Method for manufacturing energy induction type complete combustion device

A manufacturing method and complete combustion technology, applied in combustion engines, combustion air/combustion-air treatment, charging systems, etc., can solve problems such as failure to prevent or suppress exhaust gas, increased fuel consumption, and reduced service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] in figure 1 , figure 2 Among them, the manufacturing method of the present invention includes the manufacturing method of the air reformer (1), the manufacturing method of the fuel reformer (2), and the manufacturing method of the circuit rectifier (3), and the embodiments are as follows:

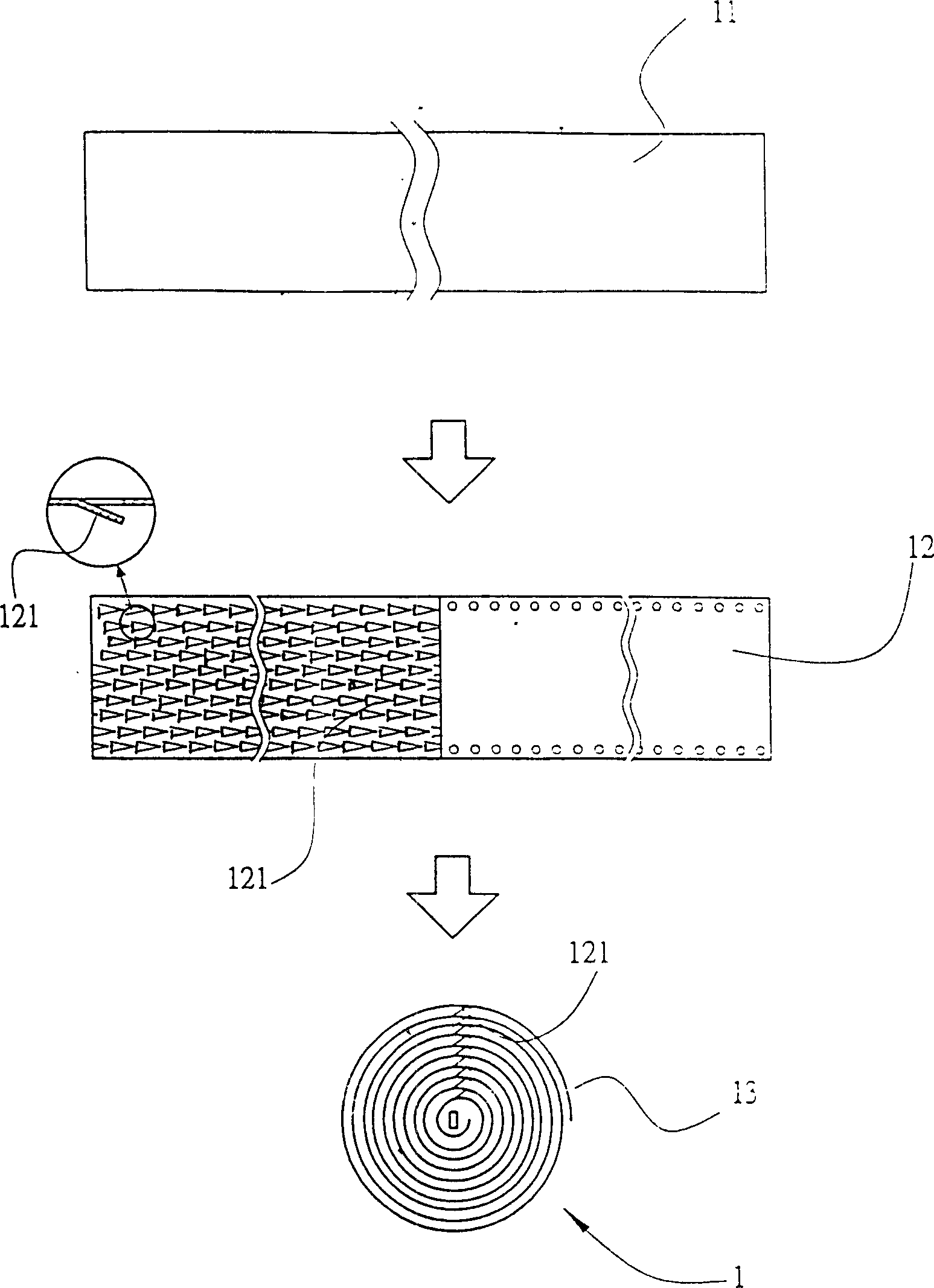

[0019] The manufacturing method of the air converter (1) is to cut an alloy steel plate (11) of appropriate thickness to an appropriate width as required, and then press the alloy steel plate (11) into a mesh plate (12) full of blades (121). Then, 0.15% composite metal titanium, 0.07% platinum, 0.05% palladium and 0.01% trace high-energy minerals are uniformly coated on the mesh plate (12), and then the mesh plate (12) is rolled into a mesh roll (13), and the blade (121) Adjust the size of the net roll (13) to make an air converter (1), such as figure 1 Shown.

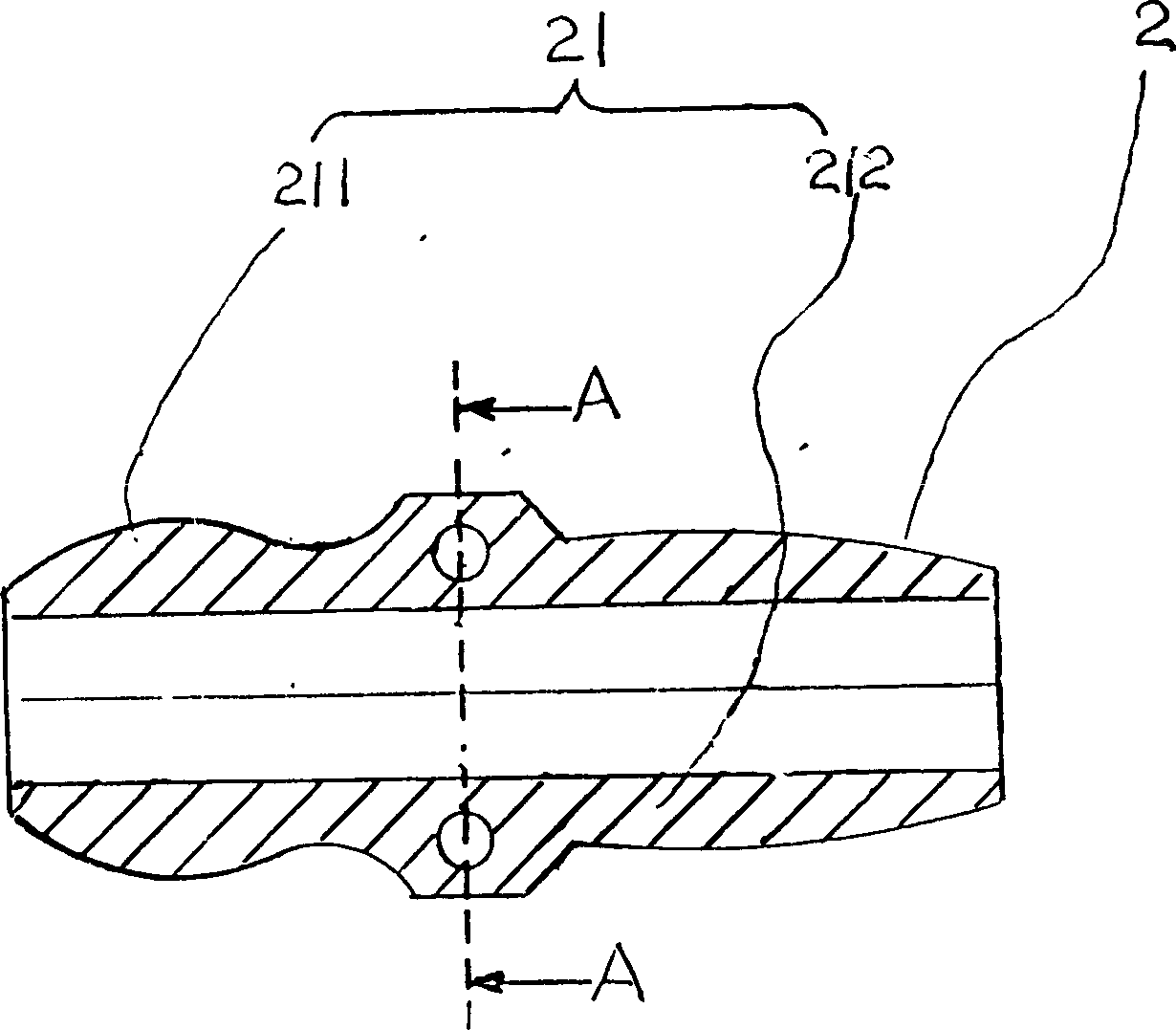

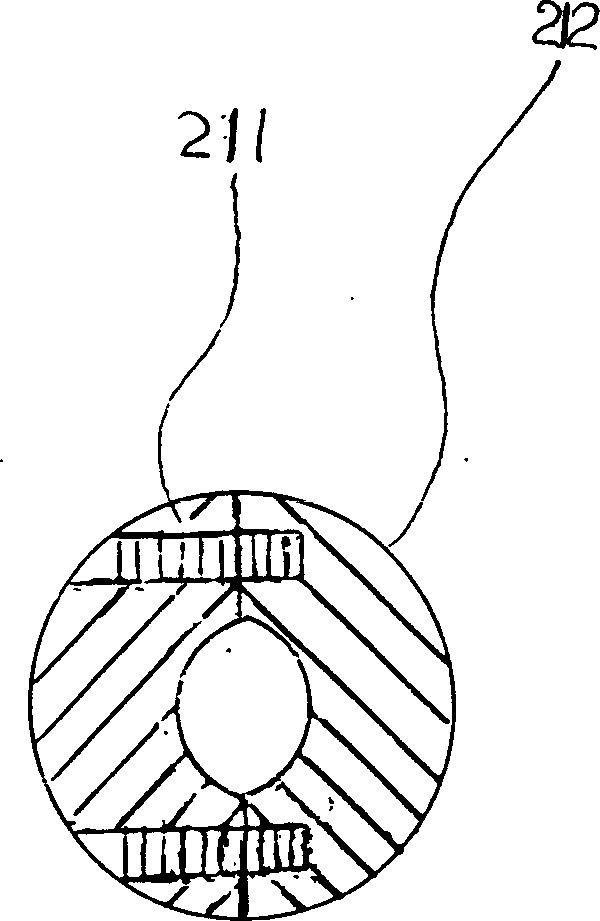

[0020] The manufacturing method of the fuel converter (2) is based on aluminum alloy, copper alloy, alloy steel, etc., mixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com