Benzoxazine resin-based high-power carbon crystal electric heating plate as well as preparation method and application thereof

A benzoxazine and resin-based technology, applied in the field of benzoxazine resin-based high-power carbon crystal electric heating plate and its preparation, can solve the problems of low power, potential safety hazards, limited heat resistance of epoxy resin, etc. problem, to achieve the effect of extending the thermal distance and reducing the cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] In a second aspect, a method for preparing the benzoxazine resin-based high-power carbon crystal electric heating plate is provided, including the following steps:

[0041] The conductive filler, dispersant and solvent are mixed and ball milled to obtain a composite conductive agent, and the composite conductive agent, benzoxazine resin, modified silicone resin and additives are mixed and ground to prepare a carbon crystal conductive ink;

[0042] Screen-print carbon crystal conductive ink on the first insulating layer prepreg, heat and cure, and then cover the second insulating layer prepreg on the conductive ink layer;

[0043] Heating and curing again, and then post-processing, that is.

[0044] In some embodiments, in the carbon crystal conductive ink, the mass ratio of conductive filler, dispersant, resin and solvent is 3-5:1:1.5-2.5:2.5-3.5.

[0045] The third aspect provides the application of the benzoxazine resin-based high-power carbon crystal electric heatin...

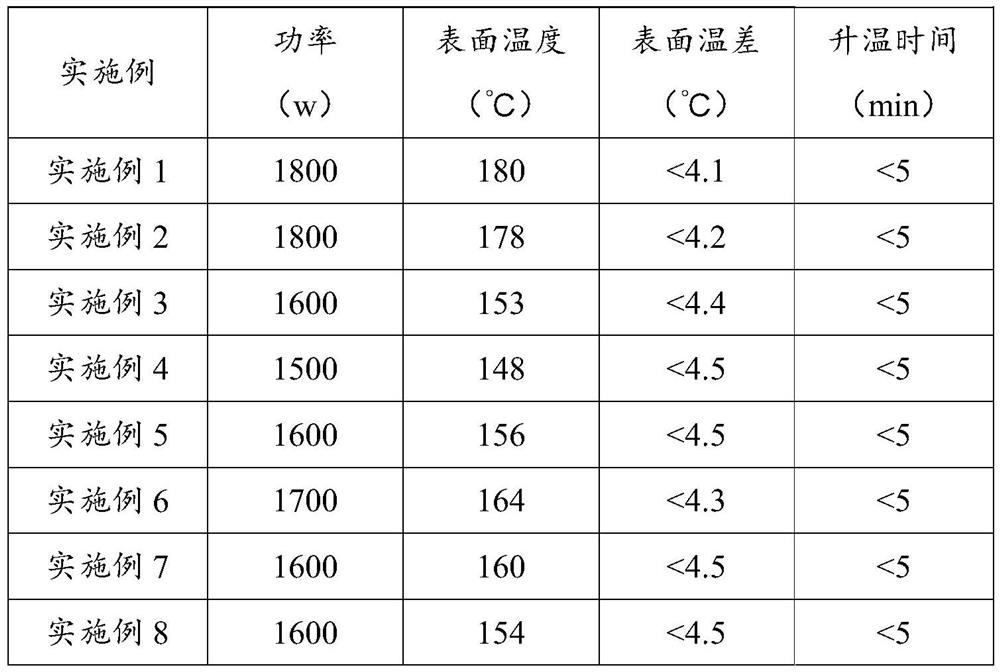

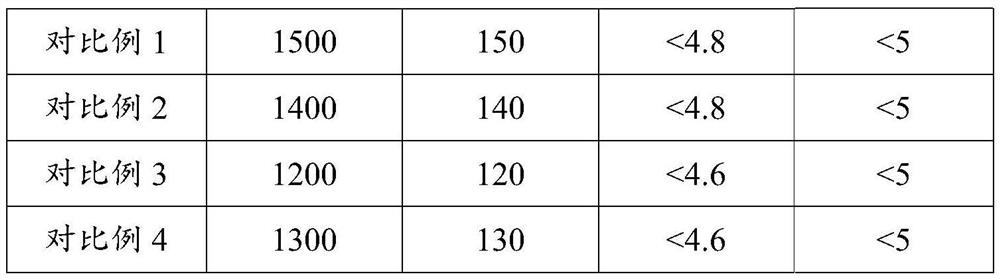

Embodiment 1

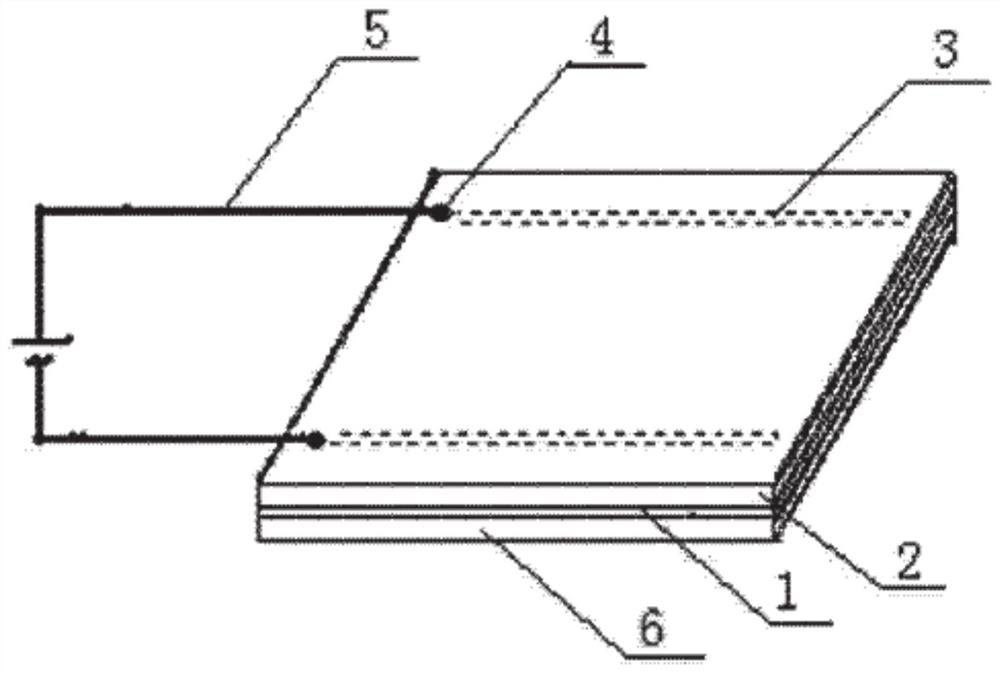

[0048] Such as figure 1As shown, the high-power carbon crystal electric heating plate mainly includes glass cloth reinforced benzoxazine resin insulating layer I, carbon crystal conductive ink layer 2 and copper foil tape 3 . The middle ink layer is encapsulated up and down by benzoxazine resin / glass fiber insulating layer I and benzoxazine resin / glass fiber insulating layer II, and the copper foil strip 3 as an electrode is also encapsulated in carbon crystal conductive ink 1 and resin / between the glass fiber insulating layer I2, and / or the carbon crystal conductive ink and the benzoxazine resin / glass fiber insulating layer II6, are connected to the wire 5 through the welding point 4, and sealed by the silicone resin.

[0049] Each of the benzoxazine resin / glass fiber insulating layer I and the benzoxazine resin / glass fiber insulating layer II includes cured benzoxazine resin, and glass cloth as a reinforcing material for the resin.

[0050] The size of the carbon crystal ...

Embodiment 2

[0066] Soak the glass cloth in the benzoxazine resin solution, dry and remove the solvent to obtain the benzoxazine resin / glass fiber prepreg, the glue content is about 50%.

[0067] Spread the benzoxazine resin / glass fiber prepreg flat, lay copper foil tape on it, and then press molding at a temperature of 180°C and a pressure of 6MPa; the above-mentioned pressed benzoxazine resin / glass fiber prepreg The material is screen printed, and after printing the carbon crystal conductive ink, it is cured at a temperature of 180°C; after the curing is completed, it is covered with benzoxazine resin / glass fiber prepreg again. Finally, it is cured and formed at a temperature of 170°C, a pressure of 8MPa, and a time of 180 minutes, and then heat-treated in an oven at 200°C for 120 minutes. The copper foil electrode and the wire are connected by welding to make a carbon crystal electric heating plate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com