Biomass burner and use method

A burner, biomass technology, applied in the combustion method, combustion equipment, combustion of solid fuel and other directions, can solve the problems of slagging, difficult to put the boiler into practical application, low combustion efficiency, etc., to achieve the effect of improving capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] In order to understand the present invention more clearly, the present invention is described in detail in conjunction with the accompanying drawings and embodiments.

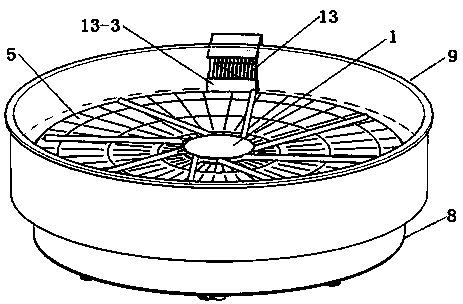

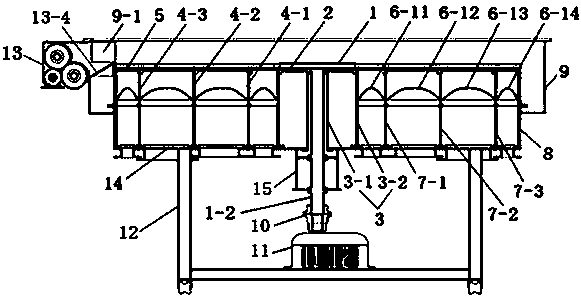

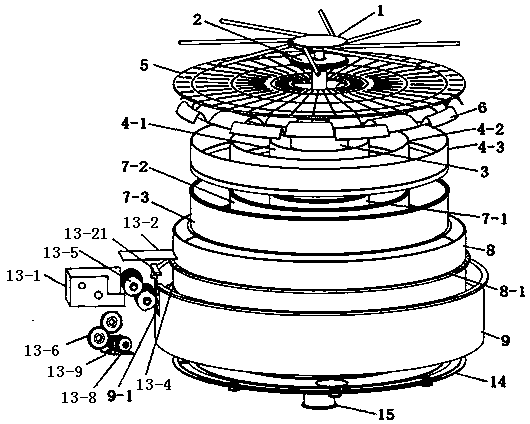

[0052] Such as Figure 1 to Figure 21 As shown, a biomass burner includes a stirring plate 1, an ash retaining plate 2, an inner cover of the air cavity 3, an outer cover of the air cavity 4, a combustion plate 5, a uniform wind shield 6, an air cavity support sleeve 7, and an outer cover of the air cavity. Support sleeve 8, ash block 9, coupling 10, motor I 11, bracket 12, slag breaking device 13, air chamber tray 14, transmission bearing chamber 15.

[0053] Stirring disc 1 comprises driving rod 1-1, vertical shaft 1-2, disc 1-3, on the circumferential surface of disc 1-3, several driving rods 1-1 are fixed obliquely at intervals, each driving rod Between one side of the low end of 1-1 and the circumferential surface of disc 1-3, a triangular support block 1-4 is respectively fixed, and a vertical sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com