Burner capable of producing multiple burning working condition characteristics

A technology of combustion conditions and burners, which is applied in the combustion of lump fuel and liquid fuel, the combustion of lump fuel and gaseous fuel, the combustion of lump fuel and powder fuel, etc., which can solve the problem of incomplete cure. Greenhouse gas emissions, difficult to change the global greenhouse effect, low utilization rate, etc., to achieve the effect of saving high temperature heat energy loss, accelerating the mitigation of greenhouse gases, and cleaning the combustion power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

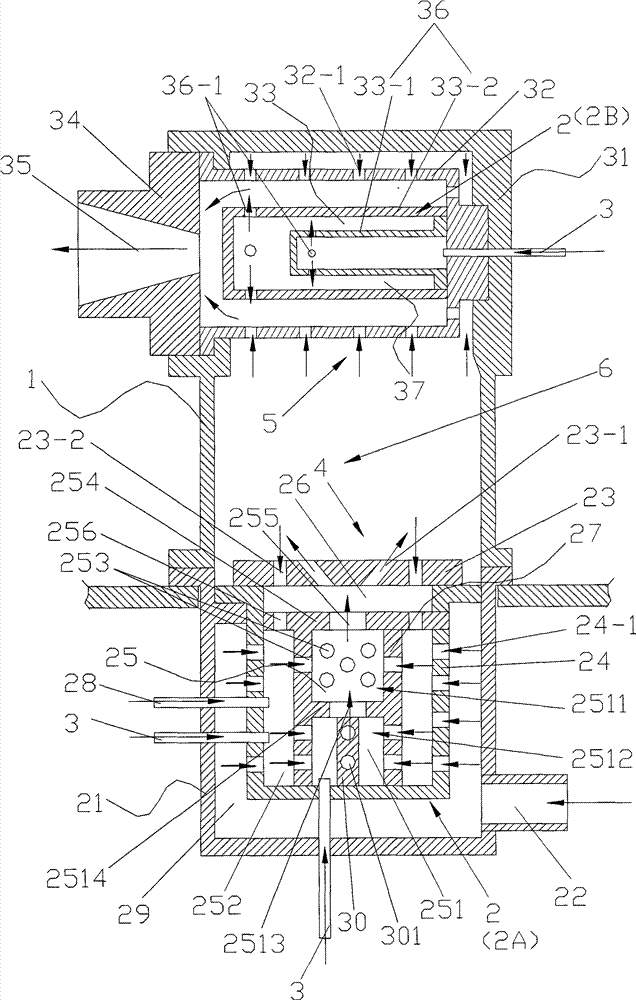

[0026] like figure 1 The illustrated burner capable of generating multiple combustion conditions includes a casing 1 on which two burners 2 are mounted. The two burners 2 are respectively installed above and below the housing 1 (in order to better distinguish the two burners 2, the burner installed below the housing 1 is the burner 2A, and the burner installed above the housing 1 is the burner 2B, see the accompanying drawings).

[0027] The burner 2A includes a furnace body 21 installed on the shell 1, an air input hole 22 is arranged below the furnace body 21, and a sealing plate 23 with a flame hole 23-1 is arranged on the furnace body 21 , the flame hole 23-1 is a plurality of through holes distributed along the central axis of the sealing plate 23 at an oblique angle of 35-65°. Furnace body one 21 is provided with the furnace one 24 that sidewall is distributed with several ventilation holes 24-1, and a catalytic converter 25 is arranged in the furnace one 24, and this ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com