Vehicle gasoline for replacing petroleum fuel and its prepn process

A technology for automotive gasoline and raw materials, applied in the field of automotive gasoline, can solve problems such as poor power performance, poor cold start, and incompatibility, and achieve the effects of good power performance, low production cost, and small equipment investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

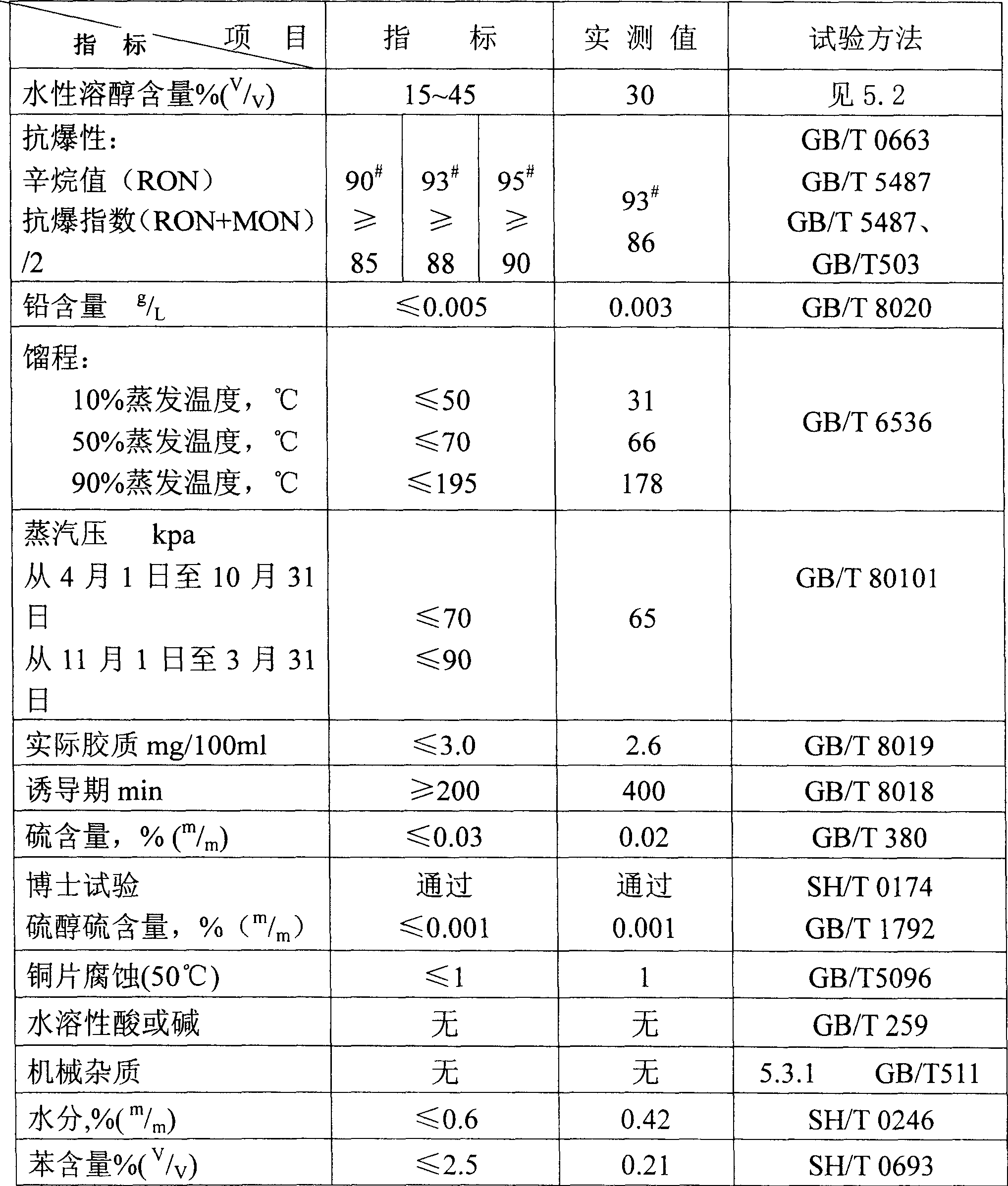

Embodiment 1

[0016] A kind of motor gasoline that replaces petroleum raw materials, is made up of the following components by weight, coal-based methanol 20%, C 2 ~C 8 Alcohol 24.97%, coal-based low-benzene aromatics 35%, dimethoxymethane 5%, catalyst 0.01%, coal-based light oil 15%, stabilizer 0.01%, metal corrosion inhibitor 0.01%; where C 2 ~C 8 Alcohol is the mixture that ethanol, propanol, butanol, pentanol, hexanol, heptanol, octanol are mixed by the ratio of 100:0.5:5:5:0.05:0.05:2, and coal base low benzene aromatic hydrocarbon is by following weight Component composition of content: toluene 95%, xylene 2.05%, C 5-12 2% alkanes, 0.95% benzene, coal-based light oil is obtained by reacting coal tar and catalyst in a distillation pot for 1 to 3 hours and then extracting fractions below 200°C and cooling. The catalyst consists of the following components by weight: 40% activated clay, 20% kaolin, 20% molecular sieves containing sulfonic acid groups, 20% 4A molecular sieves, 2,6-dime...

Embodiment 2

[0019] A kind of motor gasoline that replaces petroleum raw materials, is made up of the following components by weight, coal-based methanol 23%, C 2 ~C 8 Alcohol 19.97%, coal-based low-benzene aromatics 25%, dimethoxymethane 7%, catalyst 0.01%, coal-based light oil 25%, stabilizer 0.01%, metal corrosion inhibitor 0.01%; where C 2 ~C 8 Alcohol is the mixture that ethanol, propanol, butanol, pentanol, hexanol, heptanol, octanol are mixed by the ratio of 100:0.5:5:5:0.05:0.05:2, and coal base low benzene aromatic hydrocarbon is by following weight Component composition of content: toluene 95%, xylene 2.05%, C 5-12 2% alkanes, 0.95% benzene, coal-based light oil is obtained by reacting coal tar and catalyst in a distillation pot for 1 to 3 hours and then extracting fractions below 200°C and cooling. The catalyst consists of the following components by weight: 45% activated clay, 25% kaolin, 15% molecular sieve containing sulfonic acid group, 15% 4A type molecular sieve, 2,6-di...

Embodiment 3

[0022] A kind of motor gasoline that replaces petroleum raw materials, is made up of the following components by weight, coal-based methanol 24%, C 2 ~C 8 Alcohol 10%, coal-based low-benzene aromatics 20%, dimethoxymethane 8%, catalyst 0.01%, coal-based light oil 37.97%, stabilizer 0.01%, metal corrosion inhibitor 0.01%; 2 ~C 8 Alcohol is the mixture that ethanol, propanol, butanol, pentanol, hexanol, heptanol, octanol are mixed by the ratio of 100:0.5:5:5:0.05:0.05:2, and coal base low benzene aromatic hydrocarbon is by following weight Component composition of content: toluene 95%, xylene 2.05%, C 5-12 2% alkanes, 0.95% benzene, coal-based light oil is obtained by reacting coal tar and catalyst in a distillation pot for 1 to 3 hours and then extracting fractions below 200°C and cooling. The catalyst consists of the following components by weight: 50% activated clay, 30% kaolin, 10% molecular sieve containing sulfonic acid groups, 10% 4A molecular sieve, 2,6-dimethylphenol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com