Production method of vegetable stem made pot

A plant straw and pot technology, which is applied in the field of straw resource utilization and plant cultivation pot manufacturing, can solve the problem of not considering the influence of the container wall on the penetration of plant roots, without considering the influence of the container wall and root penetration, and is not suitable for large batches Industrial production and other issues, to achieve the effect of low production cost, enhanced strength, and reduced watering times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

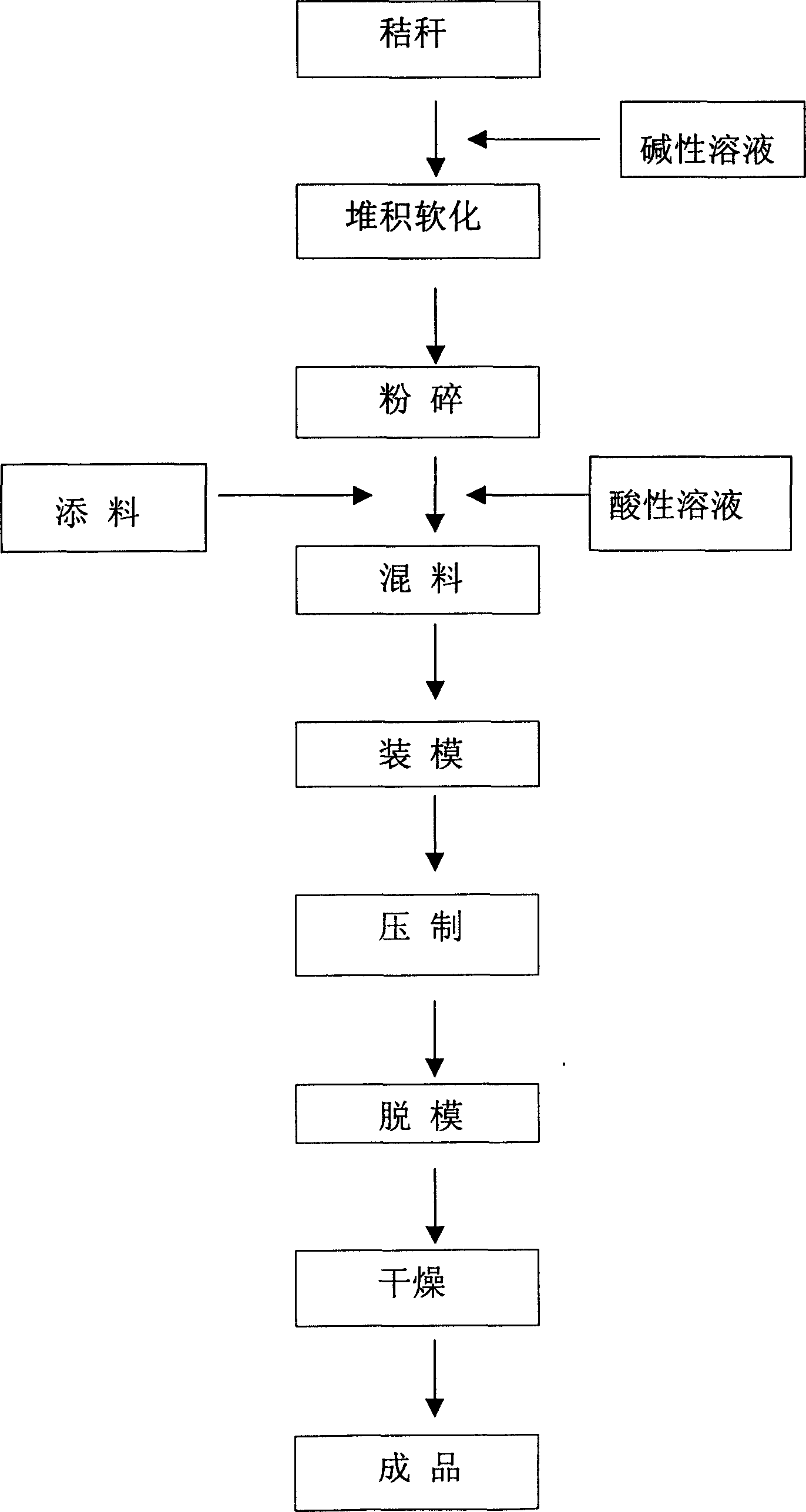

Method used

Image

Examples

example 1

[0019] Weigh 1000kg of straw, spray 300kg of quicklime water with a concentration of 10%, wet all the straw, and cover it with a plastic film to prevent it from getting wet when it rains; stack it to soften, when stacking, each pile is 1-3 meters, and stack it in summer 5-7 days, stacking for 10-15 days in spring and autumn, 15-20 days in winter, turning 1-2 times in the middle. The softened stalk is pulverized to fiber at normal temperature. Use a chain crusher to pulverize to a fiber shape with a length of 5-15 mm, place it in a mixer, spray about 100 kg of waste sulfuric acid with a concentration of 10%, and adjust the pH to about 6. Add 80kg of water-quenched slag ball mill powder, 2kg of amino acid medium and trace element chelate salts, and 1kg of powdery superabsorbent resin and stir evenly. The mixed material is placed in a mold and pressed into a mold. The mold used is a mother mold on the outside and a tire mold on the inside. There are several small protrusions dis...

example 2

[0021] Weigh 1000kg of water wheat straw, spray 600kg of 2% potassium hydroxide lye, wet all the water wheat straw, and cover it with plastic film to prevent it from raining; rice, stacked for 5-7 days in summer, 10-15 days in spring and autumn, and 15-20 days in winter, and turned 3 times in the middle. The softened stalk is pulverized to fiber at normal temperature. Use a chain crusher to grind it into a fibrous shape with a length of 5-15mm, put it in a mixer, spray about 200kg of phosphoric acid with a concentration of 15%, adjust the pH at about 6, add 50kg of water-quenched slag ball mill powder, and 1kg of powder Stir the superabsorbent resin evenly. Put it in a mold and press it into shape, which can be pressed by hydraulic press, hydraulic press or screw extruder. After pressing, it can be dried or naturally air-dried to be a finished product.

example 3

[0023] Weigh 1000kg of straw, spray 400kg of 5% lime slurry at a concentration of , wet all the straw, and cover it with a plastic film to prevent it from getting wet when it rains; stack and soften, and when stacking, each pile is 10-3 meters, stacking in summer 5-7 days, stacked for 10-15 days in spring and autumn, 15-20 days in winter, and turned twice in the middle. The softened stalk is pulverized to fiber at normal temperature. Use a chain crusher to pulverize to a fiber shape with a length of 5-15mm, place it in a mixer, spray 130kg of 10% waste sulfuric acid, adjust the pH to about 6, add 80kg of water-quenched slag ball mill powder, 2kg of amino acids, Trace element chelate salt, 1.5kg of urea-formaldehyde resin, and 1kg of powdered polyacrylamide were stirred evenly. Put it in a mold and press it into a mold. You can use a hydraulic press, a hydraulic press or a screw extruder. After pressing, it can be dried or naturally air-dried to be a finished product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com