Re-utilization of waste liquid and distillers' grains from alcohol production

A technology of reuse and distiller's grains, applied in the application, waste fuel, animal feed, etc., can solve the problems of unfavorable alcohol production rate and quality, inability to meet the requirements of water use indicators, difficult operability of technology and equipment, etc. Small land area, low operating cost and quick start

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

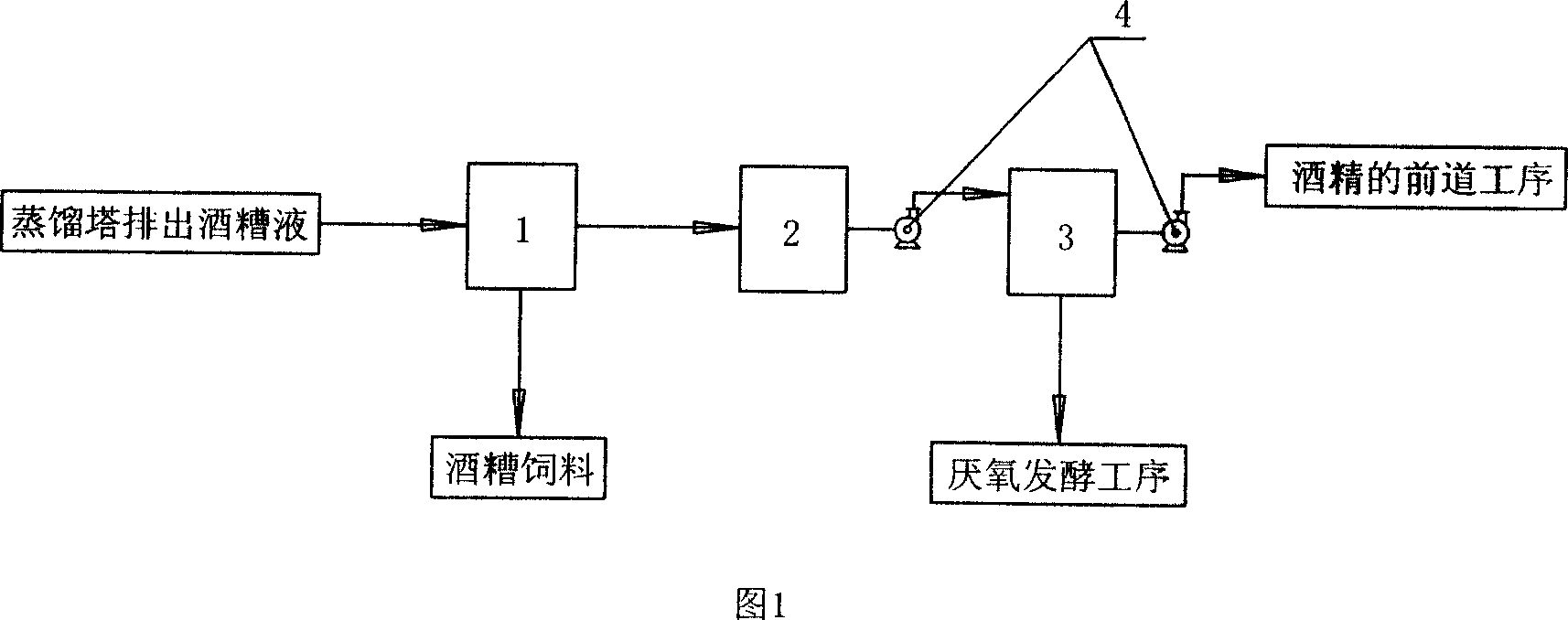

[0010] Referring to the accompanying drawings, the present invention is an embodiment of an annual production of 10,000 tons of alcohol: mainly composed of 3 waste water continuous separators 1, 1 distiller's waste water neutralization device 2, 4 waste water high-efficiency sedimentation tanks 3, 4 It is composed of 4 conveying pumps, etc.; it is characterized in that: the temperature of the waste water discharged from the distillation tower is about 85 degrees and passes through the waste water continuous separator 1, and the separated waste water enters the distiller's waste water neutralization device 2, and the neutralized waste water The pH value of the waste water is 6.8 to 7.0 and sent to the waste water high-efficiency sedimentation tank 3 by the delivery pump 4, and the supernatant after precipitation is sent to the previous process of alcohol production by the delivery pump 4 in less than 4 hours. Utilization: the distiller's grains separated by the waste water conti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com