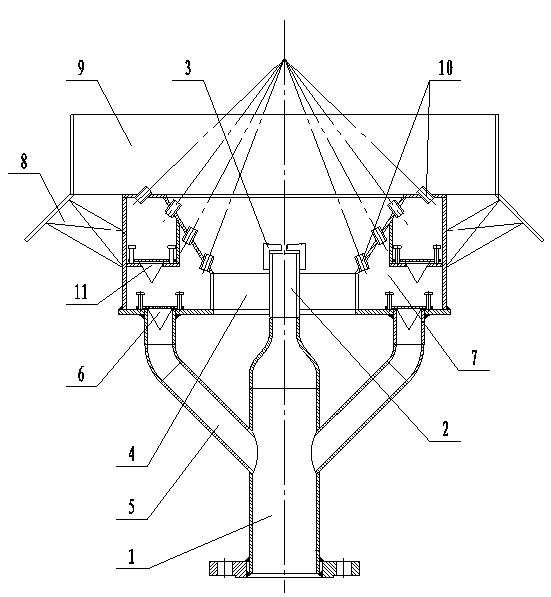

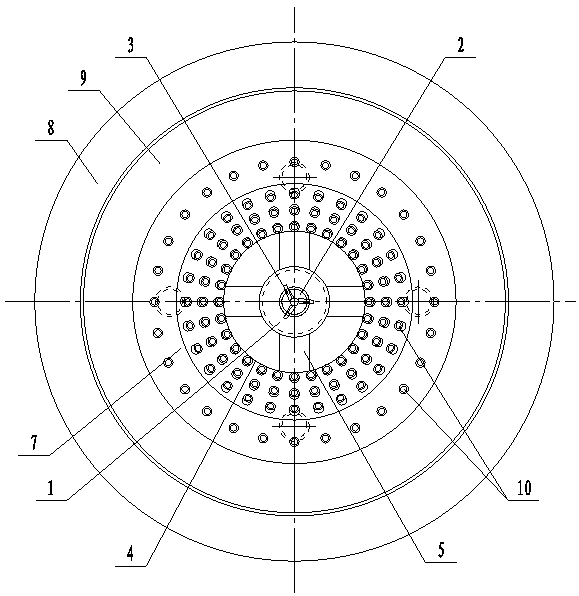

Automatic staged methane burner

An automatic grading and burner technology, applied in the direction of gas fuel burners, burners, combustion methods, etc., can solve problems such as adverse environmental impacts, achieve the effect of not wasting resource costs, reducing flame height, and meeting combustion needs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0025] Air enters the burner air mixer 9 from the central tube 4 and the Venturi air inlet 8, and the biogas enters the main burner 2 through the main vent pipe 1, and then enters the burner air mixer through the main burner spoiler 3 9 Ignite and burn after being fully mixed with air;

[0026] When the amount of biogas is greater than the set value of the primary gravity pressure regulating device 6, the main burner 8 cannot meet the venting requirements, the biogas can pass through the distribution pipe 5, lift the primary gravity pressure regulating device 6 and move on the guide column, so that the biogas enters The lower chamber of the biogas distribution chamber 7 enters the burner air mixer 9 through a secondary burner and mixes with air before burning;

[0027] When the amount of biogas is greater than the set value of the secondary gravity pressure regulating device 11, the main burner 8 and multiple secondary burners cannot meet the venting requirements, and the biog...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com