Air-flow type drying oven for drying coating layer of radiate material and blast nozzle parts thereof

A technology for air nozzles and components, which is applied in the field of drying ovens and its air nozzle components to achieve the effects of increasing orientation, reducing wind pressure loss, and increasing direct contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

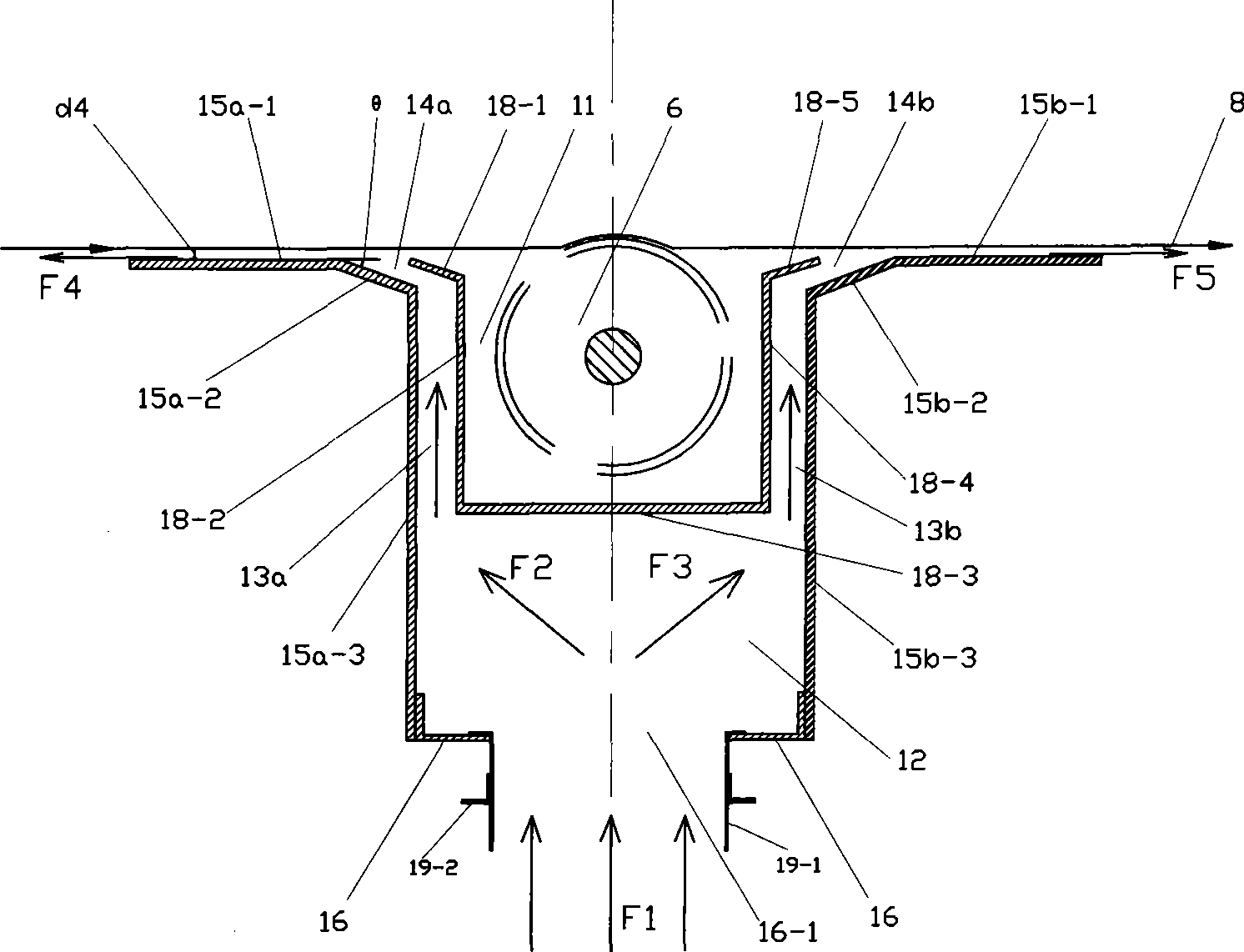

[0041] (Embodiment 1, air nozzle part)

[0042] See figure 1 and figure 2 , the tuyere component in this embodiment is a box 1 . The middle of the upper part of the box body 1 is a guide roller groove 11, and the box body 1 has an inner chamber 12 at the lower part and left air ducts 13a and right air ducts 13b directly connected with the inner chamber 12 at the left and right sides of the upper part. The air outlet of the left air channel 13a is a parallel air flow type left air nozzle 14a inclined to the left, the air outlet of the right air channel 13b is a parallel air flow type right air nozzle 14b inclined to the right, and the box body 1 also has an air inlet located at the lower part .

[0043] The box body 1 includes a left side panel 15 a , a right side panel 15 b , a bottom panel 16 , a front panel 17 a , a rear panel 17 b and a middle panel 18 .

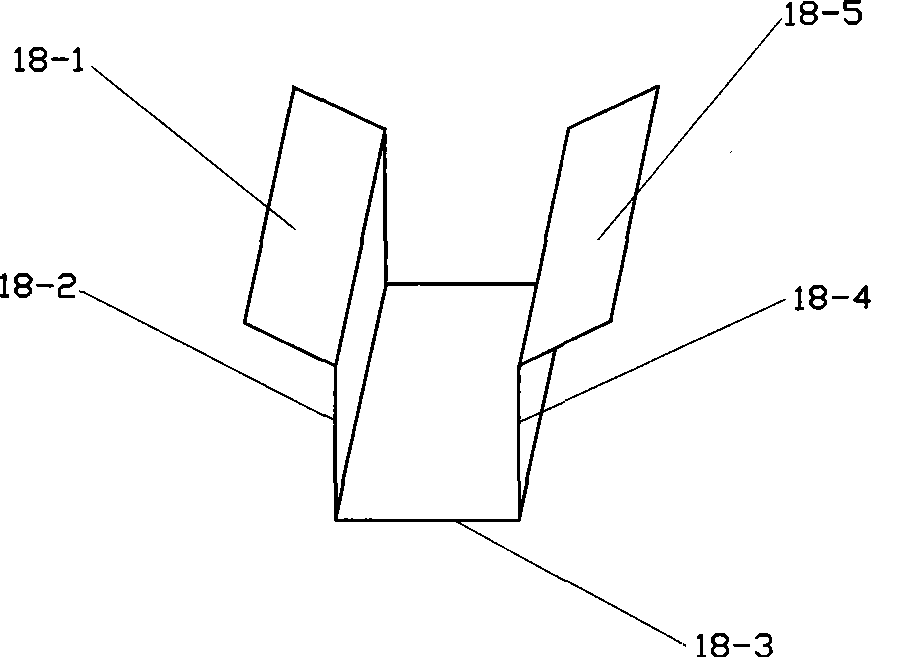

[0044] See figure 2 , the middle plate 18 is a groove-shaped folded plate, and this groove is the guide roller g...

Embodiment 2

[0056] (Embodiment 2, air nozzle parts)

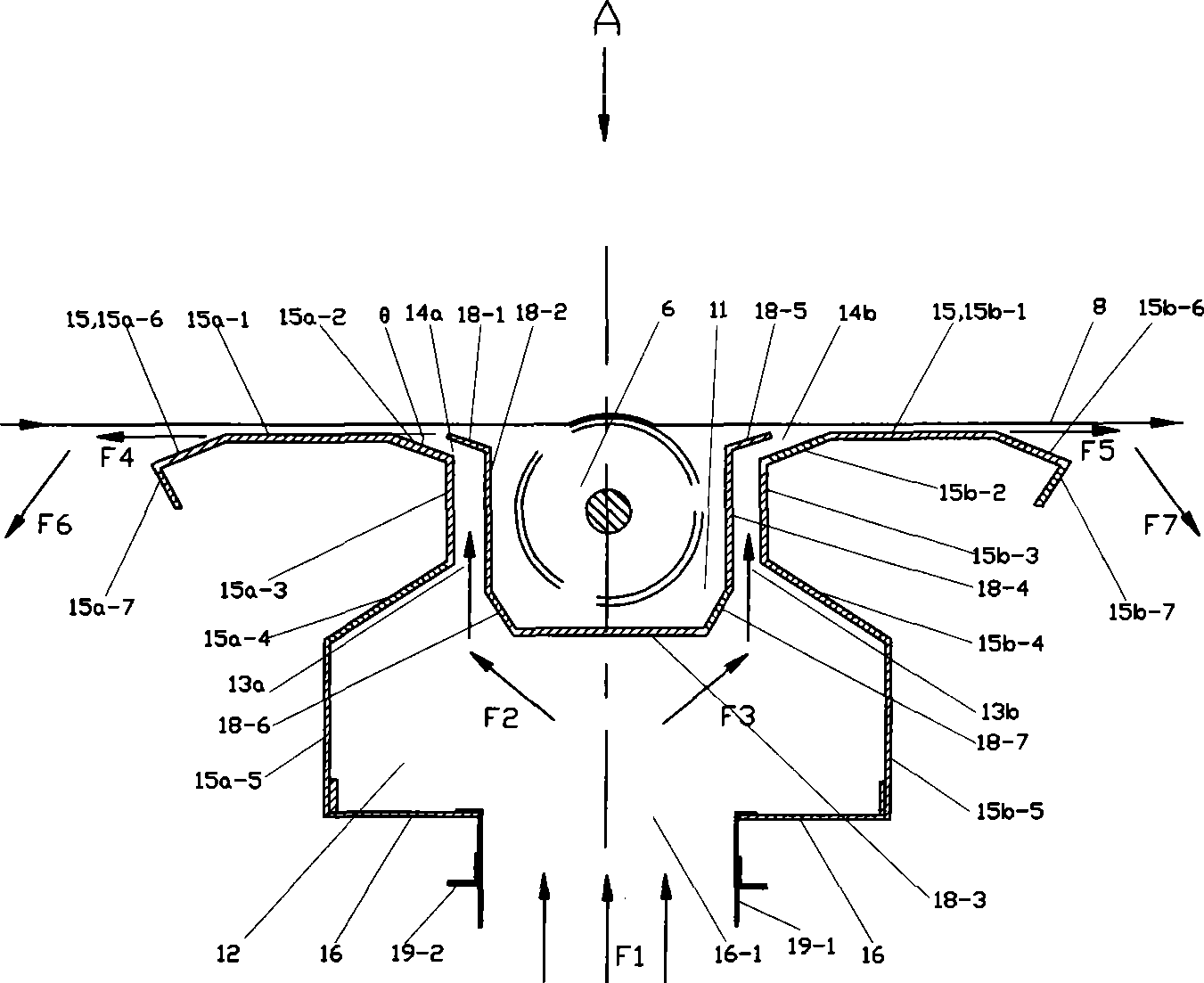

[0057] See image 3 and Figure 4 , the rest of this embodiment is the same as that of Embodiment 1, the difference is that the middle plate includes the following plate sections connected in sequence: the left air nozzle inner slant plate 18-1 inclined upward to the left, the left air duct inner plate 18-2 , the slanted plate 18-6 inside the left air duct inclined downward to the right, the upper side plate 18-3 of the horizontal box body, the inclined plate 18-7 inside the right air duct inclined downward to the left, the inner plate 18-4 of the right air duct and the The right tuyere inboard sloping plate 18-5 of upper right slant.

[0058] The left side plate 15a includes the horizontal support plate 15a-1 of the left air nozzle connected in sequence, the first outer slant plate 15a-2 of the left air nozzle inclined downward to the right, the outer plate 15a-3 of the left air duct, and the left air nozzle inclined downward to the...

Embodiment 3 and Embodiment 4

[0066] (Embodiment 3 and Embodiment 4, air nozzle parts)

[0067] still see image 3 and Figure 4 , Embodiment 3 corresponds to Embodiment 1, and Embodiment 4 corresponds to Embodiment 2. Embodiment 3 is the same as the corresponding embodiment with the rest of embodiment 4, the difference is:

[0068] The left end of the left air nozzle horizontal support plate 15a-1 of the left side plate 15a is also connected with the left air nozzle second outer slant plate 15a-6 inclined downward to the left and the left air nozzle third outer slant plate inclined to the right downward from right to left. Outer ramps 15a-7.

[0069] The right end of the right air nozzle horizontal support plate 15b-1 of the right side plate 15b is also connected with the right air nozzle second outer slant plate 15b-6 inclined downward to the right and the third right air nozzle inclined downward to the left from left to right. Outer sloped plate 15b-7.

[0070] The third outer slant plate 15a-7 of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com