Vertical rotary heating furnace of main shaft steel ingot for wind driven generator

A wind-driven generator and rotary heating technology, which is applied to heat treatment furnaces, furnaces, furnace types, etc., can solve the problems of uneven heating of the steel ingot of the main shaft of the wind-driven generator, affect the uniformity of heating, and increase the holding time, so as to improve labor efficiency, The effect of shortening the heating time and increasing the heating rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

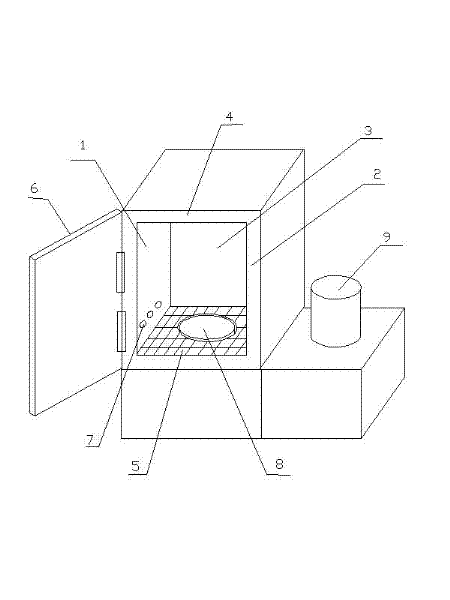

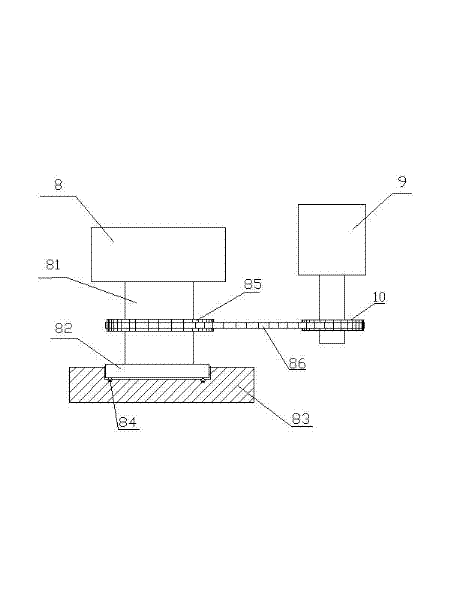

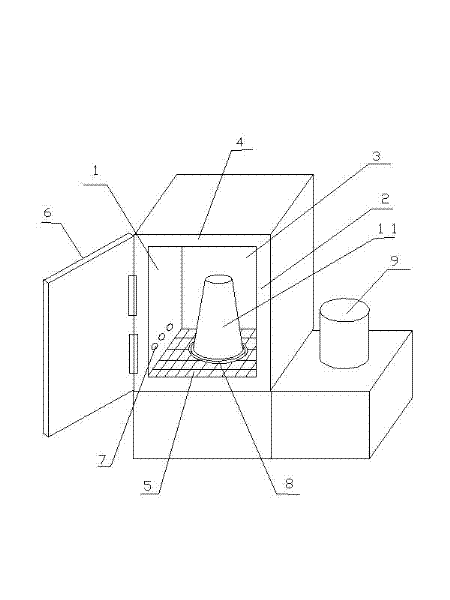

[0014] figure 1 , figure 2 , image 3 An example is given, and it was put into trial operation in our company in January 2011. Such as figure 1 , figure 2 , image 3 As shown, the wind turbine main shaft steel ingot vertical rotary heating furnace includes a left furnace wall 1, a right furnace wall 2, a rear furnace wall 3, a top furnace wall 4, a furnace bottom 5 and a furnace door 6. There is an insulation layer, the furnace bottom 5 is a refractory brick layer, and a gas burner 7 is provided at the lower part of the left furnace wall 1 and the right furnace wall 2. Turntable 8, the internal length of left furnace wall 1, right furnace wall 2 is 350cm, and internal height is 450cm, and the internal height of back furnace wall 3 is 450cm, and internal width is 350cm, and when wind power generator main shaft steel ingot 11 is heated, wind force The main shaft steel ingot 11 of the generator faces down and stands on the circular turntable 8. The rotation of the circula...

Embodiment 2

[0020] The structure of the vertical rotary heating furnace for the main shaft steel ingot of the wind power generator is the same as that in Embodiment 1. When heating the wind turbine main shaft steel ingot, put it into a heating furnace at 650°C from room temperature, keep it warm for 3 hours, then heat it at a rate of 70°C per hour, raise the temperature to 860°C, keep it warm for 4 hours, and then raise the temperature to 1240°C, using a matching special forklift to take out the furnace.

[0021] Compared with the existing heating furnace, when heating a steel ingot for the main shaft of a wind turbine, the two holding times are shortened by an average of 7 hours and 10 hours respectively, and the total time for completing a furnace is shortened by an average of 17 hours. And the heated wind turbine main shaft steel ingot is suitable for forging requirements.

Embodiment 3

[0023] The structure of the vertical rotary heating furnace for the main shaft steel ingot of the wind power generator is the same as that in Embodiment 1. When heating the wind turbine main shaft steel ingot, put it into a heating furnace at 620°C from room temperature, keep it warm for 3 hours, then heat it at a rate of 80°C per hour, raise the temperature to 830°C, keep it warm for 7 hours, and then raise the temperature to 1200 ℃, using a matching special forklift for the furnace.

[0024] Compared with the existing heating furnace, when heating a steel ingot for the main shaft of a wind turbine, the holding time of the two stages is shortened by 7 hours on average, and the total time for completing one furnace is shortened by 14 hours on average. And the heated wind turbine main shaft steel ingot is suitable for forging requirements.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com