Synthetic biology alcohol oil

A technology for synthesizing biology and alcohol oil, which is applied in the petroleum industry, liquid carbon-containing fuels, fuels, etc., can solve the problems of instability, volatility, and insufficient heat of alcohol-based fuels, and achieve odor elimination, low cost, and wide application range Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

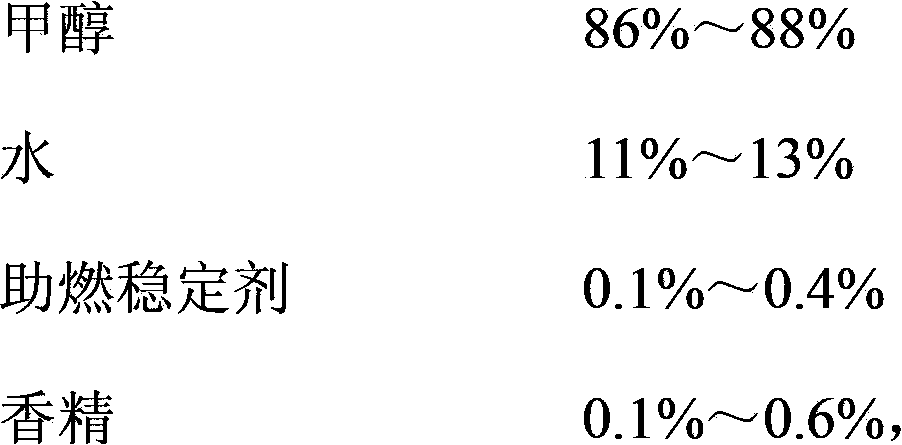

Method used

Image

Examples

Embodiment 1

[0029] A kind of synthetic biological alcohol oil is prepared according to the following steps at normal temperature and pressure:

[0030] (1). Potassium hydroxide and water are mixed according to the weight ratio of 0.8:2 and then cooled, then sodium hydroxide and water are mixed according to the weight ratio of 0.8:2 and then cooled;

[0031] (2). After mixing the cooled potassium hydroxide aqueous solution and the cooled sodium hydroxide aqueous solution;

[0032] (3). After mixing the cooling liquid in step (1) and step (2), add ethyl acetate of 4.5 times the total weight of the original potassium hydroxide and sodium hydroxide and dehydrated alcohol of 10 times the total weight in turn, and mix post-production combustion-supporting stabilizer;

[0033] (4) be that 88% methanol is added in the mixing container by weight percentage, then add successively the water of 11% by weight, the combustion-supporting stabilizer prepared in the step (1)-step (3) that the weight rati...

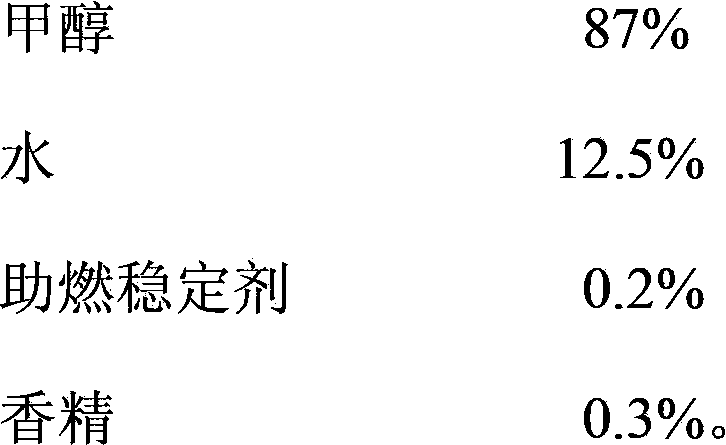

Embodiment 2

[0035] A kind of synthetic biological alcohol oil is prepared according to the following steps at normal temperature and pressure:

[0036] (1). Potassium hydroxide and water are mixed according to the weight ratio of 0.85:2 and then cooled, then sodium hydroxide and water are mixed according to the weight ratio of 0.9:2 and then cooled;

[0037] (2). After mixing the cooled potassium hydroxide aqueous solution and the cooled sodium hydroxide aqueous solution;

[0038] (3). After mixing the cooling liquid in step (1) and step (2), add ethyl acetate 5 times the total weight of the original potassium hydroxide and sodium hydroxide and dehydrated alcohol 10 times the total weight in turn, mix post-production combustion-supporting stabilizer;

[0039] (4) be that 87% methanol is added in the mixing container by weight percentage, then add successively the water of 12.5% by weight, the combustion-supporting stabilizer prepared in the step (1)-step (3) that the weight ratio is 0....

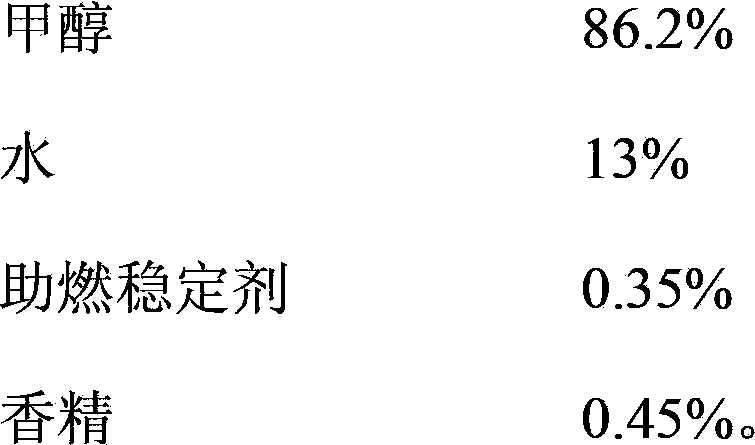

Embodiment 3

[0046] A kind of synthetic biological alcohol oil is prepared according to the following steps at normal temperature and pressure:

[0047] (1). Potassium hydroxide and water are mixed according to the weight ratio of 0.9:2 and then cooled, and then sodium hydroxide and water are mixed according to the weight ratio of 0.9:2 and then cooled;

[0048] (2). After mixing the cooled potassium hydroxide aqueous solution and the cooled sodium hydroxide aqueous solution;

[0049] (3). After mixing the cooling liquid in step (1) and step (2), add ethyl acetate 5 times the total weight of the original potassium hydroxide and sodium hydroxide and dehydrated alcohol 10 times the total weight in turn, mix post-production combustion-supporting stabilizer;

[0050](4) be that 86.2% methanol is added in the mixing vessel by weight percentage, then add successively the water of 13% by weight, the combustion-supporting stabilizer prepared in the step (1)-step (3) that the weight ratio is 0.35%...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heating value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com