Energy-saving type boiler

An energy-saving and boiler technology, which is applied to fire-tube steam boilers, steam boilers, grate and other directions. Reasonable structure and sufficient heat exchange effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

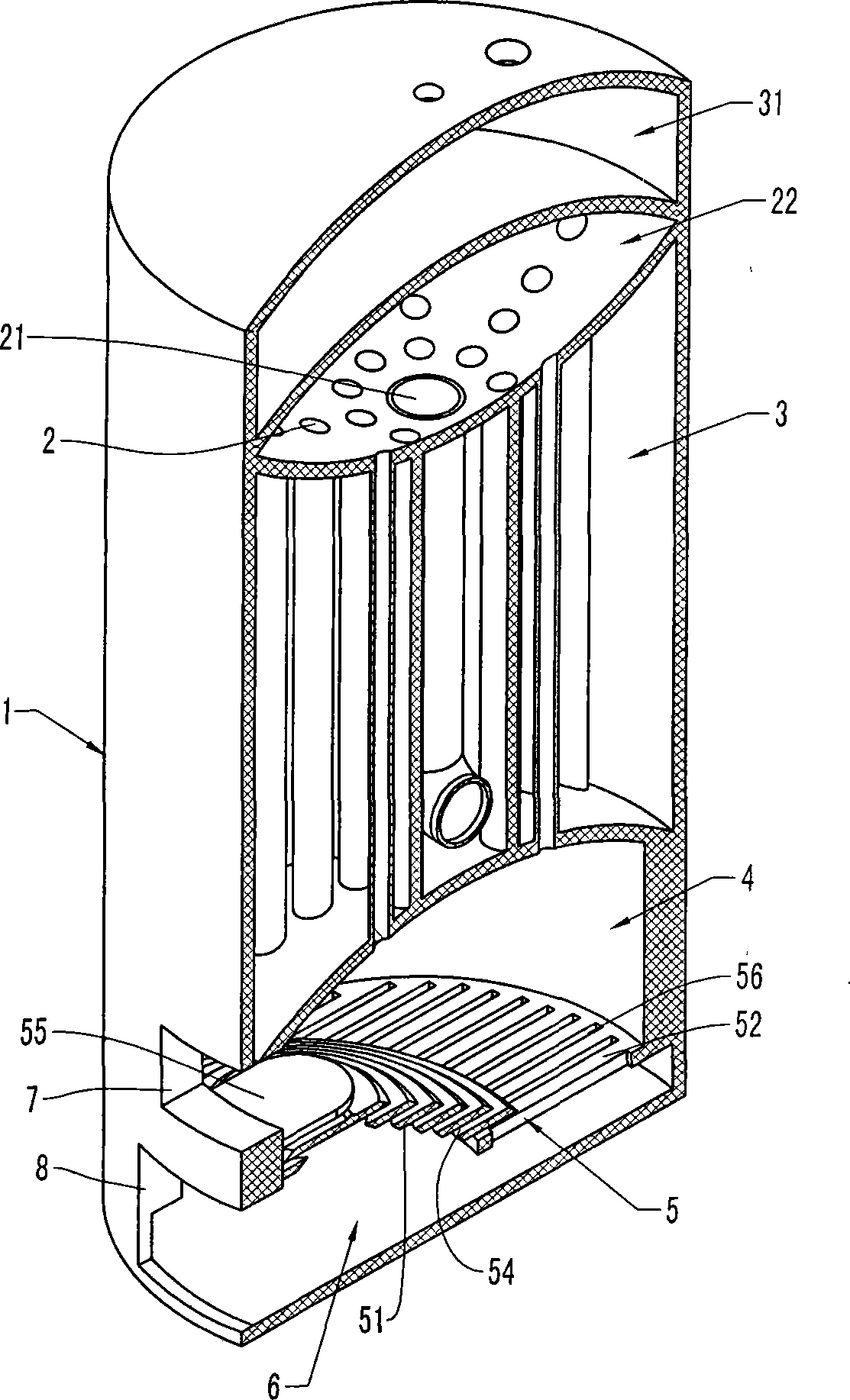

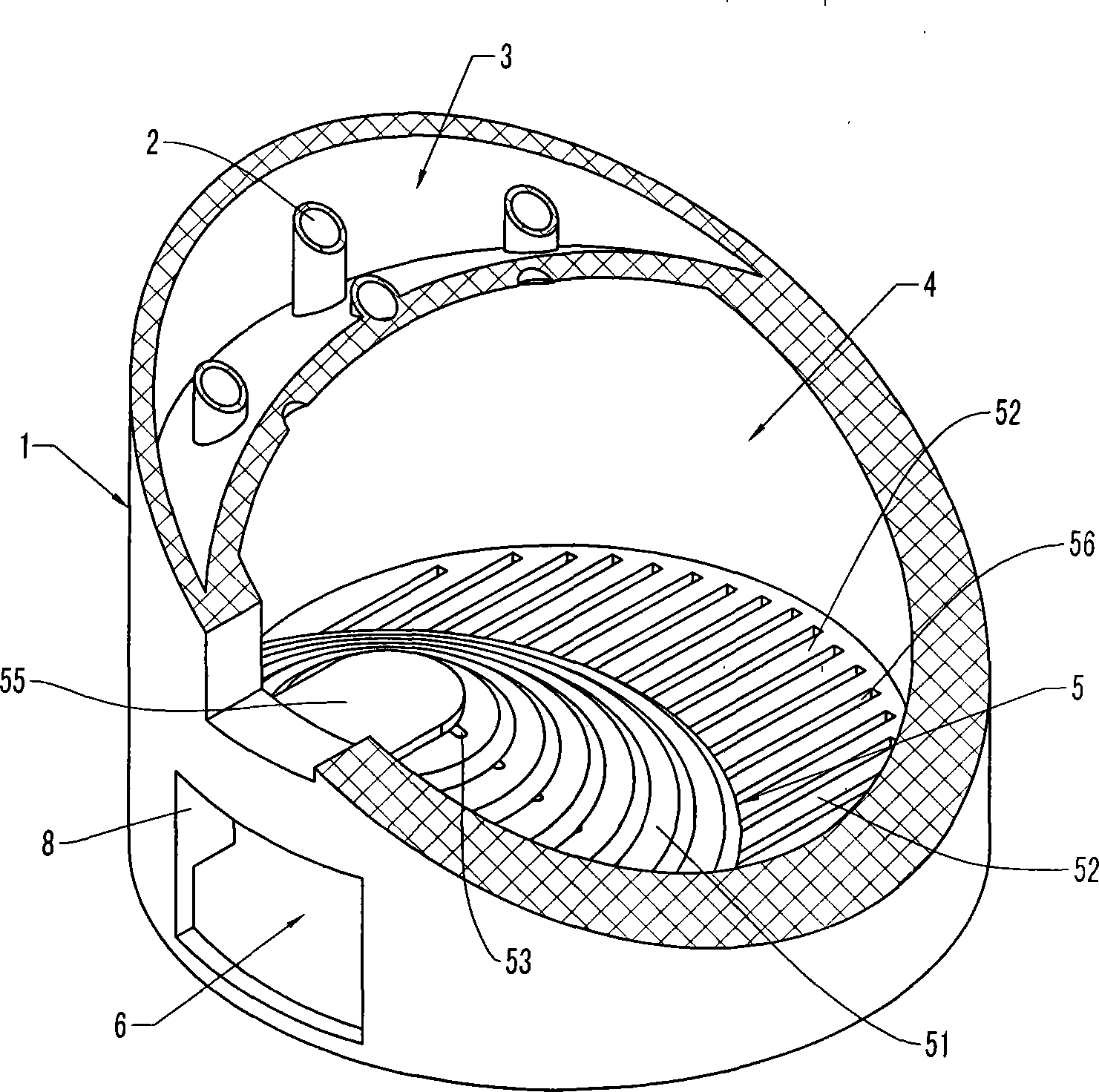

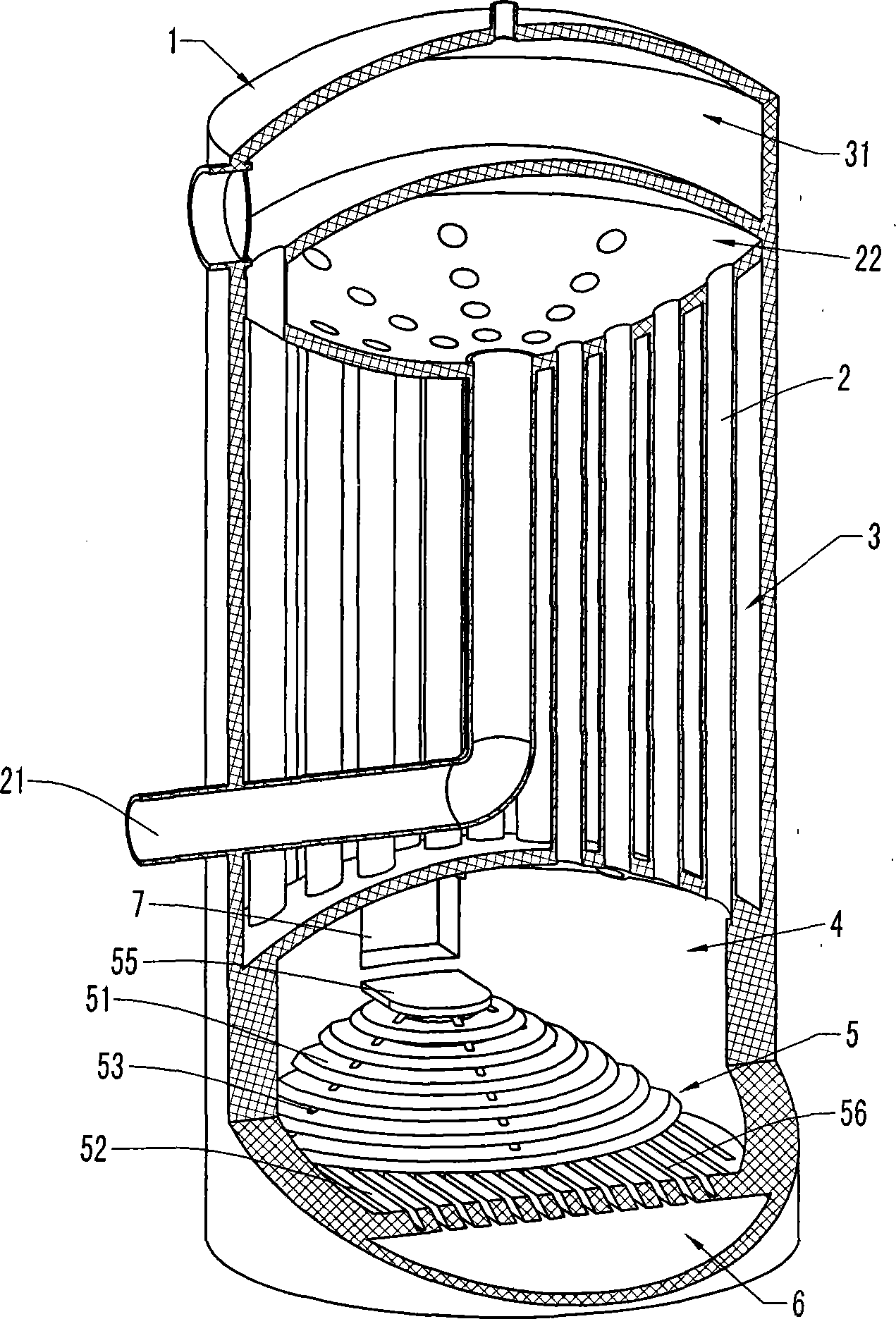

[0020] Reference figure 1 , figure 2 with image 3 , Energy-saving boiler, including the upper heat exchange chamber of the furnace body 1 and the lower combustion furnace 4, the furnace 4 is provided with a grate 5 and a slag chamber 6, and the furnace wall above the grate 5 is provided with a furnace door 7 and Slag removal port, where the grate 5 in the furnace is divided into a cone 51 and a flat surface 52, and the grate on the side close to the furnace door 7 is a cone 51, starting from the furnace door 7 from high to low into the furnace The radiation extends to the flat part, that is, a layout with high outside and low inside is formed. The fuel is fed from the furnace door 7 and can roll down along the tapered part 51 and naturally spread out to the periphery.

[0021] The above-mentioned cone-shaped grate can have two specific structures. One is that the cone-shaped grate is in a stepped structure, stacked from top to bottom from small to large, and fixed by connecting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com