Automatic-switching heat accumulation type gas burner

A gas burner, automatic switching technology, applied in the direction of burner, combustion method, combustion type, etc., can solve the problems of increasing the difficulty of furnace design and manufacture, power failure, low power, etc., to achieve low NOx emissions and complete combustion , sufficient effect of heat exchange

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

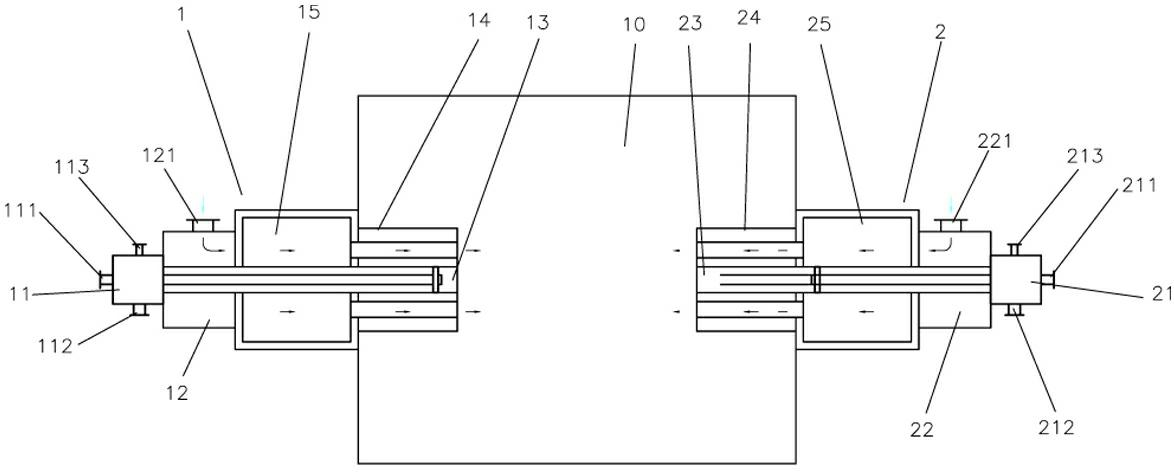

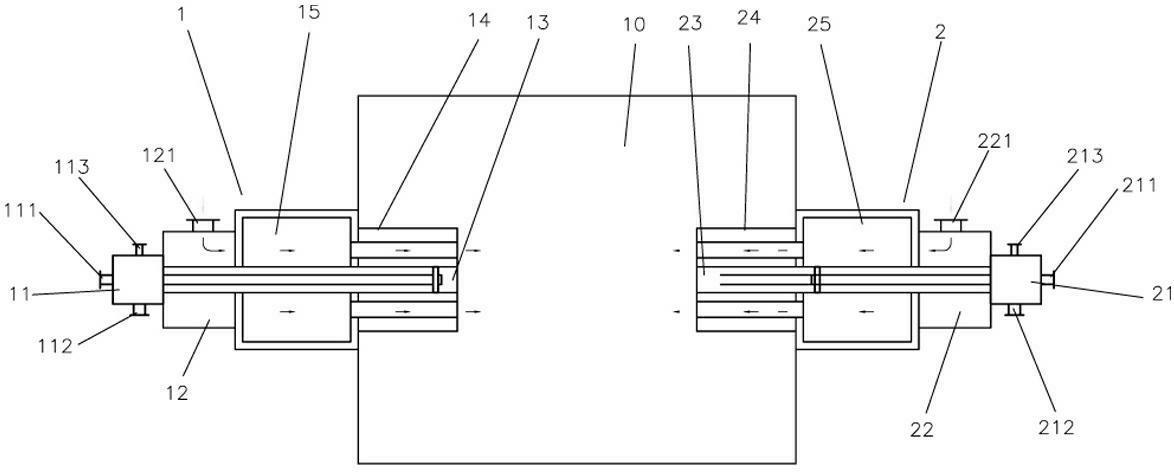

[0013] refer to figure 1 , an automatic switching regenerative gas burner, including two single gas burners with the same structure, the first gas burner 1 and the second gas burner 2 are respectively installed on both sides of the furnace body 10, the The first gas burner 1 includes a first non-heating air intake cavity 11 and a first heating air intake cavity 12, the first non-heating air intake cavity 11 is connected to the furnace body 10 through a first combustion chamber 13, and the first heating The air intake chamber 12 communicates with the first heat storage body 15 , and the first heat storage body 15 communicates with the furnace body 10 through the first air and flue gas passage 14 . The structure of the burner is simple and compact, the gas can enter and exit freely, and the heat exchange is sufficient, which greatly increases the intake temperature of the combustion-supporting air and reduces the exhaust temperature of the flue gas, so that the combustion is com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com