Chain furnace grate protecting method for incinerating biomass fuel and its special device

A technology of biomass fuel and special equipment, applied in combustion methods, incinerators, fuel supply, etc., can solve problems such as low combustion efficiency, high grate cost, unfavorable uniform air distribution, etc., to reduce operating costs, reduce costs, Avoid the effect of high temperature burnout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

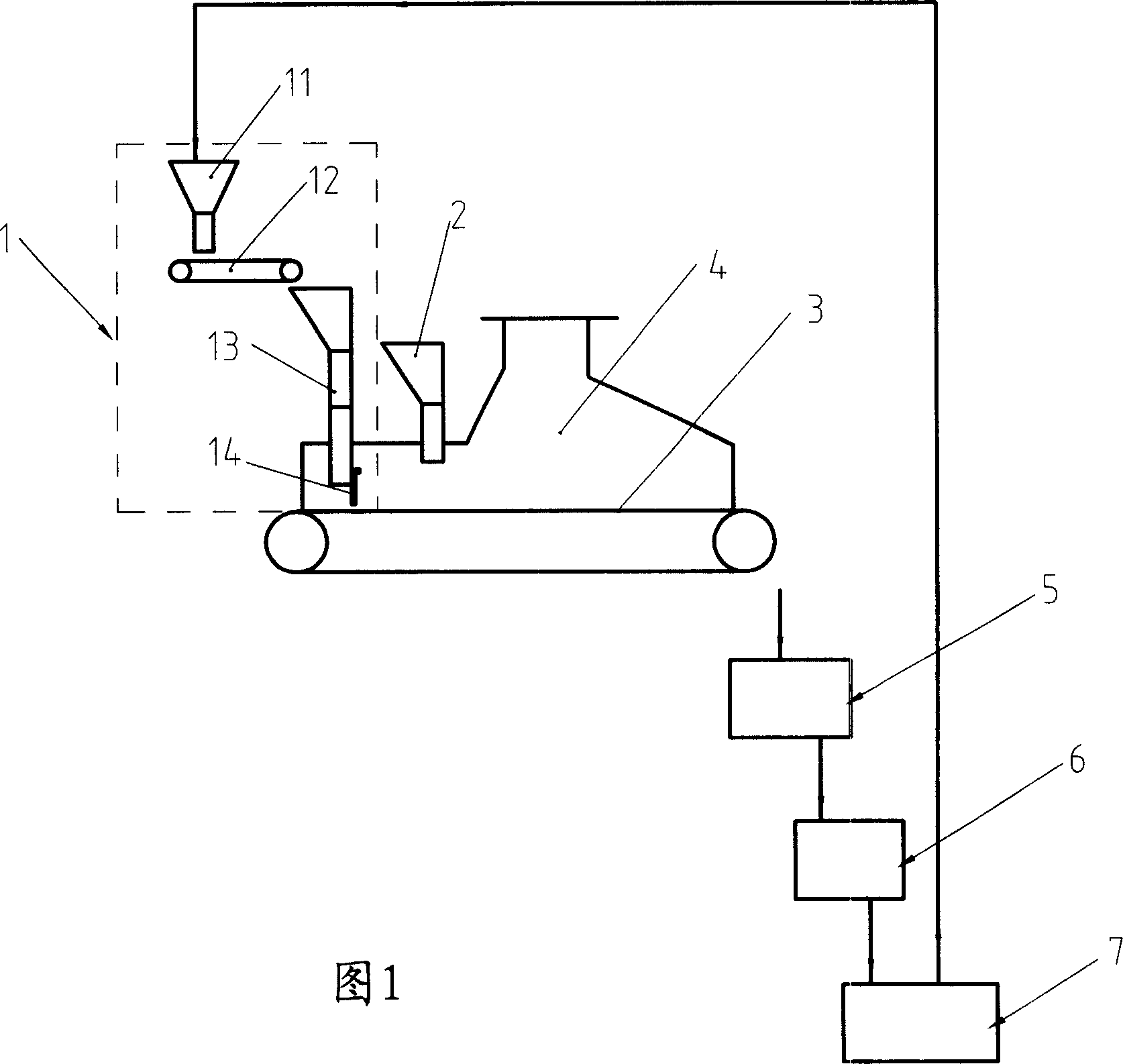

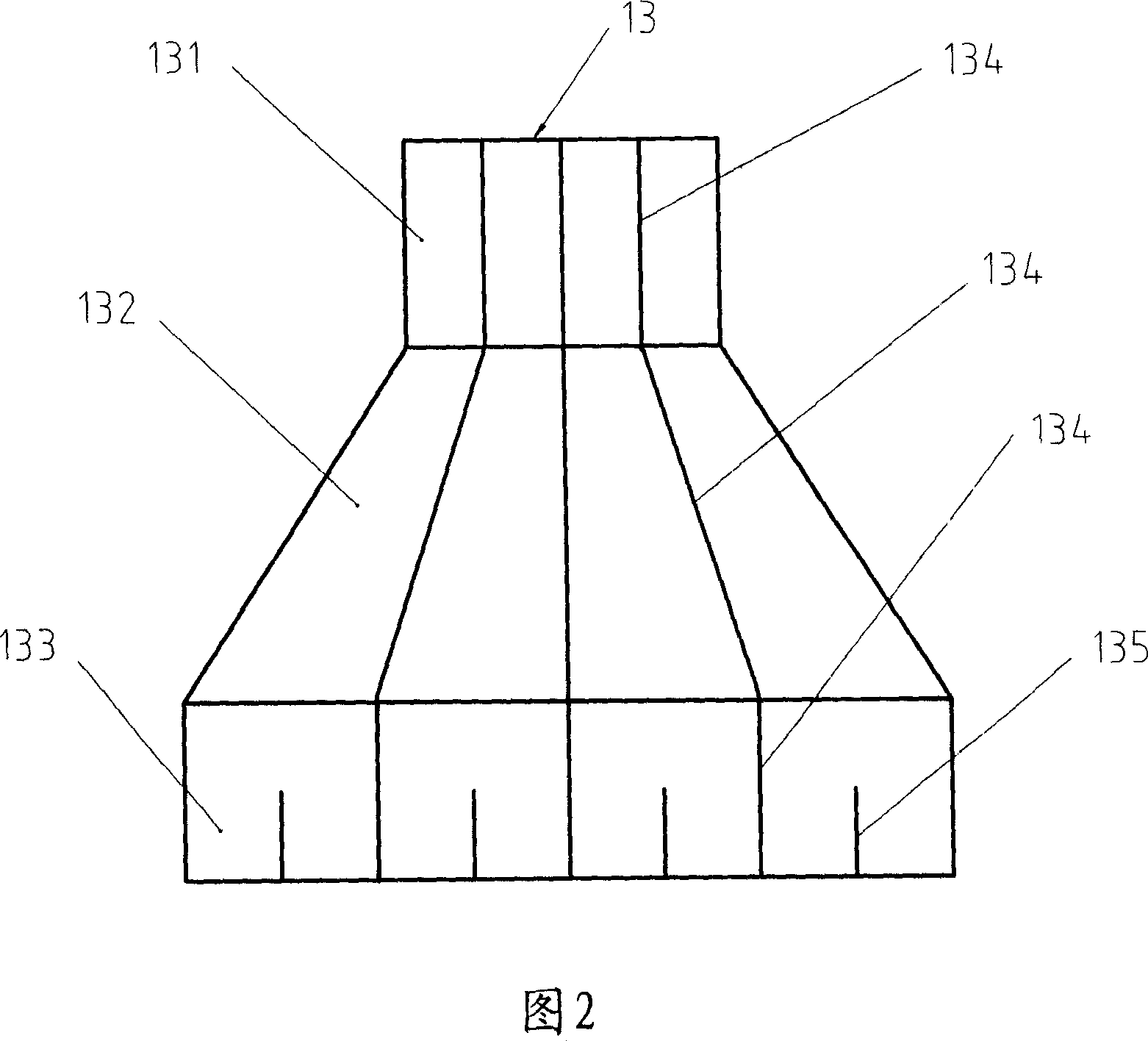

[0029] A method for protecting the grate of a chain furnace for burning biomass fuel. Before the biomass fuel is laid on the grate 3 of the chain furnace through the biomass hopper 2, the front hopper 13 at the front of the biomass hopper 2 On the fire grate 3, lay a layer of stable substances that do not chemically react with the oxides of alkali metals or alkaline earth metals contained in the ash after biomass fuel combustion, and then use the biomass hopper 2 in the stable substances Biomass fuel is placed on top.

[0030] The stable substance laid on the grate 3 is mainly composed of Al 2 o 3 Corundum particles are relatively stable in nature, resistant to high temperatures, and hardly react with alkali metals in biomass fuel ash. Therefore, using corundum particles as an isolation layer, the grate 3 cast by common materials with lower prices can be used. Do not use the expensive high-temperature-resistant and corrosion-resistant alloy steel fire grate 3, which can redu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com