A high-efficiency curing device for glass fiber reinforced plastic casing production

A technology of FRP casing and curing device, which is applied in the field of FRP casing production and molding, which can solve the problems of easy damage, affecting the pass rate of molding, and affecting the pass rate of curing molding, etc., and achieve the effect of uniform heating, improving efficiency and pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

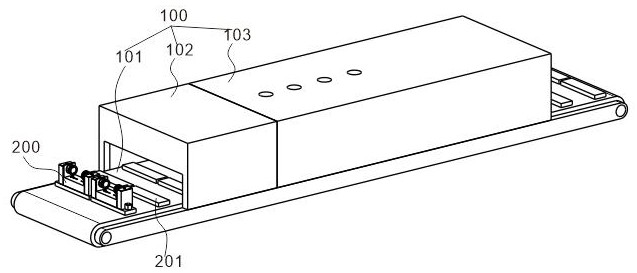

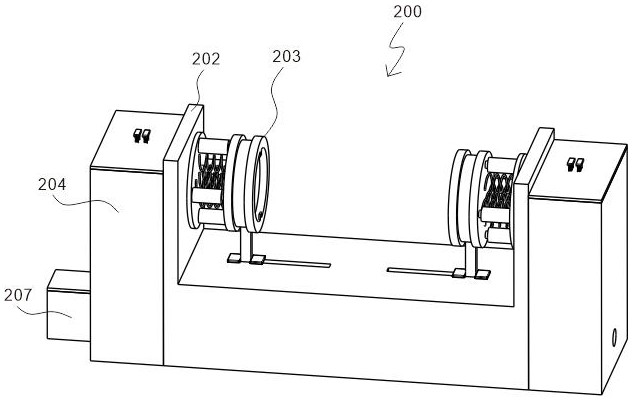

[0034] refer to figure 1 with figure 2 , is the first embodiment of the present invention, and this embodiment provides a kind of high-efficiency FRP casing production curing device, and the high-efficiency FRP casing production curing device includes a curing molding unit 100 and a clamping unit 200, and the FRP casing is solidified During the forming process, it is clamped and rotated by the clamping unit 200, so that the surface is heated more uniformly, thereby improving the efficiency and pass rate of curing and forming.

[0035] Specifically, the curing molding unit 100 includes a conveyor belt 101, a preform curing box 102 arranged on the top of the conveyor belt 101, and a deep forming curing box 103 arranged on the top of the conveyor belt 101 and on the right side of the preform curing box 102, through The conveyor belt 101 transports the FRP casing to be cured to the interior of the preformed curing box 102 and the deep forming curing box 103, pre-cures it through...

Embodiment 2

[0039] refer to Figure 2~9 , is the second embodiment of the present invention, which is based on the previous embodiment.

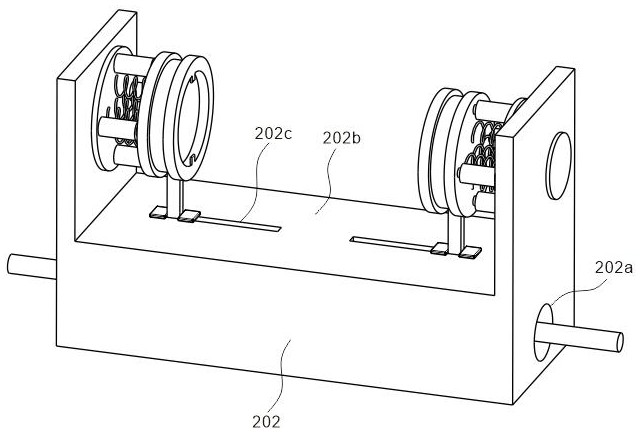

[0040] Specifically, the connection assembly 202 includes a through hole 202a disposed inside, a clamping cavity 202b disposed on the top, and a moving groove 202c disposed on the inner wall of the clamping cavity 202b. The casing is clamped and fixed to prevent it from shifting during the curing and molding process, which will affect the efficiency of curing and molding.

[0041] Preferably, the clamping assembly 203 includes a connecting plate 203a disposed inside the clamping cavity 202b, a clamping frame 203b disposed on one side of the connecting plate 203a, and a telescopic guide 203c disposed between the connecting plate 203a and the clamping frame 203b , the compression spring 203d arranged on one side of the connecting plate 203a, and the connecting rod 203e arranged on the other side of the connecting plate 203a, one end of the connecting rod...

Embodiment 3

[0047] refer to Figure 8~12 , is the third embodiment of the present invention, which is based on the first two embodiments.

[0048] Specifically, the moving part 205f includes a moving ring 205f-a, a fixed plate 205f-b arranged on the top of the moving ring 205f-a, an movable rod 205f-c arranged in the middle of the protective top cover 204b, and a movable rod 205f-c arranged on the top of the movable rod 205f-c. The pressing block 205f-d, the second tension spring 205f-e arranged at the bottom of the pressing block 205f-d, the limit frame 205f-f arranged at the bottom end of the movable rod 205f-c, the side of the moving ring 205f-a and The third tension spring 205f-g matched with the connecting plate 205b, and the limit rod 205f-h arranged on the side of the fixed rod 205d, the moving ring 205f-a includes a limiter arranged on the side and matched with the limit rod 205f-h. The position slot M, the fixed plate 205f-b includes a chute N arranged on the top and matched wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com