Self-regenerative type burner

A regenerative and burner brick technology is applied to the component parts of industrial furnaces and the field of self-regenerative burners, which can solve the problems of increased energy consumption, waste of energy, insufficient flue gas temperature, etc., to achieve low NOx emissions, complete burn effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

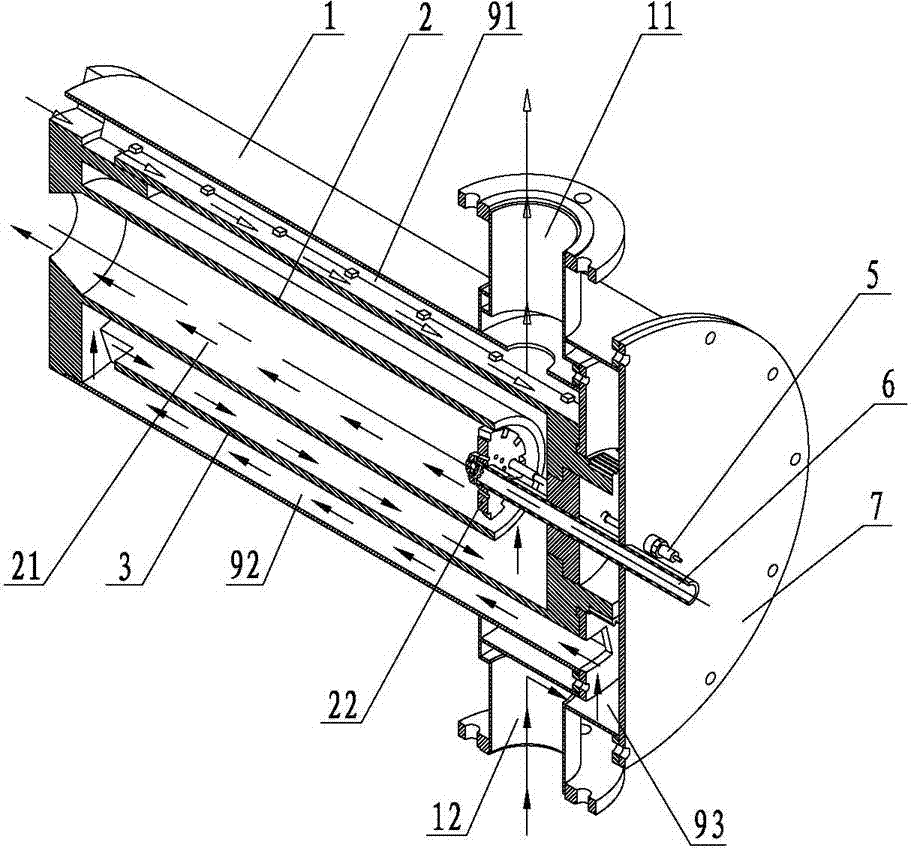

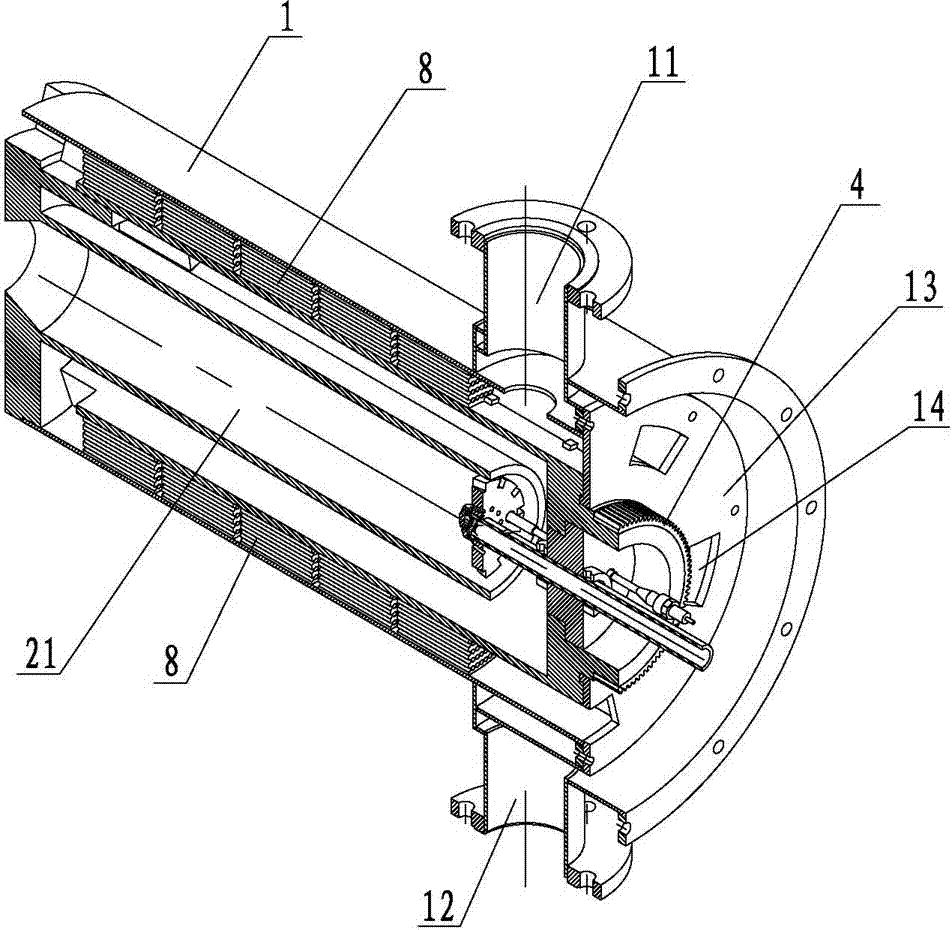

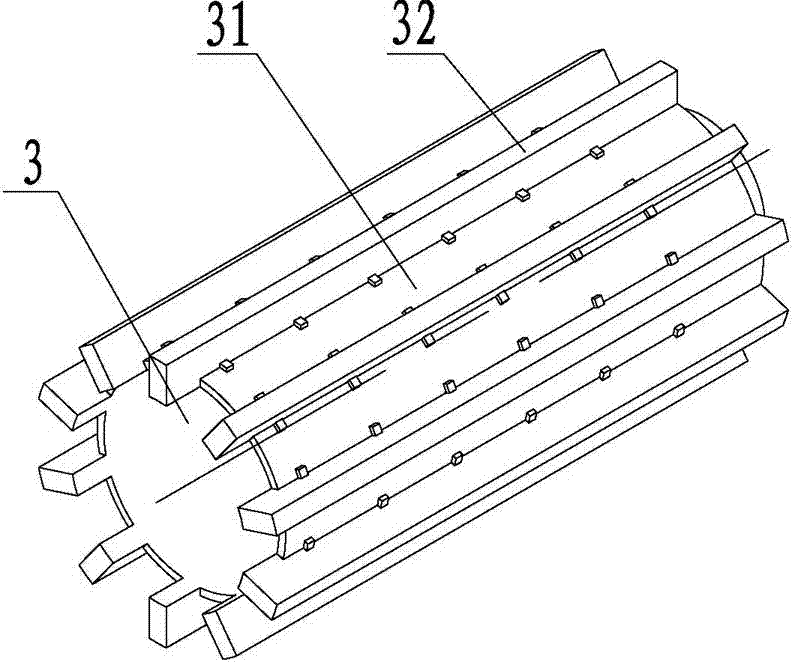

[0018] Please refer to the attached figure 1 to attach image 3 As shown, the present invention is a self-regenerative burner, which is composed of a valve body 1, a burner brick 2, a core body 3, a transmission mechanism 4, an ignition rod 5, a gas pipe 6, and an end cover 7.

[0019] Wherein, the rear end of the valve body 1 is provided with a flue gas outlet 11 , an air inlet 12 and a baffle 13 . Several fan-shaped windows 14 are uniformly distributed on the baffle plate 13, and in this embodiment, the number of the fan-shaped windows 14 is five.

[0020] The burner brick 2 is a burner brick 2 made of high temperature resistant ceramic material, which is accommodated in the valve body 1 . A combustion chamber 21 is provided in the center of the burner brick 2 . The ignition rod 5 and the gas pipe 6 respectively extend into the combustion chamber 21 . Wherein, the ignition rod 5 is used to ignite the gas, and the gas pipe 6 is used to feed the gas.

[0021] Further, a c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com