Processing method for varying wall thick taper metal pipe

A processing method and metal pipe technology, applied in metal processing equipment, forming tools, manufacturing tools, etc., can solve the problems of equal-wall-thickness conical metal pipes that cannot meet the demand, difficult to reduce production costs, high center of gravity, etc., and improve safety , Low unit cost and low center of gravity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

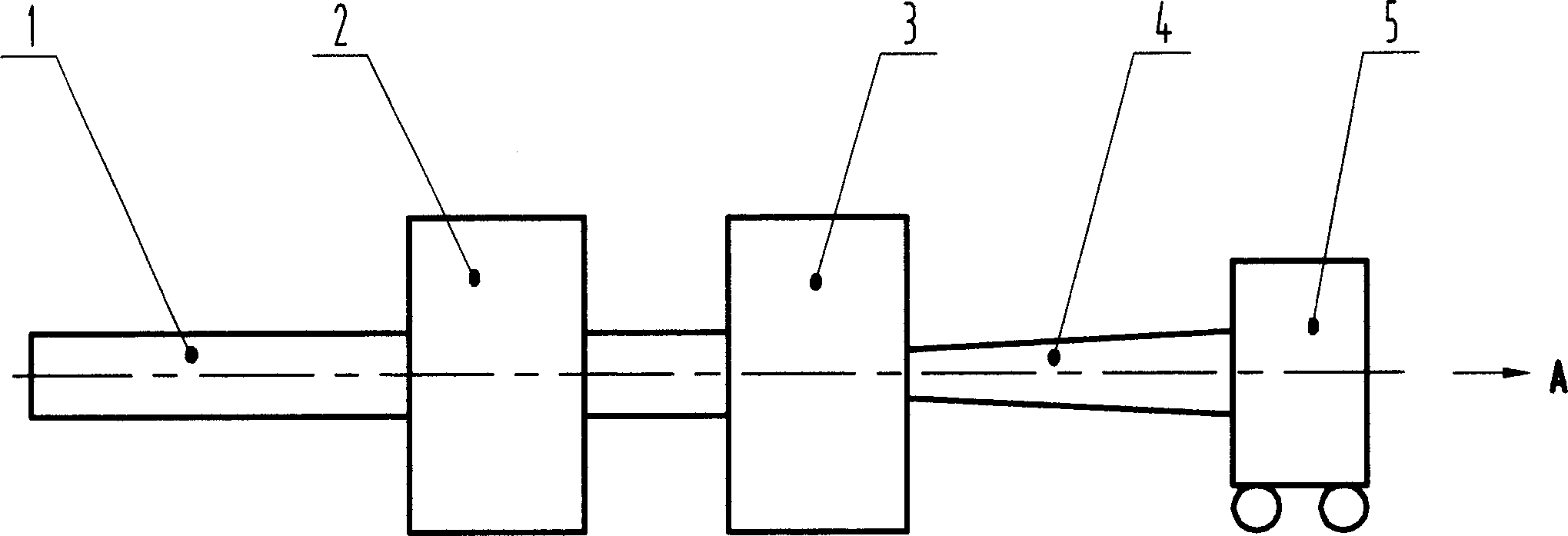

[0015] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments: the accompanying drawings simply represent the flow of a variable-wall-thickness conical metal pipe processing production line. A round pipe 1 with an outer diameter of 165 mm and a wall thickness of 7 mm is clamped on a drawing device 5 driven by a linear oil cylinder, and under the action of its pulling force, the workpiece does not rotate, and moves from 0 m / min to Accelerate at 5m / min. After being heated to 800°C by the intermediate frequency heating device 2, the three spinning wheels on the spinning mechanism 3 rotate along the circular tube 1 with equal wall thickness and feed inward at a constant speed of 25.5mm each. Become a conical metal pipe with variable wall thickness 4. The processed variable-wall-thickness conical metal pipe has a length of 8000 mm, a large end with a diameter of 165 mm and a wall thickness of 7 mm, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com