Biogas automatic grading burner

An automatic grading and burner technology, which is applied to gas fuel burners, burners, combustion methods, etc., can solve problems such as adverse environmental effects, and achieve the effect of not wasting resource costs, meeting combustion needs, and reducing flame height.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

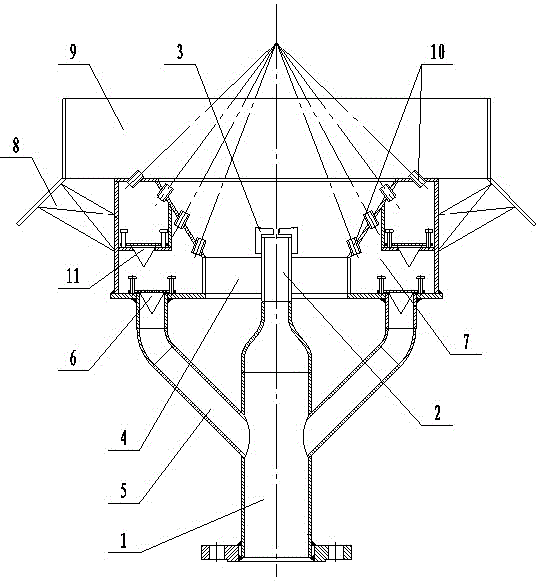

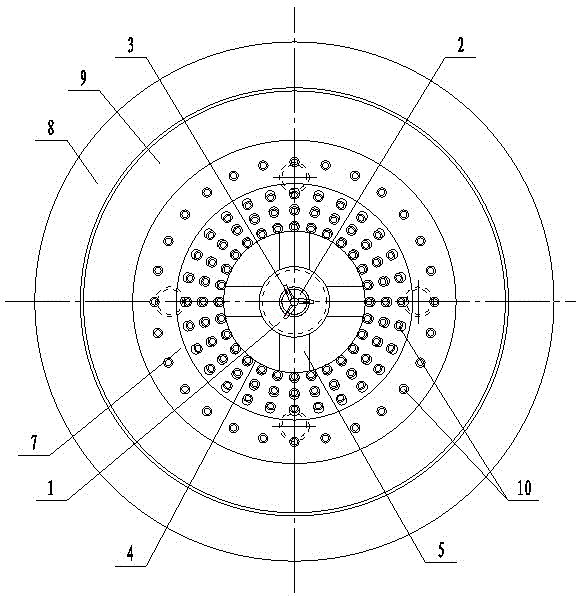

[0018] like figure 1 , figure 2 As shown, the biogas automatic graded burner of the present invention includes a main vent pipe 1, a main burner 2, a main burner spoiler 3, a center pipe 4, a distribution pipe 5, a primary gravity pressure regulating device 6, and a biogas distribution chamber 7. Venturi air inlet 8 and burner air mixer 9, the main burner 2 is installed on the upper end of the main vent pipe 1, the upper part of the main burner 2 is installed with the main burner spoiler 3, the main burner 2 The middle part is fixedly fitted with a central tube 4 with upper and lower openings, and a biogas distribution chamber 7 is set on the outer circumference of the central pipe 4. A plurality of secondary burners 10 are installed on the biogas distribution chamber 7, and the biogas distribution chamber 7 passes through A plurality of distribution pipes 5 communicate with the main venting pipe 1, and the communication port between each distribution pipe 5 and the biogas d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com