Preparation method and application of low-cost high-purity graphite material

A high-purity graphite, low-cost technology, applied in chemical instruments and methods, inorganic chemistry, silicon compounds, etc., can solve the problem of low added value of high-purity graphite waste powder, shorten the production cycle, promote volume shrinkage, and yield high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

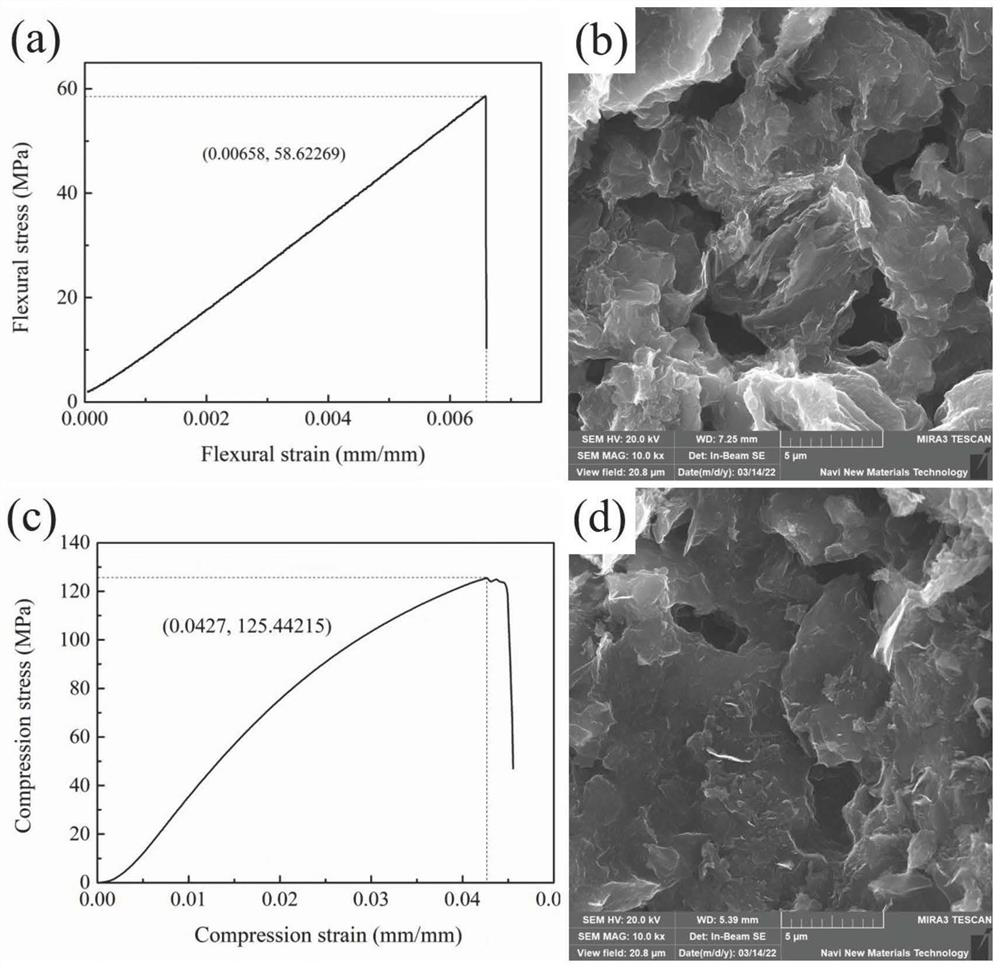

Embodiment 1

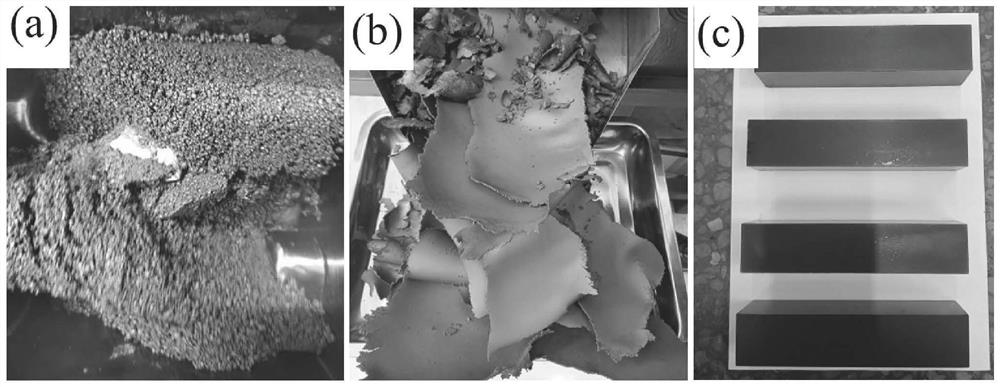

[0053] 1) Purchase isostatic graphite milling waste powder and scraps from graphite processing manufacturers at a low price, remove metal impurities introduced by the powder through magnetic separation equipment, and conduct initial grinding of milling graphite waste powder through 3R Raymond mill, and then use Graphite powder with D50≤10 μm was prepared by jet mill, which was ready for use.

[0054] 2) Accurately weigh 32 parts of pitch (17 parts of modified pitch with a softening point of 109 ℃ and 15 parts of medium-temperature pitch with a softening point of 110 ℃), 62 parts of graphite powder and 5 parts of carbon black powder (N330 carbon black 2) obtained in step 1). parts, 3 parts of N234 carbon black).

[0055] 3) After mixing the graphite powder and carbon black powder uniformly, put it into the kneading pot, mix at 120 ℃ for 1 h to remove the moisture, and the kneading pot rotates at 20 r / min and rotates forward; The powder was heated to 180 °C, and the molten asph...

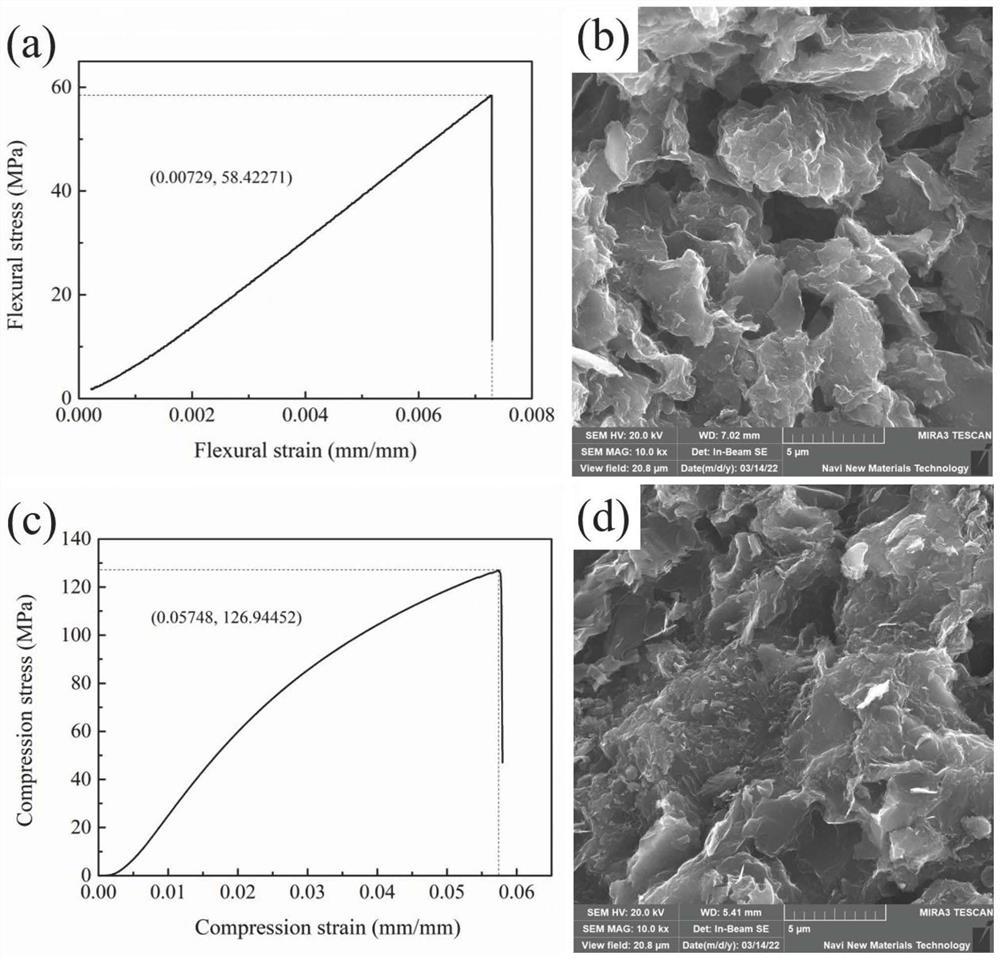

Embodiment 2

[0063] 1) Purchase isostatic graphite milling waste powder and scraps from graphite processing manufacturers at a low price, remove metal impurities introduced by the powder through magnetic separation equipment, and conduct initial grinding of milling graphite waste powder through 3R Raymond mill, and then use Graphite powder with D50≤10 μm was prepared by jet mill, which was ready for use.

[0064] 2) Accurately weigh 35 parts of pitch (20 parts of modified pitch with a softening point of 109 °C and 15 parts of medium-temperature pitch with a softening point of 110 °C), 65 parts of graphite powder and 8 parts of carbon black powder (N330 carbon black 5 parts) obtained in step 1). parts, 3 parts of N339 carbon black).

[0065] 3) After mixing the graphite powder and carbon powder evenly, put it into the kneading pot, mix at 120 ℃ for 1 h, remove the moisture, and the kneading pot rotates at 20 r / min and rotates forward; The powder was heated to 180 °C, and the melted asphalt...

Embodiment 3

[0073] 1) Purchase isostatically pressed high-purity graphite milling waste powder at a low price from graphite processing manufacturers, remove metal impurities introduced by the powder through magnetic separation equipment, and conduct initial grinding of milling graphite waste powder through 3R Raymond mill, and then use Graphite powder with D50≤10 μm was prepared by jet mill, which was ready for use.

[0074] 2) Accurately weigh 40 parts of pitch (28 parts of modified pitch with a softening point of 109 ℃ and 12 parts of medium-temperature pitch with a softening point of 110 ℃), 70 parts of graphite powder and 10 parts of carbon / carbon powder (N330 carbon black) obtained in step 1) 6 parts, 4 parts of nano carbon balls).

[0075] 3) After mixing the graphite powder and carbon powder evenly, put it into the kneading pot, mix at 120 ℃ for 1 h, remove the moisture, and the kneading pot rotates at 20 r / min and rotates forward; The powder was heated to 180 °C, and the melted a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com