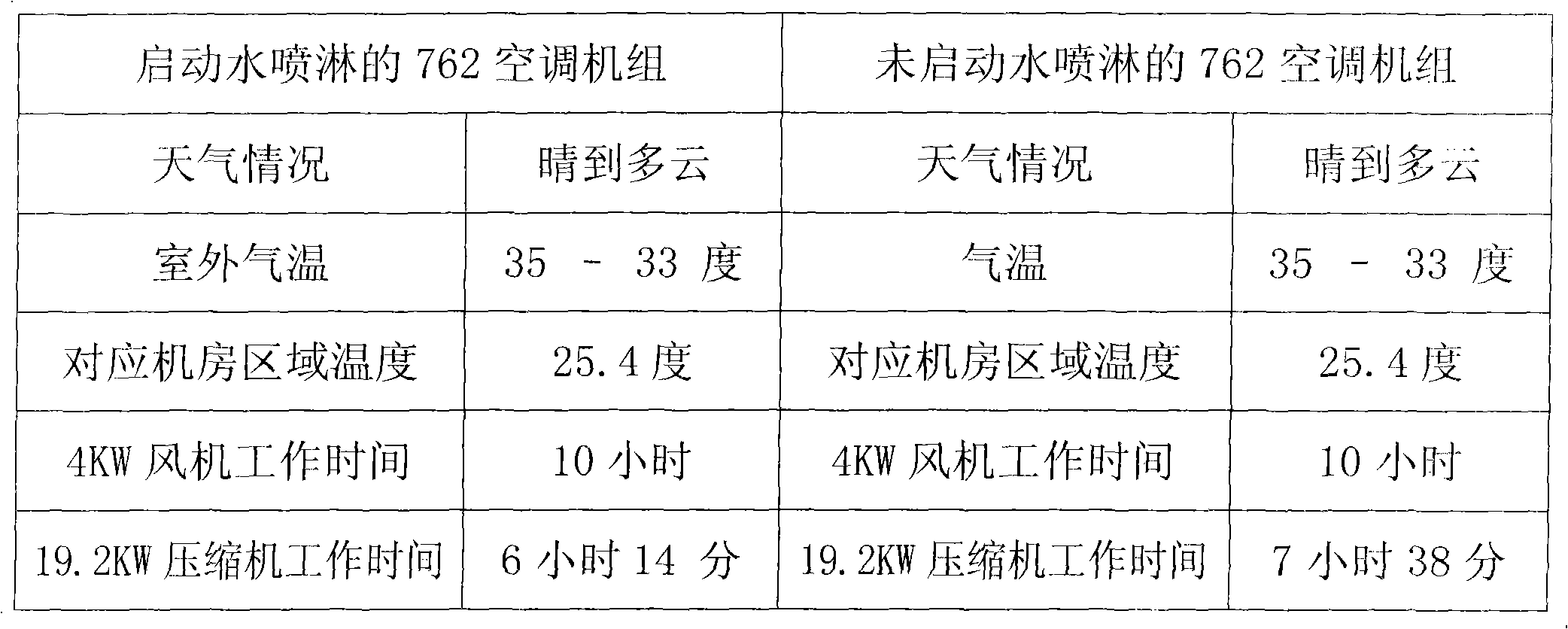

Synergistic and energy-saving system of precise machine room air conditioner

InactiveCN101672599AImprove cooling effectExtended service lifeSpace heating and ventilation safety systemsSpace heating and ventilation control systemsTemperature controlEngineering

The invention relates to an auxiliary device of a machine room air conditioner, in particular to a synergistic and energy-saving system of a precise machine room air conditioner. A spraying device isarranged below an outdoor unit of the air conditioner, wherein the spraying device comprises a main spraying pipe, and at least one branch spraying pipe is arranged on the main spraying pipe; the branch spraying pipes are arranged below the outdoor unit, and the end parts of the branch spraying pipes are provided with atomization spray heads; an electromagnetic control valve is arranged on the main spraying pipe, and a temperature control circuit is arranged on the electromagnetic control valve. The invention has simple structure, and the refrigerating effect of the air conditioner is effectively improved by carrying out spraying and water cooling on the outdoor unit of the air conditioner. In addition, the invention effectively improves the radiating capacity of the outdoor unit set, improves the working efficiency, shortens the working time of a compressor and correspondingly prolongs the service life of the machine room air conditioner.

Owner:顾觉惠

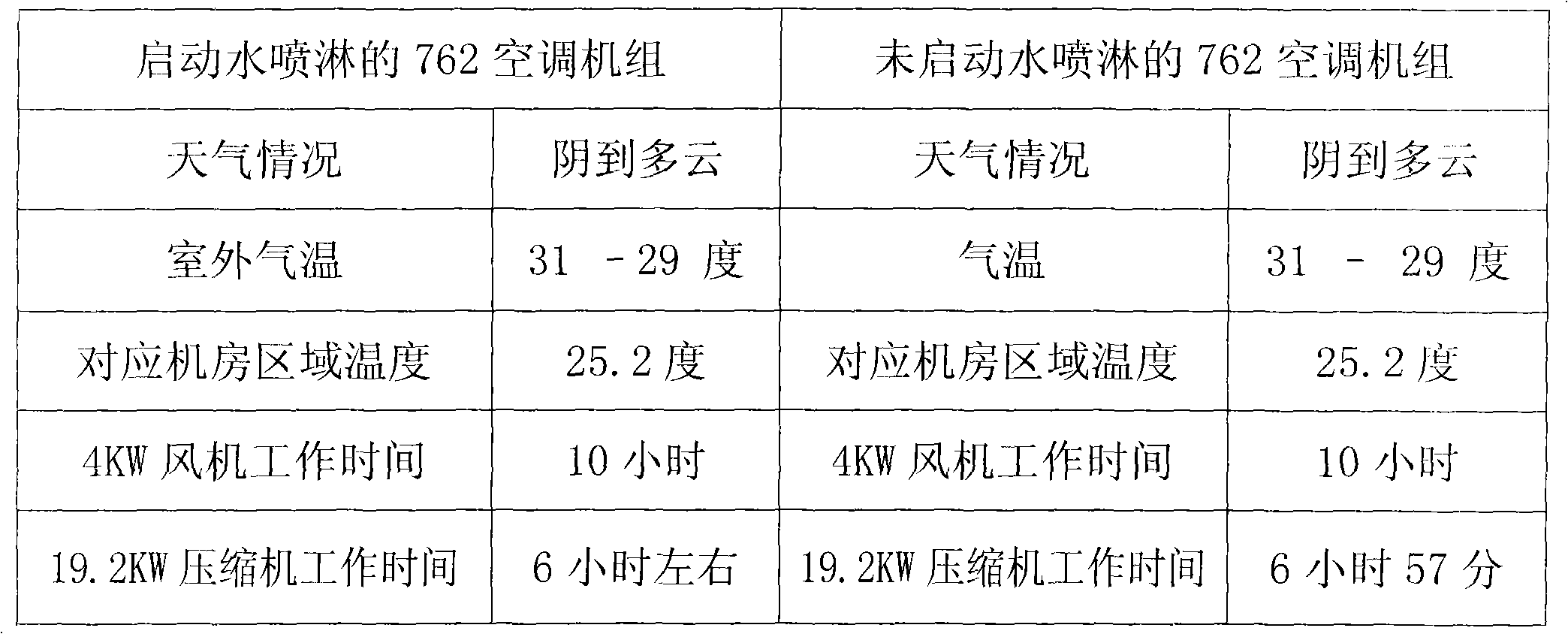

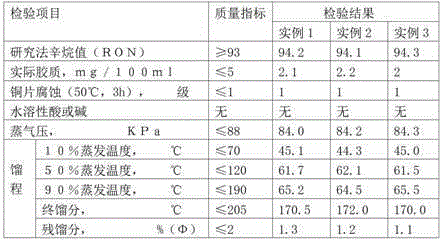

Vehicle gasoline for replacing petroleum fuel and its prepn process

The vehicle gasoline for replacing petroleum fuel consists of coal-base methanol 20-25 wt%, C2-C8 alcohol 10-25 wt%, low benzene arene 20-35 wt%, dimethoxy methane 5-10 wt%, catalyst 0.01 wt%, coal-base light oil 15-40 wt%, stabilizer 0.01 wt%, and metal corrosion inhibitor 0.01 wt%. The preparation process includes the following steps: 1. reaction of coal-base light oil and catalyst in a distiller, extracting 200 deg.c below fractions, cooling and adding stabilizer; 2. setting the other main materials into a mixer; and 3. pumping the product of the step 1 to the mixer and adding metal corrosion inhibitor to obtain the product. The vehicle gasoline is prepared with coal chemical products and biochemical products, and has high oxygen content, high power performance and capacity of maximizing the released energy.

Owner:山西新源煤化燃料有限公司

Zincizing infiltrated layer corrosion resistance process for metal

InactiveCN105839047AStrong adhesionUniform and dense thicknessSolid state diffusion coatingPotassiumRare earth

The invention relates to a zincizing infiltrated layer corrosion resistance process for metal. The zincizing infiltrated layer corrosion resistance process for metal includes the steps that a zinc and nickel infiltrated layer and a metal base body are arranged in a closed metal container to be heated at the heating speed of 50-60 DEG C / min, and subjected to heat preservation heating for 120-180 min when heated to 480-500 DEG C; the adding amount of the zinc and nickel infiltrated layer accounts for 1.5%-4.5% of the weight of the metal base body, and the zinc and nickel infiltrated layer is prepared from zinc powder, nickel powder, aluminum powder and energizer particles with the weight ratio of 1:(0.03-0.05):(0.02-0.04):(0.09-0.15), the particle diameter of the raw materials is controlled to be 0.1-1 mm, the energizer particles are composed of 40-90wt% of rare earth chloride and 10-60wt% of auxiliaries, and the auxiliaries are composed of 50-70wt% of potassium chloride, 20-40% of sodium chloride and 2-10wt% of boric acid. The zincizing infiltrated layer corrosion resistance process for metal is short in period, the strength and abrasion resistance of the infiltrated layer are good, and the mechanical performance and the corrosion resistance of finished products are excellent.

Owner:福建大统铁路精密装备股份有限公司

Method for abstracting solar energy level silicon by physics metallurgical method

InactiveCN101143722ARich sourcesSimple processing methodSilicon compoundsChemical reactionThermal insulation

The invention discloses a solar grade silicon refinery method by using physical metallurgy. The method includes the following steps: firstly, a vacuum induction melting furnace is utilized and a high purity oxide crucible is selected to avoid carbon pollution; secondly, the vacuum pumping is operated simultaneously during the heating process; thirdly, the protective gases are injected into the furnace; when the melting temperature reaches a certain value, strong oxidative gases (chlorine) are injected into the bottom of the crucible; fourthly, while stirring the silicon solution, the strong oxidative gases carry out chemical reactions with Fe-Al-Ca-P-V etc impurity elements, which lead to the gasification and thermal insulation of the elements; fifthly, the refined silicon is injected into the tundish, and the directional crystallization program is processed. The invention has a simple method, an easy operation, rapid heating and no pollution. The silicon material refined by the invention can reach 5N or higher purity.

Owner:JIAWEI SOLAR WUHAN

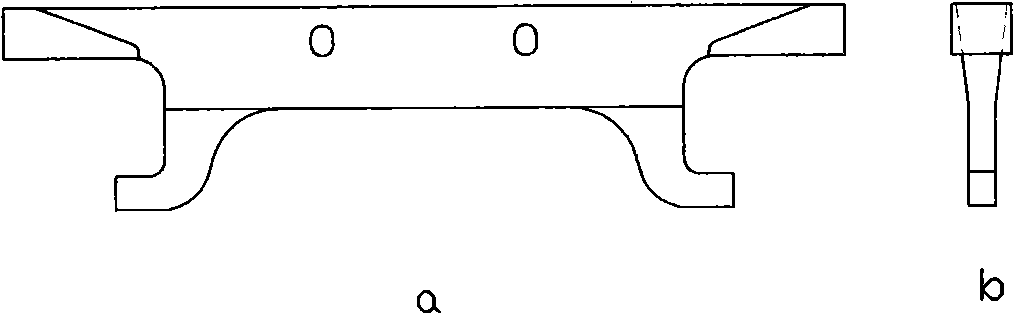

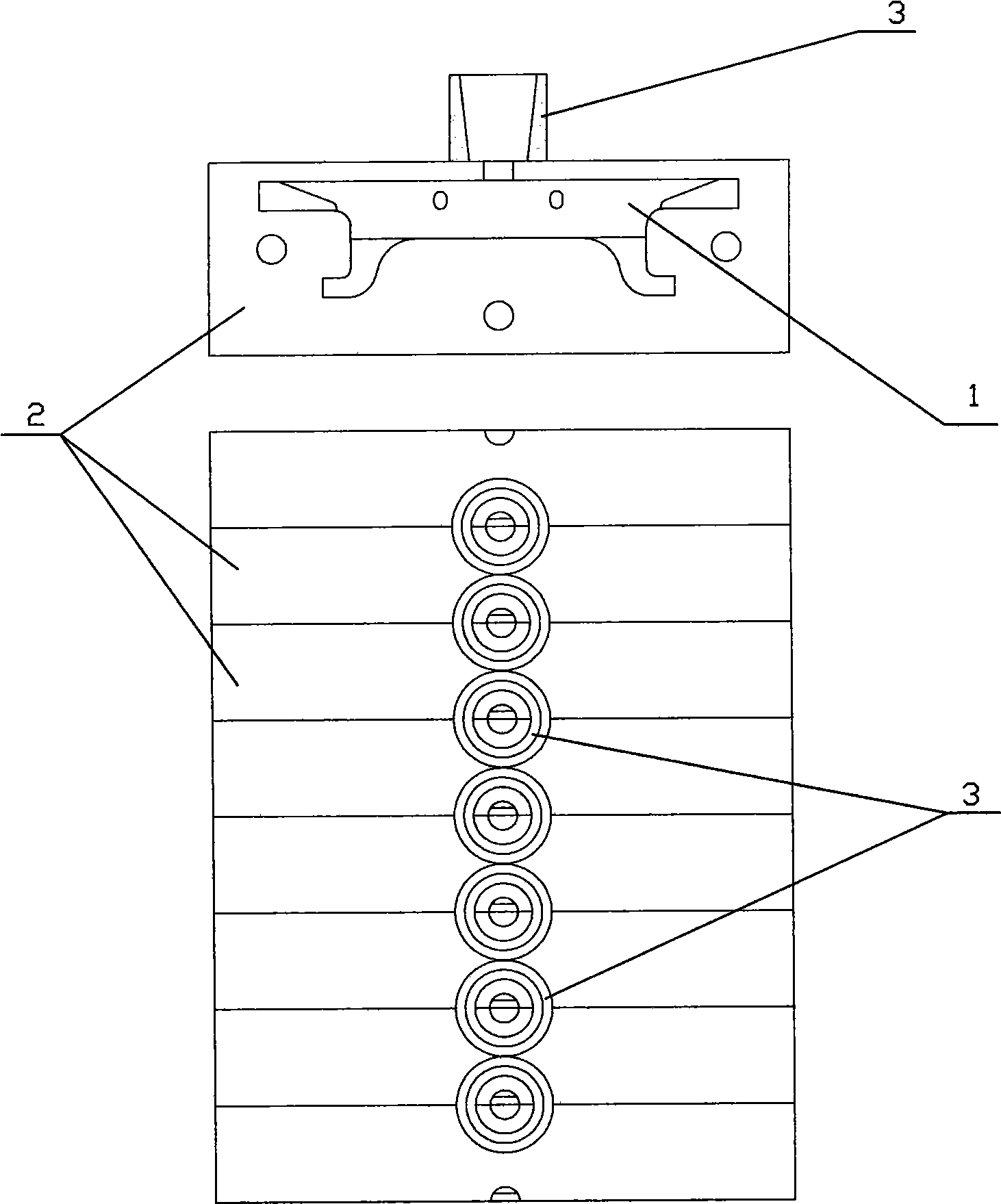

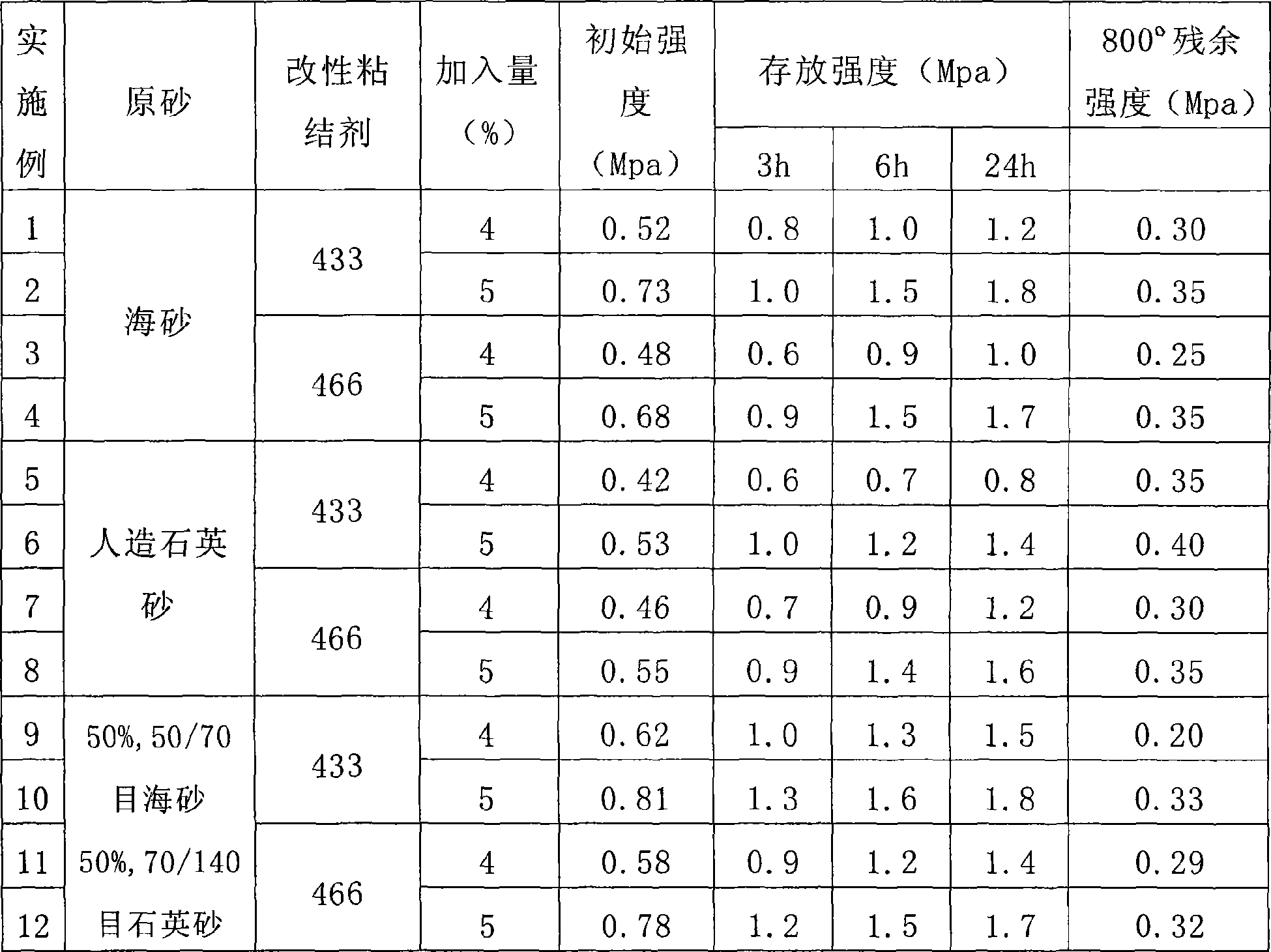

Grate production process for steel mill sintering apparatus

The invention discloses a production process of a grate bar used for sintering equipment of steelworks. The production process comprises the following steps of: mixing molding sand, namely, adding 4-5% of modified water glass to 50% of base sand (50 / 70 meshes) and 50% of base sand (70 / 140 meshes) so as to prepare the molding sand; modeling, namely, adopting a vertical molding process, injecting CO2 and then carrying out the patter drawing; coating, namely, coating the quick-dry alcohol-based coating in a curtain coating way; molding integration, namely, vertically molding the sand mold in series correspondingly; finally, preparing corresponding risers and runners for pouring-forming. The production process completely meets the special quality requirement of the grate, the production cost can be reduced by more than 10%, furthermore, the production efficiency can be improved, especially the environmental pollution can be reduced, the utilization ratio of the resource can be improved and the energy resource consumption can be reduced.

Owner:上海市机械制造工艺研究所有限公司

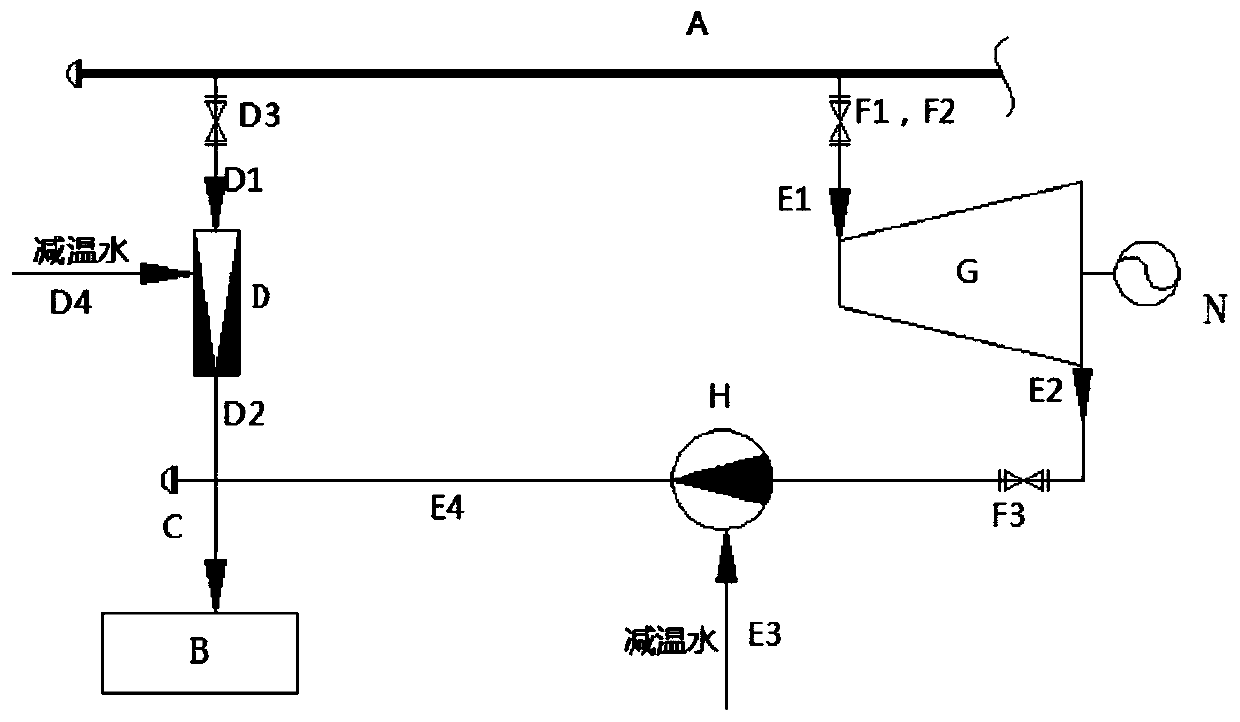

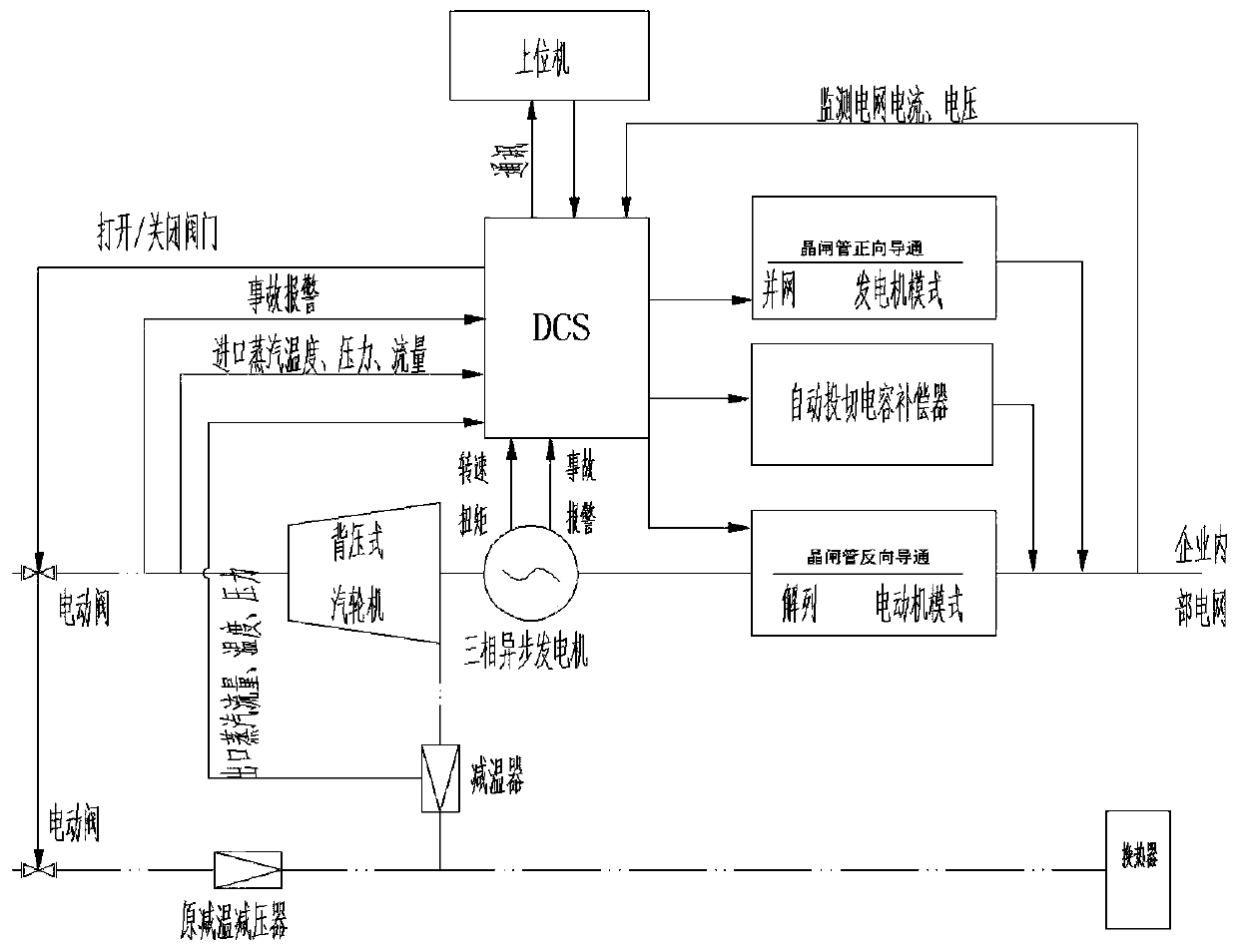

Industrial steam turbine asynchronous power generation-based energy-saving system and energy-saving control method

PendingCN111058902AImprove securityGuaranteed uptimeChemical industryMachines/enginesAutomatic controlControl system

The invention relates to an industrial steam turbine asynchronous power generation-based energy-saving system and an energy-saving control method. The system comprises a temperature and pressure reducer and at least one back pressure type steam turbine generator unit, wherein the temperature and pressure reducer is connected with a medium- and low-pressure steam incoming main pipe; an inlet steampipeline system is arranged between the temperature and pressure reducer and the medium- and low-pressure steam incoming main pipe; an outlet steam pipeline system is arranged between the temperatureand pressure reducer and a steam using device; the back pressure type steam turbine generator unit is connected with a temperature reducing device; the temperature reducing device is connected with the inlet main pipe of the steam using device; each pipeline is provided with a manual or electric regulating valve; the temperature and pressure reducer, the back pressure type steam turbine generatorunit, the steam using device, each electric regulating valve are controlled by a DCS / PLC automatic control system; steam enters the back pressure type steam turbine asynchronous generator unit; and the unit does work and generates power through the impact steam. With the system and method of the invention adopted, cost can be saved; and a construction period and project cost are 1 / 2-2 / 3 of those of a synchronous unit with the same installed capacity as the system of the invention. The system and the method can be suitable for common industrial fields such as the phosphorus compound fertilizerchemical industry, the petrochemical industry, the smelting metallurgy industry, the papermaking light textile industry and the like.

Owner:云南固废投资有限公司

Method for preparing artificial quartz stones by using kaolin desliming tailings

InactiveCN101961883AHigh strengthImprove corrosion resistanceCeramic shaping apparatusKaolin clayEngineering

The invention discloses a method for preparing artificial quartz stones by using kaolin desliming tailings, which relates to building decoration materials and comprises the following steps of: stirring unsaturated resin and colorants, adding the kaolin desliming tailings, natural river sand and silicon dioxide powder, performing stirring, adding an accelerator, a coupling agent and a curing agent, performing stirring and injecting the mixture into a mould; feeding the mould into a vacuum box for vacuumizing, pressing and forming the mixture and performing curing and heating; and performing cooling de-molding to remove the mould, performing polishing and finally cutting the molded mixture into standard artificial quartz stone slabs, wherein artificial quartz stones are made from the following raw materials in percentage by mass: 12 to 65 percent of natural river sand of 10 to 120 meshes, 15 to 35 percent of natural river sand of larger than 120 to 1,500 meshes, 5 to 15 percent of silicon dioxide powder, 0.1 to 19 percent of unsaturated resin, 0.1 to 5 percent of accelerator, 0.1 to 3 percent of coupling agent, 0.1 to 5 percent of curing agent and 0 to 5 percent of colorant. The method reduces initial investment, and is convenient to operate, easy to implement, simple and reasonable; and the products have the natural veins, stripes and rich colors of marbles, also have the hardness of the quartz stones and are suitable for industrialization.

Owner:XIAMEN UNIV

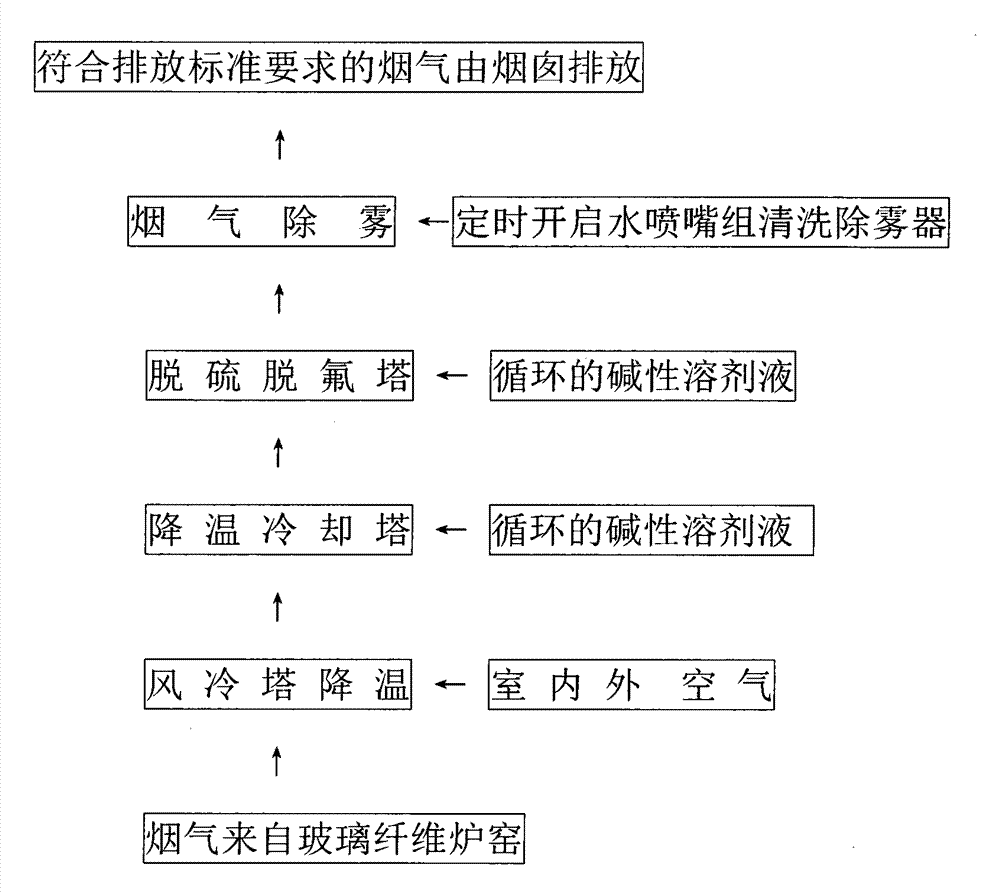

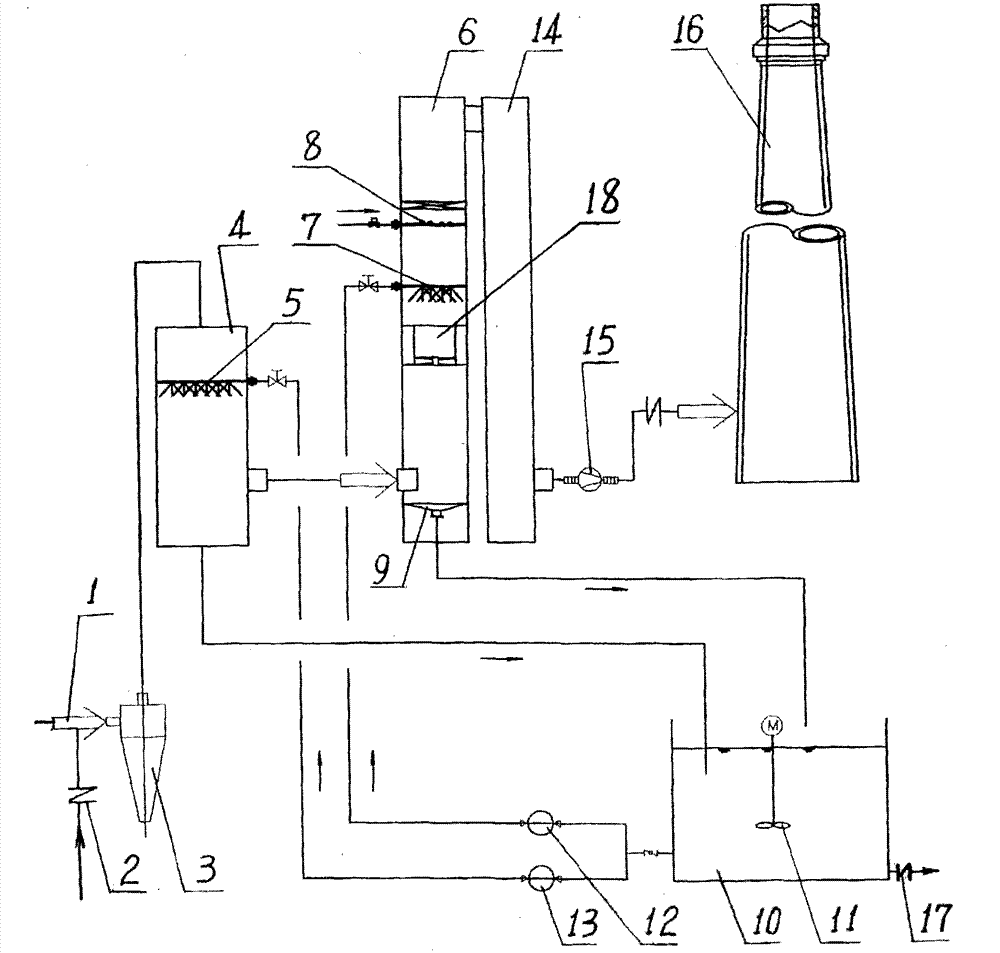

Glass fiber furnace kiln waste gas desulfurization device with turbo-charging turbulator and process

InactiveCN104841263APromote mutual mixingFull chemical reactionDispersed particle separationGlass fiberEngineering

The invention discloses a glass fiber furnace kiln waste gas desulfurization device with a turbo-charging turbulator, and a process, belonging to the technical field of environment protection. According to the glass fiber furnace kiln waste gas desulfurization device, a furnace kiln fume tube and an air supplement valve, an air cooling tower and a cooling tower, the cooling tower and a desulfurization tower are fixed by using pipelines; the furnace kiln fume tube is fixed with the air cooling tower, and the cooling tower is fixed with an atomization nozzle group; the cooling tower and a receiving tank are fixed with a pipeline inserting into a circulation tank; the inner wall of the desulfurization tower is fixed with a water nozzle group, a desulfurization nozzle group, the turbo-charging turbulator and the receiving tank in sequence; a stirrer is arranged inside the circulation tank; the circulation tank is fixed with a desulfurization pump as well as an atomization pump by pipelines; the desulfurization pump is fixed with the desulfurization nozzle group by a pipeline, and the atomization is fixed with and the atomization nozzle group by a pipeline; the desulfurization tower is fixed with a secondary tower flue by a pipeline, the secondary tower flue is fixed with a draft fan by a pipeline, the draft fan is fixed with a chimney by a pipeline, and the circulation tank is fixed with a blow-down valve by a pipeline. The process comprises the steps that fume is subjected to air cooling, temperature reduction, desulfurization, defluorination, demisting and discharge and the liquid is refluxed, the overall operation is organic, automatic and continuous, and thus sewage can be discharged in appropriate time. The glass fiber furnace kiln waste gas desulfurization device is applied to fume desulfurization and defluorination. The device is smart and simple in process, and stable in effect.

Owner:刘启杰

Biochemical crude oil

InactiveCN102154040APromote leapfrog developmentLow costBiofuelsLiquid carbonaceous fuelsChemical industryPetroleum

The invention discloses biochemical crude oil which mainly consists of biological oil and petroleum and / or alcohol ether fuel. In the invention, fossil petroleum is subversively replaced with a biomass from the raw material phase, so that an economic structure which does not depend on the fossil petroleum is established, and by ecological restoration of saline alkali and mineral waste lands, the greening of the heavy chemical industry is promoted simultaneously when biorefinery is developed; the biochemical crude oil is prepared by the existing petroleum production, refining and sale system or equipment of oil refining enterprises, chemical plants, clean fuel enterprises and the like; and the biochemical crude oil can be pumped and stored by a pump and is conveyed by a pipeline, a road, a railway and an oil tanker. Therefore, the original eliminated unenlightened or polluted productivity is converted into the productivity of a green oil field, a low sulphur oil refinery and a greening industry; the biochemical crude oil not only has little investment and low cost and is rapid to start; in the developing process, the environment is protected, the original huge productivity is prevented from changing into waste properties so as to promote the forward development of the emerging industry and the low-carbon economy.

Owner:窦观一

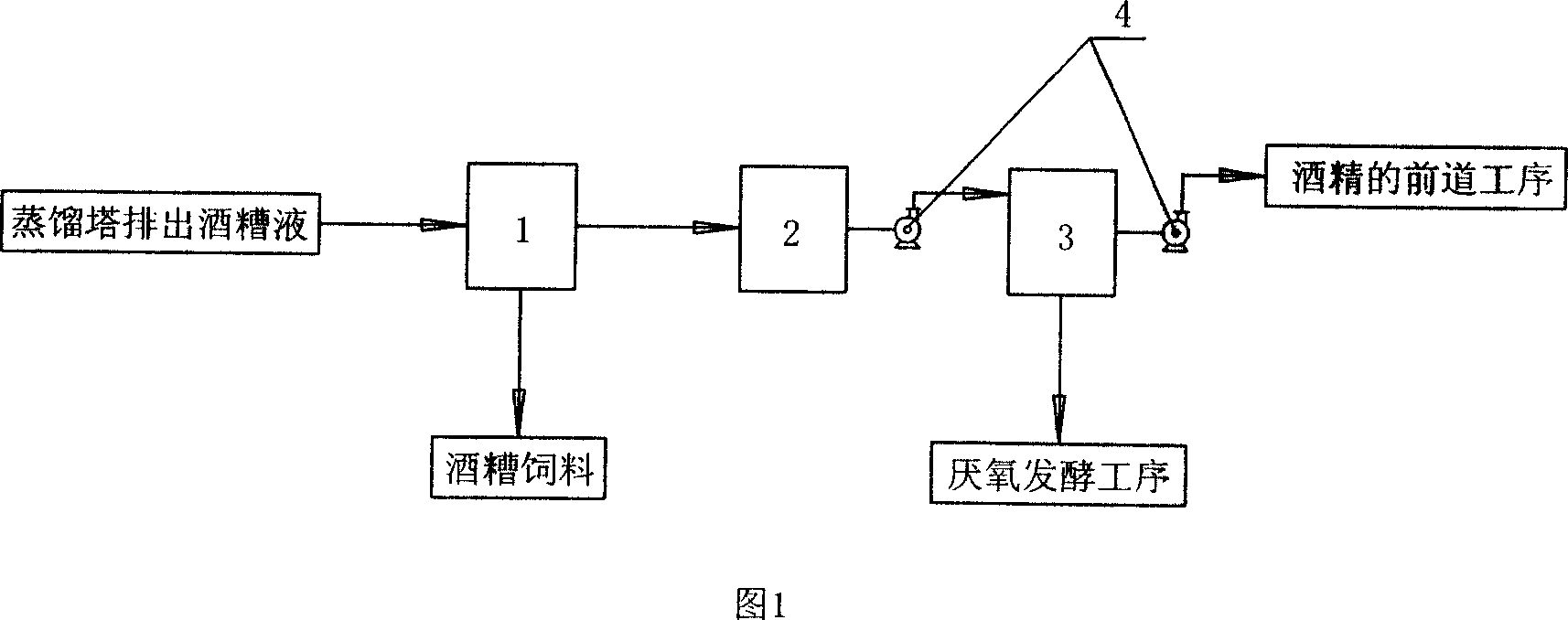

Re-utilization of waste liquid and distillers' grains from alcohol production

InactiveCN1939844AReduce pollution control costsSimple processFood processingAnimal feeding stuffLiquid wasteAlcohol production

Reutilization of alcohol and grain effluent is carried out by passing grain effluent to solid-liquid separator by distilling tower, entering the separated effluent into grain effluent neutralizer, delivering the neutralized grain effluent into efficient grain effluent deposition tank by transfer pump, entering deposited supernatant into pre-process to produce alcohol by transfer pump, separating out grain as feed by solid-liquid separator and delivering deposit into anaerobic jar to produce marsh gas. The equipments consist of solid-liquid separator, grain effluent neutralizer, efficient grain effluent deposition tank and transfer pump. It's simple, cheap, fast, has no environmental pollution and saves energy resources.

Owner:倪隆

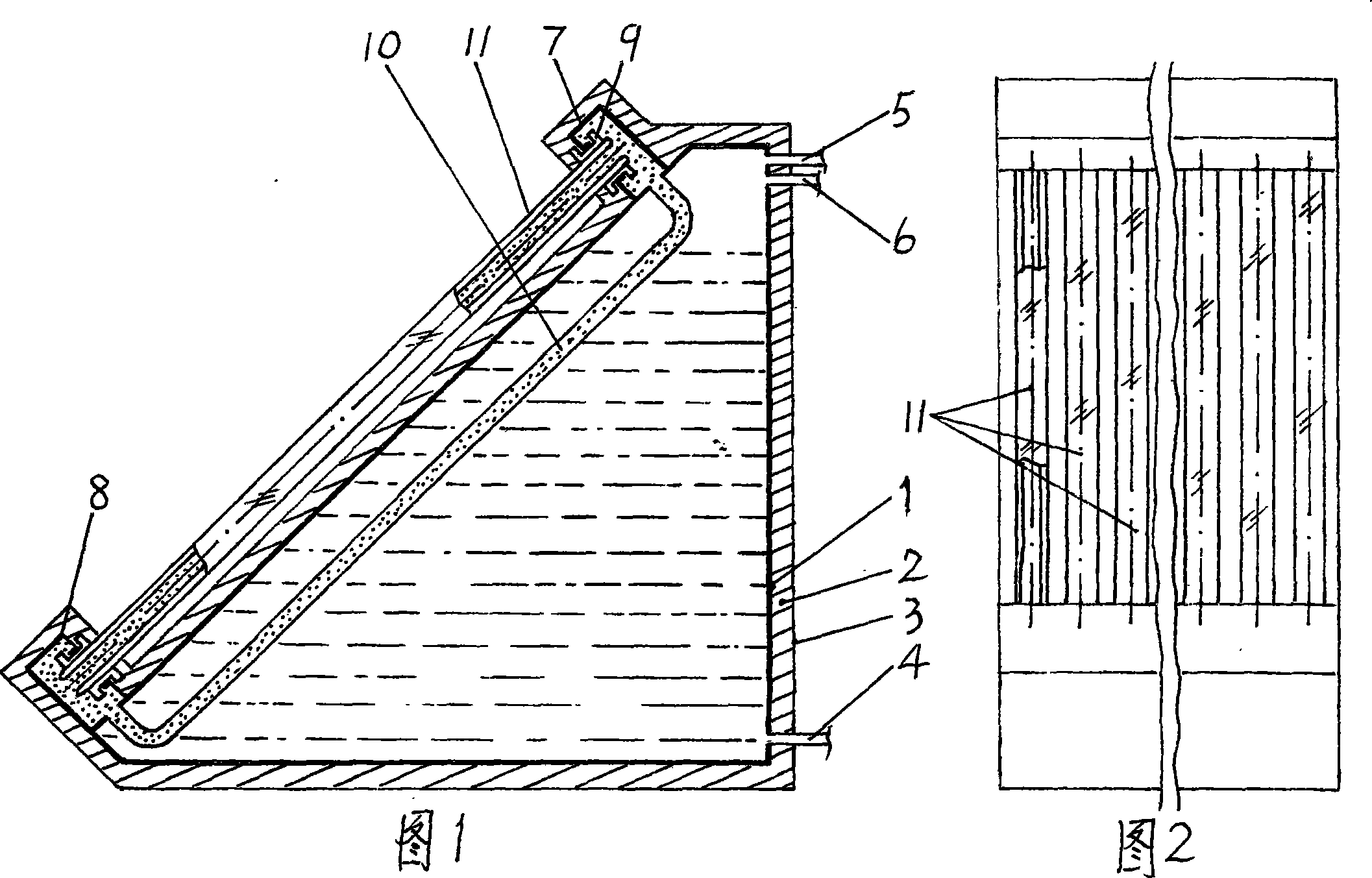

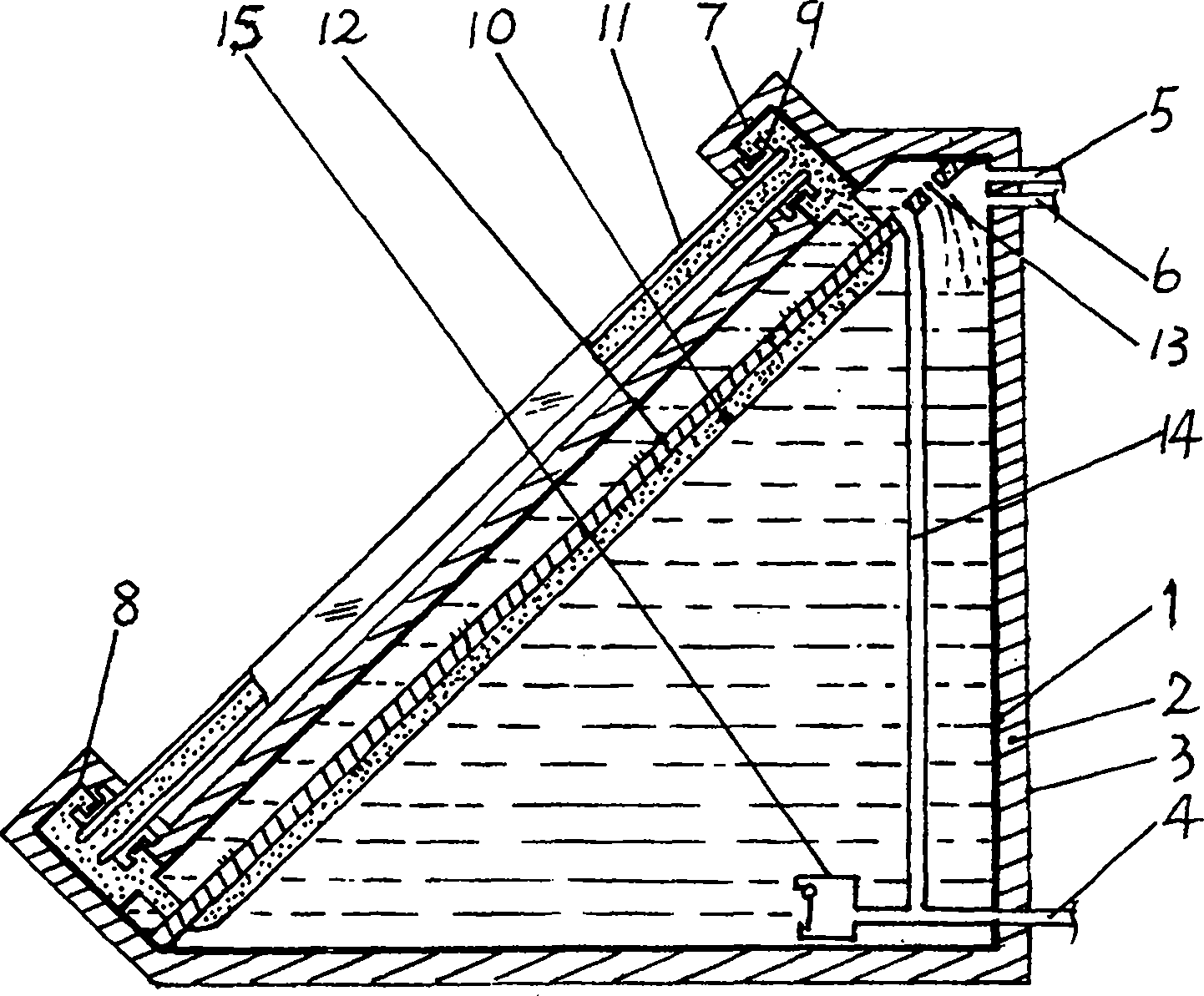

Horizontal type solar water heater

InactiveCN103471262AReduce volumeIncrease in sizeSolar heating energySolar heat devicesWater storage tankSolar water

The invention relates to a horizontal type solar water heater. One group of solar vacuum glass pipes on the exterior of a water storage tank is mutually communicated with one group of metal heat transfer pipes in the water storage tank to form a sealed loop, and heat conduction liquid is filled into the sealed loop. The solar water heater has the advantages that by using sunlight to heat the solar vacuum glass pipes and the heat conduction liquid, and utilizing the characteristics of liquid ascending by temperature rising and liquid descending by temperature lowering and the temperature difference between the interior of the water storage tank and the solar vacuum glass pipes, the heat conduction liquid circularly flows in the sealed loop to continuously heat the water in the water storage tank, and the metal heat transfer pipes also can quickly transfer the heat to heat the water, so the heat transfer efficiency is high; the water does not flow in the vacuum glass pipes, the sealing performance is good, the pipe explosion is avoided, and the vacuum glass pipes can run under the pressure condition; the water is completely isolated from a rubber ring and heat insulation material, the edible level sanitation is reached, and the purposes are expanded; a bracket is not required, the size is small, the weight is light, the cost is low, the transportation and the installation are convenient, the water heater can be directly arranged on the ground, the installation density is high, and the water heater can be conveniently hung on the wall; the capacity is very large, and the application range is greatly expanded; the structure is simple, the production and processing are realized by common technical equipment, the investment is little, the beginning is easy, and the period is short.

Owner:苗军

Zinc-nickel seeping layer ferrous metal corrosion protection process

ActiveCN101319300BHigh hardnessImprove wear resistanceSolid state diffusion coatingAl powderRolling resistance

The invention discloses a process for resisting ferrous metal corrosion of a zinc nickel diffusion layer. The process comprises the steps of alkaline degreasing, shot blasting, heating diffusion layer, water washing dust removal and colorful closing according to the requirement of a customer, wherein in the heating diffusion layer step, the zinc nickel diffusion layer and a metal matrix are put in a sealed metallic container and heated; the zinc nickel diffusion layer is prepared by evenly mixing the following powders in mass proportion: 20 to 30 percent of Zn powder, 0.5 to 1.4 percent of Nipowder, 3 to 12 percent of Al powder, 2 to 6 percent of rare earth, 1 to 4 percent of NH4Cl ammonium chloride, the balance being Al2O3 powder. The diffusion layer has the advantages of high rigidity,good wear resistance, unchangeableness of original mechanical performances of products, high adhesion strength, bumping and rolling resistance, good solderability, moisture and heat resistance and acid and alkali resistance; the diffusion layer has uniform thickness and compactness, and appearances of finished products have good uniformity; and no three-waste emission occurs during the course of processing, so the process belongs to the clean production process and is environment-friendly.

Owner:CHONGQING DAYOU SURFACE TECH

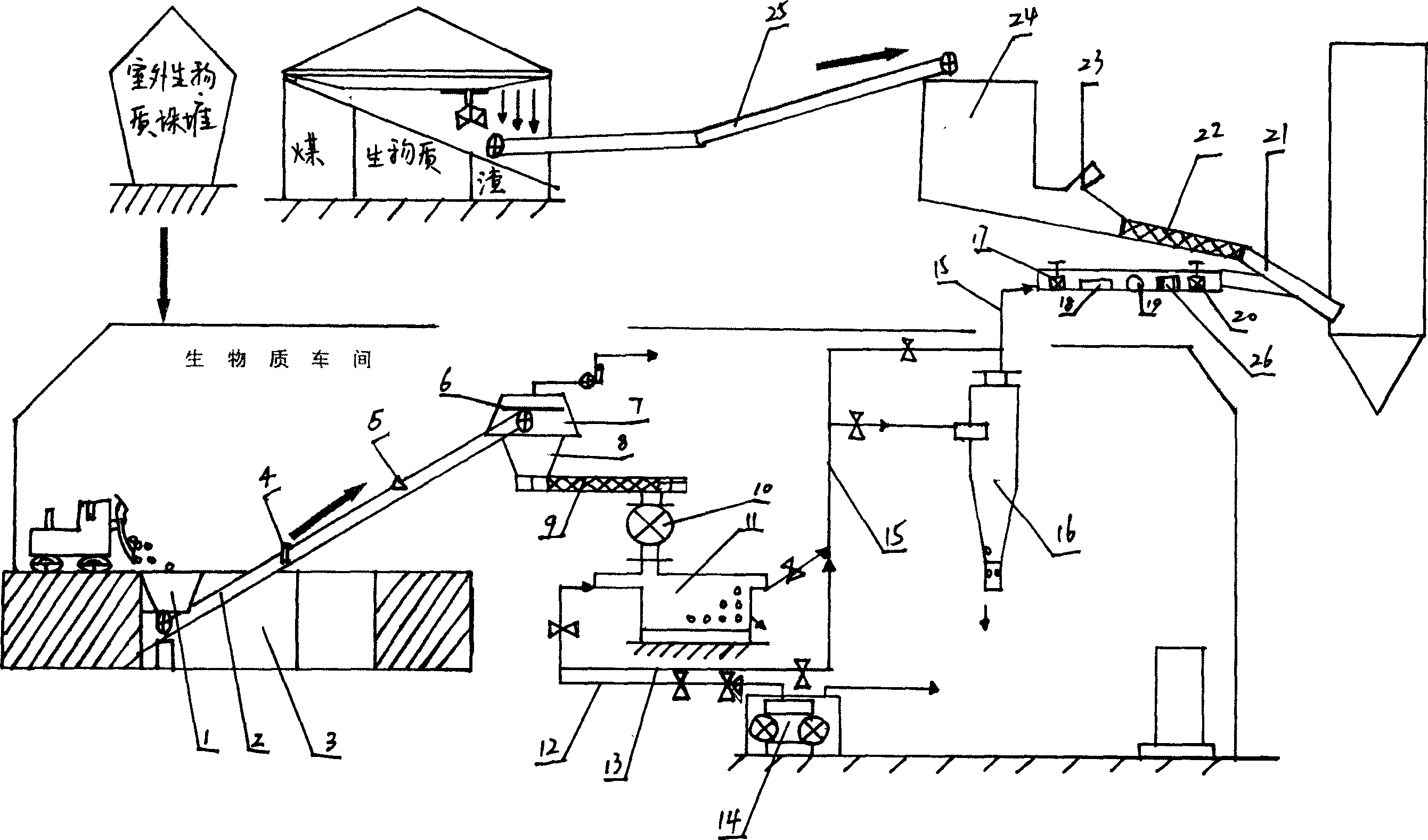

Device and system for feeding large bio-material to furnace for directly burning generating

InactiveCN1912468AAdaptableContinuous and stable deliveryLump/pulverulent fuel feeder/distributionMixed flowDirect combustion

A method for conveying large amount of raw material into furnace for directly burning to generate power includes cutting raw materials to be stubs then applying wind force to directly convey air and solid two-phase mixed flow formed by wind and raw material directly to internal phase zone of fluidized bed boiler through pipeline for burning to generate power, removing off sand and mud impurities while raw material is conveyed by wind force. The conveying system for realizing said method is also disclosed.

Owner:LIANYUNGANG XIEXIN ENVIRONMENT PROTECTION BIOLOGICAL THERMOELECTRIC

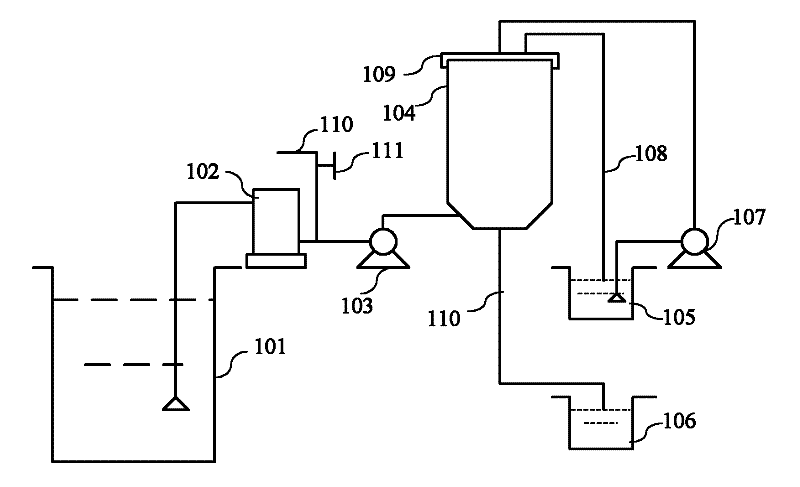

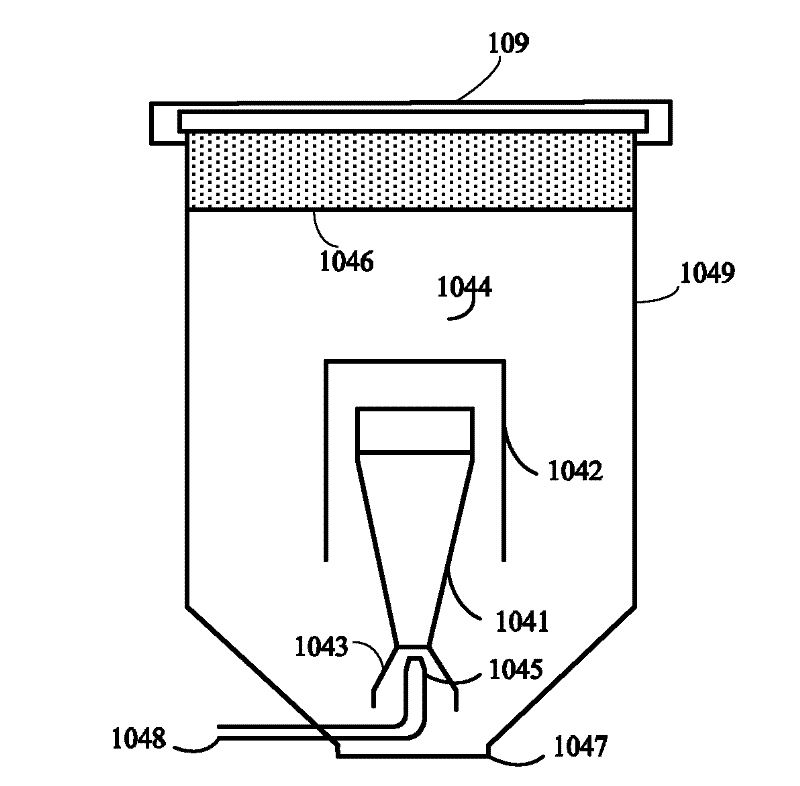

Fluorine-containing waste water processing apparatus and processing method thereof

ActiveCN102225814AEasy control joinEasy to operateMultistage water/sewage treatmentSludgeWater processing

The invention discloses a fluorine-containing waste water processing apparatus. A technical scheme of the apparatus is characterized in that: the apparatus comprises a waste water pool, a clean water pool, a sludge pool, a self-priming tank, a waste water pump, a purifier and a clean water pump; the waste water pool, the self-priming tank and the waste pump are connected in sequence through pipelines; an outlet of the waste water pump is connected to the lower part of the purifier through an inlet tube; the upper part of the purifier is provided with an opening, the opening part is provided with an upper cover, the upper cover is provided with a first through hole, the first through hole is provided with an inlet pipeline of the clean water pump, and an outlet pipeline of the clean water pump is connected to the clean water pool; and the lower part of the purifier is connected with the sludge pool through a sludge discharge tube, and the front end of the waste water pump is provided with a drug adding pipeline. The invention also discloses a fluorine-containing waste water processing method. The technical scheme of the present invention has the characteristics of thoroughly waste water processing and qualified discharge.

Owner:黑龙江省牡丹江农垦湠奥石墨烯深加工有限公司

High-cleanness alcohol ether fuel

InactiveCN105219450AImprove cleanlinessQuality improvementLiquid carbonaceous fuelsIsobutanolPolyethylene glycol

The invention discloses a high-cleanness alcohol ether fuel. A formula of the high-cleanness alcohol ether fuel particularly comprises the following concrete substances in parts by weight: 20-70 parts of an alcohol ether main agent, 3-15 parts of a compound modifier, 15-40 parts of light oil, 10-40 parts of signed gasoline and 0.3-1 part of a fine purifying agent, wherein the alcohol ether main agent is prepared by mixing the following components in parts by weight: 90 parts of methanol or / and dimethyl ether, 10 parts of C5, 10 parts of C9 and 10 parts of an additive; the additive comprises the following components in parts by weight: 20 parts of propanol, 10 parts of ethyl acetate, 20 parts of butyl butyrate, 10 parts of Tween, 10 parts of dimethyl carbonate and 20 parts of isopropyl ether; a formula of the compound modifier comprises the following components in parts by weight: 1) 3-20 parts of polymethyl amine, 2) 50-70 parts of absolute ethyl alcohol, 3) 5-25 parts of isobutanol, 4) 5-20 parts of pentanol, 5) 3-10 parts of octanol, 6) 60-90 parts of ethylene glycol monomethyl ether, 7) 15-20 parts of xylene, 8) 15-40 parts of polymethyl aldehyde, 9) 10-25 parts of light oleic acid with specific gravity less than 0.8 and 10) 5-15 parts of nitrobenzene. As the consumption of the compound modifier is low, the production cost of the high-cleanness alcohol ether fuel is low. The octane number index of the high-cleanness alcohol ether fuel is more than or equal to 93, and various indexes of the high-cleanness alcohol ether fuel reach the national standard.

Owner:叶晓丹

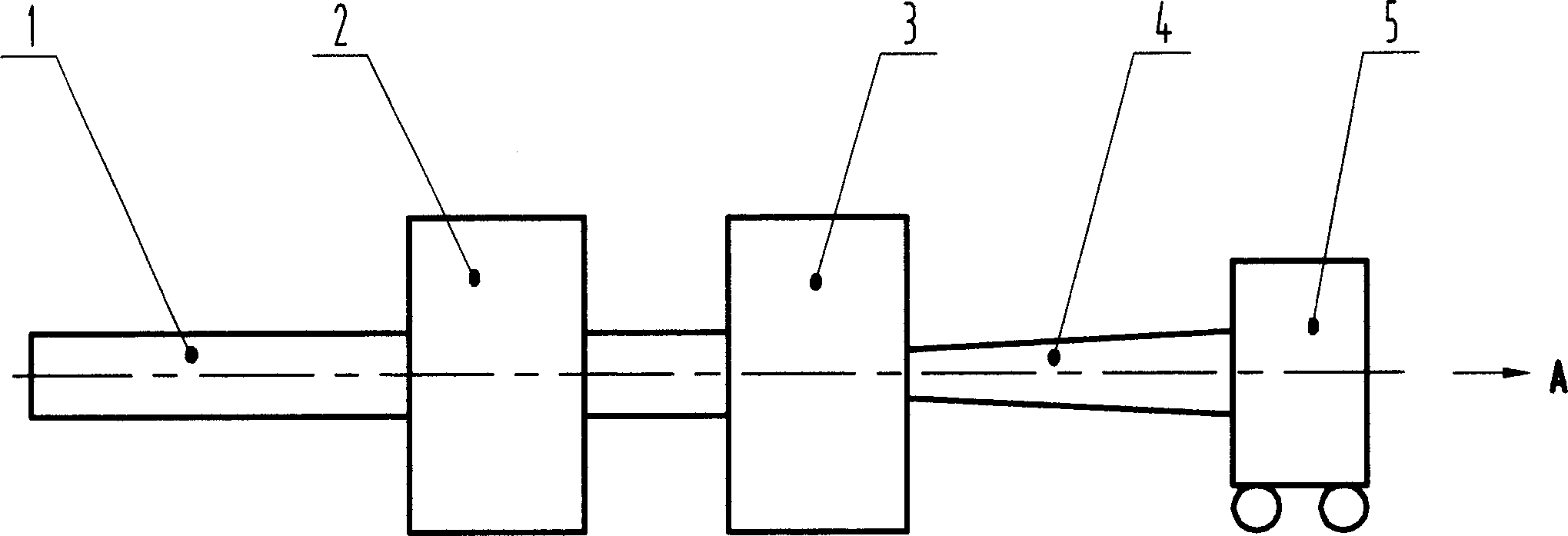

Processing method for varying wall thick taper metal pipe

InactiveCN1907589ALess investment in equipmentGet on the horse fastShaping toolsEngineeringCircular cone

The invention relates to a method for processing variable-wall taper metal tube, wherein it comprises: the constant-wall round tube via heater and rotator is clamped inside the drawer; said round tube, via drawing force of drawer, will move with accelerated speed relative to the heart and rotator; the round tube via heated by said heater for several times, and rotated via the rotator, will uniformly feed and rotate and compress, to obtain the variable-wall taper metal tube. The invention has wider application.

Owner:石家庄轴承设备有限公司

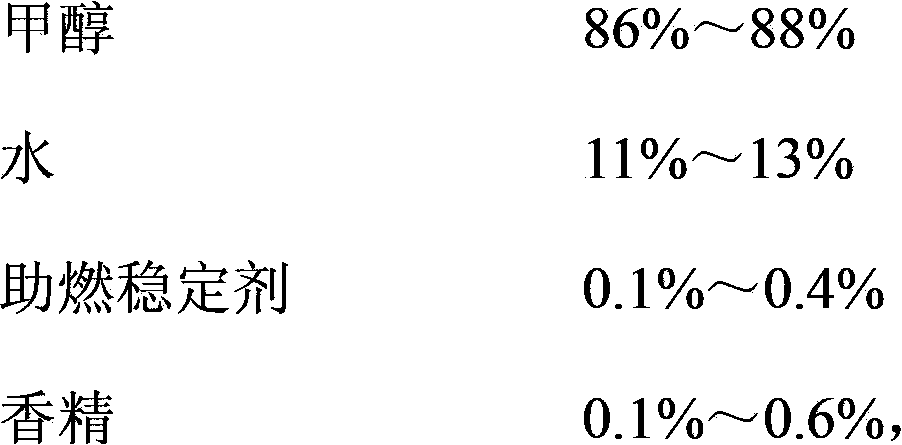

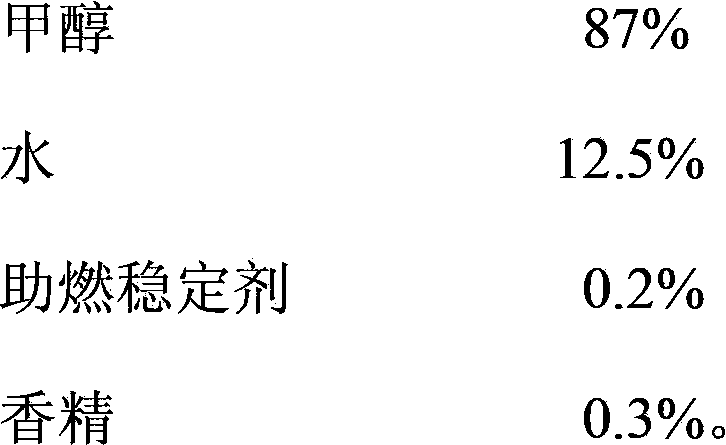

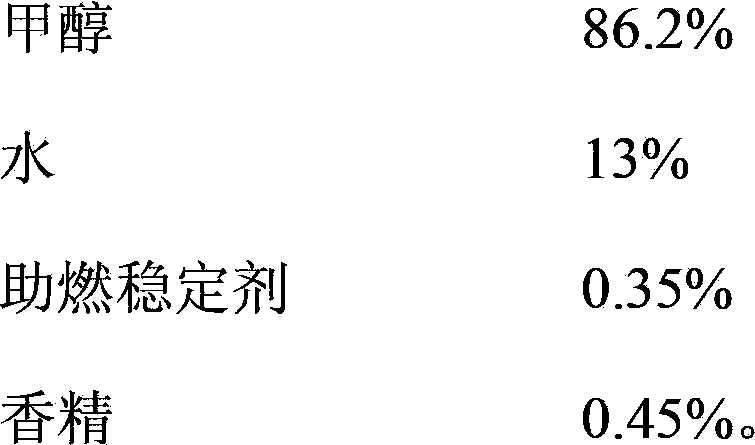

Synthetic biology alcohol oil

InactiveCN103789048AWide range of raw materialsLow costLiquid carbonaceous fuelsPotassium hydroxideEthyl acetate

The invention provides synthetic biology alcohol oil, which is prepared by mixing 86-88% of methanol, 11-13% of water, 0.1-0.4% of combustion-supporting stabilizing agent and 0.1-0.6% of essence under normal temperature and normal pressure. The combustion-supporting stabilizing agent is prepared by mixing potassium hydroxide, sodium hydroxide, water ethyl acetate and absolute ethyl alcohol. The biology alcohol oil has the advantages of sanitation and hygiene, and green and environmental protection. The fuel has the advantages of high oxygen content, full combustion, no black smoke, no carbon formation, no black pan bottom, and no raffinate residue. The synthetic biology alcohol oil can be stored, transported and used under normal temperature and normal pressure, the storage by a high pressure steel cylinder is not required, so that a common metal or plastic container for storage is used.

Owner:刘大钊

Fruit juice milk

The invention relates to a daily drinking beverage, in particular to a fruit juice milk, which is characterized in that fruit juice is mixed into milk. The fruit juice able to be mixed into milk includes: grape, strawberry, dark plum, hawthorn, peach, apricot, pear, orange, lemon, apple, coconut, pomelo, watermelon, hami melon, kiwi fruit, pineapple, tomato, carrot and the like.

Owner:THE KE SHI MEDICAL IMAGE TECHN RES INST

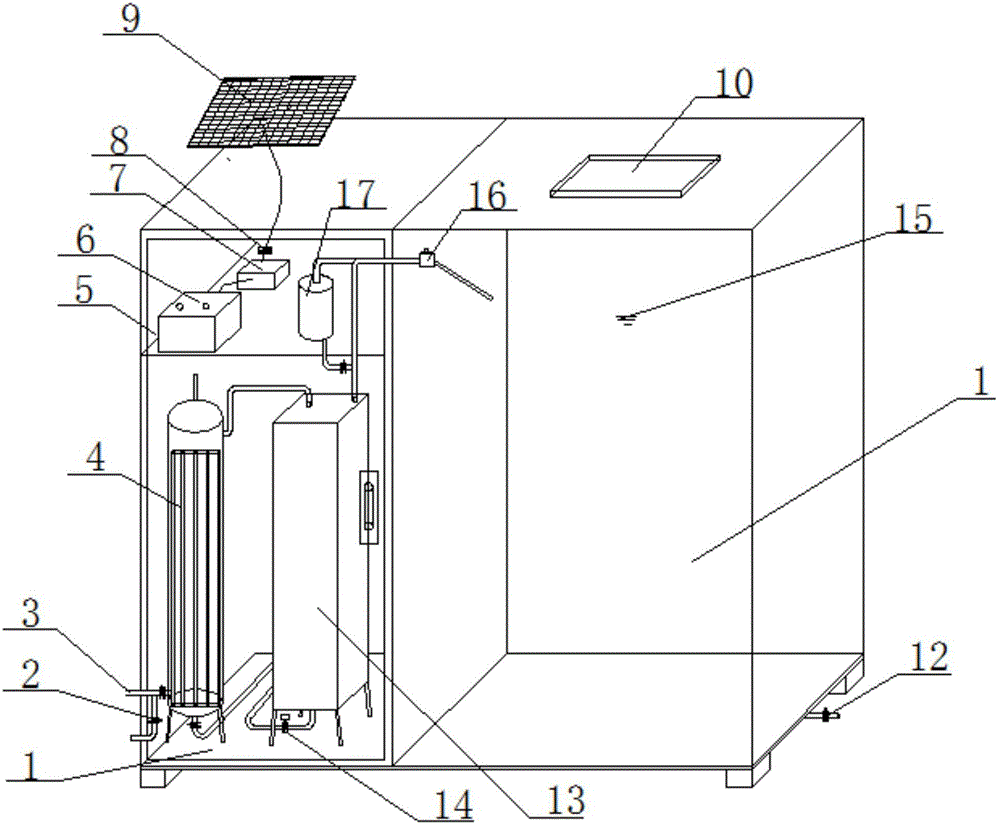

Small solar energy one-piece water purifier

InactiveCN106007108AReduce investmentOvercoming the disadvantages of no water supply pressureWater treatment parameter controlTreatment involving filtrationFiltrationTurbidity

The invention discloses a small solar energy one-piece water purifier, which consists of: a filtration chamber, a pressure release valve, a water inlet pipe, a fine filter, a control chamber, a storage battery, a control regulator, a conversion device, a solar cell panel, an access opening, a water purification tank, a water outlet pipe, a polymer slow filter, an automatic blowdown valve, a full water level scale plate, a ball float valve and a slow release disinfection machine. The small solar energy one-piece water purifier provided by the invention adopts a solar energy power source to supply energy for intelligent control, is suitable for places without power, has a light structure, can be combined, is small in volume and mobile, is suitable for regions with traffic inconvenience and no road, the polymer slow filter adopts a polymer material, the raw water turbidity is less than 300 and reaches the drinking water standard, water feeding adopts an automatic pressure relief mode, and avoids the problem that most equipment cannot work normally because of too high raw water pressure, the equipment has the water purification tank in itself, thus avoiding reconstruction of a clear water pool and reducing fund input, and the equipment has water supply pressure of its own, thus overcoming the disadvantage of no water supply pressure at conventional equipment outlets.

Owner:四川拓璞环保科技有限公司

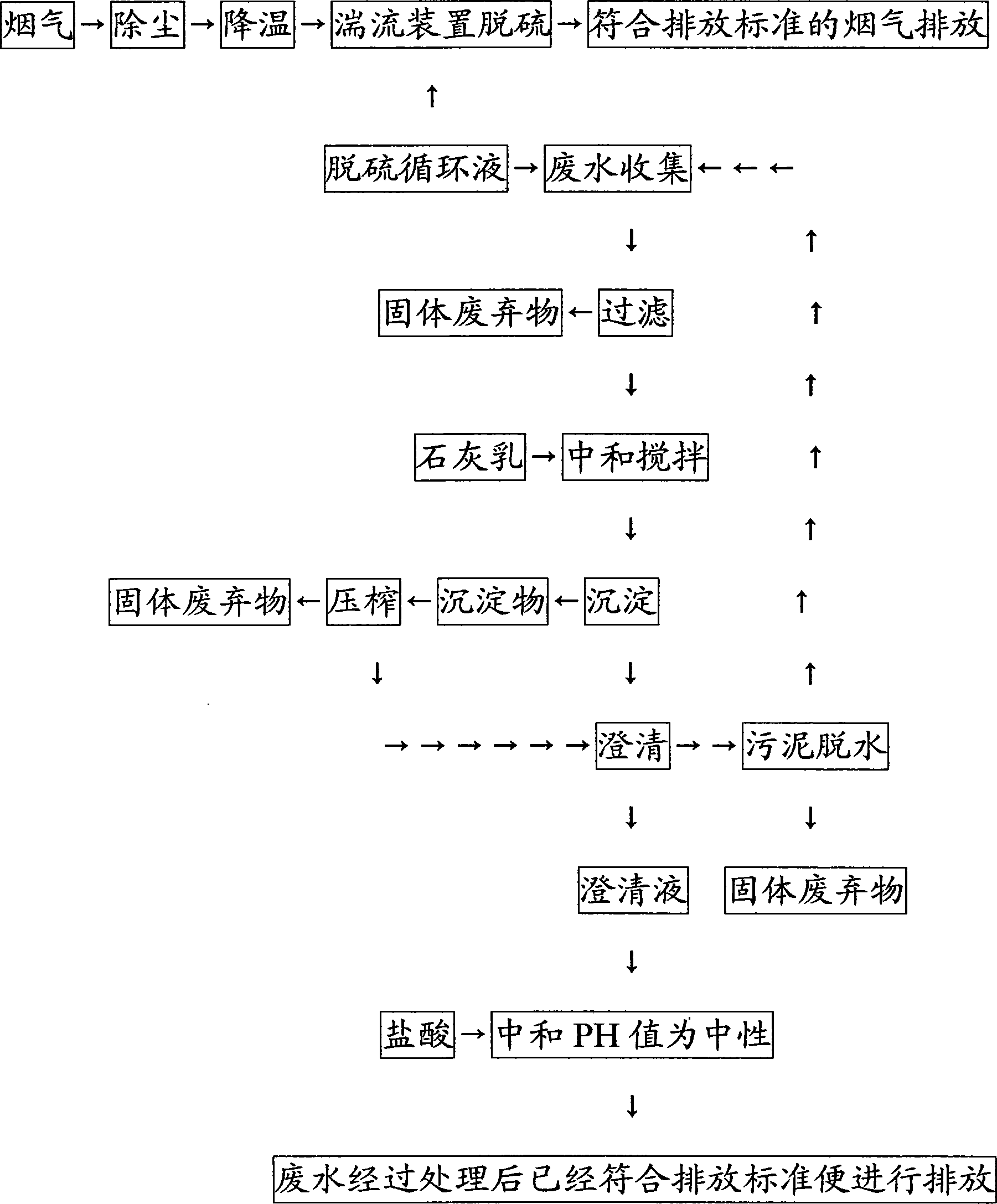

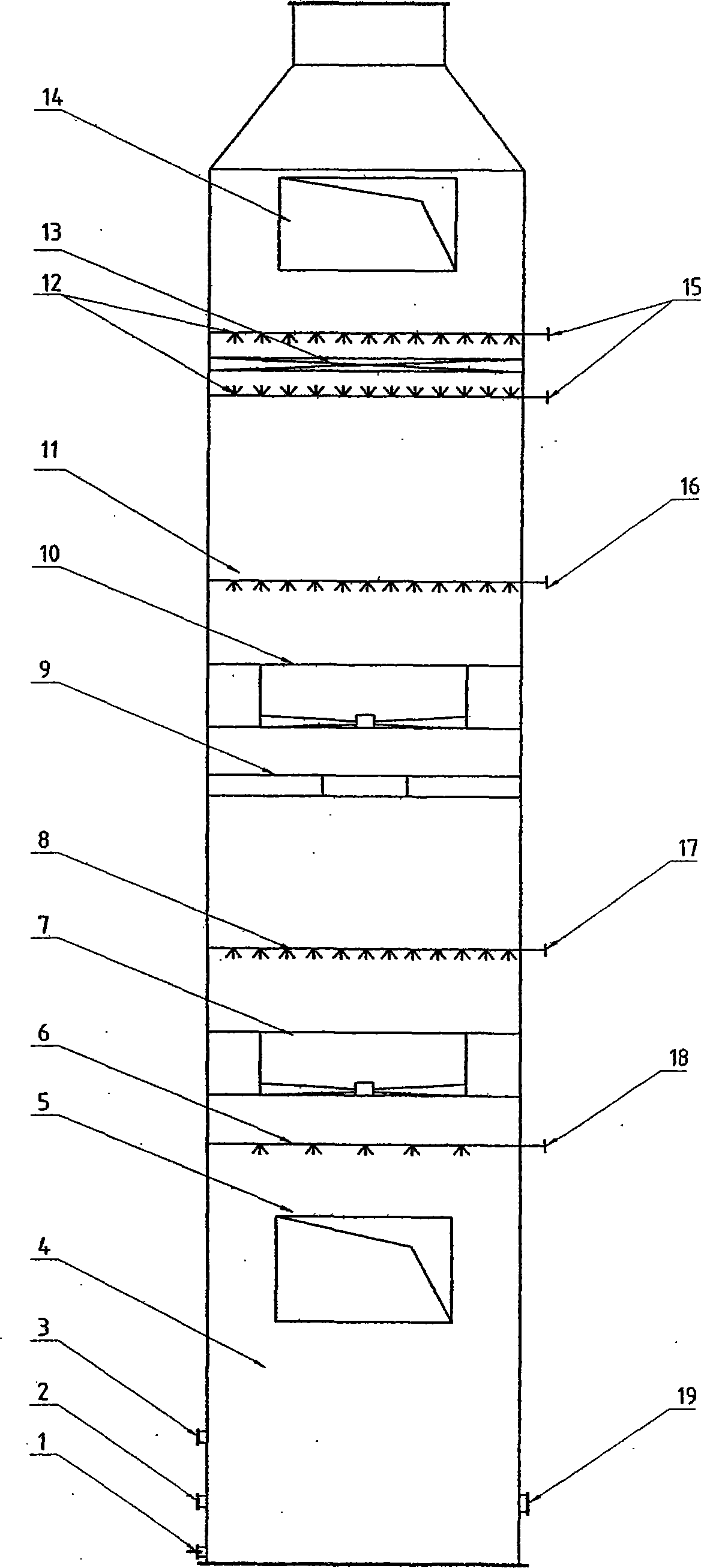

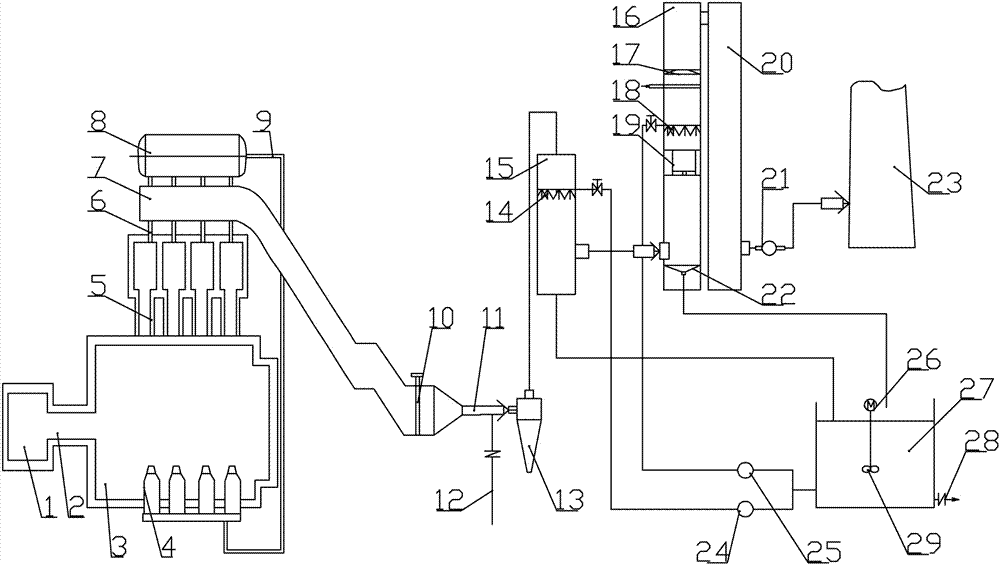

Process technology for turbulent wet-process flue gas desulfurization and desulfurization wastewater treatment

InactiveCN104028097AAdvanced technology and scienceEasy to operateDispersed particle separationMultistage water/sewage treatmentFlue gasEngineering

The invention discloses a process technology for turbulent wet-process flue gas desulfurization and desulfurization wastewater treatment and relates to the technical field of environmental protection. A body of a device is provided with a flue gas inlet and a flue gas outlet and is fixed with a blow-off pipe, a desulfurizing agent supplementing inlet, a water pipe and a desulfurizing agent outlet, the body between the flue gas inlet and the flue gas outlet is fixed with a desulfurizing agent inlet, a first-stage turbocharging turbulator, a first-stage desulfurizing agent inlet, a receiving tank, a second-stage turbocharging turbulator, a second-stage desulfurizing agent inlet, a first water inlet pipe, a demister and another water inlet pipe respectively from bottom to top, a liquid outlet pipe of the receiving tank penetrates out of the body, the desulfurizing agent inlet is fixed with a spray nozzle, the desulfurizing agent inlet is fixed with a first-stage spray nozzle, the second-stage desulfurizing agent inlet is fixed with a second-stage spray nozzle, and the water inlet pipes are fixed with water spray nozzles; and the wastewater treatment process comprises the steps of collecting wastewater, filtrating, neutralizing with lime milk, precipitating, clarifying, neutralizing with hydrochloric acid and then draining. The process technology is applied to flue gas desulfurization and wastewater treatment; and the device is ingenious, and the effect is good.

Owner:BEIJING ZHONGYE LONGSHENG ENVIRONMENTAL PROTECTION TECH

Glass kiln exhaust gas waste-heat utilization and exhaust gas desulfurization system

InactiveCN107303464AIncrease profitForced insulationGas treatmentDispersed particle separationMelting tankHazardous substance

The invention provides a glass kiln exhaust gas waste-heat utilization and exhaust gas desulfurization system which comprises a melting tank of a glass kiln, wherein the melting tank is connected with a working tank through a throat; an oil gun is arranged at the bottom of the melting tank; a heat storage chamber is arranged on the other side of the melting tank; the heat storage chamber is connected with a waste-heat boiler steam pot through a boiler exhausting pipe; the waste-heat boiler steam pot is heated and dried by the heat storage chamber through a vaporizing pipe and then is in parallel connection with the oil gun; a main flue is arranged at the top of the heat storage chamber; an exhaust gas gate is arranged on an outlet position of the main flue; an exhaust gas outlet is formed on the rear side of the exhaust gas gate; and an exhaust gas desulfurization system is arranged on the rear side of the exhaust gas outlet. The system can fully utilize the outward dispersing waste heat of the glass kiln, can additionally generate a large amount of steam for production and life, can save energy and can reduce environmental pollution. The exhaust gas desulfurization system is used for increasing the exhaust gas treating efficiency and reducing the damage of harmful matters to a human body.

Owner:宜昌晶品玻璃制品有限公司

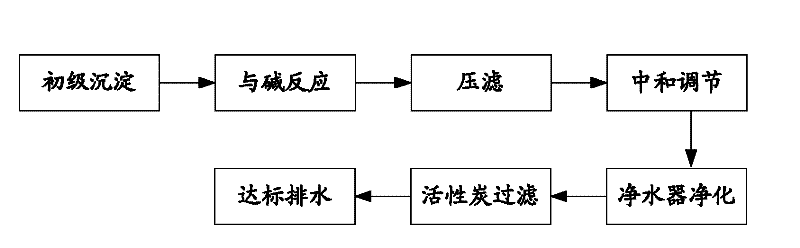

Multi-metal recovery processing technique of waste liquid generated in germanium producing process

InactiveCN101671777BSolve problems that cannot be exploitedShort processPhotography auxillary processesProcess efficiency improvementIndiumKerosene

The invention relates to a multi-metal recovery processing technique of waste liquid generated in a germanium producing process, belonging to the technical field of non-ferrous metal wet method metallurgy. The multi-metal recovery processing technique comprises the following steps: extracting germanium from the waste liquid generated in the germanium producing process by an extractant A and a kerose diluent, washing, carrying out back-extraction, removing impurities, purifying, depositing the germanium and electrolyzing to obtain the metal germanium with the purity of 99.99%; firstly extracting iron and partial impurities from the residual waste liquid after extracting the germanium by an extractant B and the kerose diluent, and extracting indium from the residual waste liquid after extracting the iron by the same organic extractant B, adjusting the pH, extracting the indium by the extractant A, carrying out the back-extraction, neutralizing, oxidizing, removing the impurities and replacing to obtain spongy indium, and then briquetting and casting to obtain 99% metal indium. The invention has the advantages of short process flow, small occupied area, few investment, fast implementation and good working conditions, solves the problems that the valuable metal in the waste acid solution can not be recovered and has higher value of the resource comprehensive utilization. Furthermore, the metal recovery rate is larger than 92%; the purity of the obtained product, metal germanium, is 99.99%, and the purity of the metal indium is 99%.

Owner:湖南福欣锗业科技有限公司

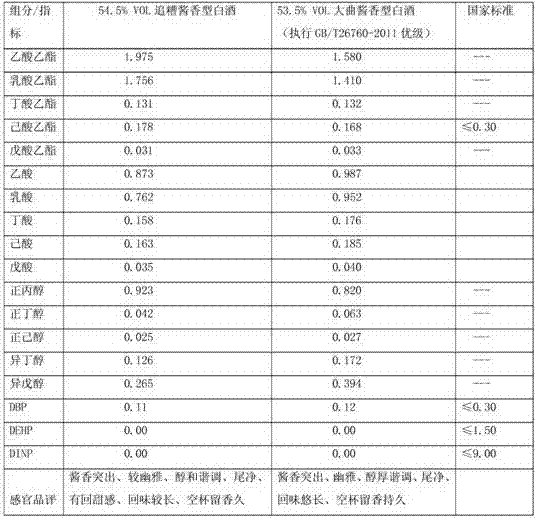

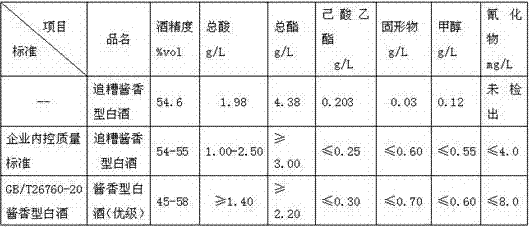

A kind of production process of soy sauce-flavored liquor

ActiveCN104152339BAdaptableShorten the production cycleMicroorganism based processesAlcoholic beverage preparationYeastProduction rate

Owner:福建省建瓯黄华山酿酒有限公司

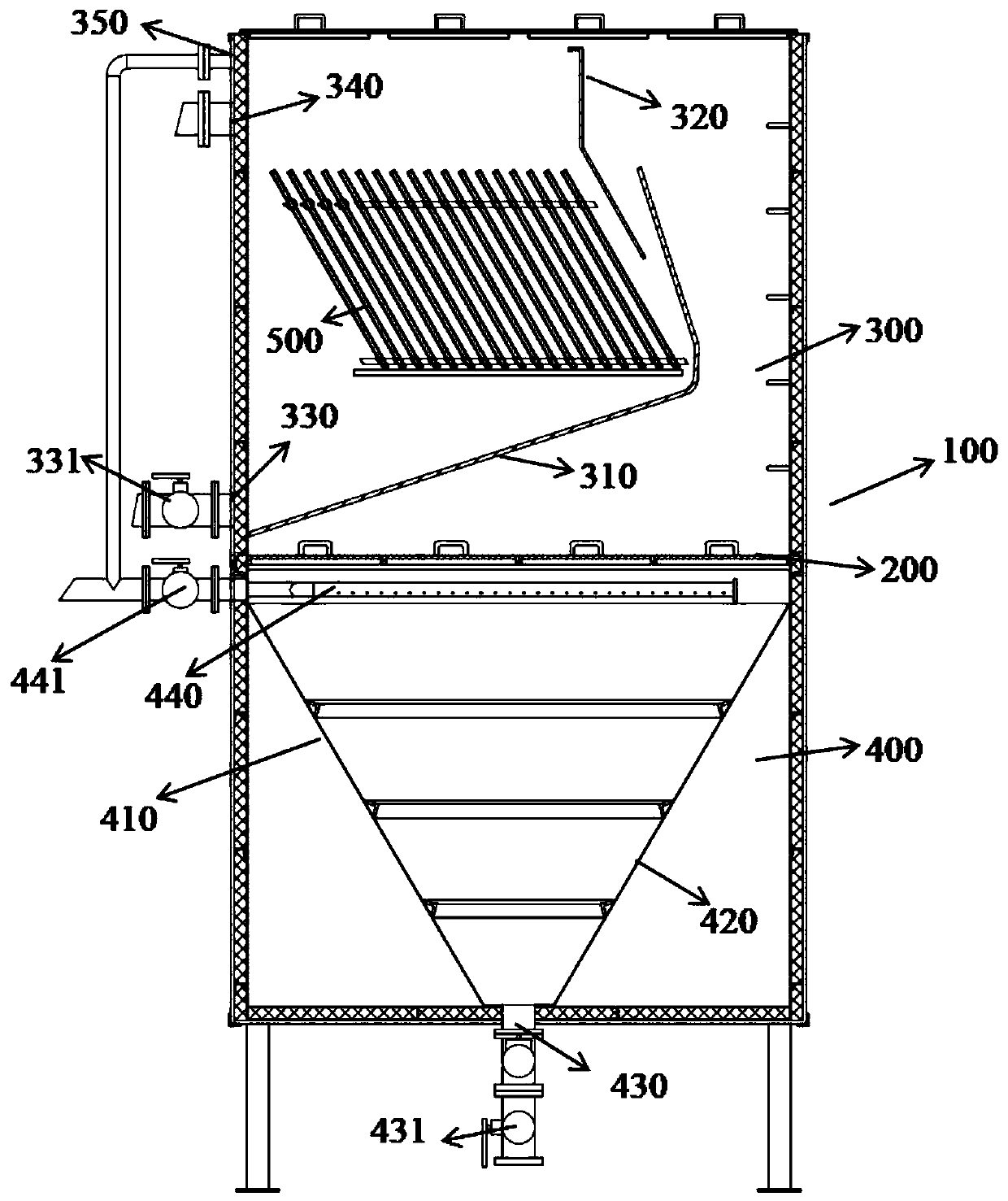

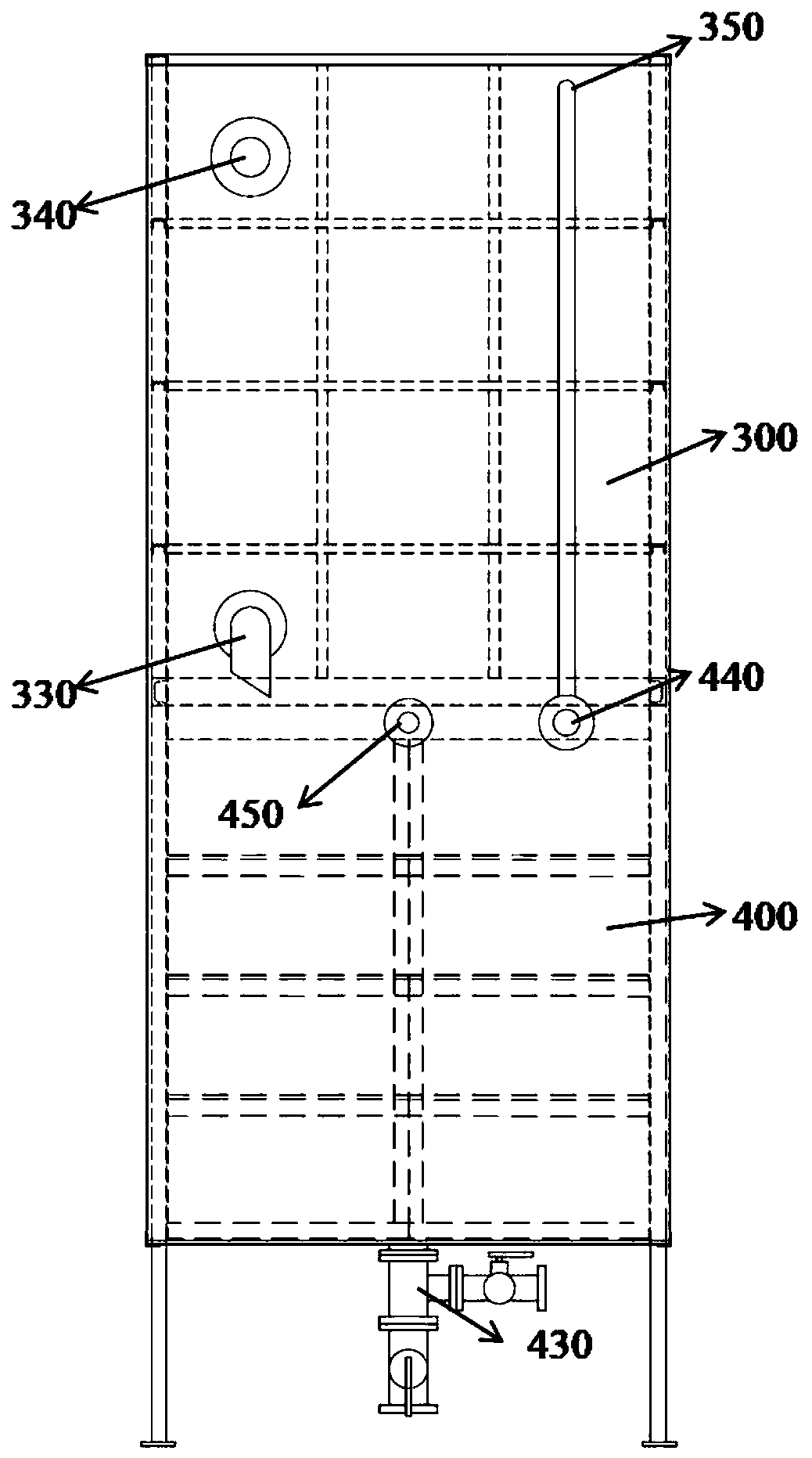

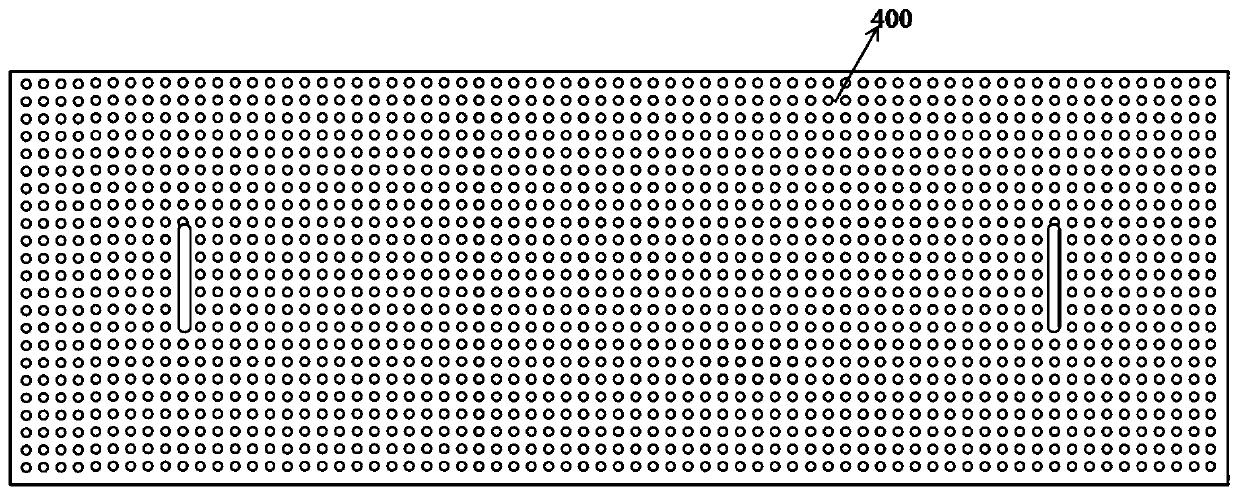

Natural settling tank for efficiently removing lead and zinc

InactiveCN111001197AImprove efficiencySimple structureIron halidesSedimentation settling tanksMechanical engineeringWaste management

The invention discloses a natural settling tank for efficiently removing lead and zinc. The natural settling tank comprises: a tank body; a flow equalizing plate arranged in the middle of the tank body and dividing the tank body into an upper part and a lower part; a liquid inlet formed below the flow equalizing plate; a first inclined plate and a second inclined plate arranged at the lower part of the tank body and forming a trapezoidal tank with the bottom of the tank body, wherein the liquid inlet is positioned above the trapezoidal tank; a residue outlet formed in the bottom of the tank body and communicated with the trapezoidal tank; a partition plate arranged at the upper part of the tank body; a baffle arranged at the upper part of the tank body and forming a tank with an opening with the partition plate, wherein the tank with the opening is communicated with the lower part of the tank body through the opening; an inclined tube sedimentation device arranged in the tank with theopening; and a residue discharge port arranged at the upper part of the tank body and communicated with the tank with the opening. According to the natural settling tank capable of efficiently removing lead and zinc, by arranging the inclined plate and the inclined tube, the treatment capacity is high, solid-liquid separation can be effectively carried out, and the lead and zinc removal effect isgood through three separations.

Owner:江苏荣信环保科技有限公司

Method for purifying polysilicon by using silicon and tin alloy

InactiveCN102139879BHigh puritySimple processSilicon compoundsShielding gasDirectional solidification

Owner:XIAMEN UNIV

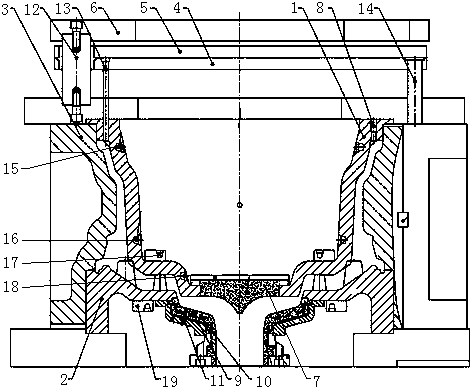

A low-pressure casting mold for truck aluminum wheels

Owner:NORD WHEEL MFG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com