Fire grate of boiler

A technology for boilers and grates, which is applied to grates, lighting and heating equipment, etc. It can solve the problems of short service life, waste of raw materials, easy melting and damage, etc., and achieve good ventilation effect, good effect and protection of the furnace body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

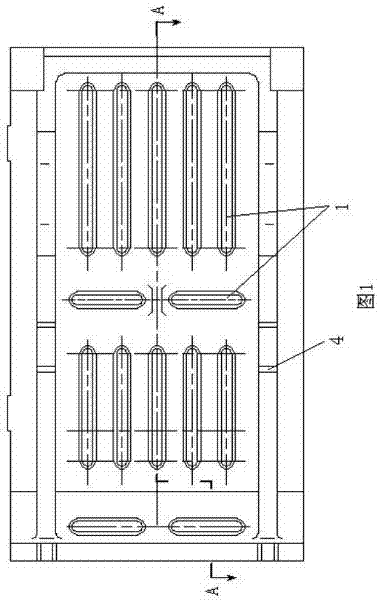

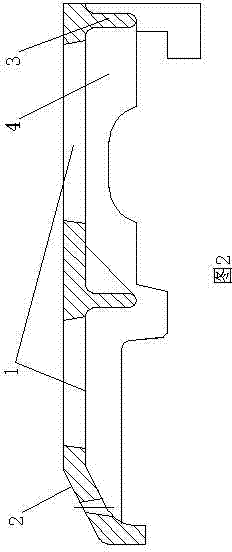

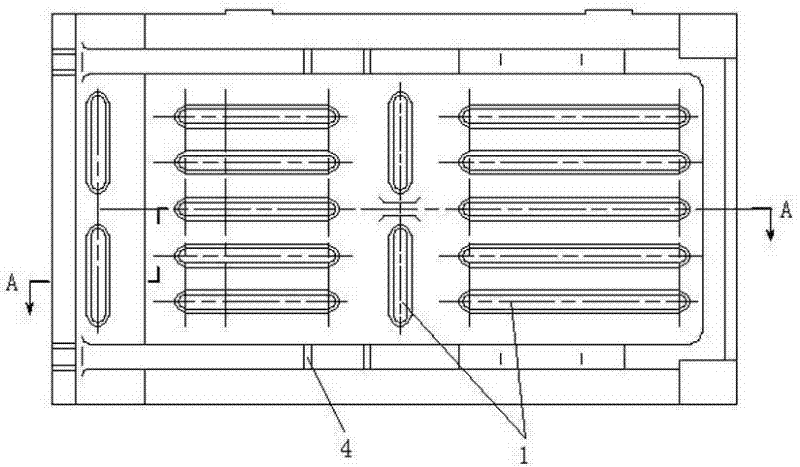

[0021] Embodiment 1: as Figure 1-Figure 2 As shown, the present invention is placed at the bottom of the boiler and consists of a plurality of independent rows arranged side by side, and a plurality of ventilation holes 1 are opened on the single row. When the present invention is in use, a plurality of rows of sheets are arranged side by side, and are installed on the furnace beam through the fixing claws 3 .

[0022] In this example, the material composition of sheet 1 is calculated by weight percentage: 8% aluminum, 9.5% silicon, 2% chromium, 15% carbon steel, and the rest is pig iron.

[0023] The processing technology of sheet arrangement 1 in this example comprises the following steps:

[0024] (1) Smelting a mixture of carbon steel and pig iron;

[0025] (2) Add silicon and chromium when the smelting temperature is 900°C;

[0026] (3) When the smelting temperature is 1100°C, add aluminum and smelt for 10 minutes;

[0027] (4) Casting molding.

Embodiment 2

[0028] Embodiment 2: The overall structure of this embodiment is the same as that of Embodiment 1, the difference is that: the end of the single row facing the inner side of the boiler has a slope 2, and a plurality of ventilation holes 1 are opened on it. A reinforcing rib 4 is provided on the side facing the outside of the boiler of the single row.

[0029] When the present invention is in use, a plurality of slabs are arranged side by side, installed on the furnace beam through the fixed claw 3, and the slope 1 of the plurality of slabs forms a large slope, which is beneficial to slagging and combustion in the furnace.

[0030] The material composition of sheet 1 in this example is calculated by weight percentage: aluminum 11%, silicon 10.5%, chromium 6%, carbon steel 35%, and the rest is pig iron.

[0031] The processing technology of sheet arrangement 1 in this example comprises the following steps:

[0032] (1) Smelting a mixture of carbon steel and pig iron;

[0033] ...

Embodiment 3

[0036] Embodiment 3: The overall structure of this example is the same as that of Example 1, but the difference is that the material components of sheet 1 in this example are by weight percentage: 10% aluminum, 10% silicon, 5% chromium, 25% carbon steel, and the rest are pig iron.

[0037] The processing technology of sheet arrangement 1 in this example comprises the following steps:

[0038] (1) Smelting a mixture of carbon steel and pig iron;

[0039] (2) Add silicon and chromium when the smelting temperature is 950°C;

[0040] (3) When the smelting temperature is 1200°C, add aluminum and smelt for 12 minutes;

[0041] (4) Casting molding.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com