Vertical drying machine uniform in air distribution

A technology of vertical dryer and drying cylinder, which is applied in the direction of dryer, drying, drying gas arrangement, etc., which can solve the problems of uneven drying of materials, high flow of hot air, and heating of materials, so as to avoid drying Non-uniform, sufficient heat exchange, uniform heating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

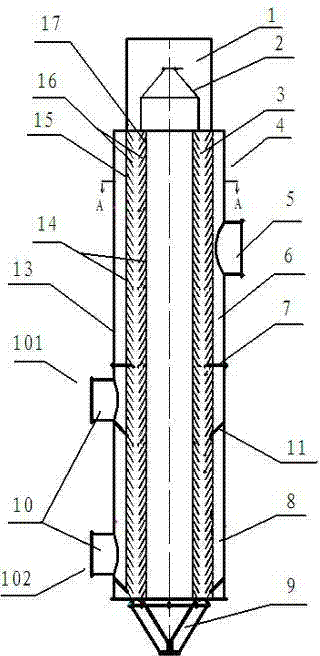

[0014] The present invention will be described in detail below in conjunction with the accompanying drawings.

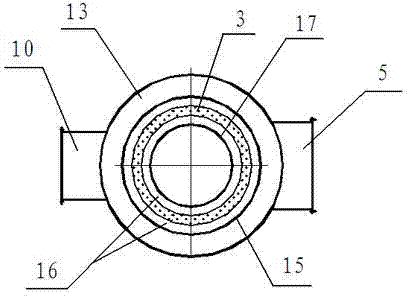

[0015] Such as figure 1 , figure 2 As shown, the vertical dryer of the present invention includes a feed bin 1, a material distribution cone 2, a drying cylinder 4, and a discharge hopper 9, and the material is lifted into a sealed feed bin 1 through an elevator (not shown in the accompanying drawings) Elevator), the material distribution cone 2 in the feed bin 1 disperses the material into a cylindrical material layer, and the material layer enters the drying cylinder 4 under the action of gravity, and the material is discharged from the discharge hopper 9 after drying.

[0016] The drying cylinder 4 includes an inner cylinder 17, an outer cylinder 15 and an air cylinder 13. A retaining ring 16 is formed between the inner cylinder 17 and the outer cylinder 15, and a material drying channel is formed in the gap between the retaining ring 16. 3. There are annular t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com