Abrasion resisting fire grate segment

A grate piece and body technology, which is applied to grates, incinerators, combustion methods, etc., can solve problems such as loose connection between parts, easy breakage of the grate piece, and difficulty in maintenance and replacement, and achieve long service life, simple structure, The effect of simple maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention is further explained below with specific embodiments, but is not intended to limit the protection scope of the present invention.

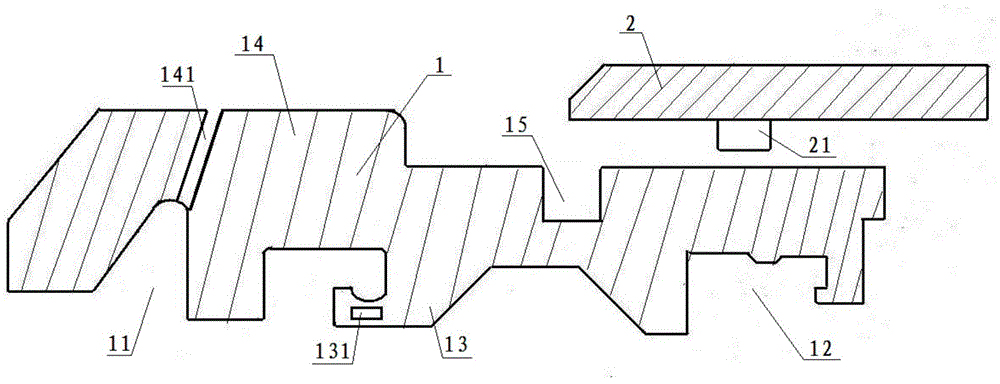

[0017] see figure 1 It is a wear-resistant grate piece, which is a split structure, and specifically includes a grate piece body 1 and a connecting block 2, wherein the connecting block 2 is movably connected to the top of the grate piece body 1, so as to facilitate the connecting block 2 and the grate piece. For the installation and disassembly between the main bodies 1, compared with the integral structure in the prior art, the present invention finds that, during the working process of the grate pieces, there is not a phenomenon of overall wear, but a serious problem of local wear. Depending on the degree of wear, the grate piece is designed to be a detachable split structure, which simplifies the difficulty of maintenance and reduces the maintenance cost on the basis of ensuring that the performance of the ov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com