Patents

Literature

32results about How to "Increase combustion power" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

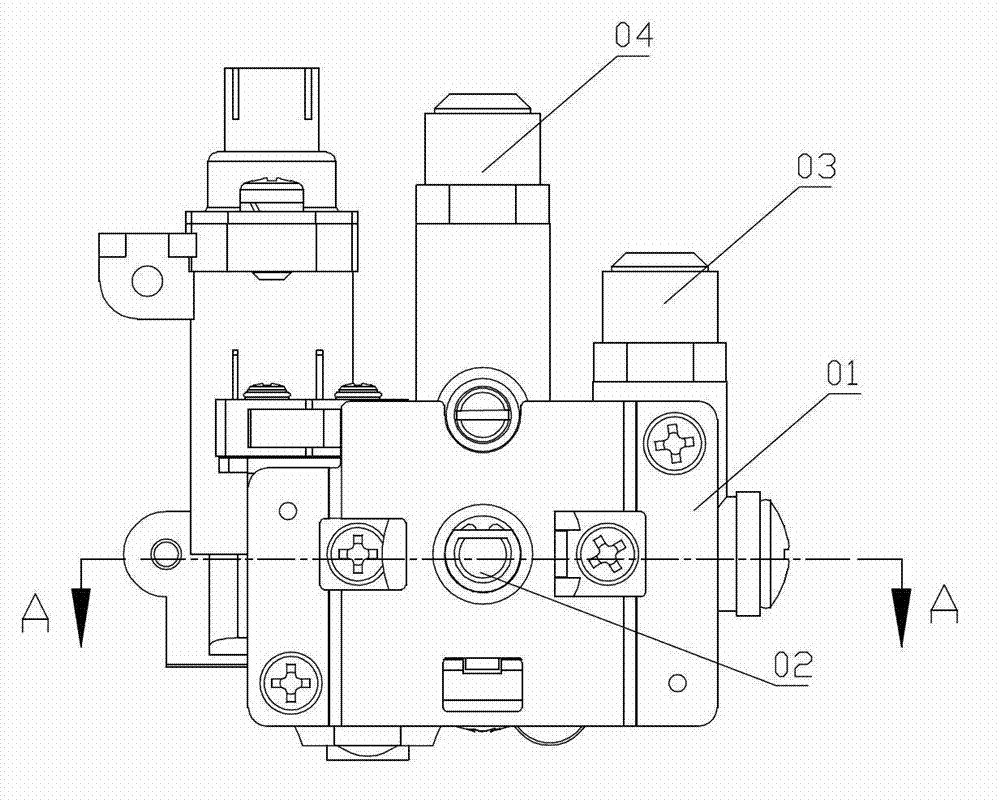

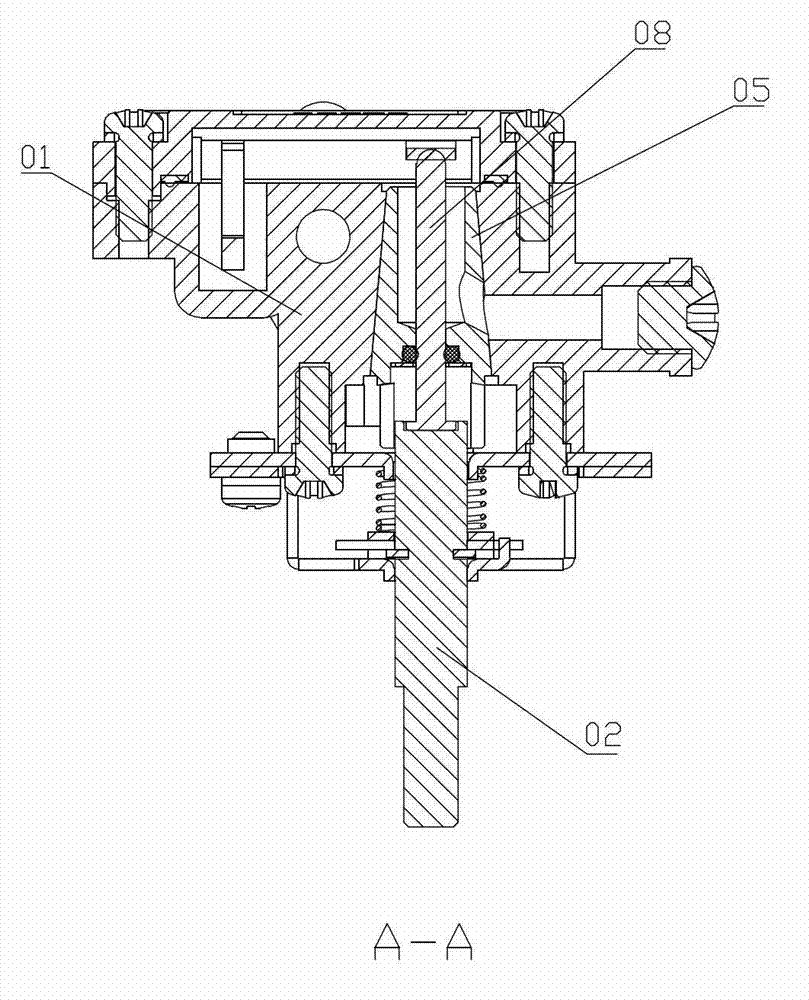

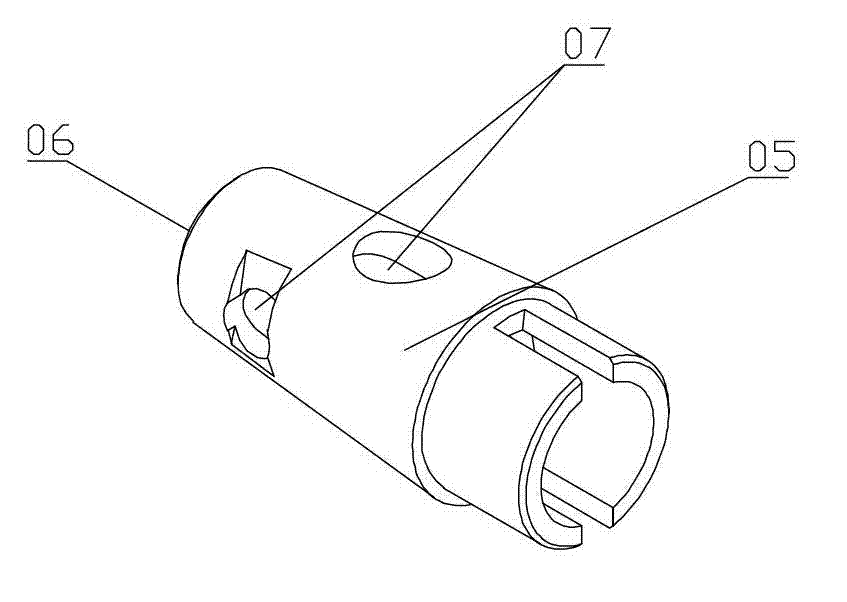

Plug valve assembly for embedded gas stove

ActiveCN102966761AThere will be no hidden dangers of lax closureElimination of hidden dangers of lax closureMultiple way valvesPlug valveEngineering

The invention relates to a plug valve assembly for an embedded gas stove. The plug valve assembly comprises a valve body, a knob, a first trigger block, a first detection component, a gas feeding port, a gas discharging port and a valve core; wherein the valve core is arranged between the gas feeding port and the gas discharging port, the knob is connected with the valve core in a rotating way, the valve core is cylindrical or conical and is provided with a gas feeding hole and a gas discharging hole, and a cavity is arranged in the valve core; the first trigger block is arranged on the knob, and the first detection component is used for detecting the state of the first trigger block; and the gas discharging port comprises a first gas discharging port and a second gas discharging port. The plug valve assembly is characterized by also comprising a second trigger block and a second detection component, an included angle is formed by the second trigger block and the first trigger block, the second detection component is used for detecting the state of the second trigger block, and the gas feeding hole and the gas discharging hole of the valve core are arranged on the sidewall of the valve core. The plug valve assembly for the embedded gas stove has the advantages that hidden risks of non-tight closing of the valve core can be eliminated, and control signals can be sent more intelligently to an electrical device connected with the plug valve assembly.

Owner:浙江博顿燃具科技有限公司

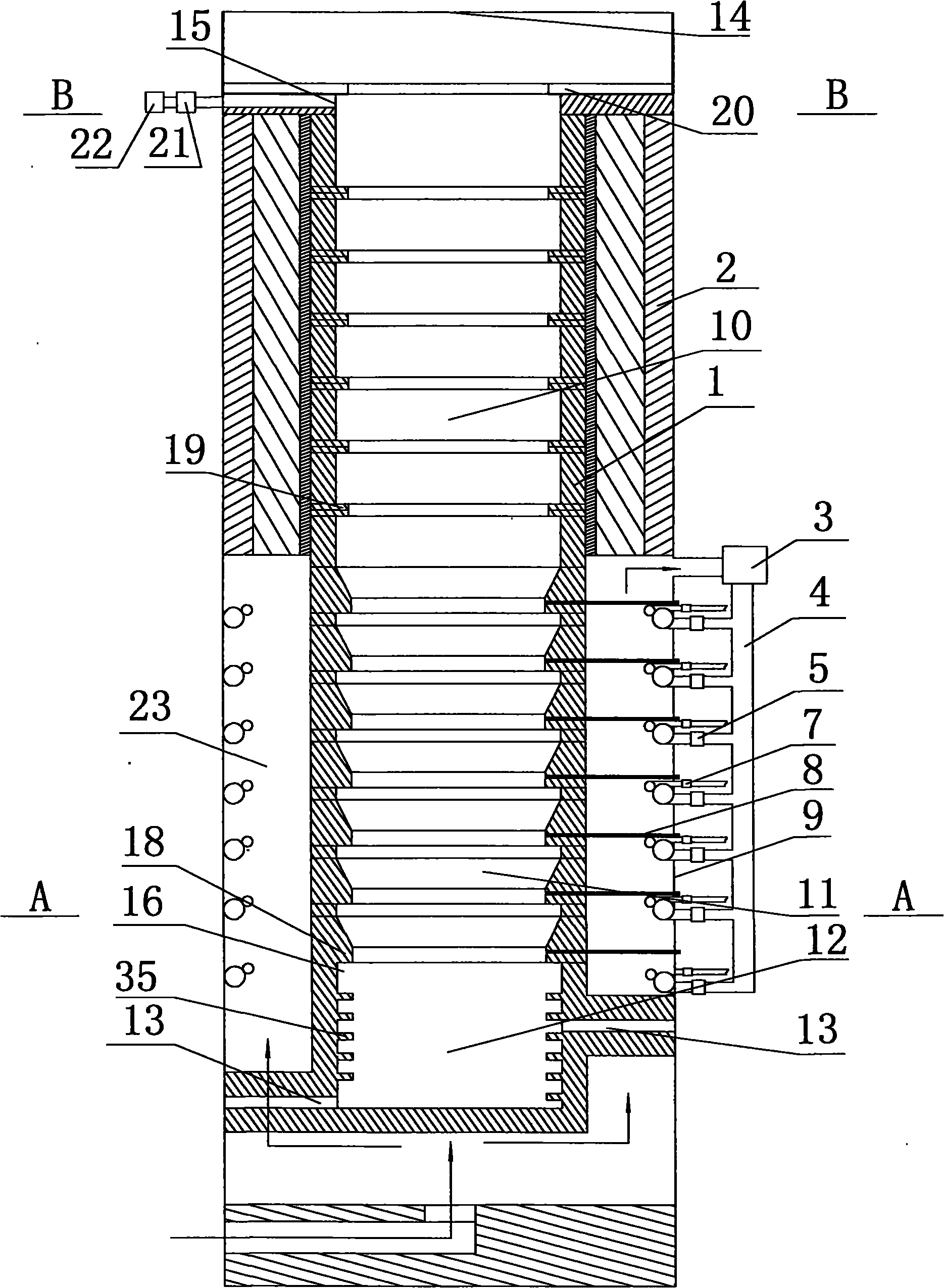

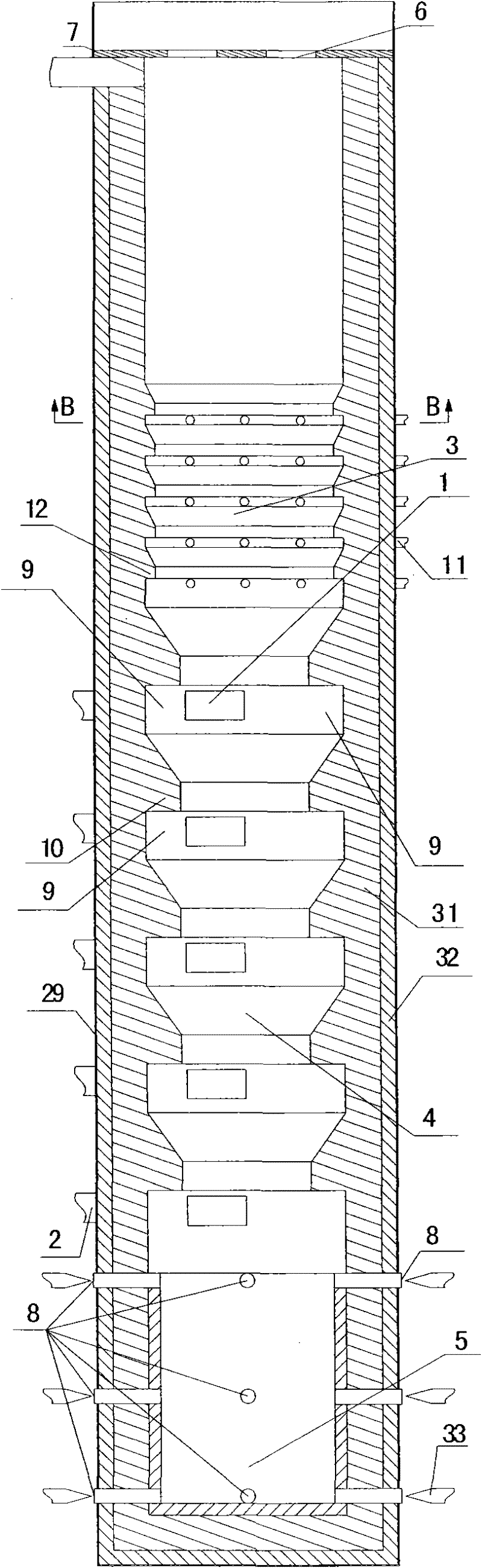

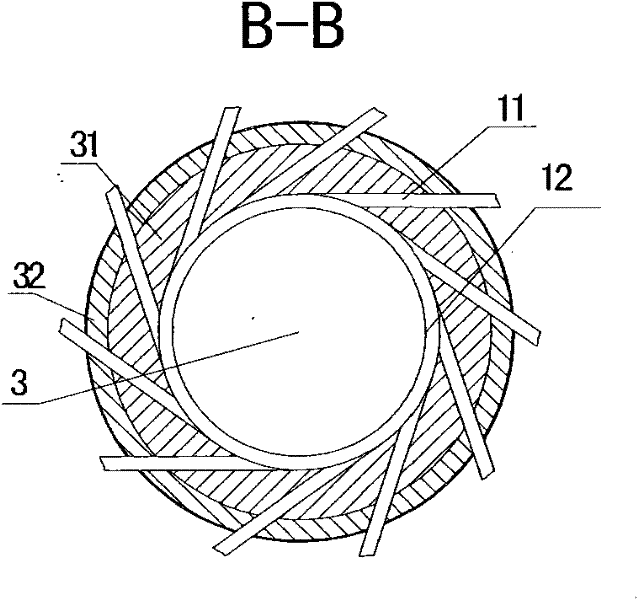

Smelting furnace

InactiveCN102121788AReduce pollutionReduce wasteVertical furnacesCeramic materials productionSteelmakingInlet channel

The invention provides a smelting furnace. The smelting furnace comprises refractory materials, heat insulating materials, a blower, a pipeline, valves, ignition devices, fuel supply devices and temperature measuring devices. The smelting furnace is characterized in that a furnace chamber is provided with a heating chamber and a smelting chamber; the lower part of the heating chamber is communicated with the smelting chamber; the lower part of the smelting chamber is provided with a hearth; the hearth is provided with hearth discharge holes; the upper part of the heating chamber is provided with a heating chamber feeding hole and a heating chamber gas outlet; at least a flame path is arranged around the inner wall of the smelting chamber; at least an inlet channel is arranged on the side walls of the flame paths; and the inlet channels are communicated with the flame paths. The smelting furnace is energy-saving and environment-friendly, can be used for smelting various metals and alloys, can be used for smelting aluminium by a fire method and can be used for refining aluminium alloys. The smelting furnace can adopt any mineral for smelting, can realize carbothermal reduction of any metallic oxide and can smelt alloys even with soil or garbage, so the smelting furnace can turn stone and soil into gold and is true alchemy. The smelting furnace dispenses with cokes and synchronously completes ironmaking and steelmaking. The heat generated through steelmaking is fully utilized and the waste gases are unitedly treated. The smelting furnace can be used for producing glass, ceramic frits, sodium silicate and the like. The smelting furnace can adopt various materials, can refine precious elements, does not produce slag and can bring metallurgy revolution.

Owner:陈久斌

Alcohol-based fuel intelligent oven

PendingCN108180512AHigh energy consumptionSpeed up the flowDomestic stoves or rangesLiquid heating fuelElectricityAlcohol

The invention discloses an alcohol-based fuel intelligent oven. The alcohol-based fuel intelligent oven comprises an oven body, an oven core, a battery, a fan, a minitype fuel pump, a delay igniter, astove probe, a control panel, a controller and a supporting component; an opening in the oven body is communicated with a hollow structure in the oven body; the oven core, the battery, the fan, the minitype fuel pump and the delay igniter are fixedly connected with the interior of the oven body; an air outlet of the fan is communicated with the oven core; one end of the minitype fuel pump is communicated with a hose and the other end of the minitype fuel pump is communicated with the interior of the oven core; an ignition needle of the delay igniter and the stove probe are fixedly connected with the interior of the oven core; the control panel is fixedly connected with the outer side of the side wall of the oven body; the controller which is electrically connected with the fan, the minitype fuel pump, the delay igniter and the stove probe is arranged on the control panel; the controller is electrically connected with the battery; the supporting component is arranged on the outer sideof the top of the oven body. The alcohol-based fuel intelligent oven has the following advantages: liquid alcohol-based fuel can be directly combusted and the alcohol-based fuel does not need to be subjected to gasification treatment in advance, so that the production cost can be reduced and the potential safety hazard also can be reduced.

Owner:重庆希元盛节能科技有限公司

U-shaped high-temperature waste recycling furnace

The invention relates to the field of waste treatment, and provides a U-shaped high-temperature waste recycling furnace, which has the advantages of high treating capacity, environmental friendliness, economic efficiency, high metal recovering rate and high waste suitability. The U-shaped high-temperature waste recycling furnace comprises a vertical combustion tower, a horizontal smelting pond and a vertical disinfecting tower, wherein the top wall of one end of the smelting pond is provided with a first smelting pond inlet hole; the end wall of the smelting pond is provided with a second smelting pond inlet hole; the top wall of the other end of the smelting pond is provided with a smelting pond outlet hole; the top wall of the combustion tower is provided with a combustion tower inlet hole; the bottom wall of the combustion tower is provided with a combustion tower outlet hole; the bottom wall of the disinfection tower is provided with a disinfection tower inlet hole; the top end of the disinfection tower is provided with a smoke outlet; a first turbulent burner is arranged in the combustion tower inlet hole; the combustion tower outlet hole is in butt joint with the first smelting pond inlet hole; the smelting pond outlet hole is in butt joint with the disinfection tower inlet hole; and the side wall of the disinfection tower is provided with at least two air inlet holes. Due to the adoption of the U-shaped high-temperature waste recycling furnace, the problems of poor working condition stability during combustion of wastes and discharge of toxic gases in tail gas out of the standard are solved.

Owner:ZHEJIANG HUANYI TECH

Smelting furnace

InactiveCN101922861ATake advantage ofAvoid ironVertical furnacesCeramic materials productionSteelmakingThermal insulation

The invention relates to a smelting furnace comprising refractories, thermal insulation materials, a fan, a pipeline, a valve, an ignition hole, a fuel supply device and a temperature measurement device. A furnace chamber is provided with a heating chamber and a smelting chamber; the lower part of the heating chamber is communicated with the smelting chamber; the lower part of the smelting chamber is provided with a hearth; the hearth is provided with a hearth discharge hole; the upper part of the heating chamber is provided with a heating chamber feeding hole; the upper part of the heating chamber is provided with a heating chamber gas outlet; a plurality of flame paths are arranged around the inner wall of the smelting chamber; the side walls of the flame paths are provided with a plurality of inlet channels; and the inlet channels are communicated with the fire paths. The invention saves energy and protects the environment, does not need coke when in ironmaking, can use various fuels and raw coal, synchronously completes ironmaking and steelmaking without disposing steel slag, sufficiently utilizes the heat generated by the steelmaking, carries out uniform treatment on waste gas, can be used for directly carrying out ironmaking, iron casting, steelmaking and steel casting by using ore and the like, can be used for producing glass, ceramic frits, sodium silicate and the like, can use various materials, such as the ores, mineral powder and the like, can synchronously extract noble elements, can realize refining and can bring material revolution.

Owner:陈久斌

Smelting furnace

InactiveCN101749931AAchieve synchronous completionOne-gas synthesisCeramic materials productionVertical furnacesSteelmakingFrit

The invention relates to a smelting furnace, comprising a furnace chamber, fire-resistant materials, insulation materials, a fan, channels, an ignition device, a fuel supply device and a discharging device. At least one air inlet is arranged on the side wall of the furnace chamber, at least one air inlet passage is connected with the air inlet, and the air inlet passage is connected with the fan; the side wall of the furnace chamber is provided with a plurality of fire paths, and the air inlet is communicated with the fire paths; the furnace chamber is provided with a heating chamber and a smelting chamber, wherein the lower part of the heating chamber is communicated with the smelting chamber, the lower part of the smelting chamber is provided with a hearth, at least one feeding inlet of the heating chamber is arranged on the upper part of the heating chamber, and at least one air outlet is arranged on the upper part of the heating chamber; at least one discharge port of the hearth is formed in the hearth; and the discharge port of a smelting tank is provided with the discharging device. The invention is characterized in that a plurality of fuels and raw coal can be used in the smelting furnace; smelting iron and smelting steel can be synchronously completed; steel slag is no needed to be removed; the heat produced by smelting steel is fully utilized, waste gases are uniformly treated; smelting iron, casting iron, smelting steel and casting steel can be directly carried out by using ores and the like; glasses, ceramic clinker, sodium silicate and the like can be produced in the smelting furnace; and noble elements can be refined, refining can be achieved and the revolution of materials is brought out. The invention has the advantages of saving energy, protecting environment and smelting iron without coke.

Owner:陈久斌

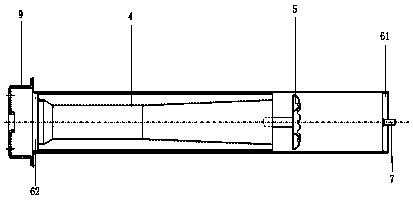

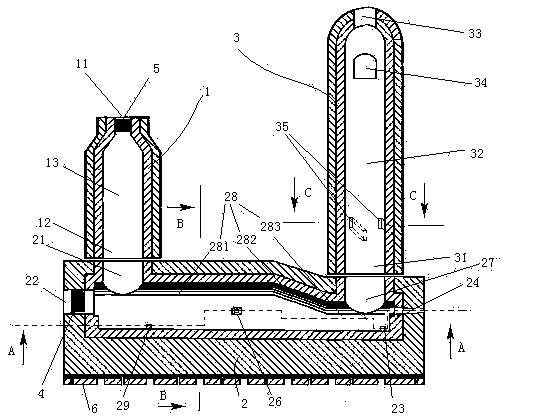

Electronic vaporizing combustion equipment based on alcohol-based liquid fuel

InactiveCN108592021AUniform gasificationFaster preheating and vaporizationBurnersDomestic stoves or rangesAlcoholSpray nozzle

The invention provides electronic vaporizing combustion equipment based on alcohol-based liquid fuel. The electronic vaporizing combustion equipment based on alcohol-based liquid fuel comprises a spray nozzle, a spark electrode arranged nearby the spray nozzle, a cover arranged on the peripheries of the spray nozzle and the spark electrode in a sleeving manner, a vaporizing channel arranged in a cover body, an electric heating device, a circuit control device and a burner body connected to the spray nozzle, wherein the burner body may comprise a first fire spraying hole formed in a spherical burning head, and may further comprise a second fire spraying hole formed in a T-shaped burning disc; gases and air are mixed very well through the two fire spraying holes and the combination of the spherical burning head and an air mixing cavity, so that the full burning of the alcohol-based liquid fuel is facilitated, and the burning efficiency is relatively high; and as the diameters of the firespraying holes are relatively large, the power of a burner is relatively high. Meanwhile, the power of the burner can be further improved by additionally arranging the T-shaped burning disc above thespherical burning head and the air mixing cavity or by additionally arranging an air channel matched with a draught fan.

Owner:万专知识产权运营有限公司

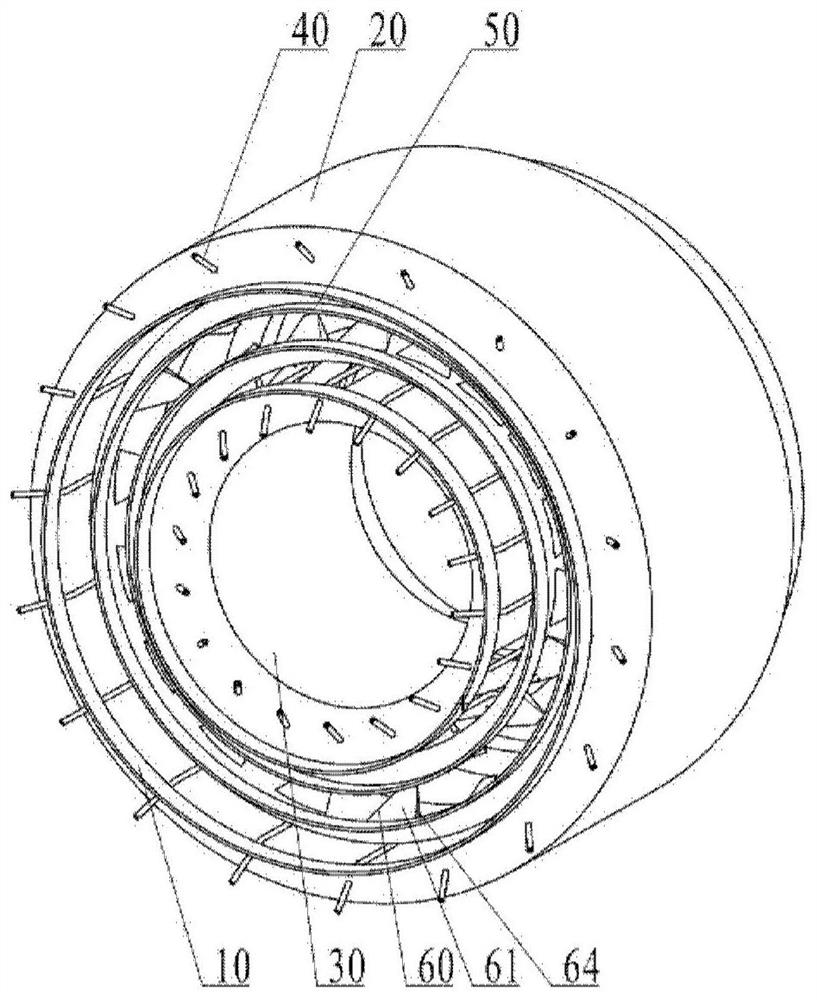

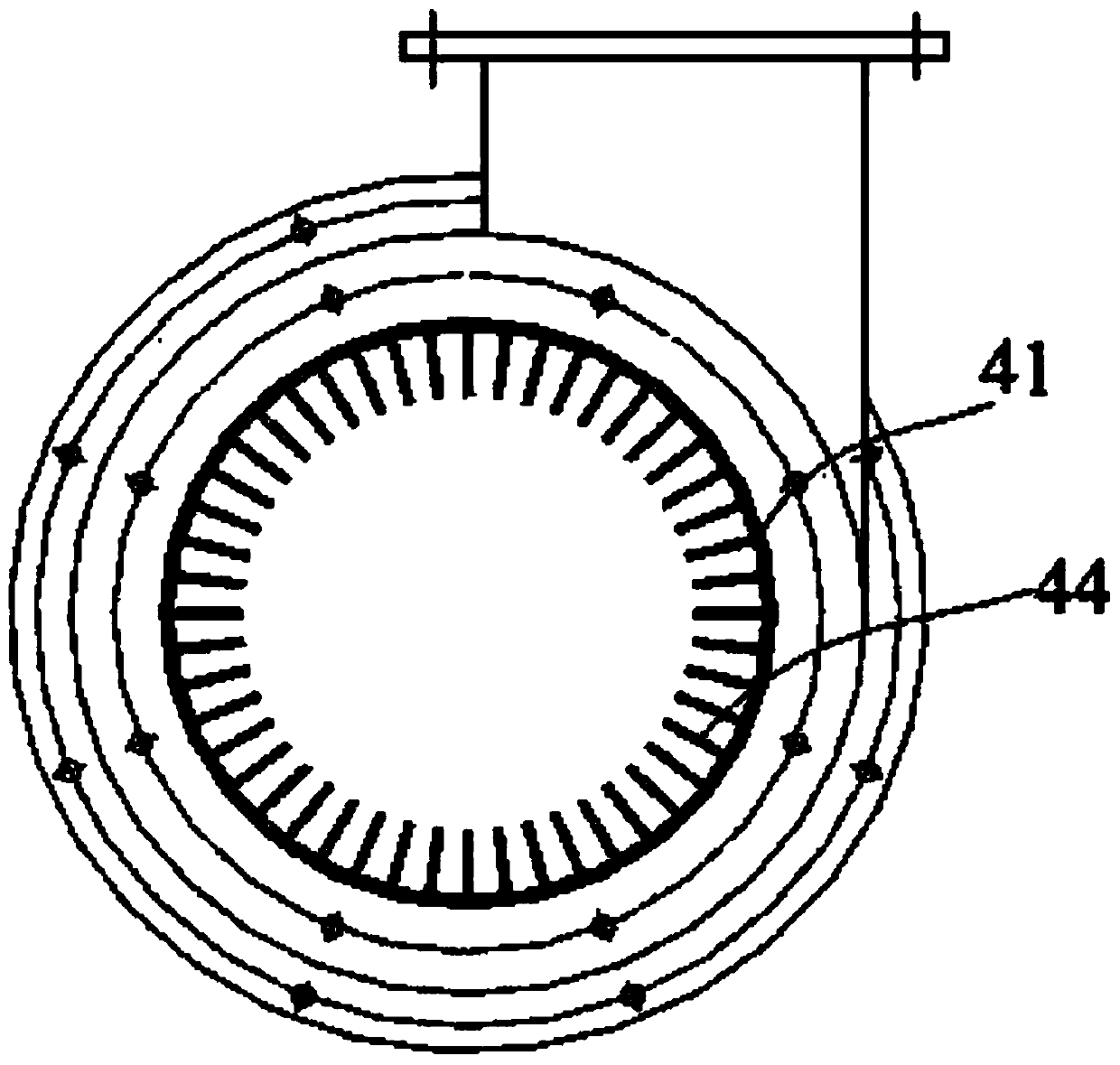

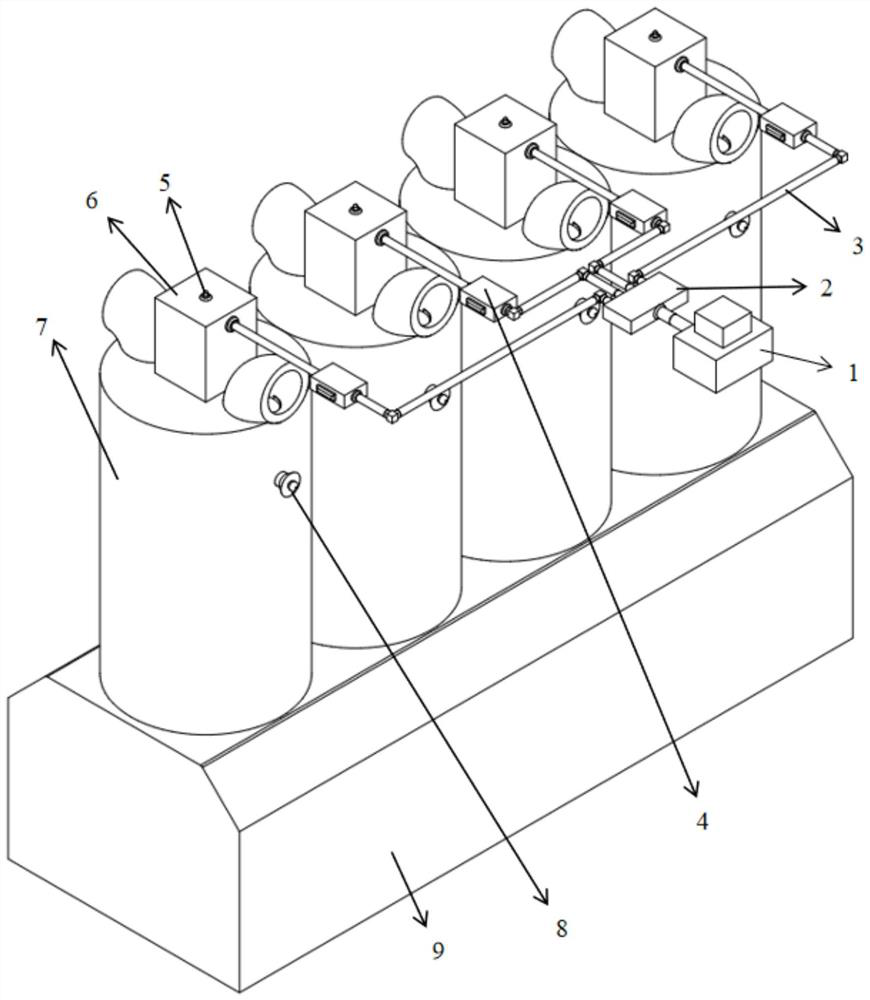

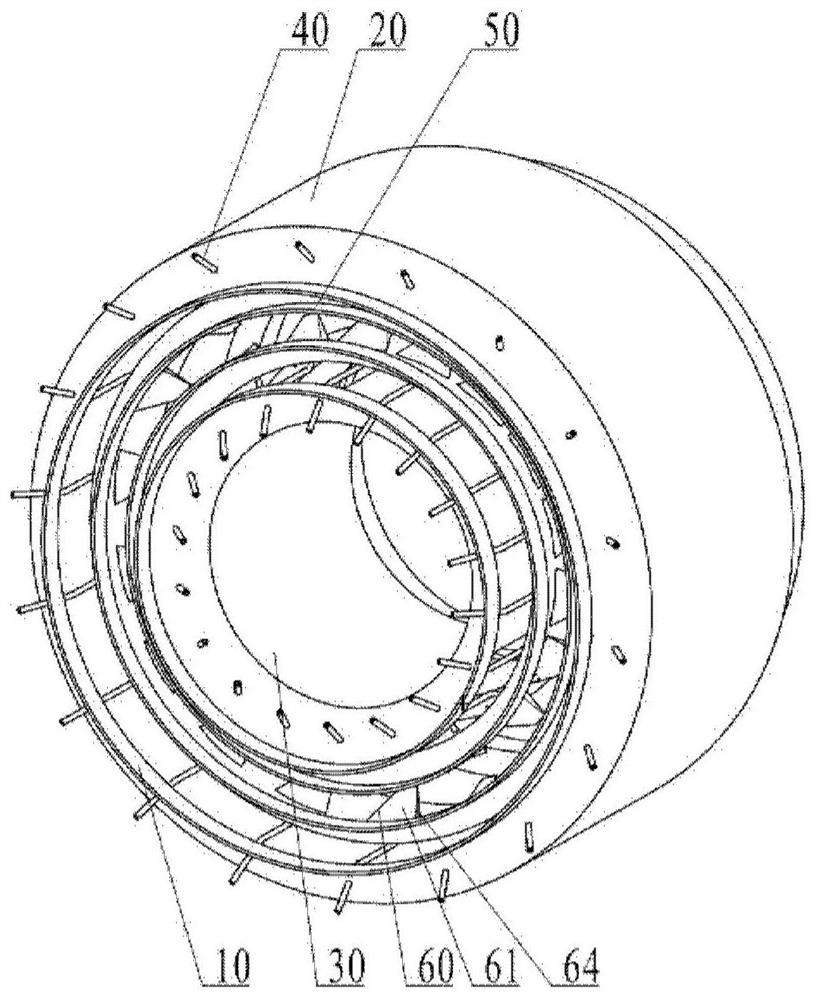

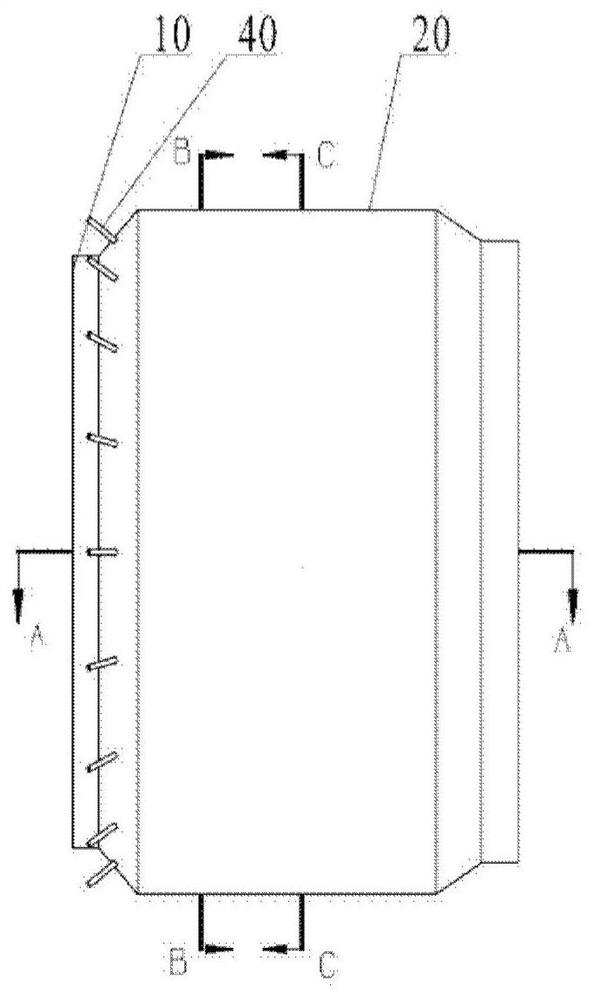

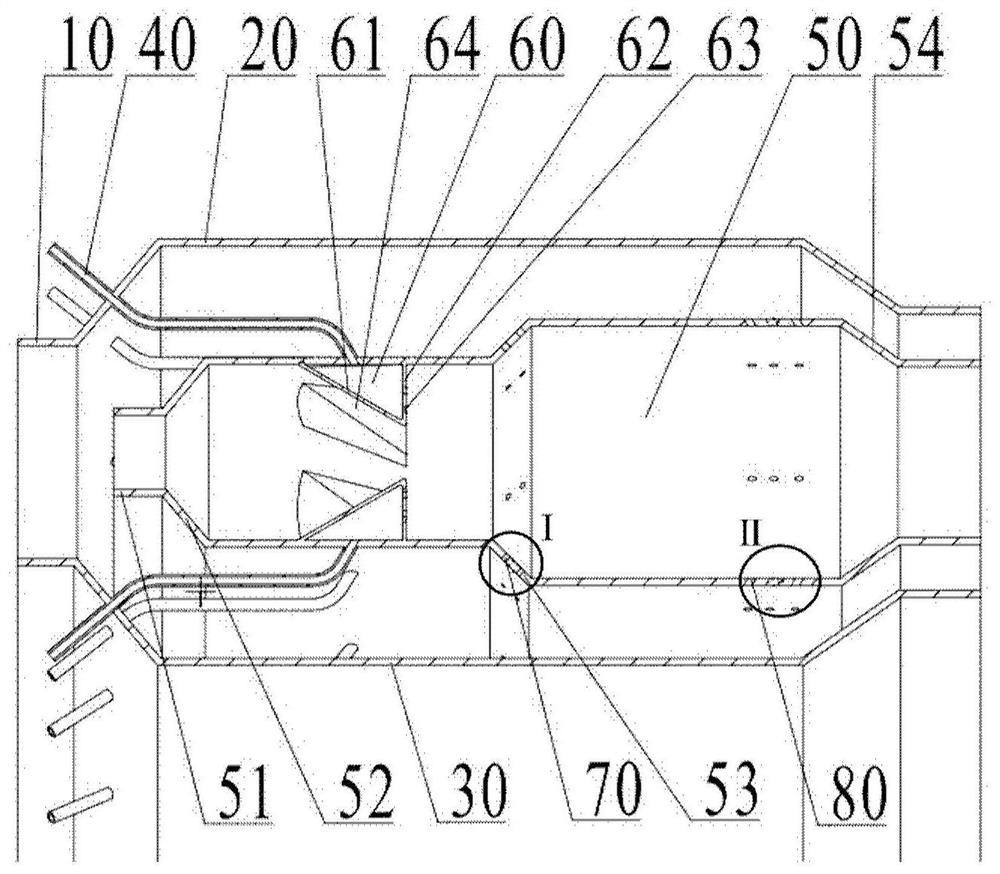

Hydrogen combustion chamber based on axial vortex opposite arrangement mixing

ActiveCN113137631AEfficient combustionOvercome temperingContinuous combustion chamberIndirect carbon-dioxide mitigationCombustion chamberEngineering

The invention provides a hydrogen combustion chamber based on axial vortex opposite arrangement mixing. The hydrogen combustion chamber comprises a flame tube which comprises an outer ring and an inner ring, an outer casing, an inner casing and at least two axial vortex generators; an air circulation outer channel is defined by the outer casing and the outer ring of the flame tube; the inner casing is fixedly connected inside the outer casing, and an air circulation inner channel is defined by the inner casing and the inner ring of the flame tube; each axial vortex generator is a tetrahedral cavity; the axial vortex generators are fixedly connected to the outer ring and the inner ring of the flame tube respectively and are suitable for providing axial vortexes to enable fuel to be mixed and combusted. According to the hydrogen combustion chamber based on axial vortex opposite arrangement mixing, the design scheme that the axial vortexes and tiny tangential jet flow are combined is provided, the axial vortexes are generated by the tetrahedral structures for mixing, compared with a combustion chamber adopting a swirler, the hydrogen combustion chamber has the advantages that no backflow area and no low-speed area exist, pure hydrogen can be effectively combusted, and the problems of tempering, self-ignition and unstable combustion are solved.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

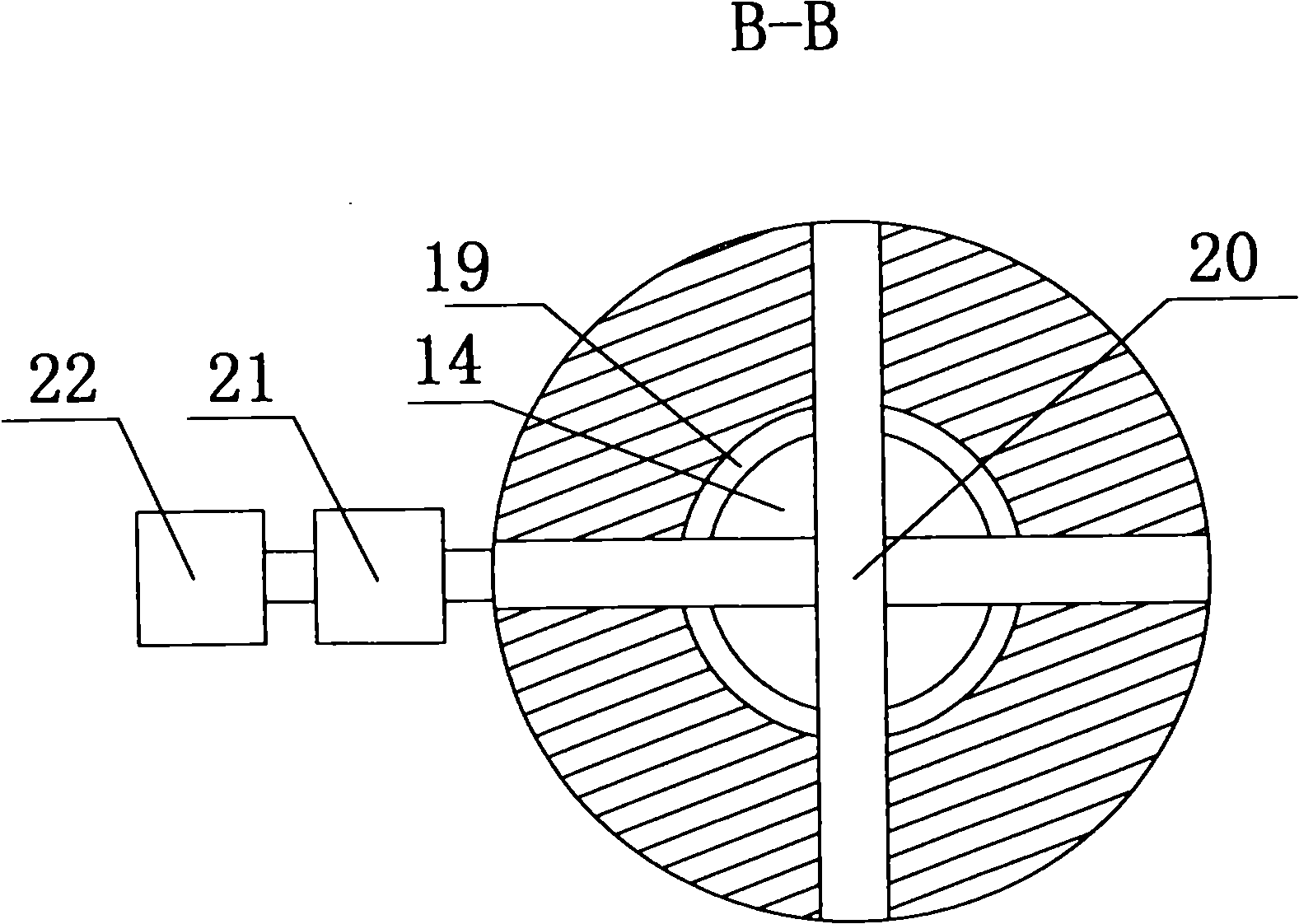

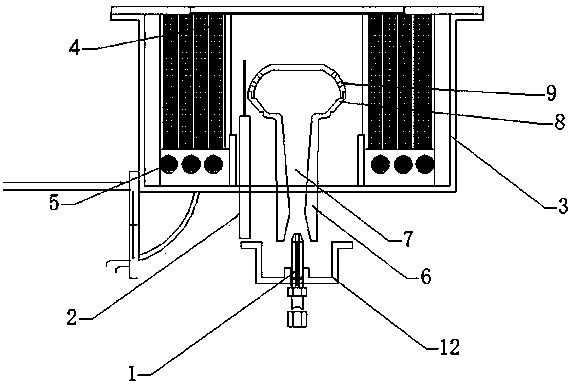

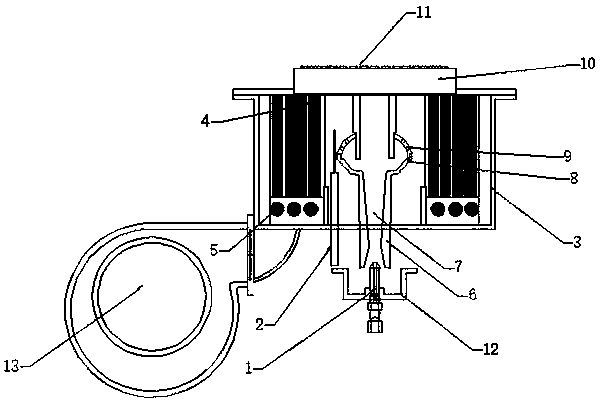

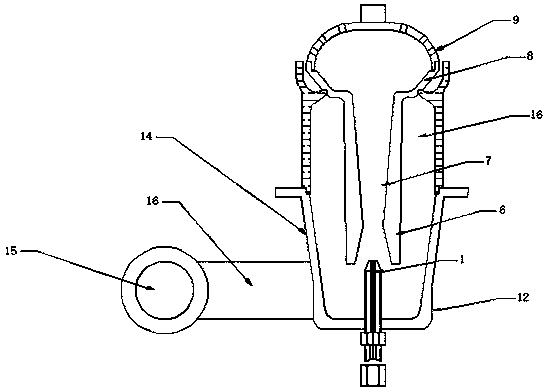

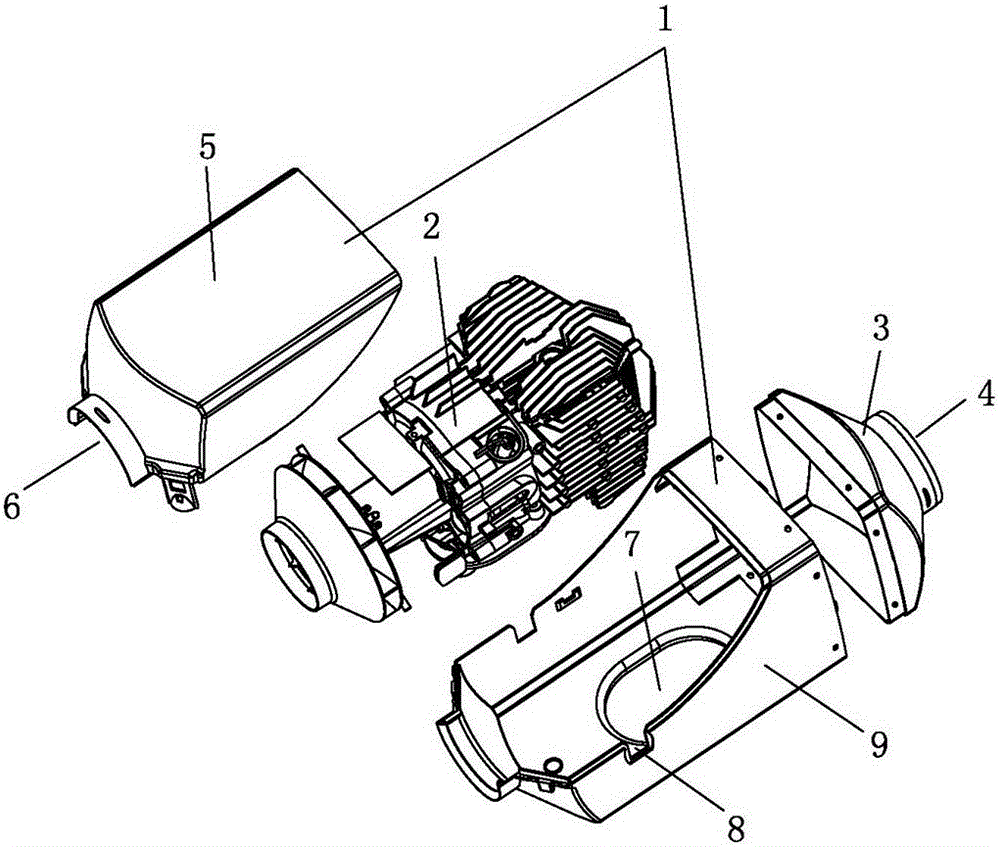

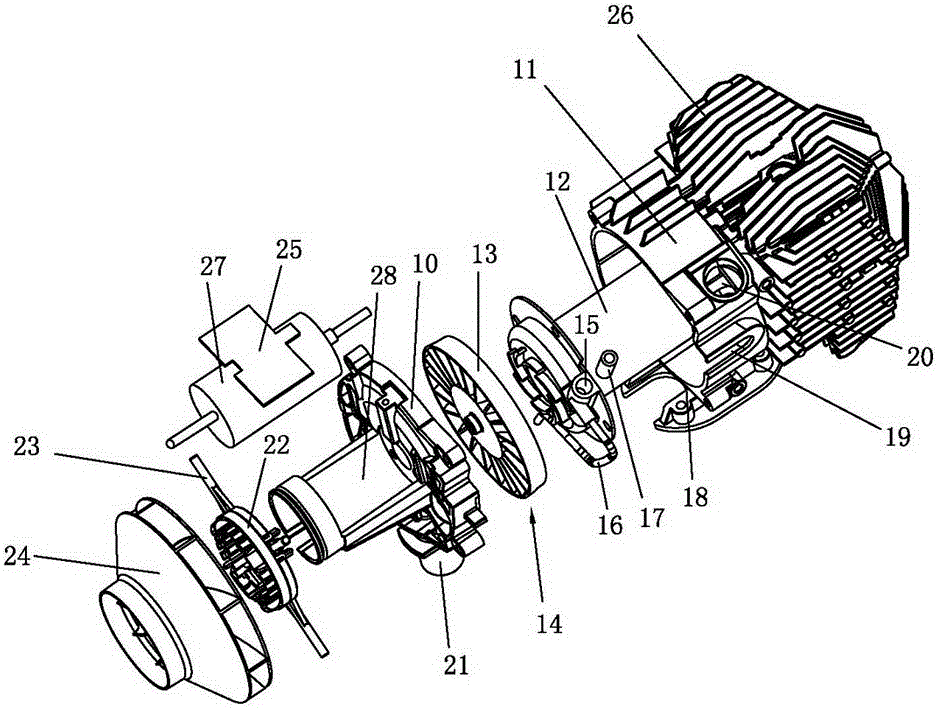

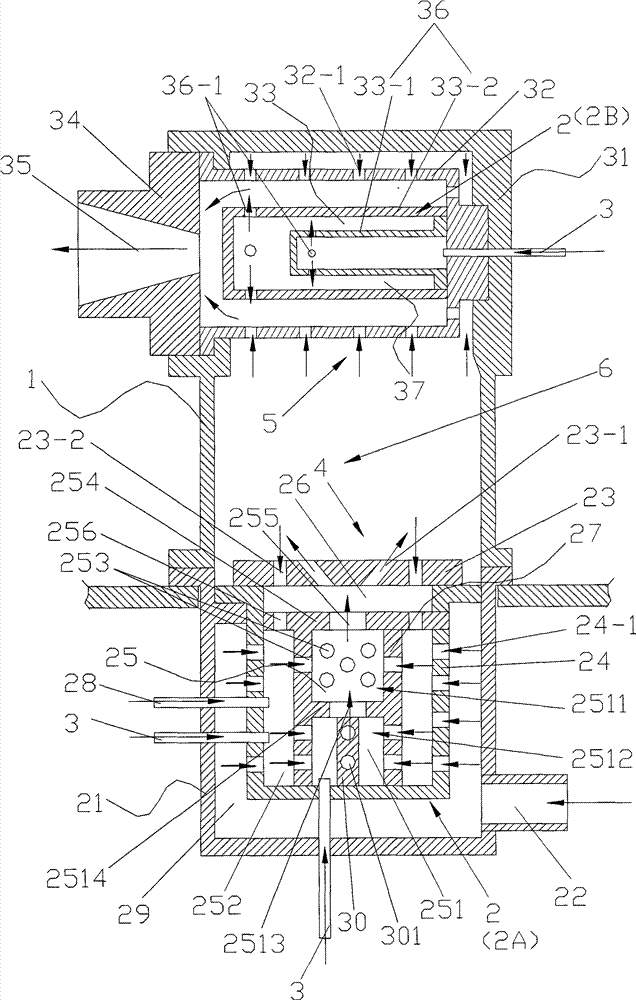

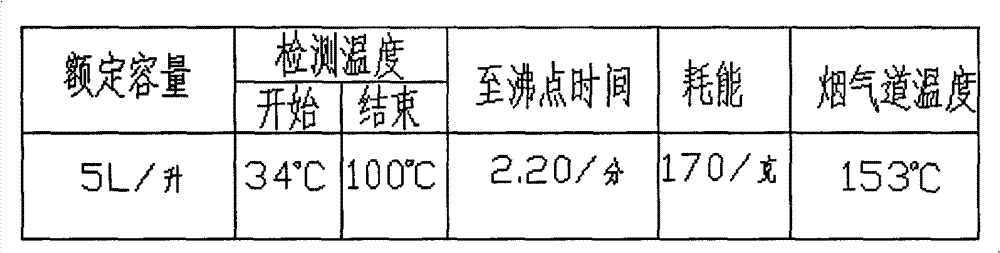

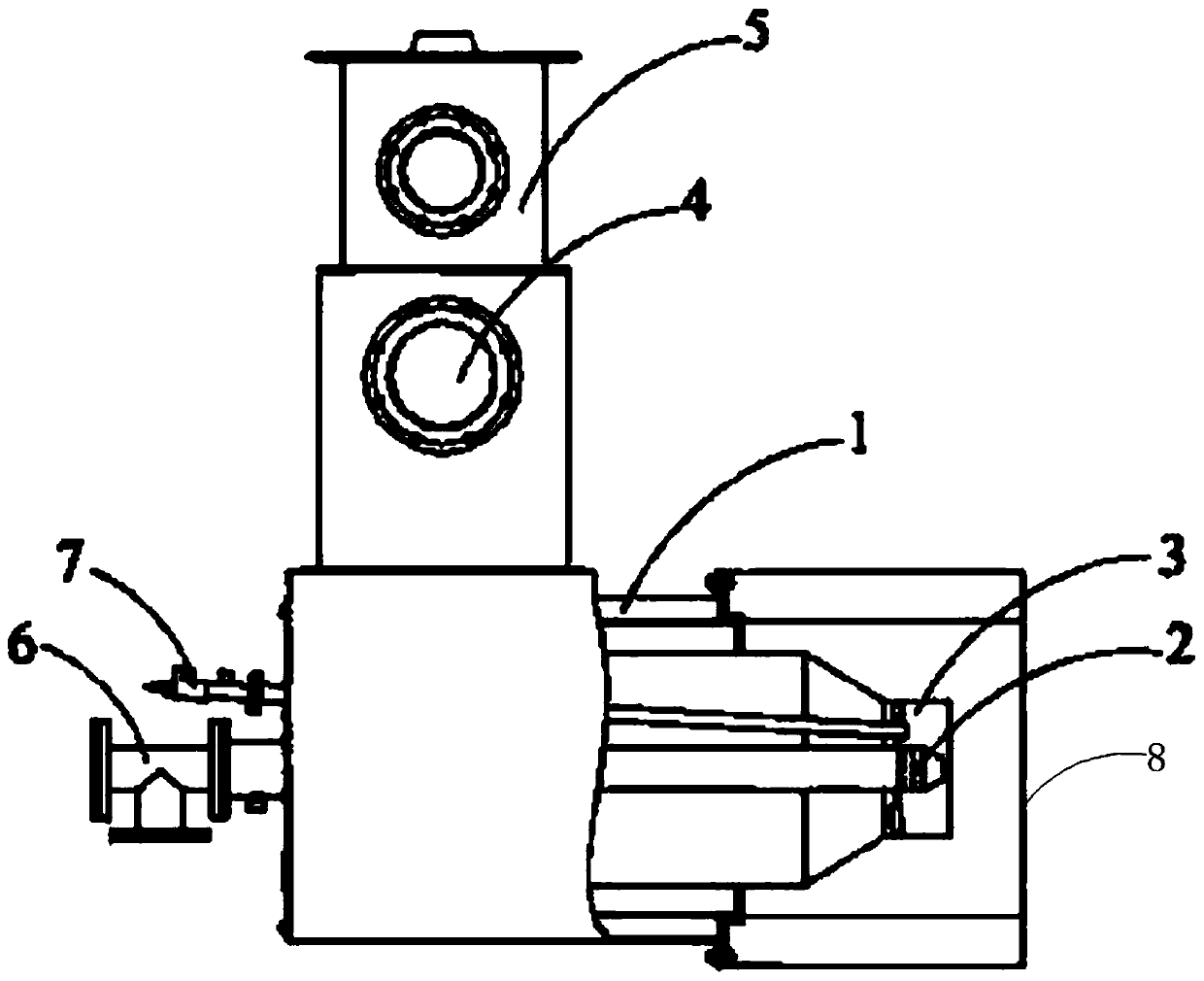

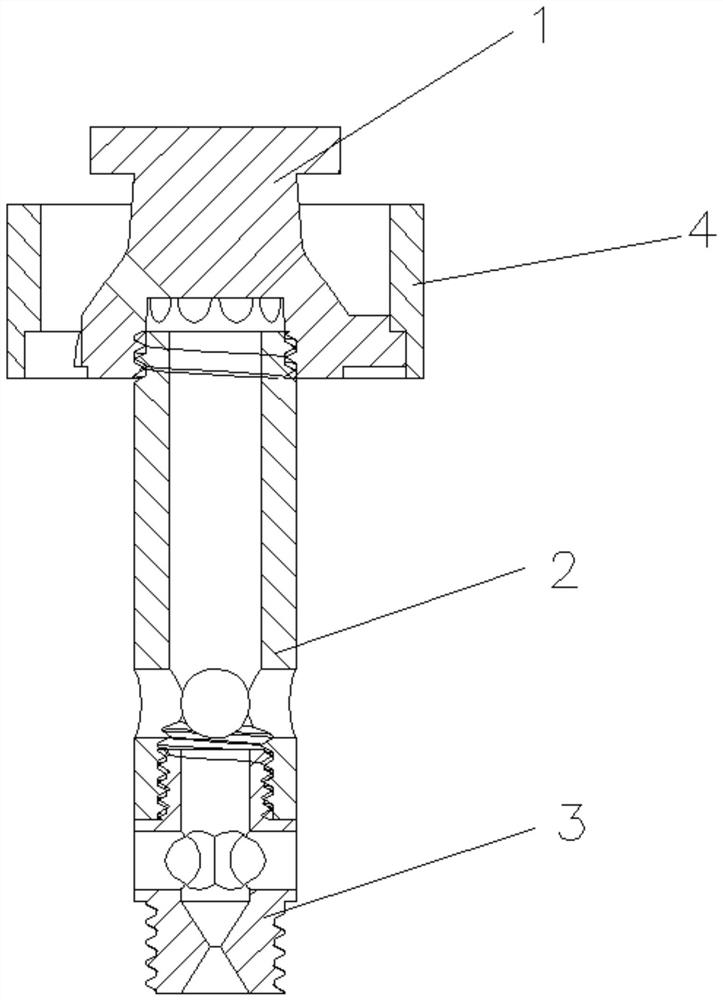

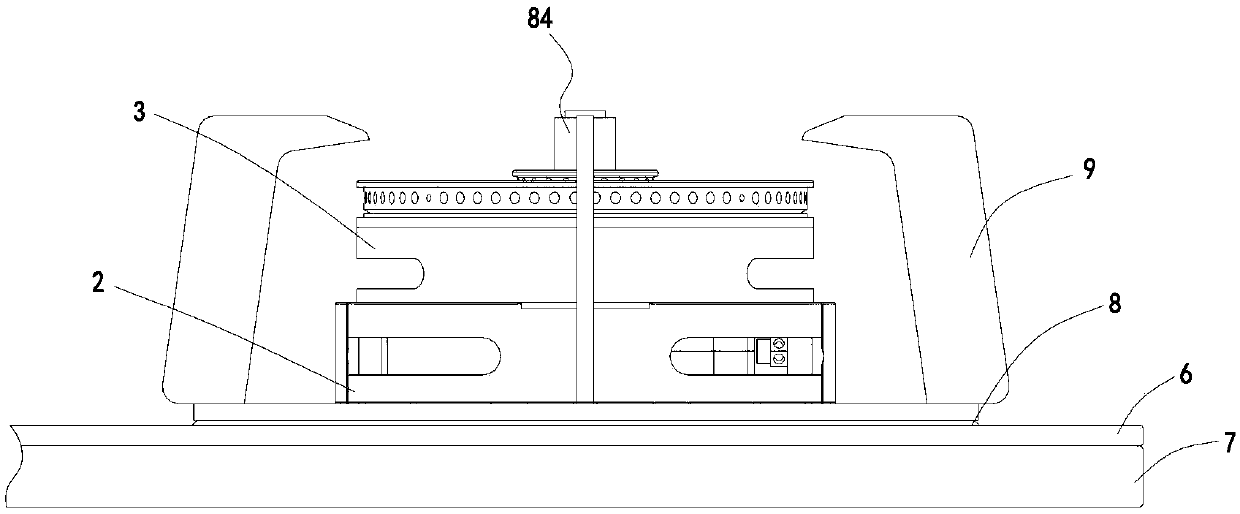

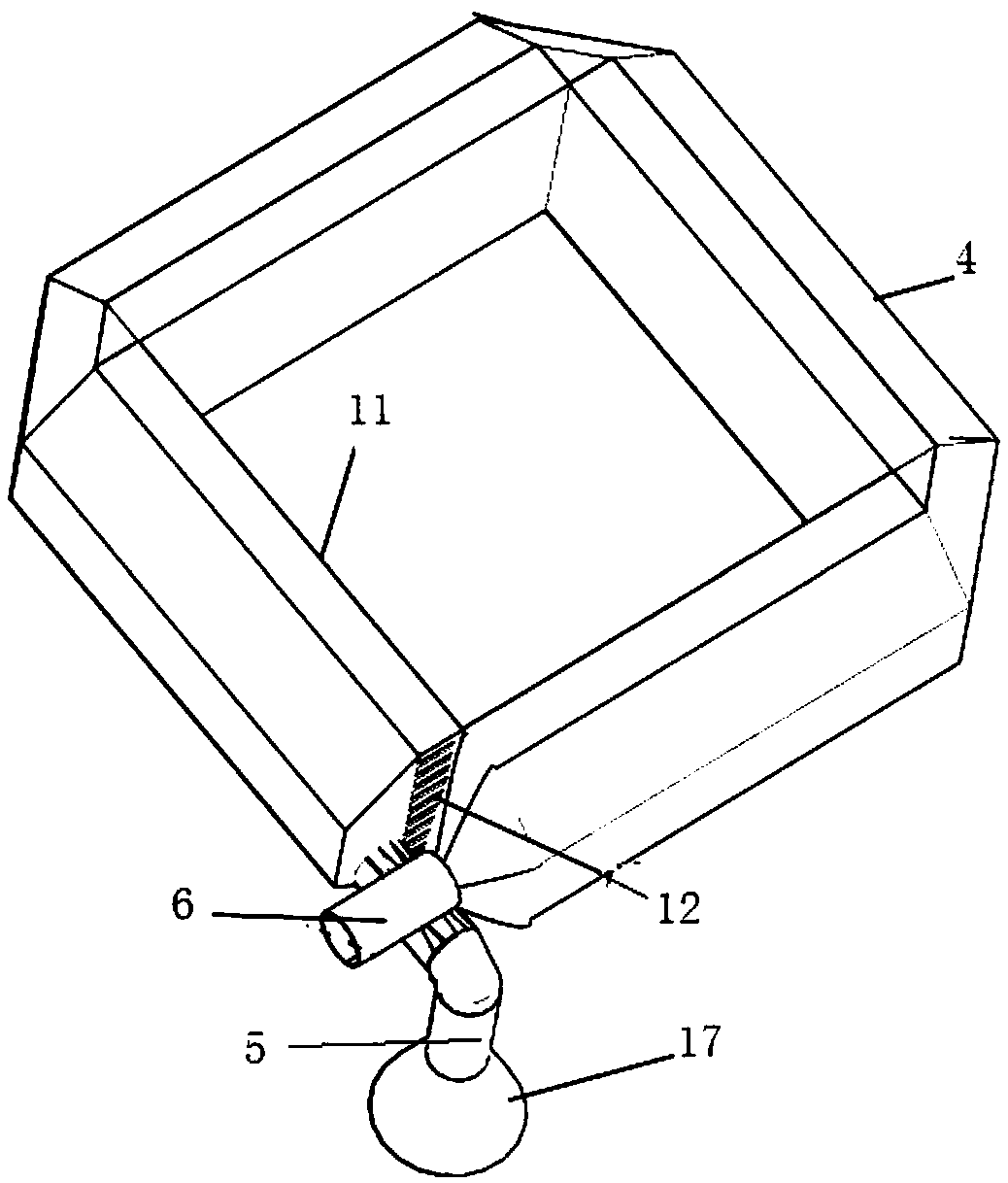

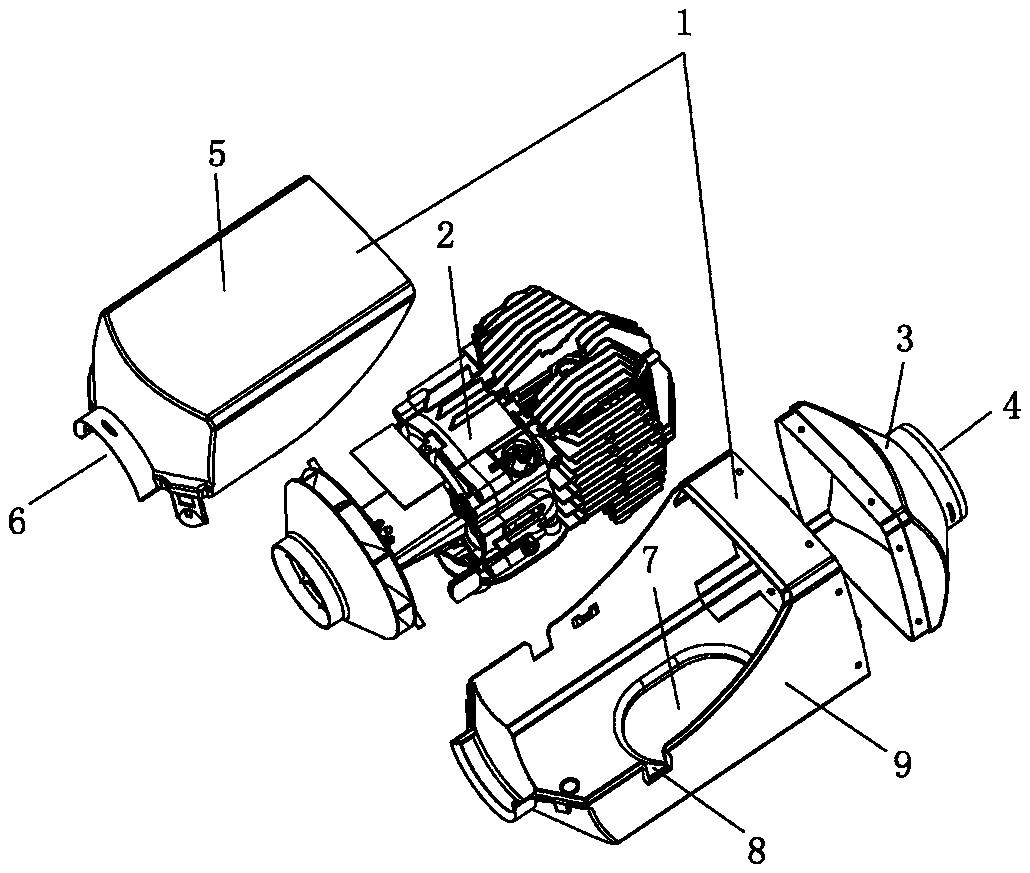

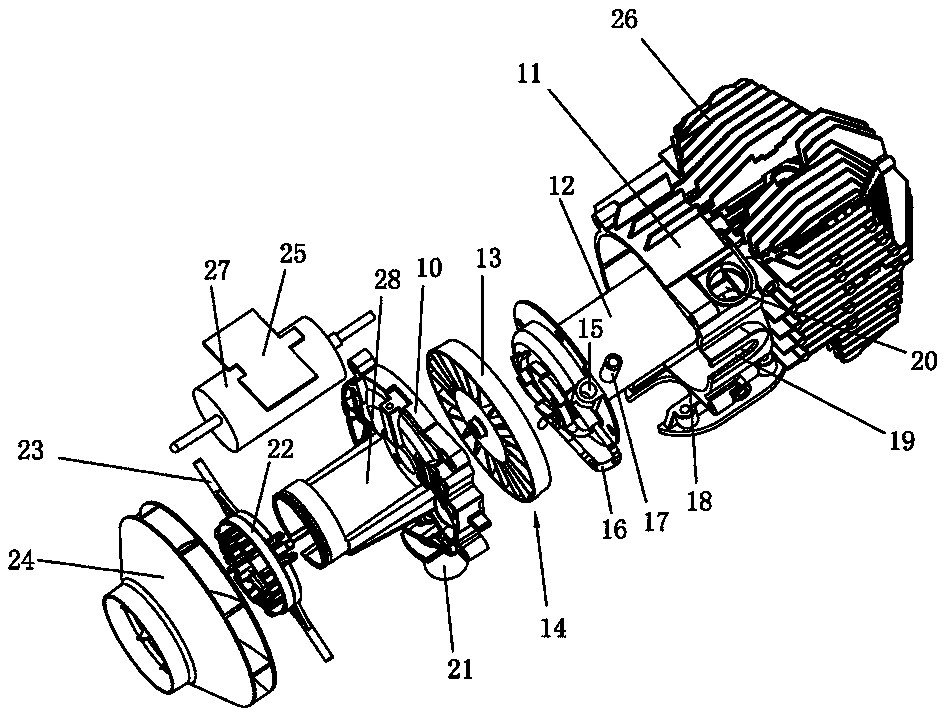

Fuel heater

InactiveCN105003366AFast ignitionIncrease heatMachines/enginesThermal treatment of fuelThermodynamicsElectric machine

The invention relates to a fuel heater which comprises a ventilator box body and a heating device assembly, wherein the heating device assembly comprises a motor mounting frame; a motor is arranged in the motor mounting frame; a flange plate is arranged at the right end of the motor mounting frame; a heat dissipation hood is in screwed connection with the right end of the flange plate; a heating tube is arranged in the heat dissipation hood; an atomizing chamber is formed after the left end of the heating tube is in sealed and screwed connection with the middle part of the flange plate; an atomizing fan is arranged in the atomizing chamber; an ignition hole is formed in the left end of the heating tube; an oil inlet tube is arranged in the middle of the ignition hole; an air inlet fan is arranged at the left part of the motor mounting frame, namely an air inlet hole; through rapid atomizing ignition of diesel oil in the atomizing chamber, heat is supplied to the heating rube, dissipated by the heat dissipation hood to the interior of the ventilator box body, and pushed by the air inlet fan in the air inlet hole out of an air outlet, so that the advantages of high power, low noise, low oil consumption and high heat can be realized; moreover, carbon dioxide and other harmful gases in the heat dissipation hood can be exhausted through an exhaust pipe, so that the pollution is reduced.

Owner:宁波中创机电有限公司

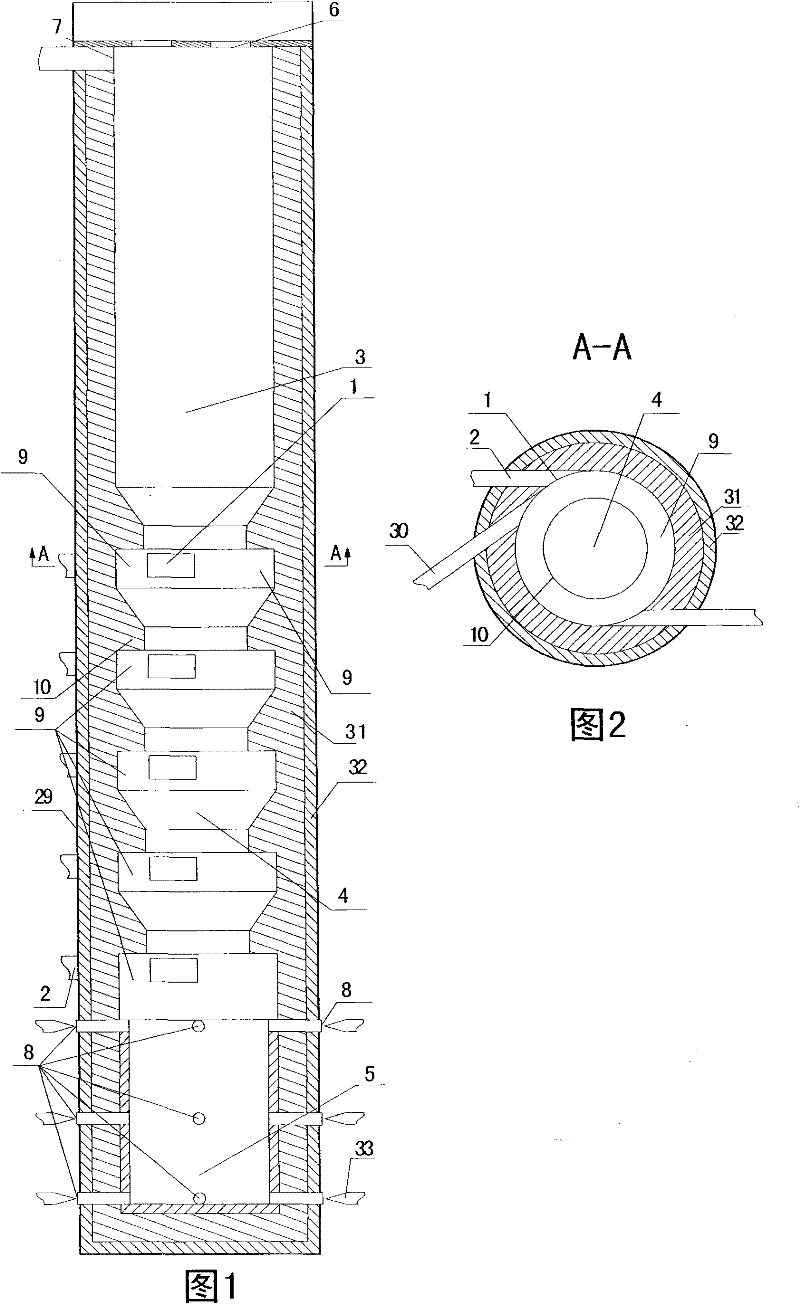

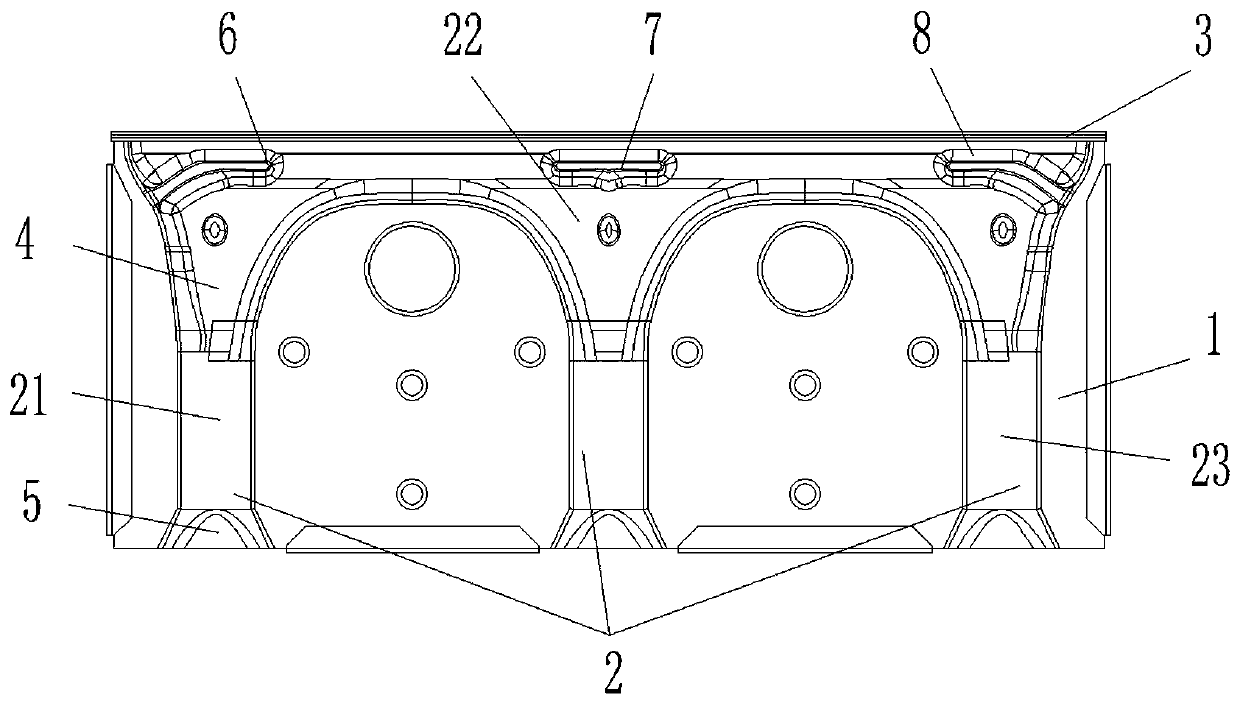

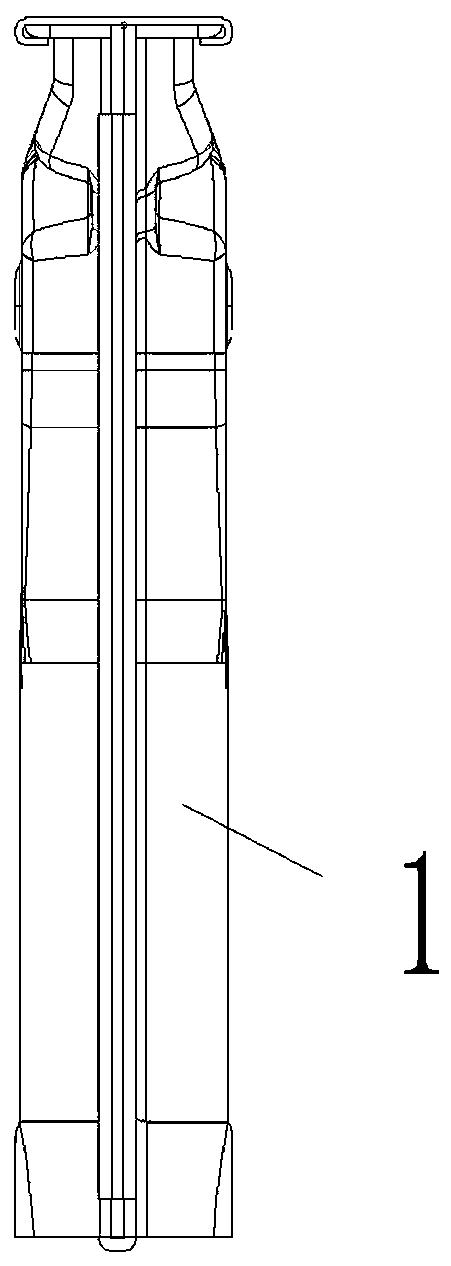

Burner capable of producing multiple burning working condition characteristics

InactiveCN103075726AAchieve complete combustionNon-existent processingCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCombustorEngineering

The present invention discloses a burner capable of producing multiple burning working condition characteristics. A purpose of the present invention is to provide a burner capable of completely burning a fuel so as to avoid discharge of a large amount of harmful gas during fuel burning. The burner comprises a housing (1), wherein the housing (1) is provided with two or more burners (2), each burner (2) is provided with at least a fuel inlet (3), and a burning port (4) of the one burner (2) is an air inlet (5) of the other burner (4). The burner has characteristics of simple structure, high fuel burning efficiency, and efficient energy-saving and environmental protection performance.

Owner:伍镜清

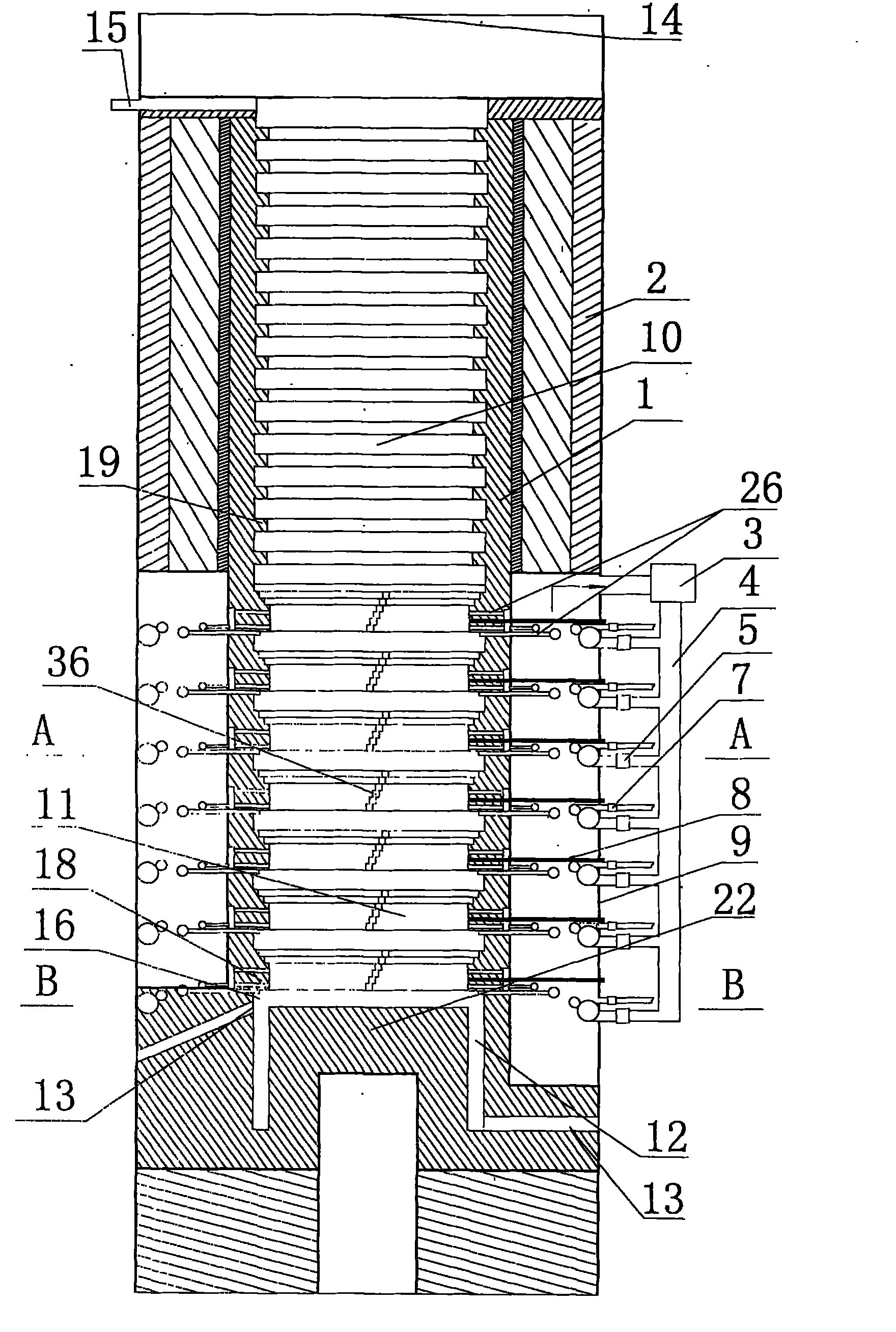

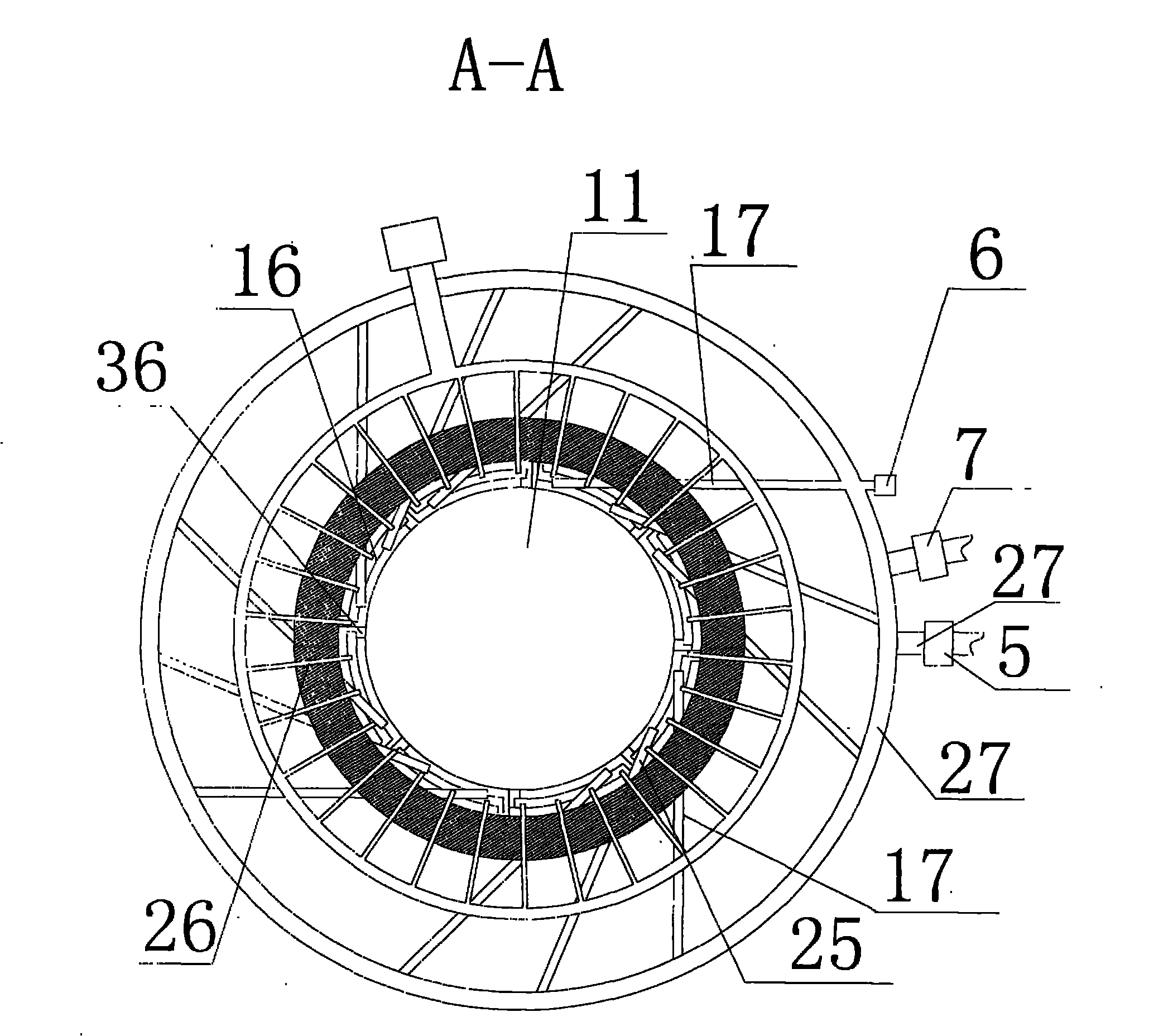

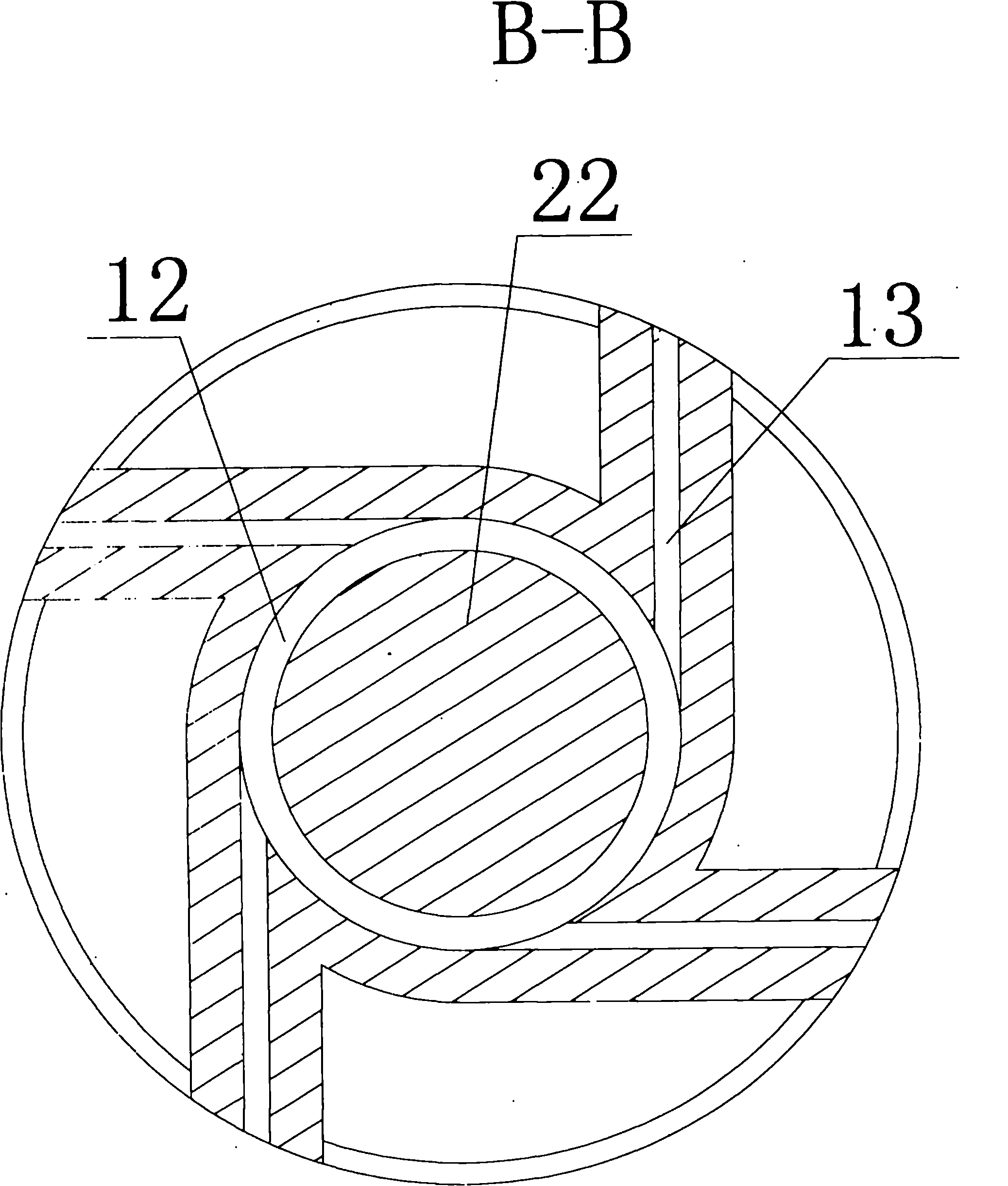

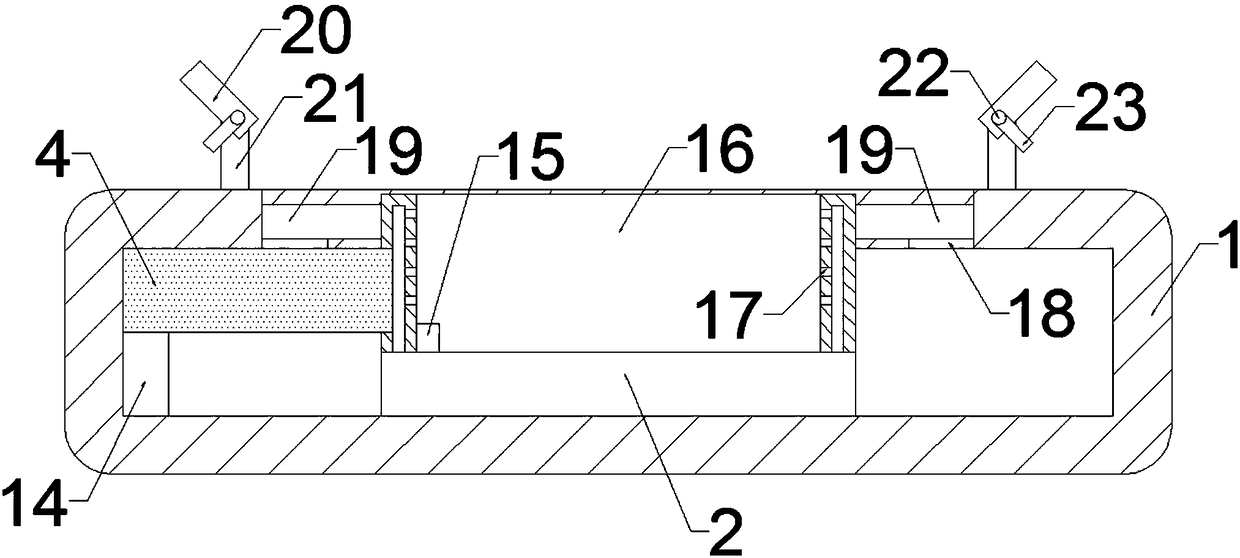

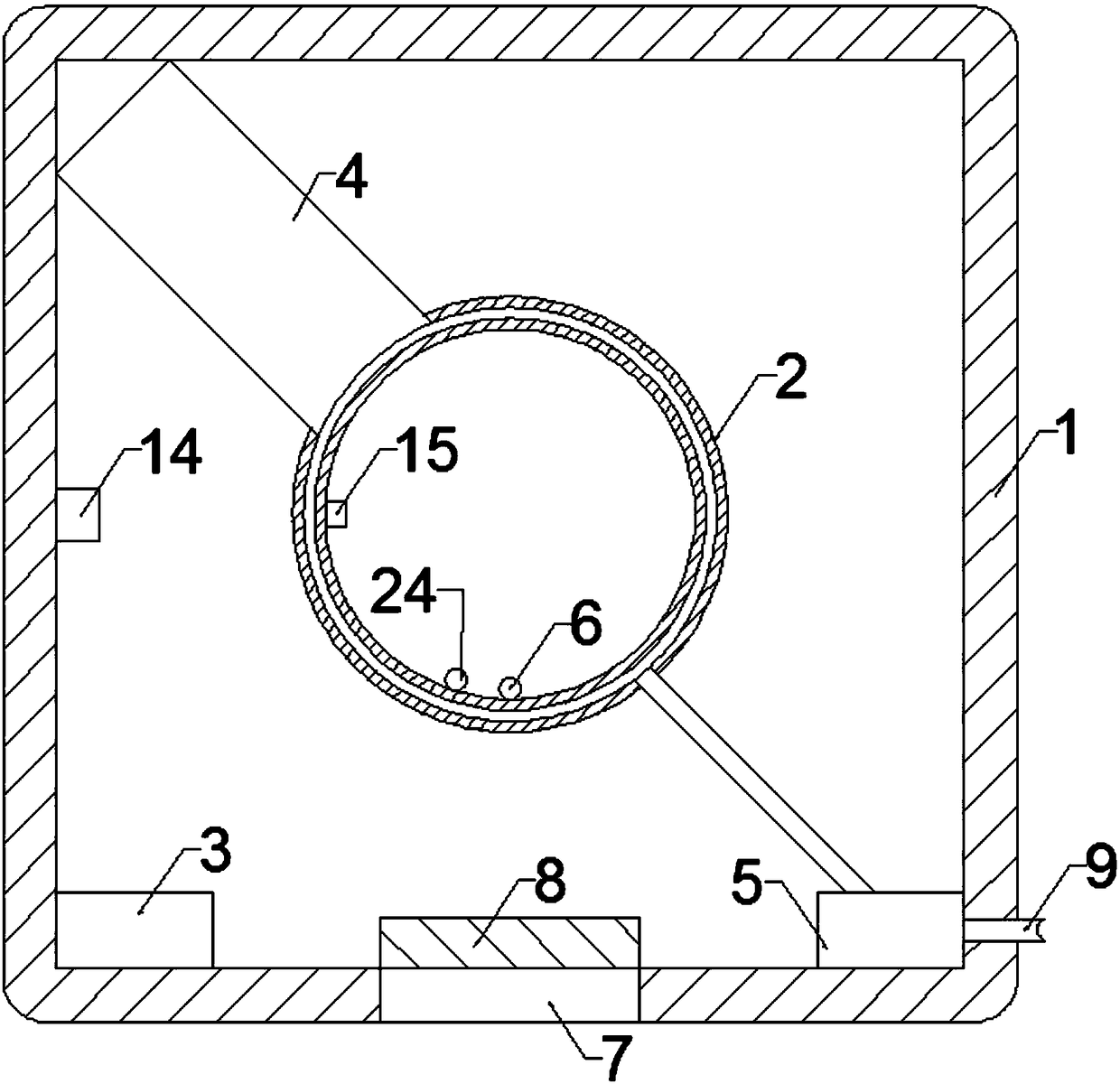

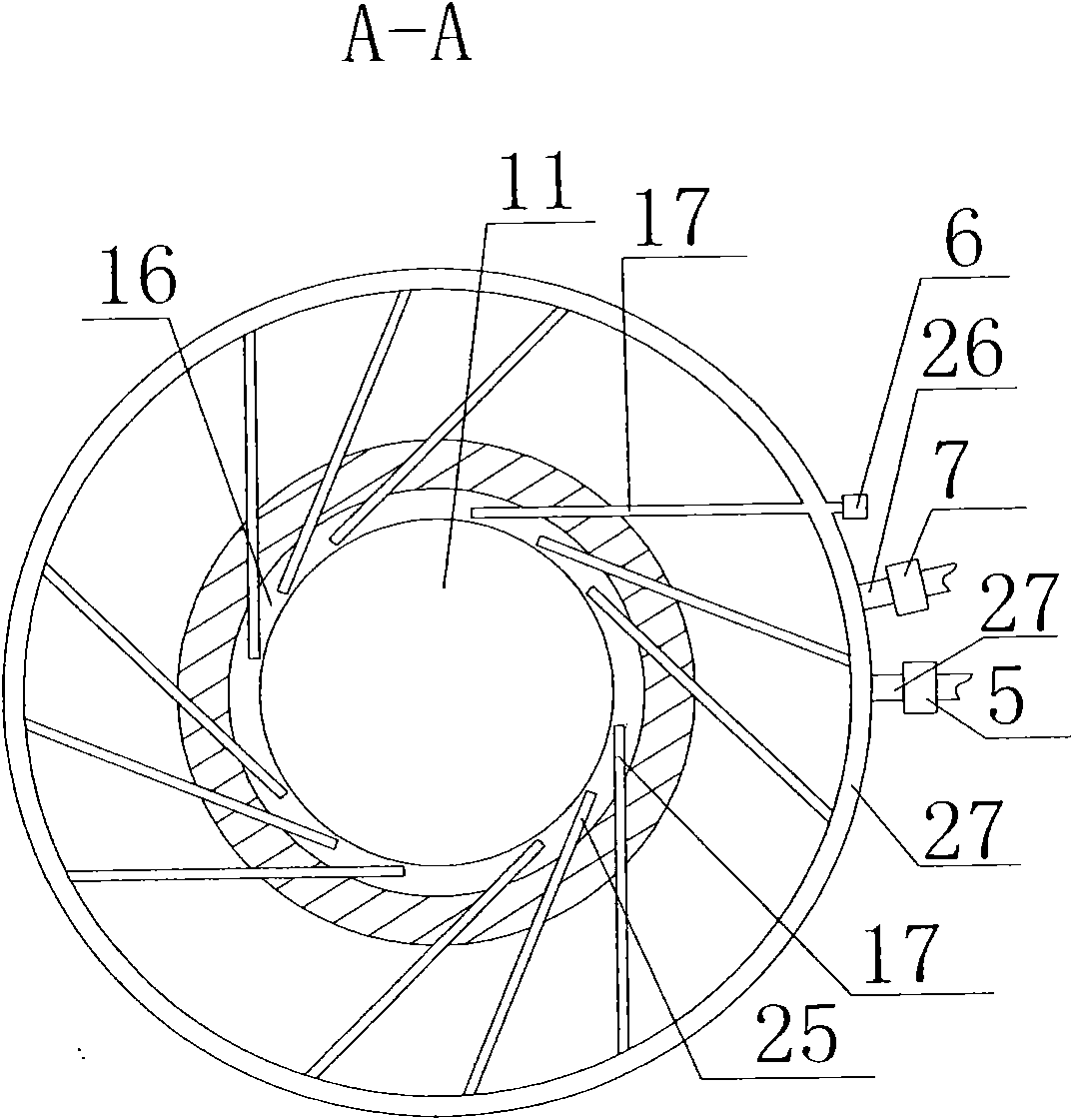

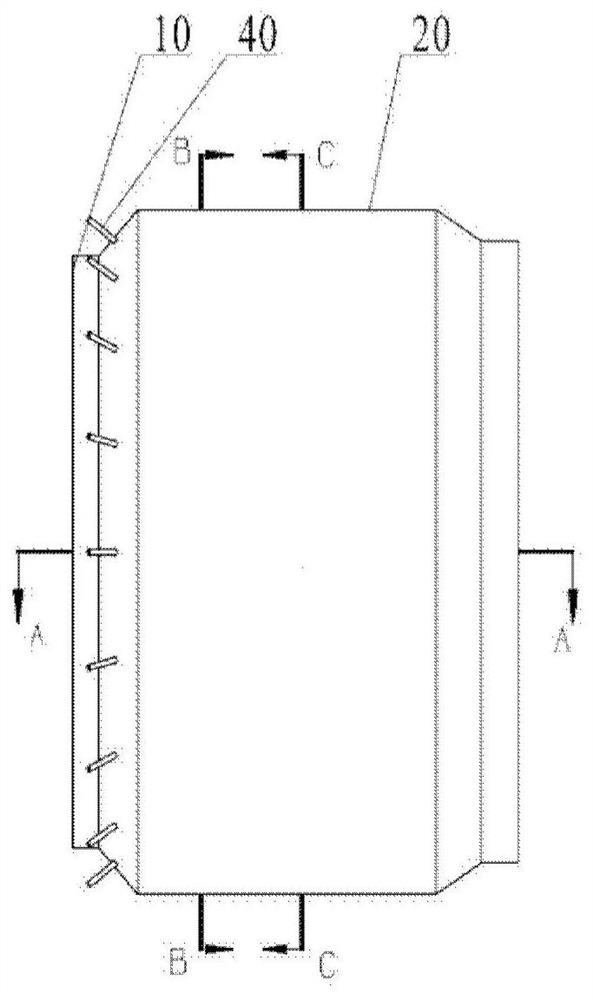

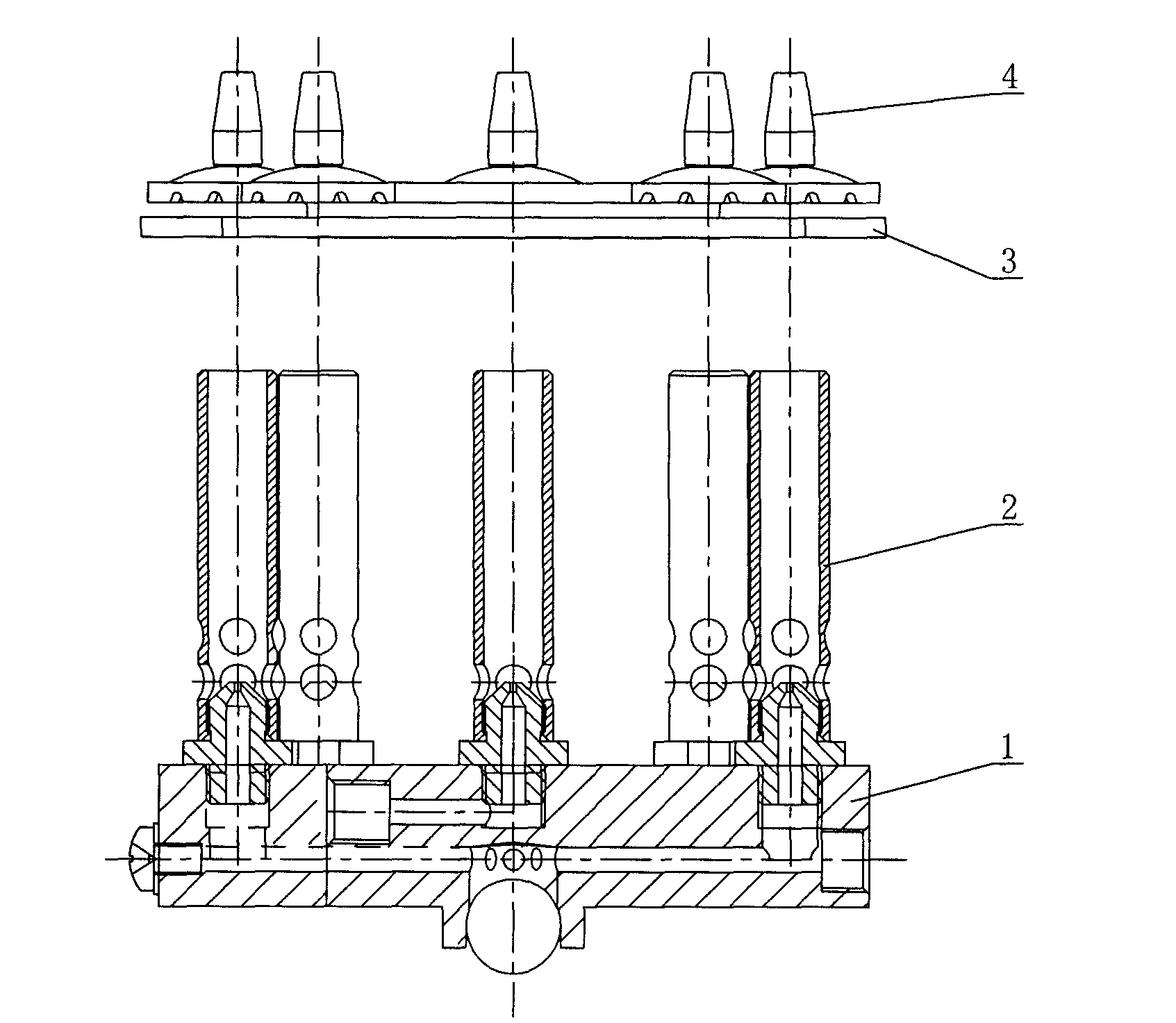

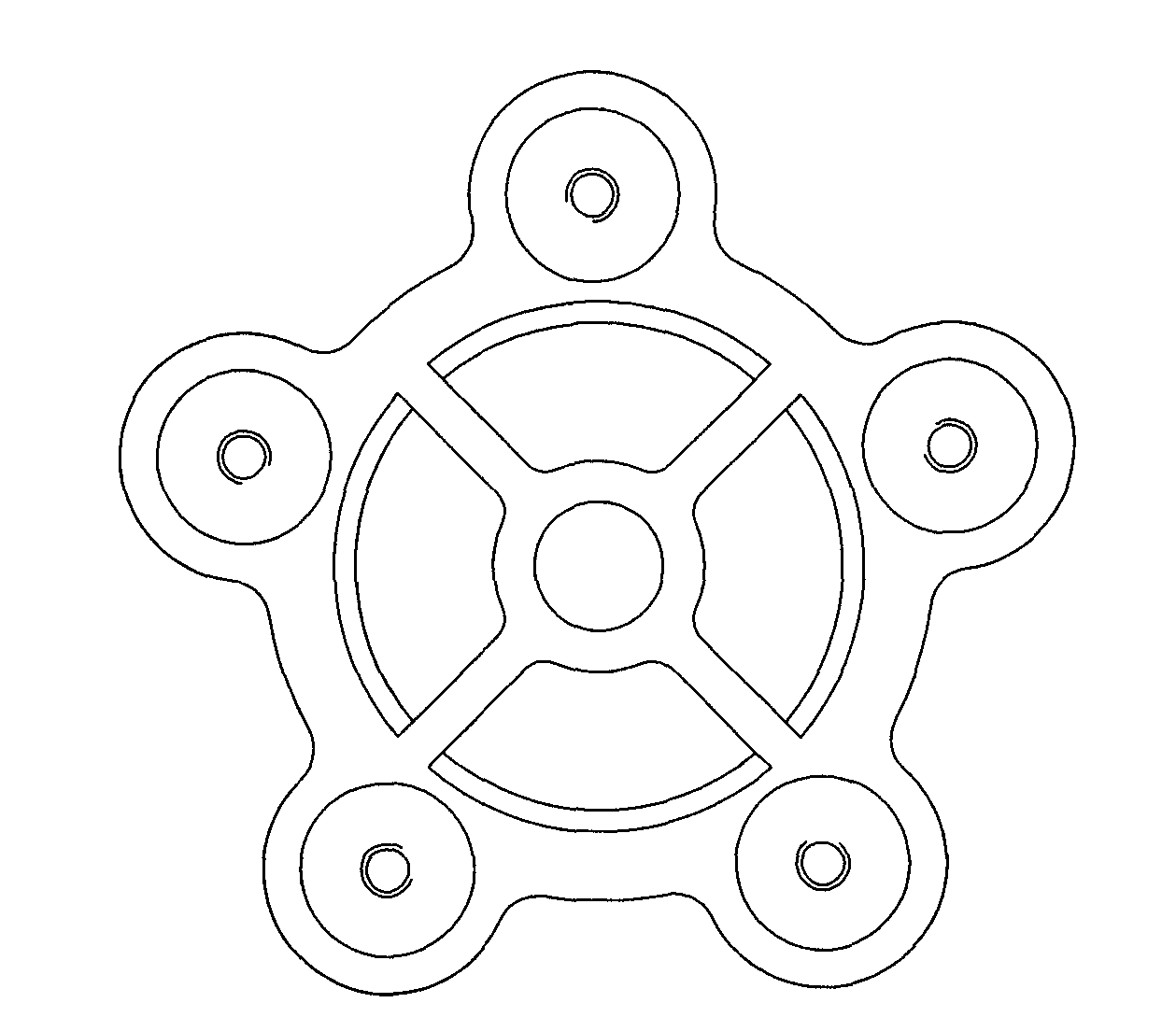

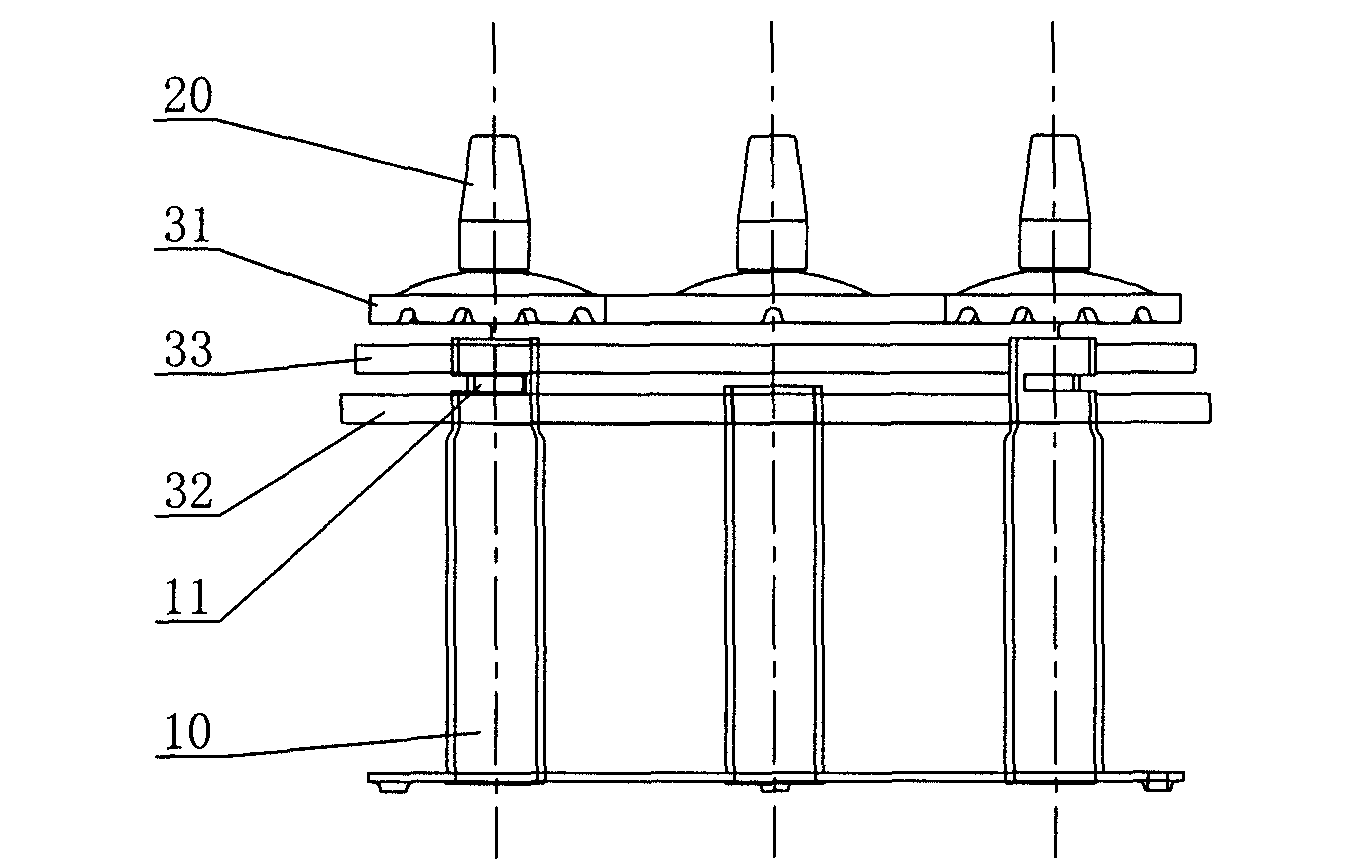

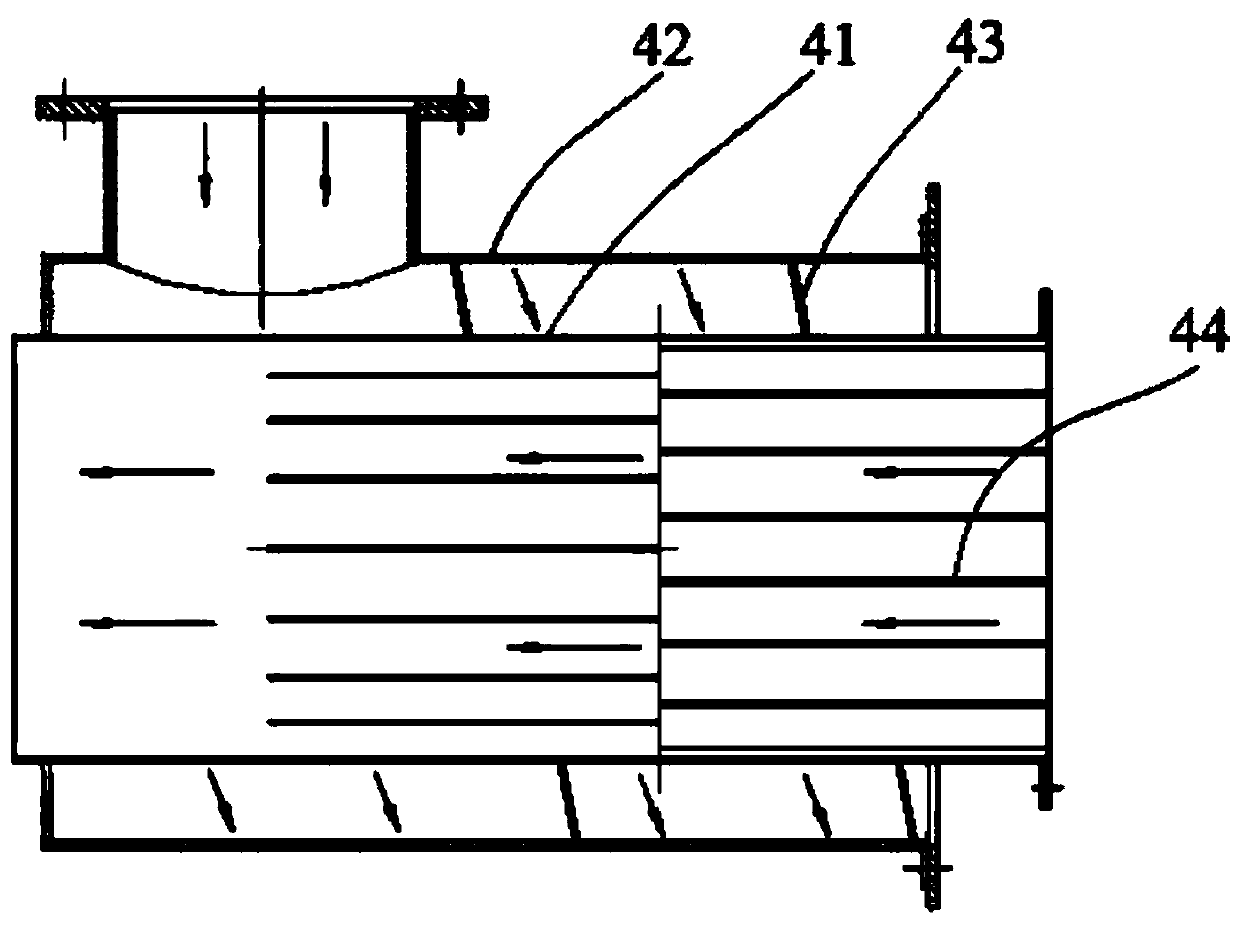

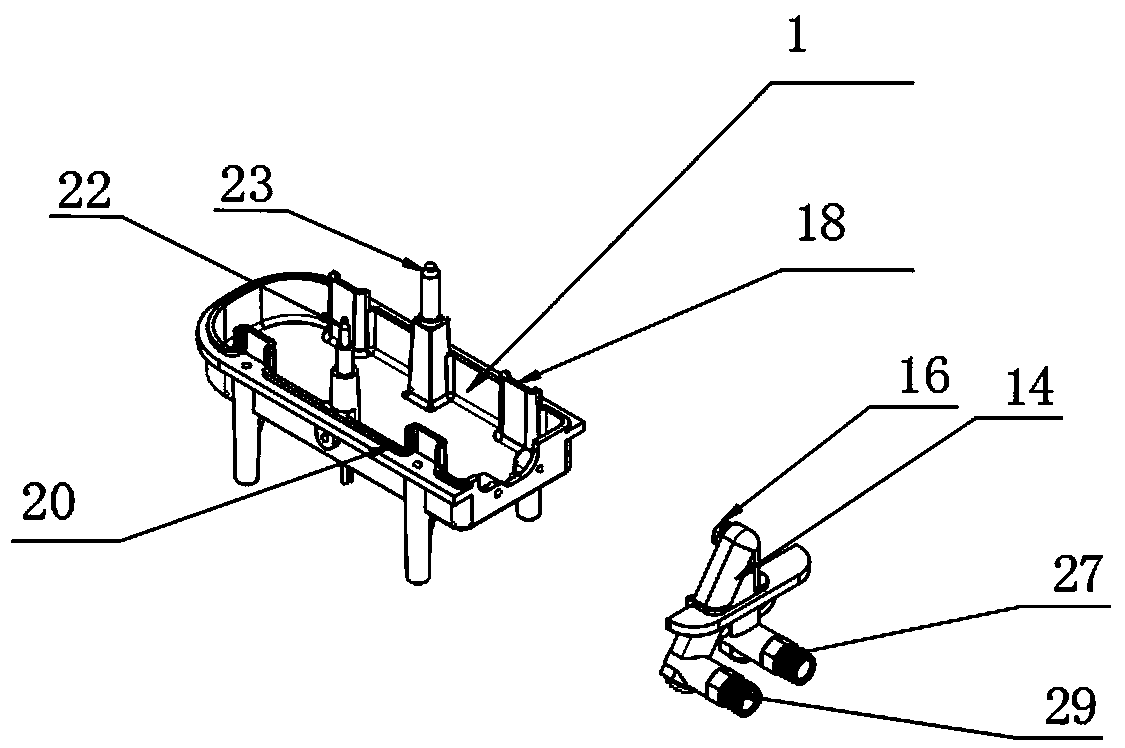

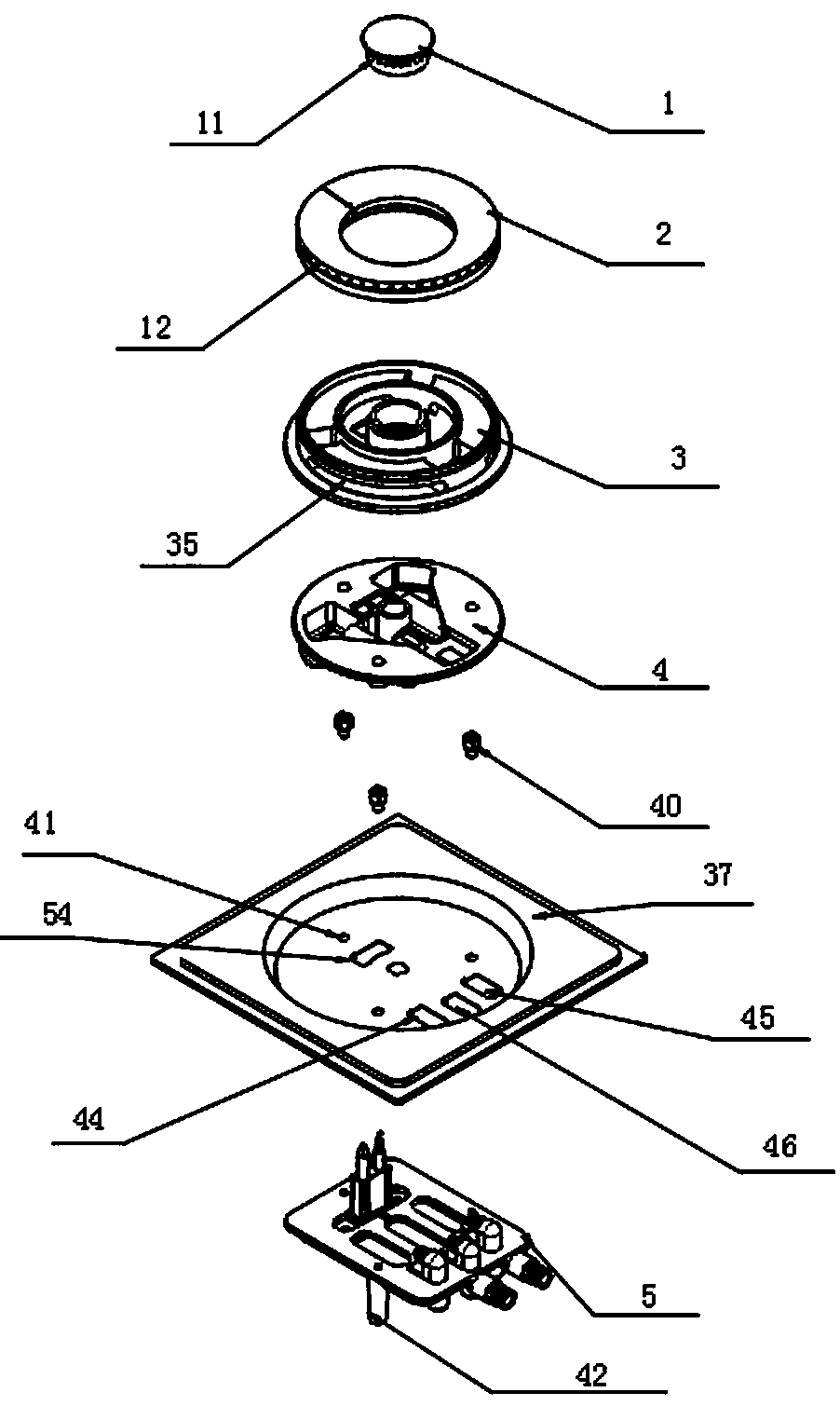

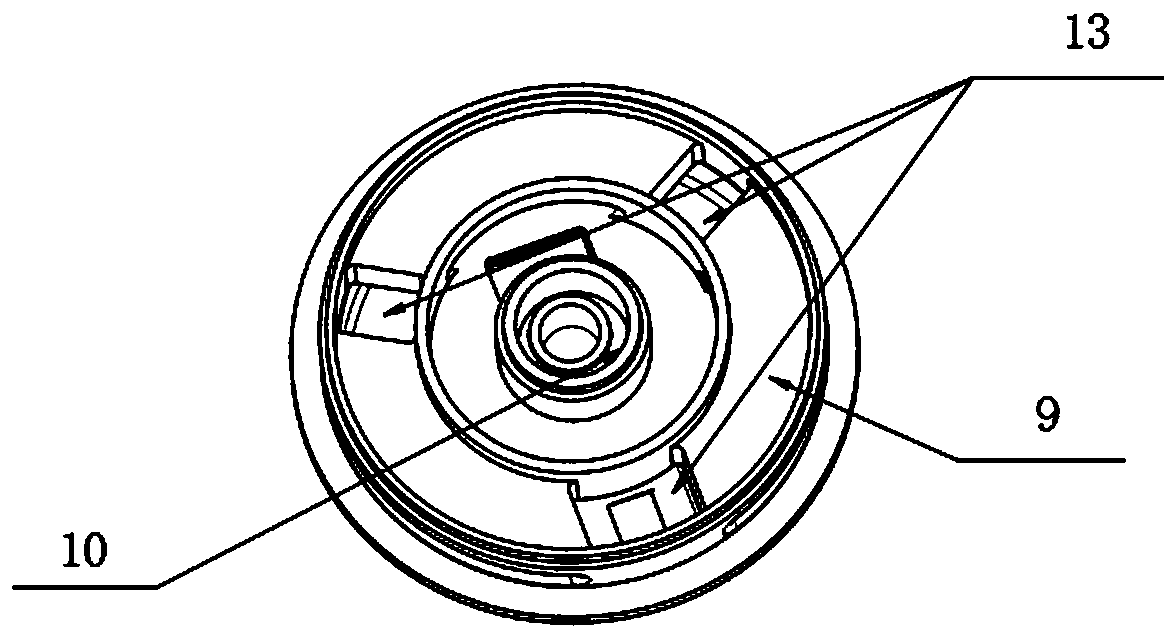

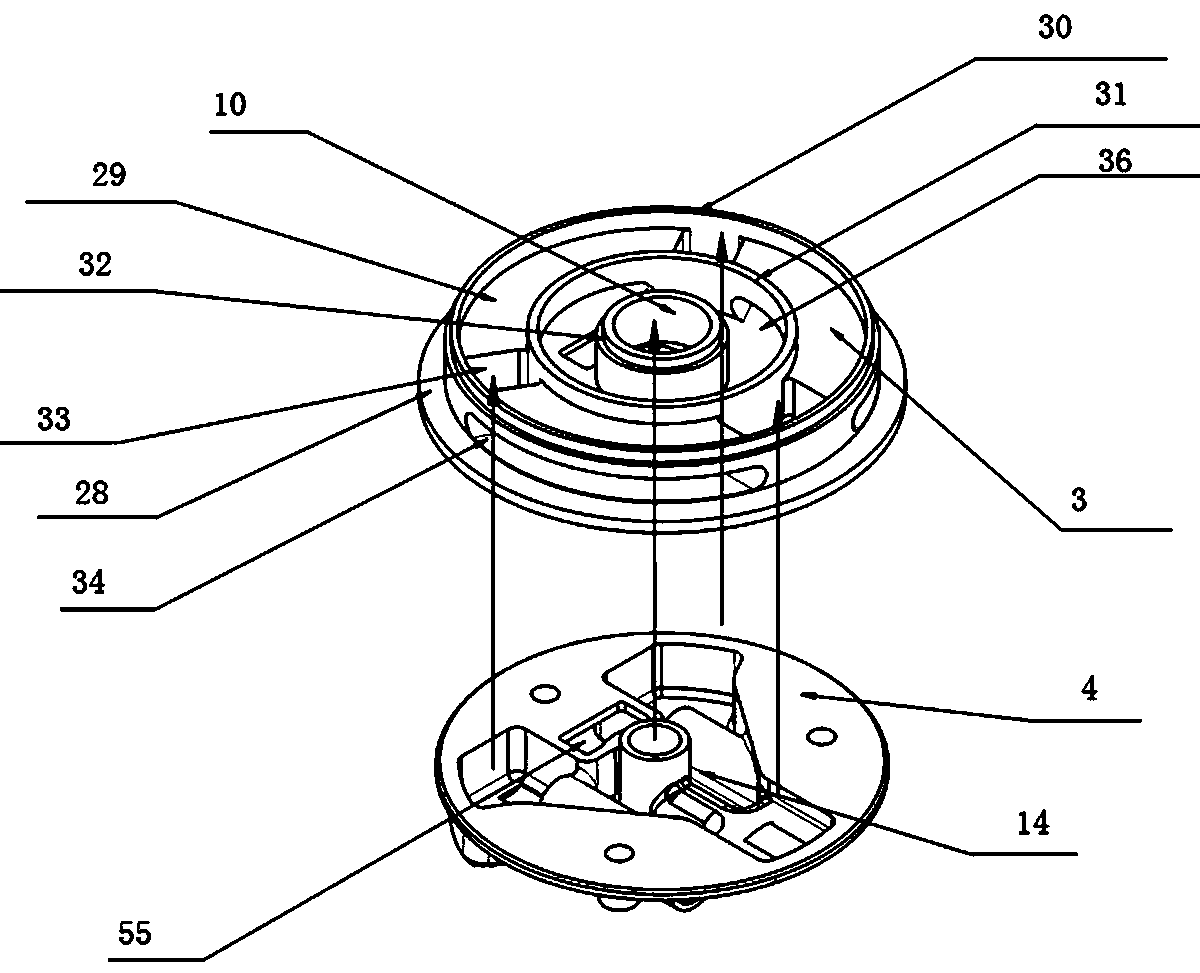

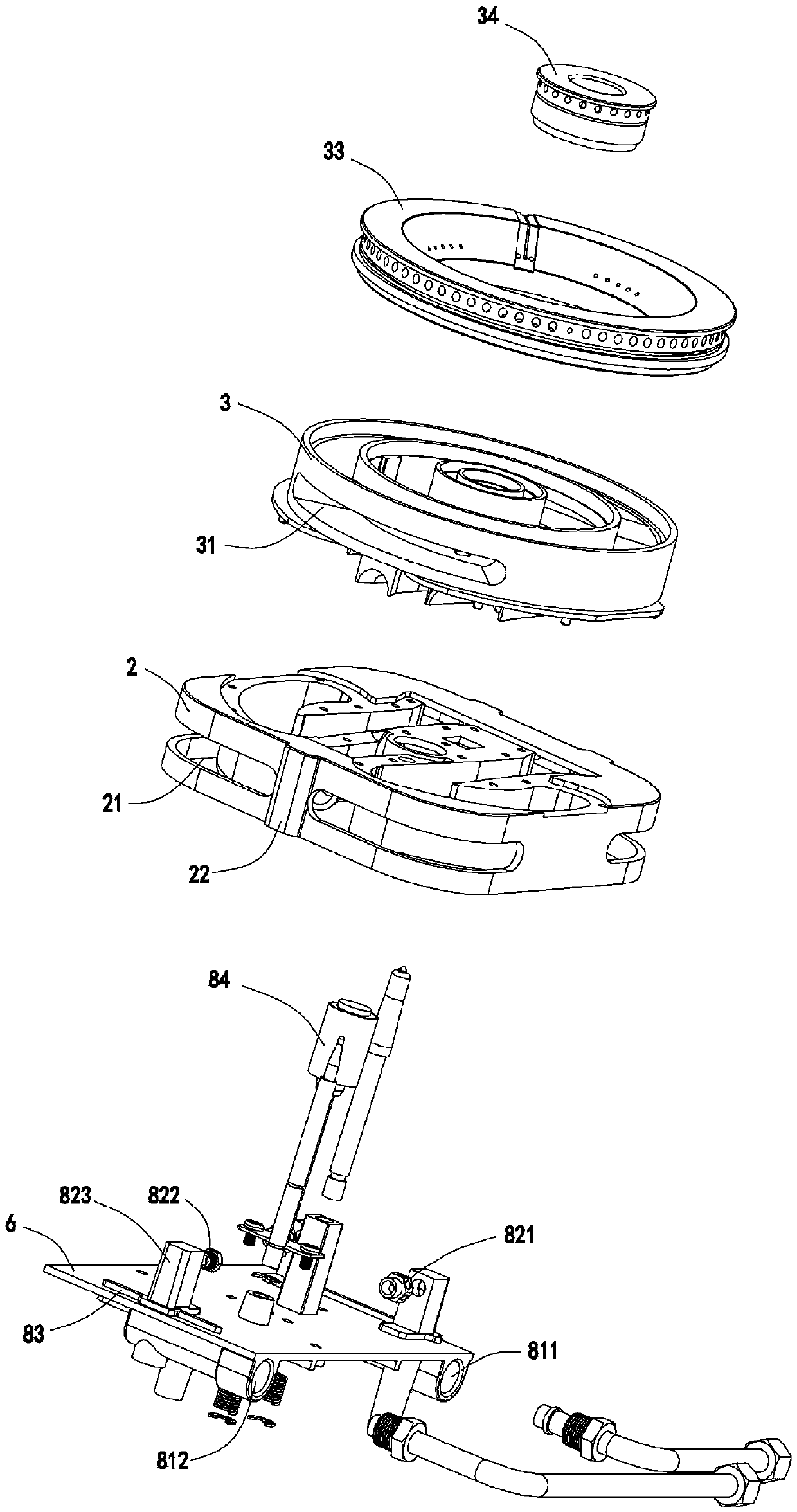

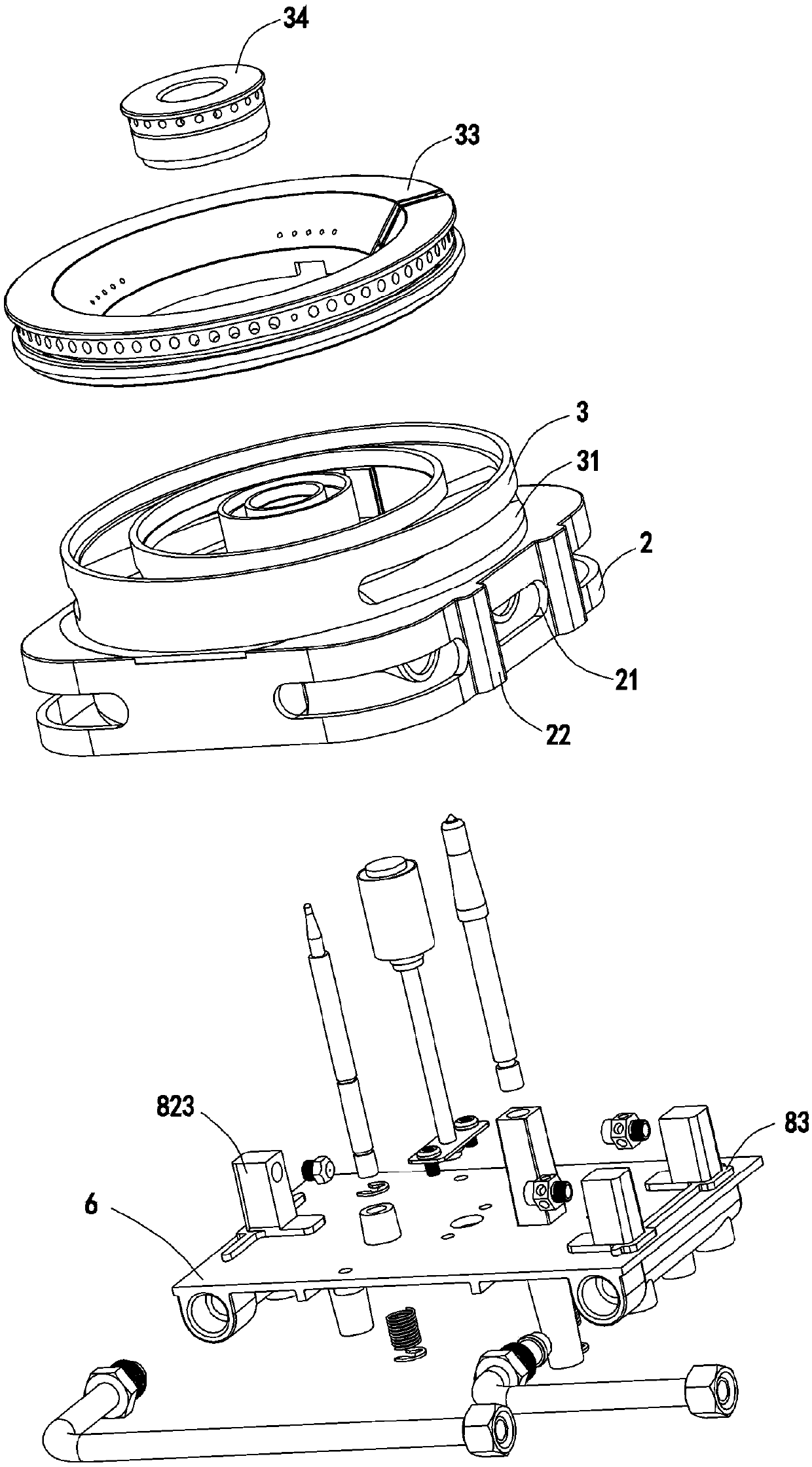

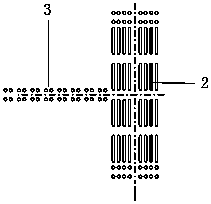

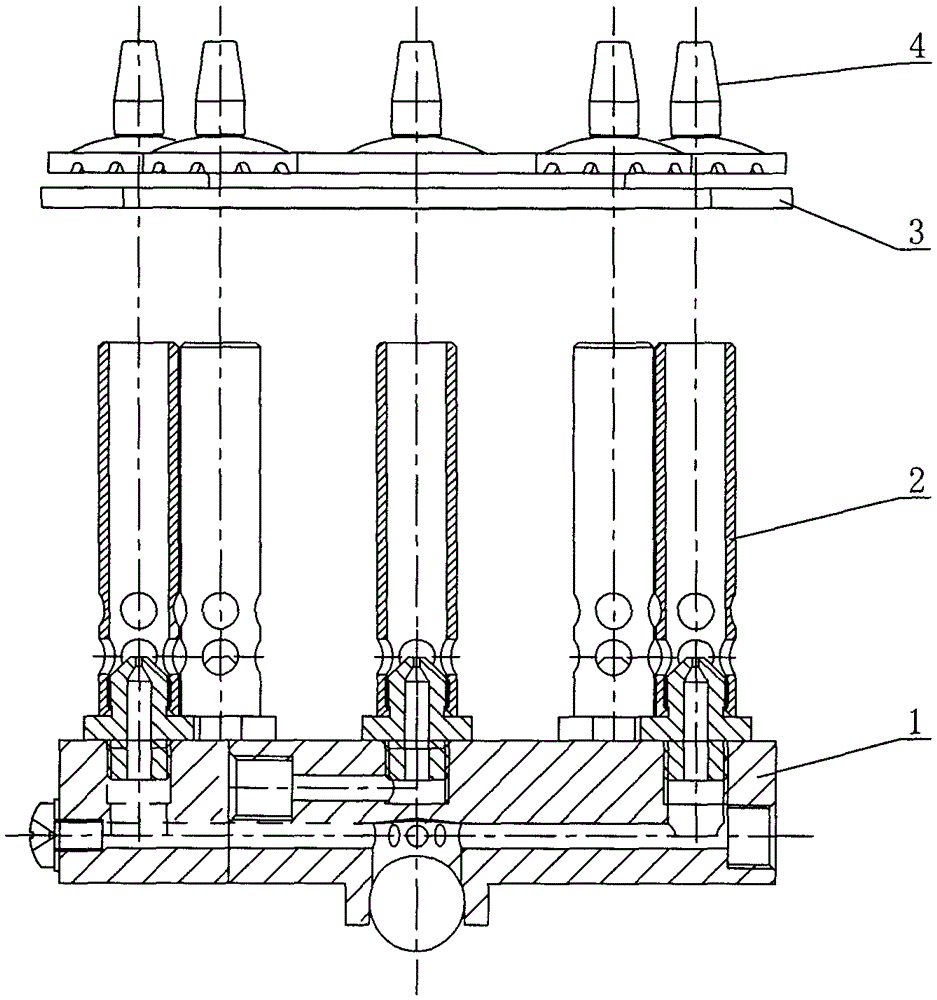

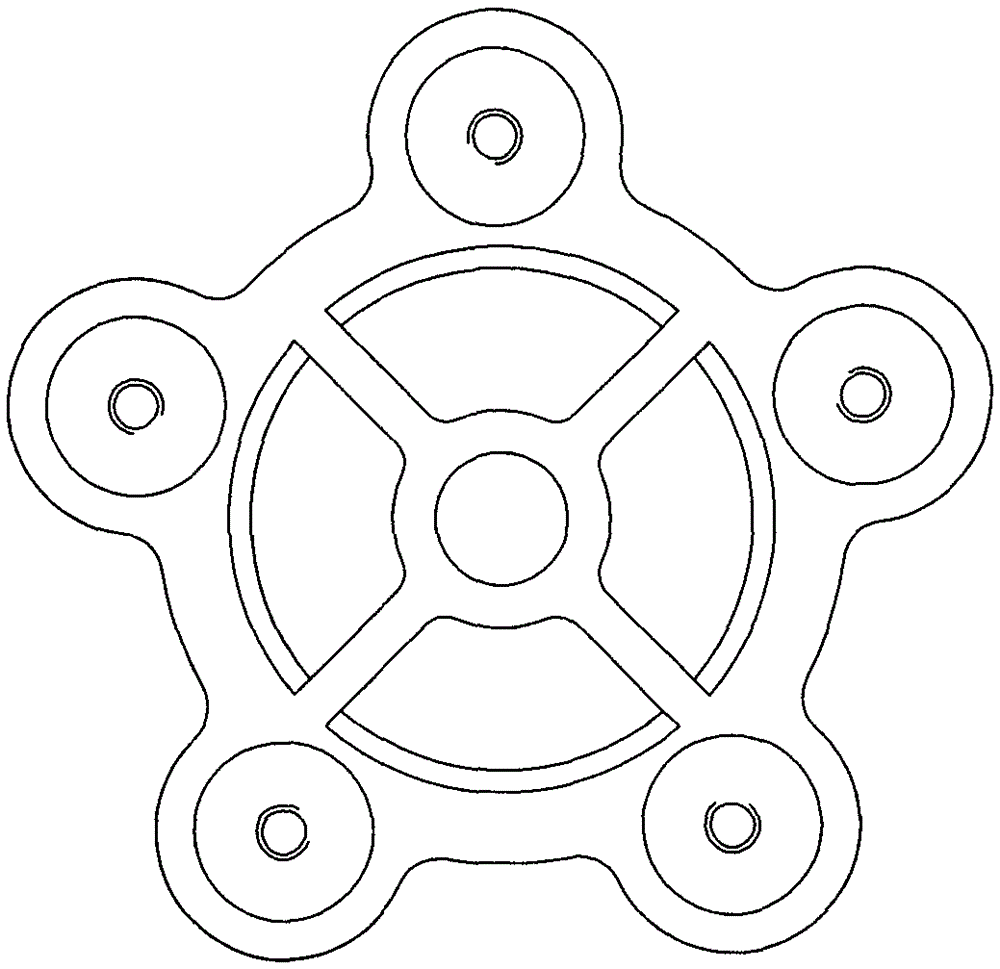

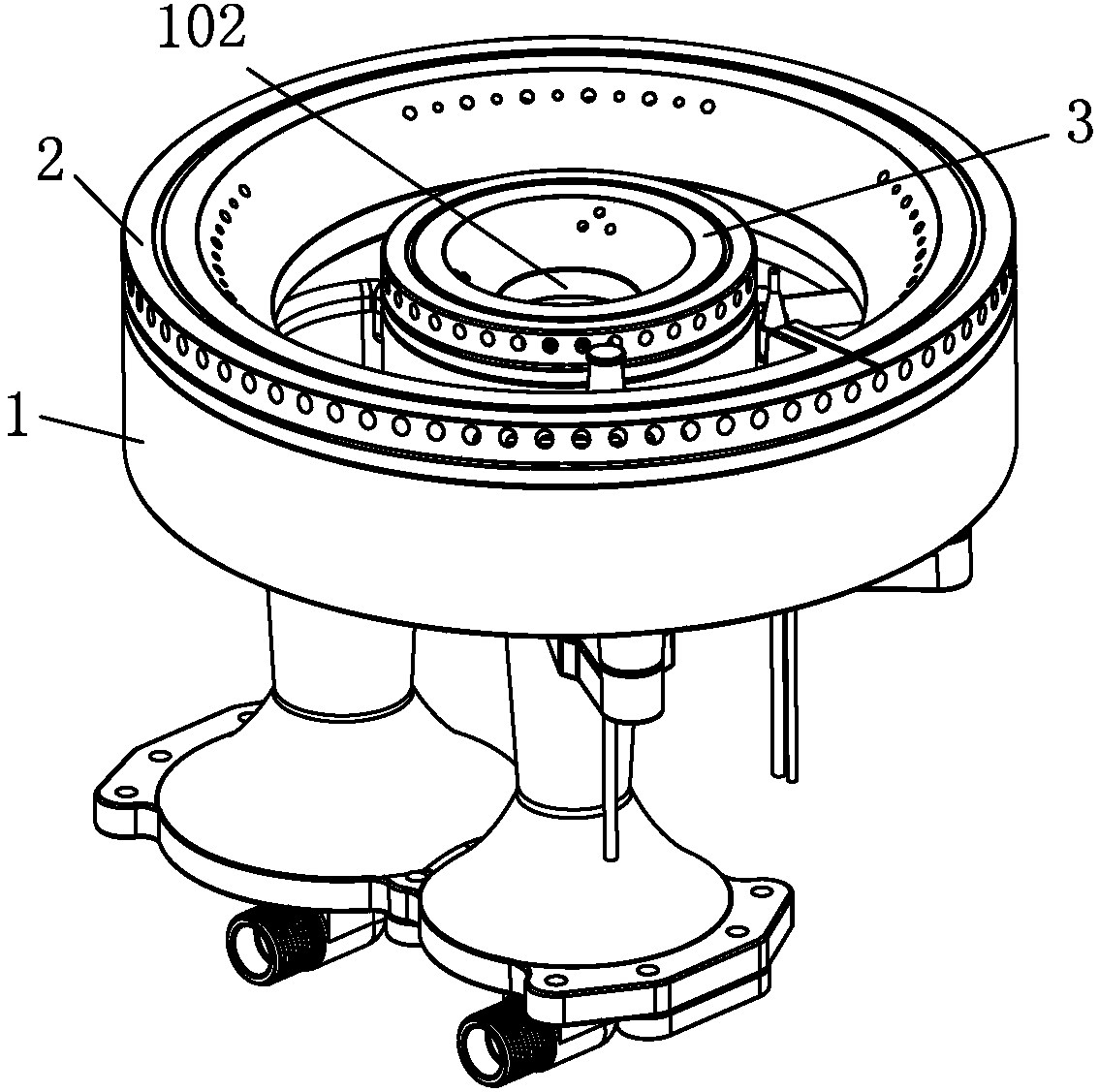

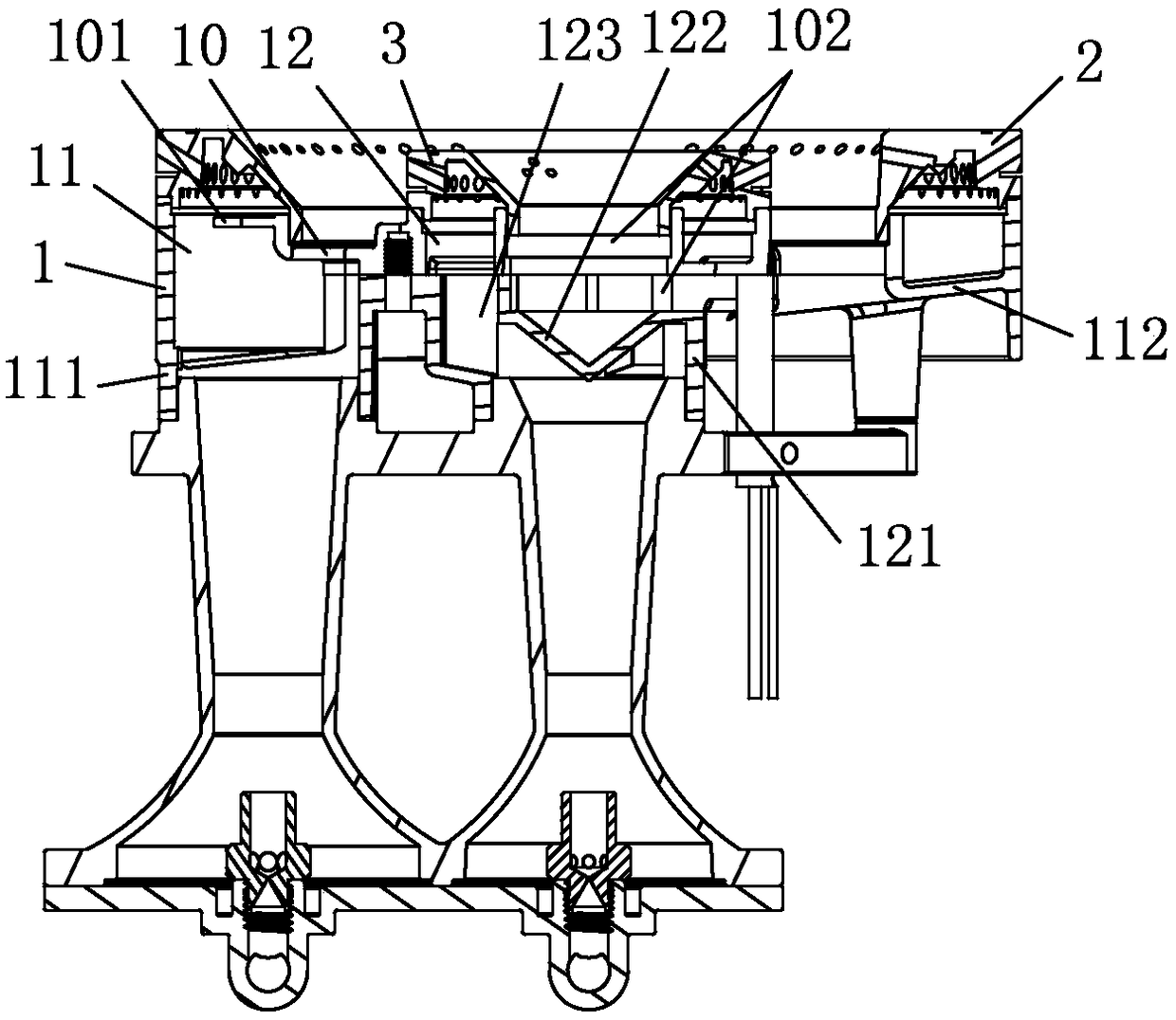

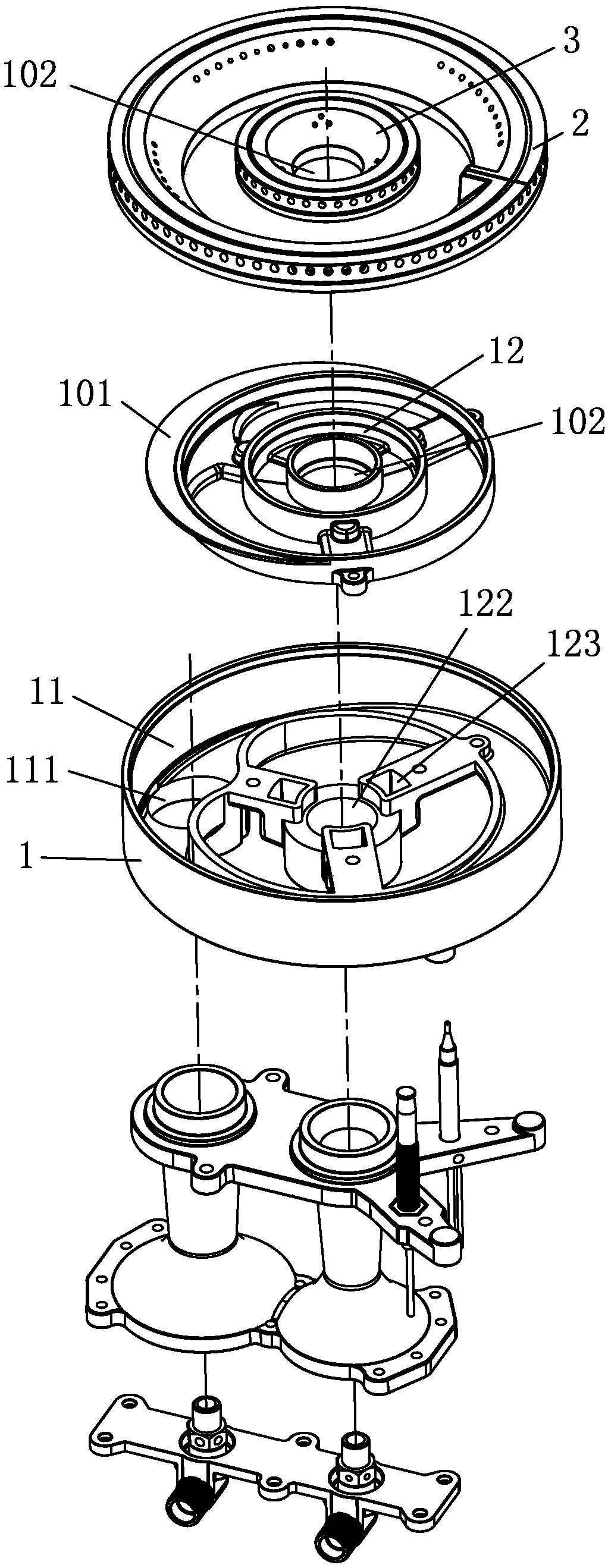

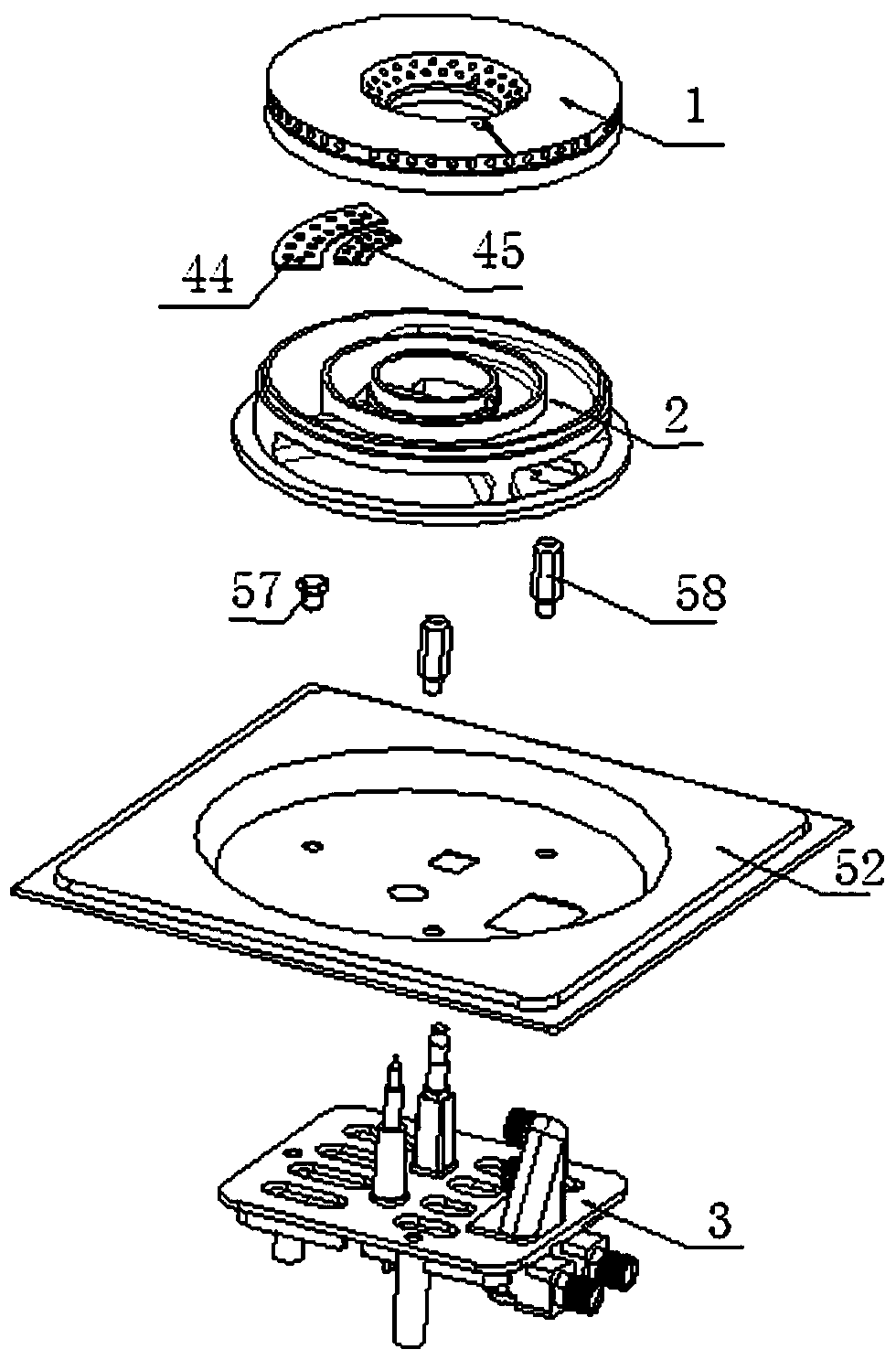

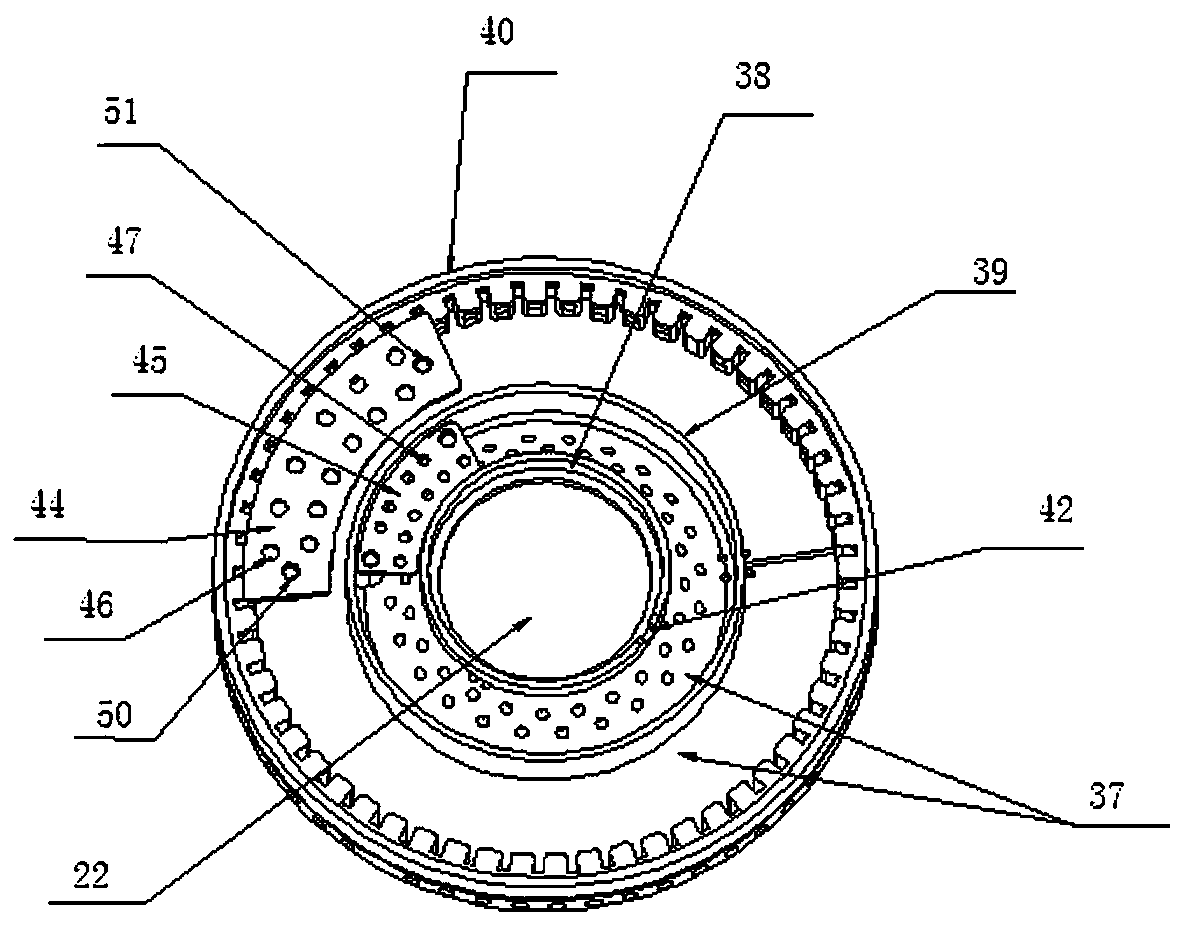

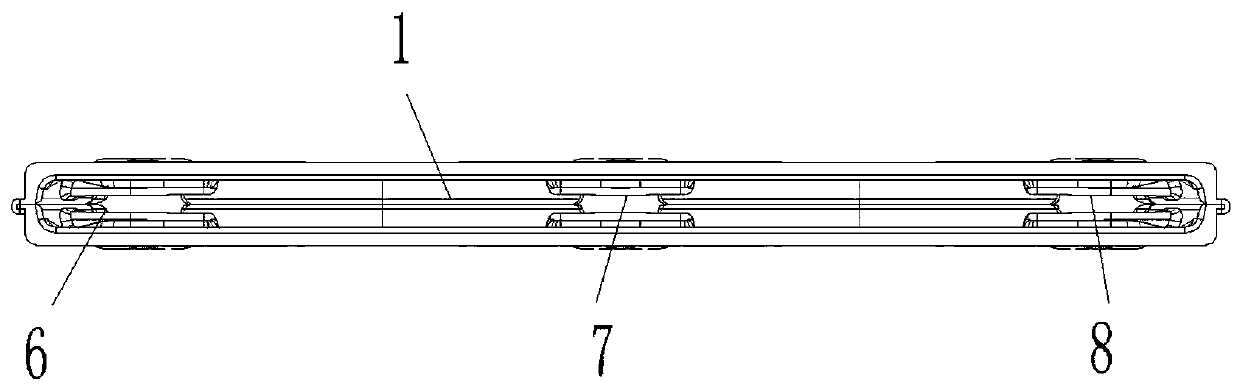

Efficient combustor assembly

ActiveCN103727540AIncrease the burning areaEliminate or reduce white spaceGaseous fuel burnerCombustorEngineering

An efficient combustor assembly comprises a distributor and a furnace end gas distribution base corresponding to a gas circuit of the distributor. The distributor is connected with gas guide tubes. The distributor and the gas guide tube located at the center form a center flame layer. The distributor and the gas guide tubes located on the periphery form peripheral flame layers. The peripheral flame layers are divided into at least two layers. The distributor comprises an upper distributor cover and a lower distributor cover. The upper distributor cover and the lower distributor cover are repeatedly stacked up and down or are stacked in a staggered mode. The distributor further comprises a middle distributor cover. The upper distributor cover and the middle distributor cover form one peripheral flame layer, and the middle distributor cover and the lower distributor cover form the other peripheral flame layer, or the upper distributor cover forms one peripheral flame layer, and the middle distributor cover forms the other peripheral flame layer. By the adoption of the efficient combustor assembly, the combustion area of flames is increased, coverage blanks of flames are reduced or eliminated, the combustion power of the combustor assembly is greatly increased, heat efficiency is improved, the waste gas emission load is reduced, and the environment friendliness effects of saving energy and reducing emission are possessed.

Owner:广东年代集成厨电有限公司

Gasoline blending agent

InactiveCN109022065APromotion labelLabel increaseLiquid carbonaceous fuelsFuel additivesDimethylcarbinolN-Butanol

The invention relates to a gasoline blending agent. The gasoline blending agent comprises 5-10 g of barium petroleum sulfonate, 10-15 g of n-butanol, 10-15 g of methyl tert-butyl ether, 10-20 g of dimethylcarbinol, 0.1-0.2 g of ferrocene, 10-15 g of t-butyl acetate, 15-20 g of fatty alcohol and 24-28 g of anhydrous alcohol. The gasoline blending agent can reduce sediments, increase the combustionpower of gasoline, increase the label number of the gasoline, reduce the pollution of combustion of the gasoline to air and reduce the explosiveness of the gasoline, and also has the advantages of lowprice, simplicity, and easiness in operation.

Owner:齐广浩

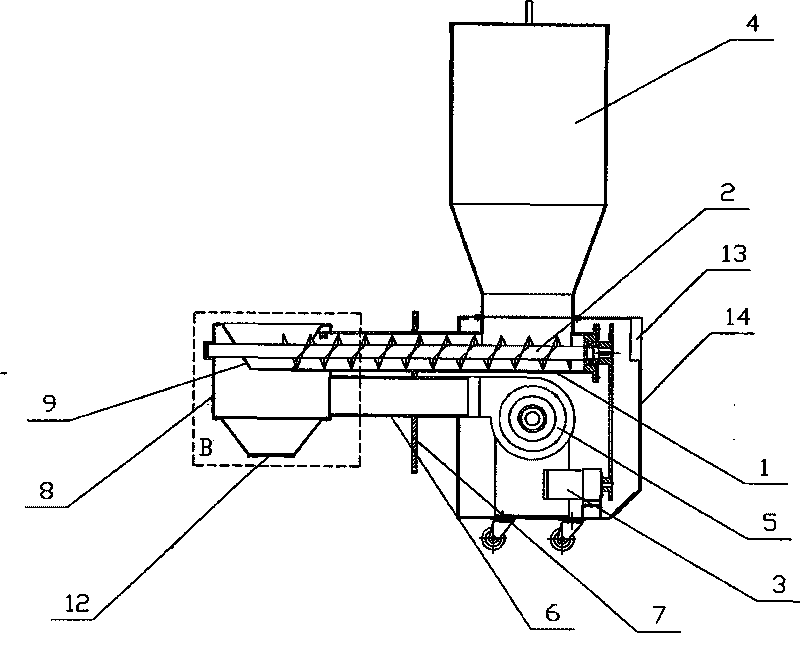

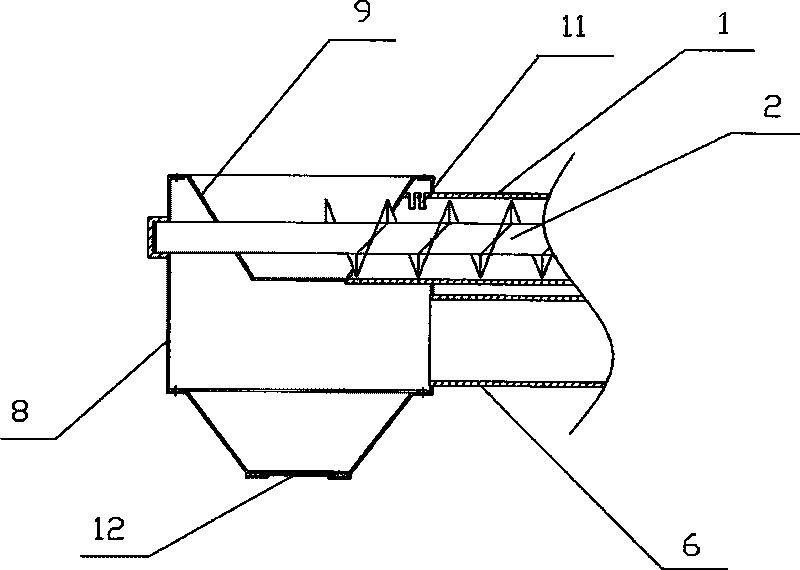

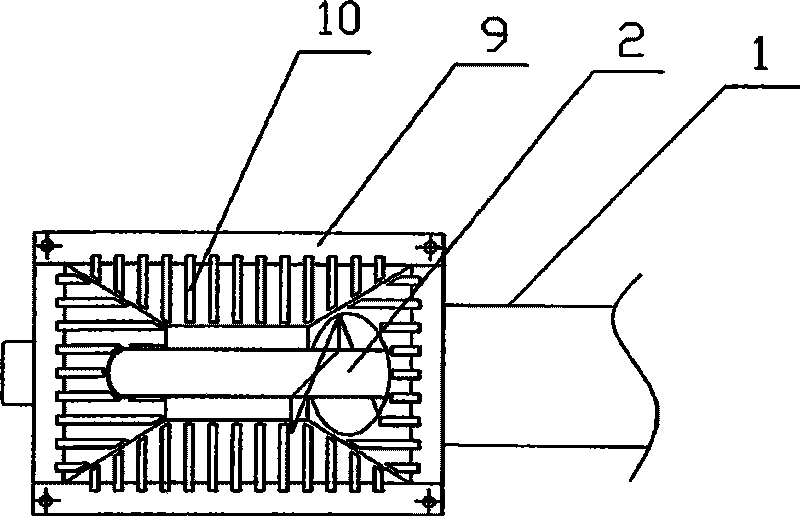

Biomass granule material combustor

InactiveCN101354131BInhibit carbon depositionSolve the smokePulverulent fuel combustion burnersAir/fuel supply for combustionCombustion systemEngineering

The invention discloses a biomass granule burner, comprising a feeding system, an air supplying system and a burning system. The feeding system comprises a feeding pipe, a feeding auger installed in the feeding pipe, a reducing motor and a feed box; the air supplying system comprises a blower and air pipes; the feeding pipes are positioned in the upper part of the air pipe and arranged in a co-rotating parallel way, the burning system is provided with a bellows, as the top surface of the bellows, a burning material disc is fixedly connected to the top of the bellows, and provided with an air vent, the bellows is connected to the air pipes of the air supplying system, while the burning material disc is fixedly connected to the feeding pipe of the feeding system, and a connecting flange thatcan be connected to a heating boiler is arranged between the air pipes and the feeding pipe. The burning system of the bellows structure has simple structure and low production cost; since the burning material disc is positioned on the bellows, the air is evenly distributed, with high burning efficiency and thermal efficiency and good environmental protection effect; the feeding pipe in the bellows is opened with the air vent, the air pressure in the bellows can prevent the fume in the burning material disc from entering the feed box, thus settling the smoking problem of the feed box.

Owner:LIYANG ZHENGYANG GAS EQUIP MFG +1

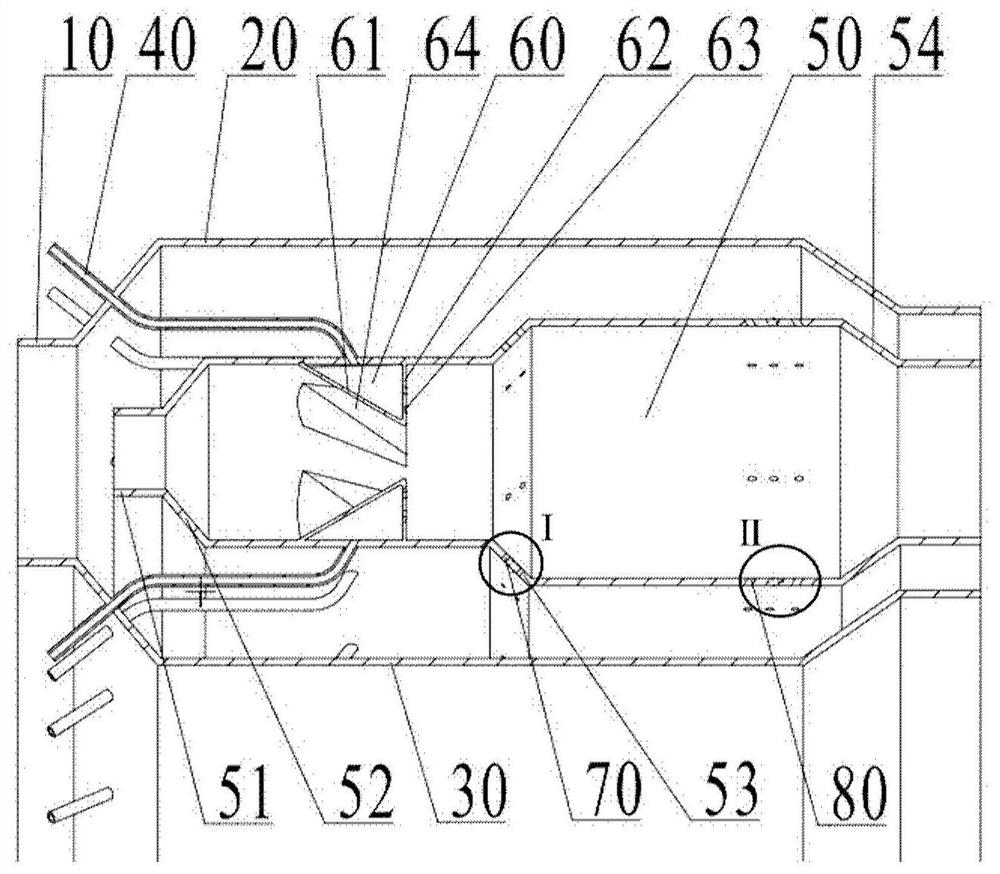

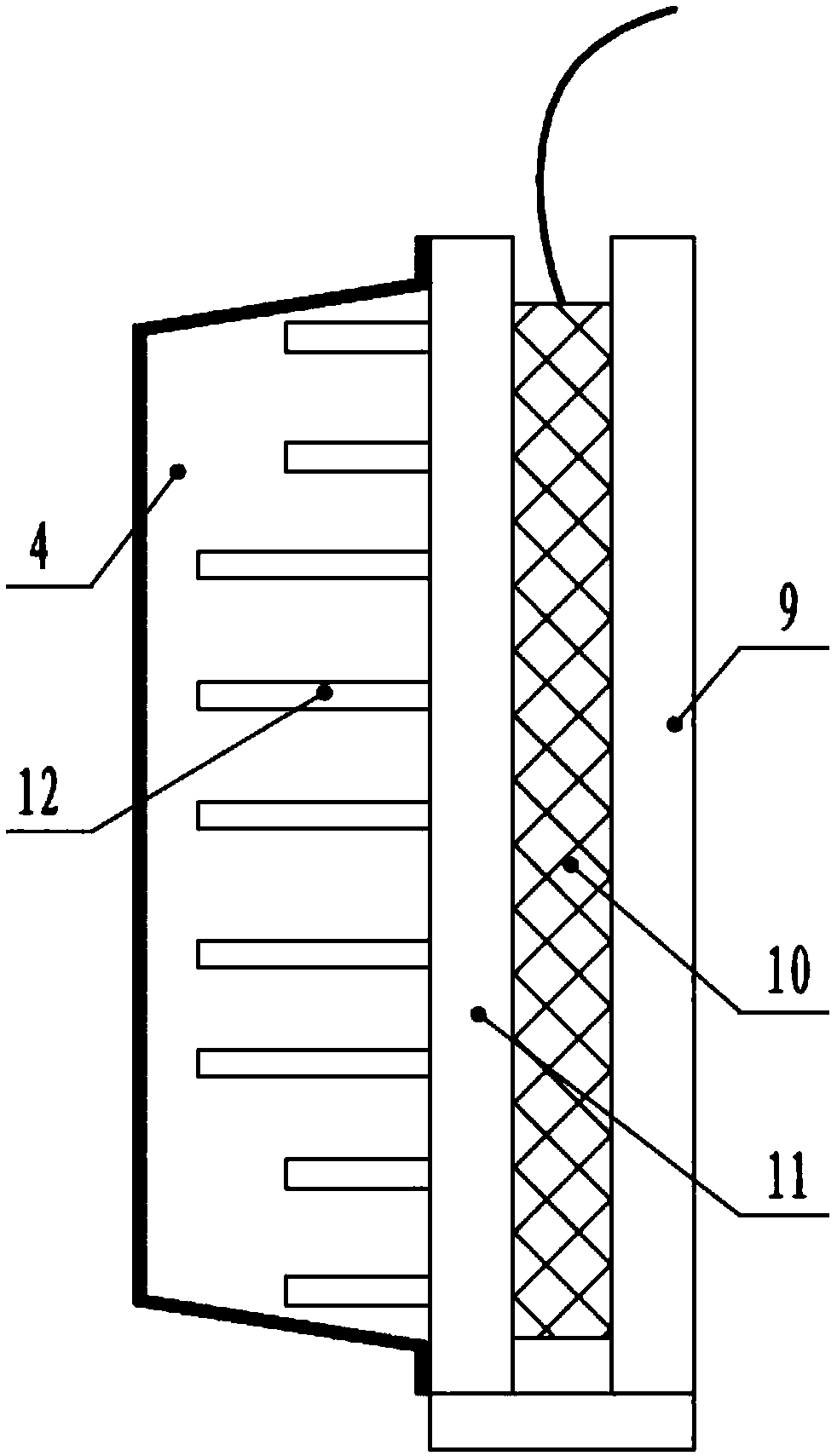

Production device for industrial kiln

InactiveCN110726308AImprove anti-burn performanceExtended service lifeGaseous fuel burnerWaste heat treatmentCombustion chamberBrick

The invention discloses a production device for an industrial kiln, and relates to a combustor. The production device is mainly composed of a heat exchanger, an air inlet pipe, a combustion chamber, amixer arranged in the combustion chamber and a main gun, wherein the heat exchanger is provided with an air runner and a smoke runner, the air inlet pipe is arranged on the heat exchanger and communicates with the air runner of the heat exchanger, the combustion chamber communicates with the air runner of the heat exchanger and the air inlet pipe, and the main gun communicates with the mixer andis used for gas conveying. The combustion chamber of the production device is of a cylinder cavity structure formed by a burner brick formed by combining a heat-resistant steel pipe framework and fireproof materials, the combustion chamber and the burner brick are of an integrated structure, and therefore the burning loss resisting capability of the combustion chamber can be greatly improved, andthe service life is prolonged; and through a through hole, the device ventilation effect is improved, and the service life of the device is prolonged.

Owner:湖北中琛窑炉设备有限公司

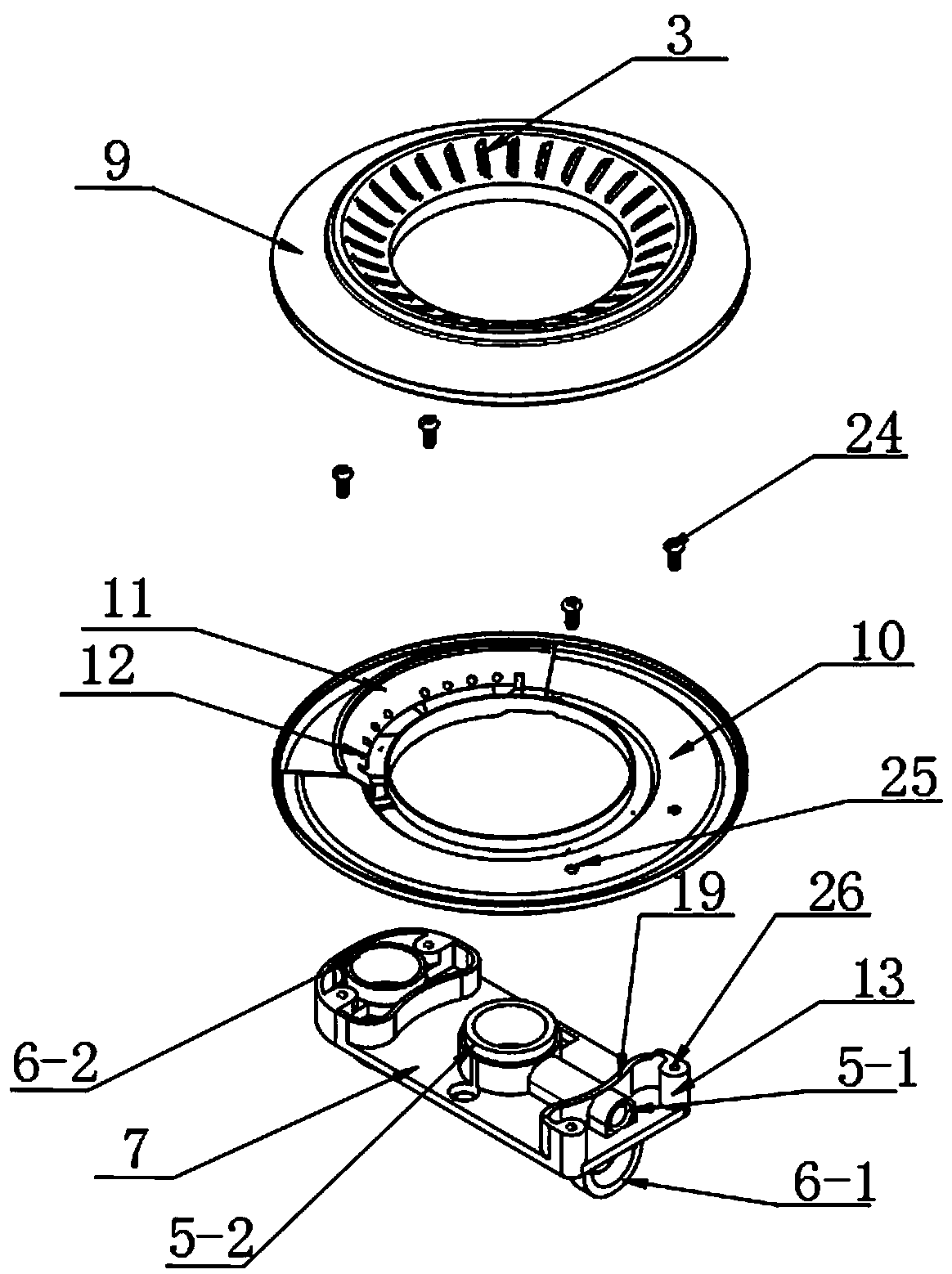

Totally upward air inlet combustor

PendingCN110425532AHigh working reliabilityEliminate depositsGaseous fuel burnerHome appliance efficiency improvementCombustorEngineering

The invention relates to a totally upward air inlet combustor which comprises a combustor base, an injection module, a main fire dividing assembly and a center fire outlet cover. A main fire dividingcavity is formed in the main fire dividing assembly, the injection module is arranged on the combustor base and comprises a center fire injector, a main fire injector and a horizontal partition plate,and a main fire air outlet end of the main fire injector communicates to the main fire dividing cavity; a main fire air inlet end of the main fire injector is fixed to the lower surface of the horizontal partition plate, and the main fire air outlet end of the main fire injector penetrates the horizontal partition plate and communicates to the main fire dividing cavity; a center fire air inlet end of the center fire injector is fixed to the upper surface of the horizontal partition plate; a vertical partition plate is fixed to the horizontal partition plate, the vertical partition plate is arranged behind the end surface of the center fire air inlet end of the center fire injector, the upper end surface of the vertical partition plate is in contact with the lower surface of the main firedividing assembly, and two ends of the vertical partition plate stretch to two sides of the end surface of the center fire air inlet end of the center fire injector. The totally upward air inlet combustor is compact in structure, good in stability, high in combustion power and high in working reliability.

Owner:陈毅

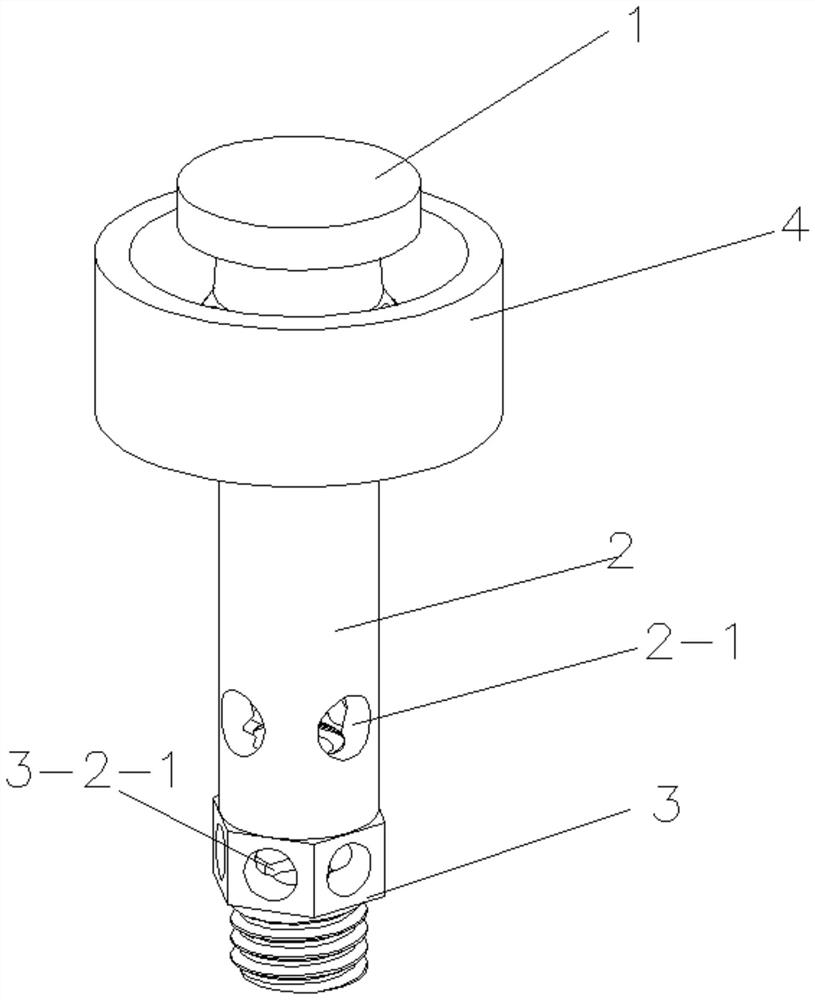

Combustion furnace and combustor thereof

PendingCN111964057AImprove access speedWell mixedDomestic stoves or rangesGaseous fuel burnerCombustorFlue gas

The invention discloses a combustion furnace and a combustor thereof. The combustor comprises an inner core, an air inlet pipe and a nozzle which are sequentially connected from top to bottom; at least one first air outlet hole is formed in the side wall of the inner core; the first air outlet hole is in communication with the air inlet pipe; the upper part and the lower part of the nozzle are incommunication with each other, the upper end of the nozzle is connected with the air inlet pipe, and the lower end of the nozzle is provided with a first connecting part; an hourglass-shaped channel is formed in the first connecting part; at least one first air inlet hole is formed in the side wall, above the first connecting part, of the nozzle; and at least one second air inlet hole is formed inthe side wall of the air inlet pipe. According to the combustion furnace and the combustor thereof, the channel with the hourglass-shaped longitudinal section is arranged at the gas inlet end, the gas inlet speed is increased, the air inlet holes are formed in the gas inlet pipe and the nozzle correspondingly, air is introduced, gas and air are fully mixed through secondary air inlet, then the combustion efficiency is improved, combustion is sufficient, the carbon content of flue gas is reduced, and pollution is reduced.

Owner:利邦厨具有限公司

Complete-upper-air-intake combustor with centrally-arranged mixing cavity

PendingCN110657432ASmall sizeWell mixedDomestic stoves or rangesGaseous fuel burnerMechanical engineeringMechanics

The invention discloses a complete-upper-air-intake combustor with a centrally-arranged mixing cavity. The combustor comprises a center burner cap, an outer ring burner cap, a combustor head, a combustor bottom, a combustor support, a center fire ejector, a first main fire ejector, and a second main fire ejector. An outer ring fire dividing cavity and a center fire mixing cavity are formed in thecombustor head, an air dividing channel is formed in the combustor head, the upper end of the air dividing channel communicates with the outer ring fire dividing cavity, the main fire centrally-arranged mixing cavity is formed in the combustor bottom, and the lower end of the air dividing channel communicates with the main fire centrally-arranged mixing cavity. The combustor is compact in structure, good in ejection capacity, high in stability, large in combustion power and high in work reliability.

Owner:陈毅

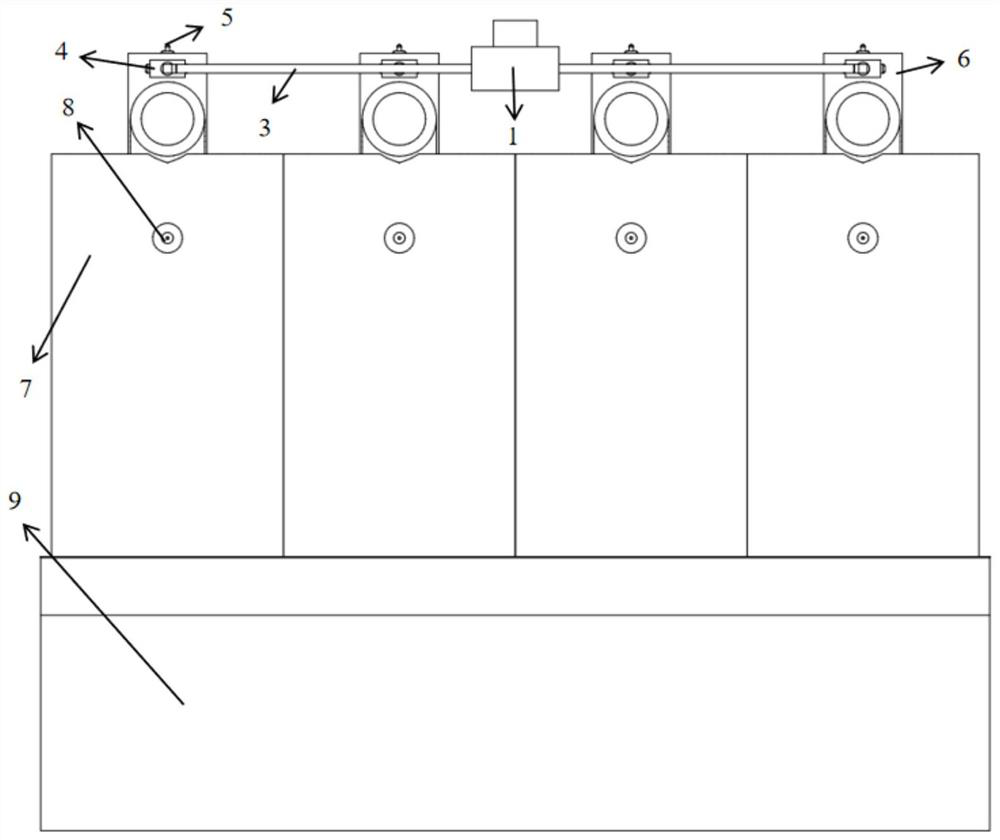

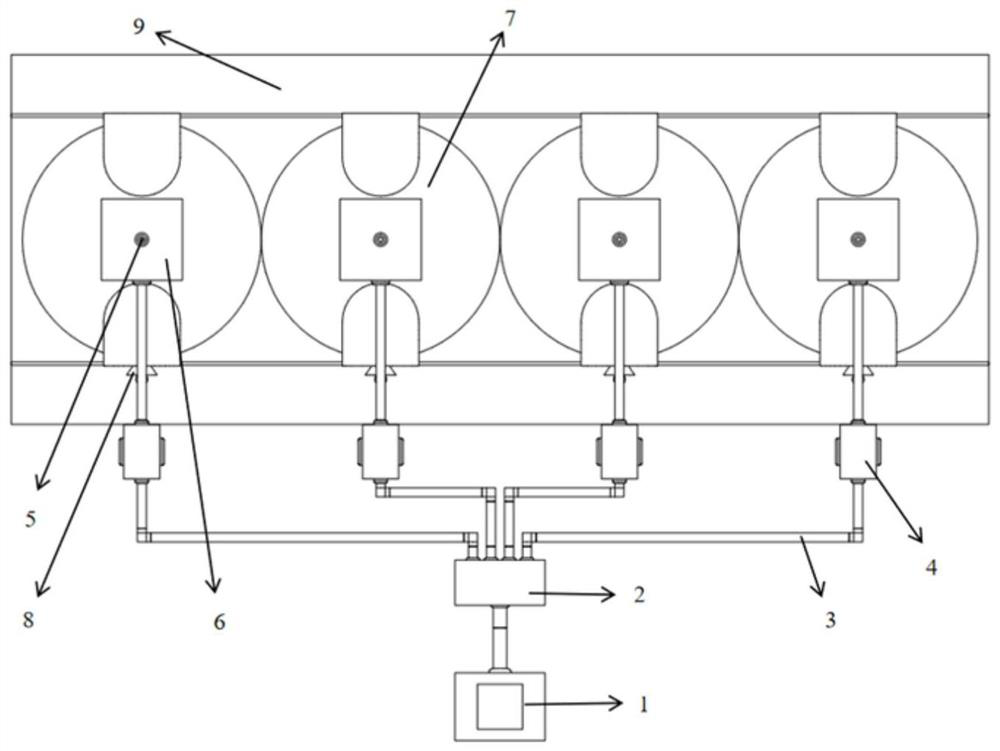

Microwave gasoline hybrid cylinder type engine

InactiveCN111810326ABurn fullyIncrease motivationInternal combustion piston enginesCombustion-air/fuel-air treatmentPollutant emissionsInlet valve

The invention discloses a microwave gasoline hybrid cylinder type engine. The microwave gasoline hybrid cylinder type engine comprises an internal combustion engine and a microwave system, wherein theinternal combustion engine comprises a plurality of cylinders; pistons are arranged in the cylinders in a matched manner; a spark plug, an air / oil inlet valve and an air outlet valve are arranged ona combustion area on one side of the piston in each cylinder; the microwave system comprises electromagnetic shielding cavities which are in one-to-one correspondence with the cylinders and magnetronswhich are used for inputting stable and continuous microwaves into the electromagnetic shielding cavities; the electromagnetic shielding cavities independently control on and off of microwave input through respective microwave switches; the microwave switches and the spark plugs of the corresponding cylinders are synchronously opened and closed; microwave mode converters which are used for converting the input microwaves from a rectangular waveguide mode to a circular waveguide mode are arranged on the electromagnetic shielding cavities; and a high-temperature-resistant microwave passing window through which the microwaves pass is arranged between each electromagnetic shielding cavity and the combustion area of the corresponding cylinder. The microwave gasoline hybrid cylinder type enginecan enable gasoline to be combusted more fully, improves the combustion efficiency, reduces pollutant emission, and is simple in structure and high in safety.

Owner:WUHAN UNIV

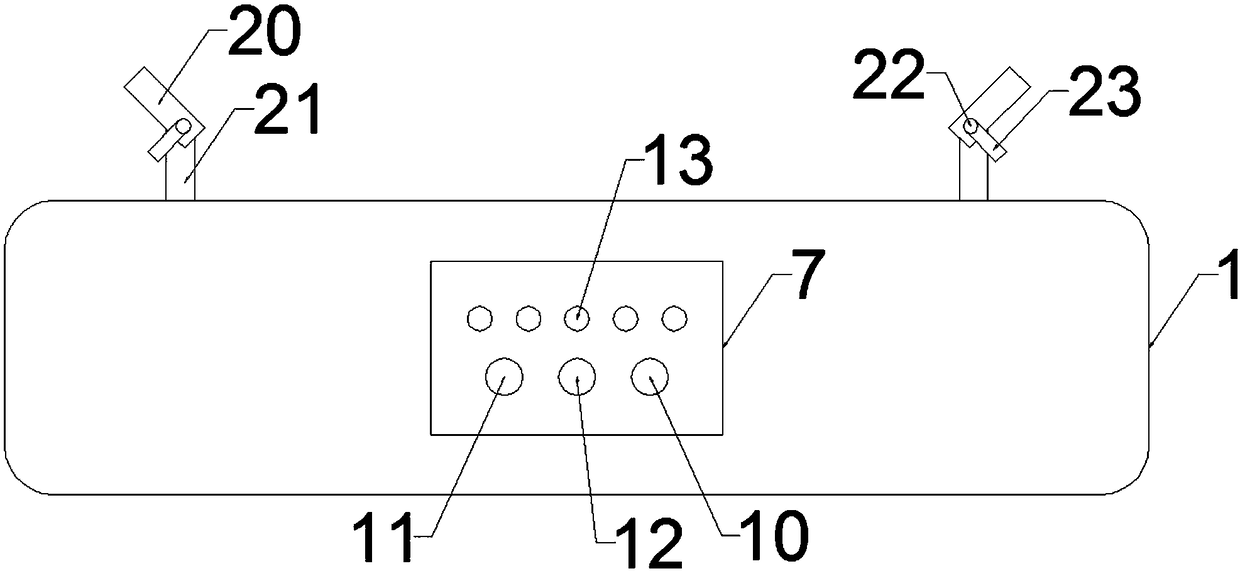

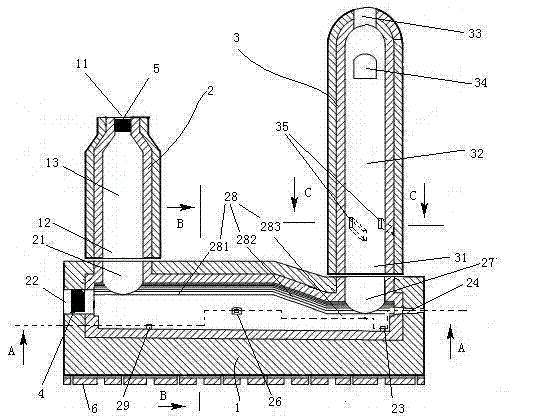

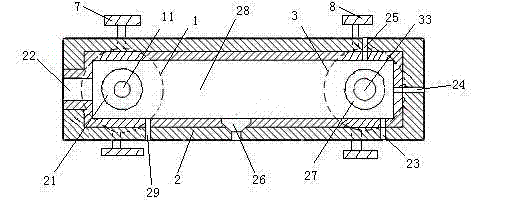

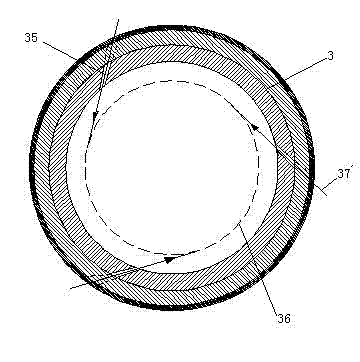

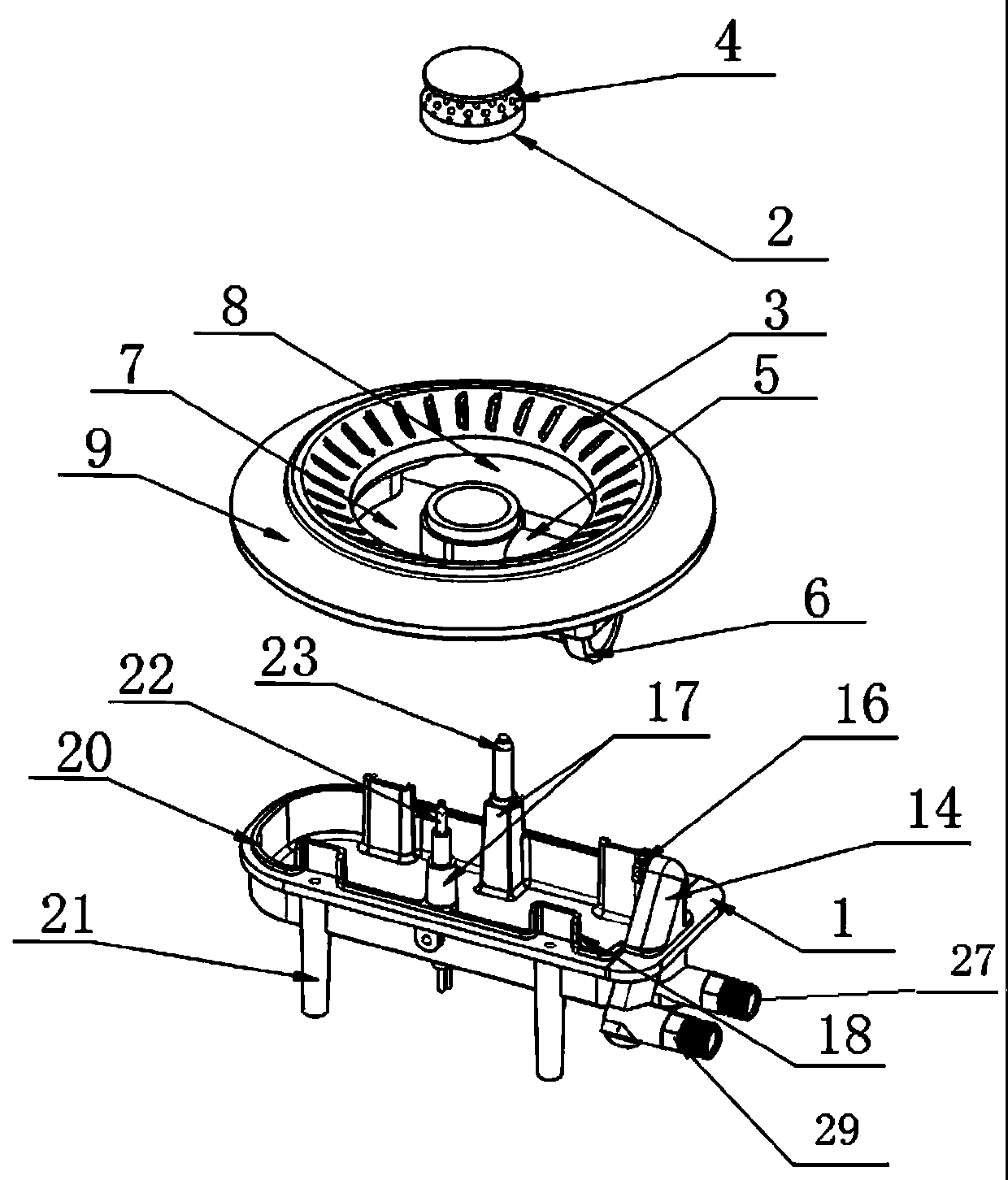

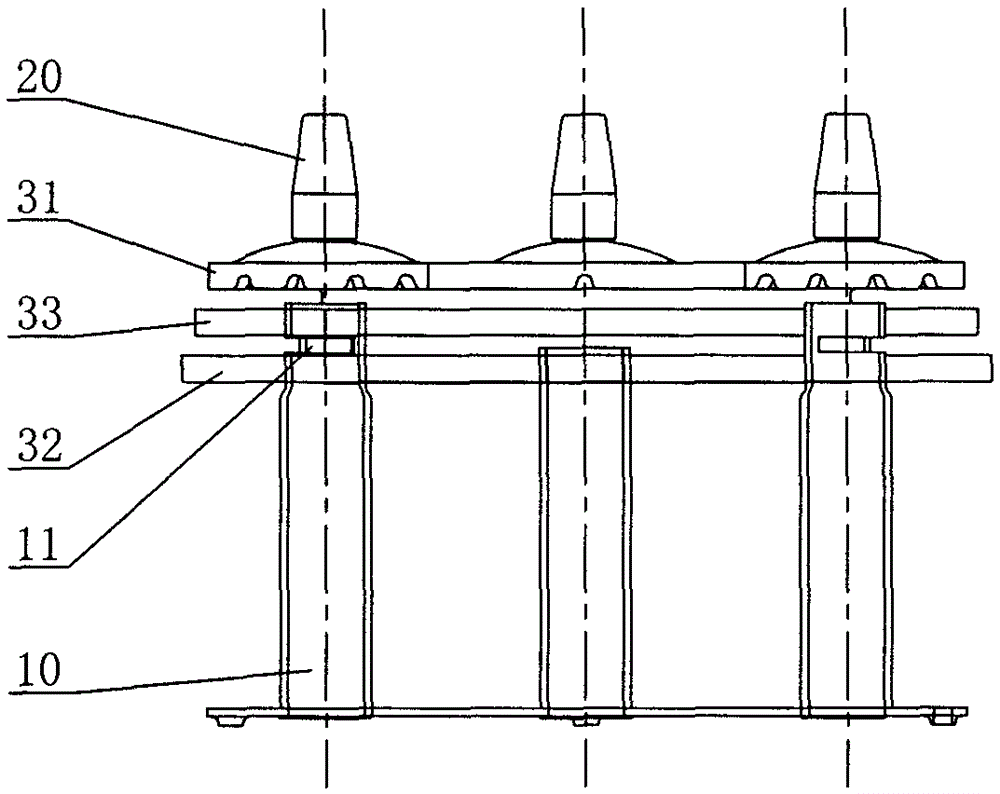

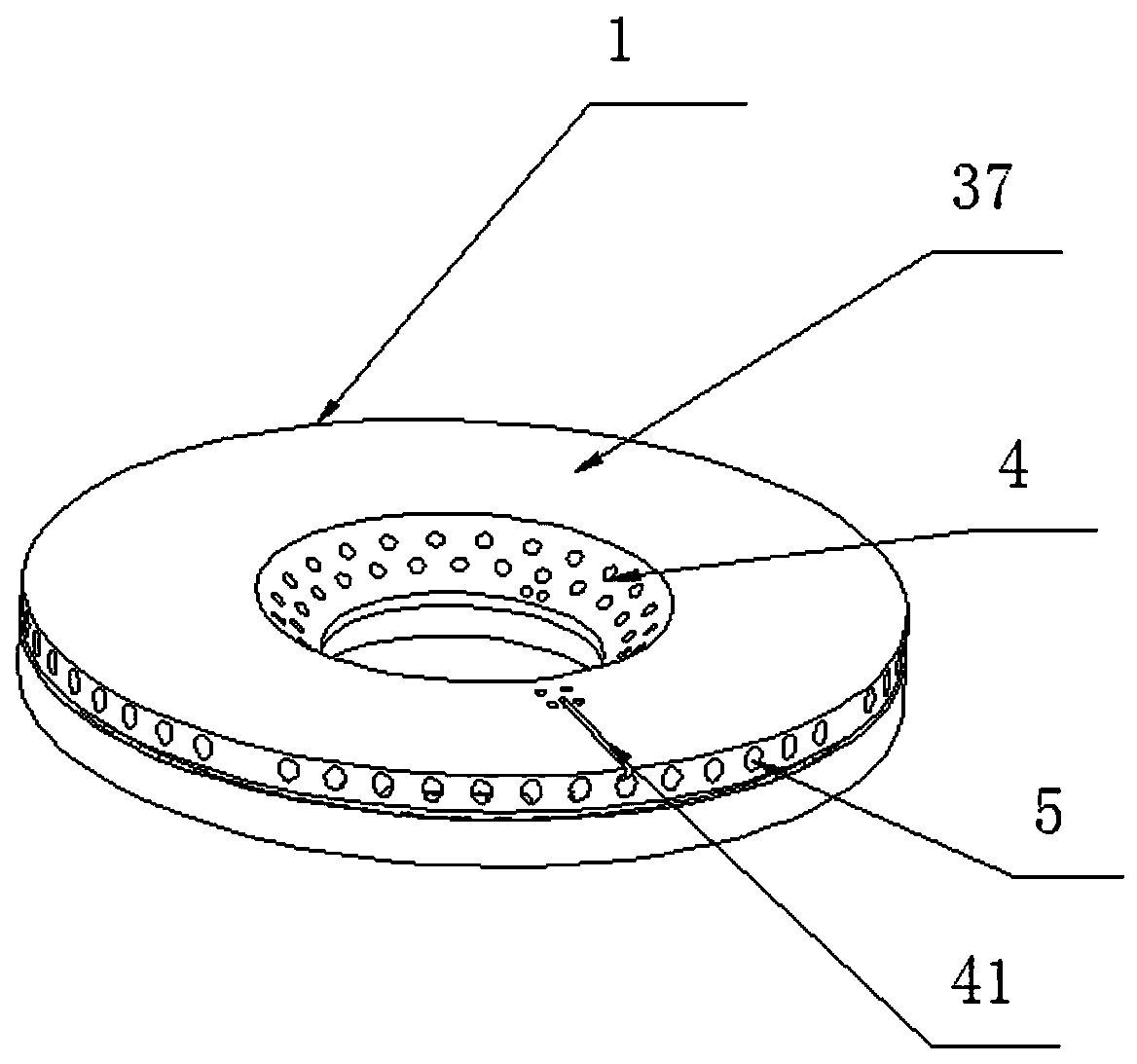

gas cooker

ActiveCN108332200BBest combustion powerIncrease combustion powerGaseous fuel burnerCombustorCombustion

The invention discloses a gas cooker. The gas cooker comprises a bottom shell, a panel, a fixed disc and a pot bracket, and a burner is mounted above the fixed disc. The bottom surface of the panel isprovided with a gas inlet passage, the upper surface of the panel is provided with a nozzle, and the nozzle is disposed opposite to a gas inlet on the burner. A primary air intake groove for the inflow of air is formed in the burner, and the primary air intake groove is located above the fixed disc. The burner includes an upper portion body and a lower portion body, the upper portion body is integrally casted to form three pipe-like protrusions, and the lower portion body is integrally casted to form three pipe-like depressions. After being combined, a first external fire ejector, an inner fire ejector and a second external fire which are horizontally arranged in an adjacent mode are formed. According to the gas cooker, the burner is installed above the fixed disc, and the air required for combustion comes from the upper portion of the panel. The mixing effect of gas and the air is good, the combustion effect is good, and the combustion power is large. The burner is formed by rivetingand connecting the upper portion body and the lower portion body which are integrally casted, the manufacturing process is simple, the ejector coefficient is large, the combustion effect is good, andthe hygienic property is good.

Owner:SHENGZHOU FUHUA GAS APPLIANCE

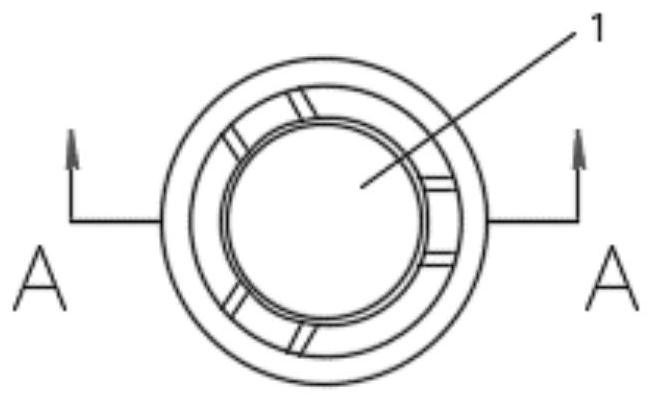

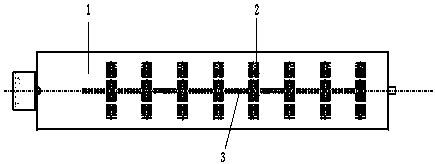

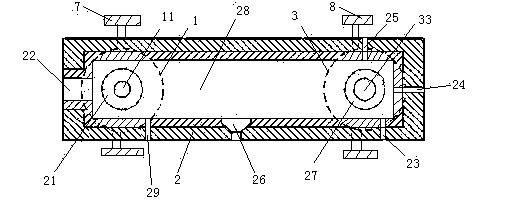

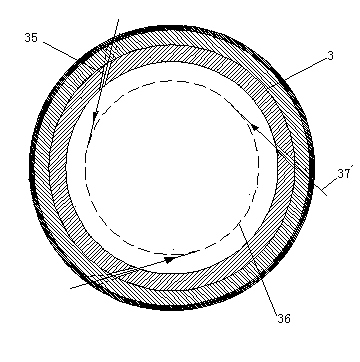

Atmospheric tubular burner with built-in gas uniform distributor ejector

The invention provides an atmospheric type tubular combustor with built-in gas uniform distributor and ejector. The atmospheric type tubular combustor comprises a combustor body, wherein the combustor body is a round-tube-shaped combustor. Combined fire holes composed of round holes and square holes are uniformly distributed in the outer surface of the combustor body; fire ignition holes are formed between the adjacent combined fire holes; an ejection tube and the gas uniform distributor are arranged in the combustor body; an opening in one end of the combustor body is sealed with an end cover flange; a fixing pin is mounted at the center of the flange so that the flange is convenient to position and fix; the other end of the combustor body is packed by another flange which sleeves the ejection tube.

Owner:深圳市安普节能科技有限公司

High Efficiency Burner Assembly

ActiveCN103727540BIncrease the burning areaEliminate or reduce white spaceGaseous fuel burnerEnvironmental resistanceCombustor

An efficient combustor assembly comprises a distributor and a furnace end gas distribution base corresponding to a gas circuit of the distributor. The distributor is connected with gas guide tubes. The distributor and the gas guide tube located at the center form a center flame layer. The distributor and the gas guide tubes located on the periphery form peripheral flame layers. The peripheral flame layers are divided into at least two layers. The distributor comprises an upper distributor cover and a lower distributor cover. The upper distributor cover and the lower distributor cover are repeatedly stacked up and down or are stacked in a staggered mode. The distributor further comprises a middle distributor cover. The upper distributor cover and the middle distributor cover form one peripheral flame layer, and the middle distributor cover and the lower distributor cover form the other peripheral flame layer, or the upper distributor cover forms one peripheral flame layer, and the middle distributor cover forms the other peripheral flame layer. By the adoption of the efficient combustor assembly, the combustion area of flames is increased, coverage blanks of flames are reduced or eliminated, the combustion power of the combustor assembly is greatly increased, heat efficiency is improved, the waste gas emission load is reduced, and the environment friendliness effects of saving energy and reducing emission are possessed.

Owner:广东年代集成厨电有限公司

U-shaped high-temperature waste recycling furnace

InactiveCN102380501BEnhance gas-solid two-phase separationReduce dust contentSolid waste disposalEngineeringWaste treatment

The invention relates to the field of waste treatment, and provides a U-shaped high-temperature waste recycling furnace, which has the advantages of high treating capacity, environmental friendliness, economic efficiency, high metal recovering rate and high waste suitability. The U-shaped high-temperature waste recycling furnace comprises a vertical combustion tower, a horizontal smelting pond and a vertical disinfecting tower, wherein the top wall of one end of the smelting pond is provided with a first smelting pond inlet hole; the end wall of the smelting pond is provided with a second smelting pond inlet hole; the top wall of the other end of the smelting pond is provided with a smelting pond outlet hole; the top wall of the combustion tower is provided with a combustion tower inlet hole; the bottom wall of the combustion tower is provided with a combustion tower outlet hole; the bottom wall of the disinfection tower is provided with a disinfection tower inlet hole; the top end of the disinfection tower is provided with a smoke outlet; a first turbulent burner is arranged in the combustion tower inlet hole; the combustion tower outlet hole is in butt joint with the first smelting pond inlet hole; the smelting pond outlet hole is in butt joint with the disinfection tower inlet hole; and the side wall of the disinfection tower is provided with at least two air inlet holes. Due to the adoption of the U-shaped high-temperature waste recycling furnace, the problems of poor working condition stability during combustion of wastes and discharge of toxic gases in tail gas out of the standard are solved.

Owner:ZHEJIANG HUANYI TECH

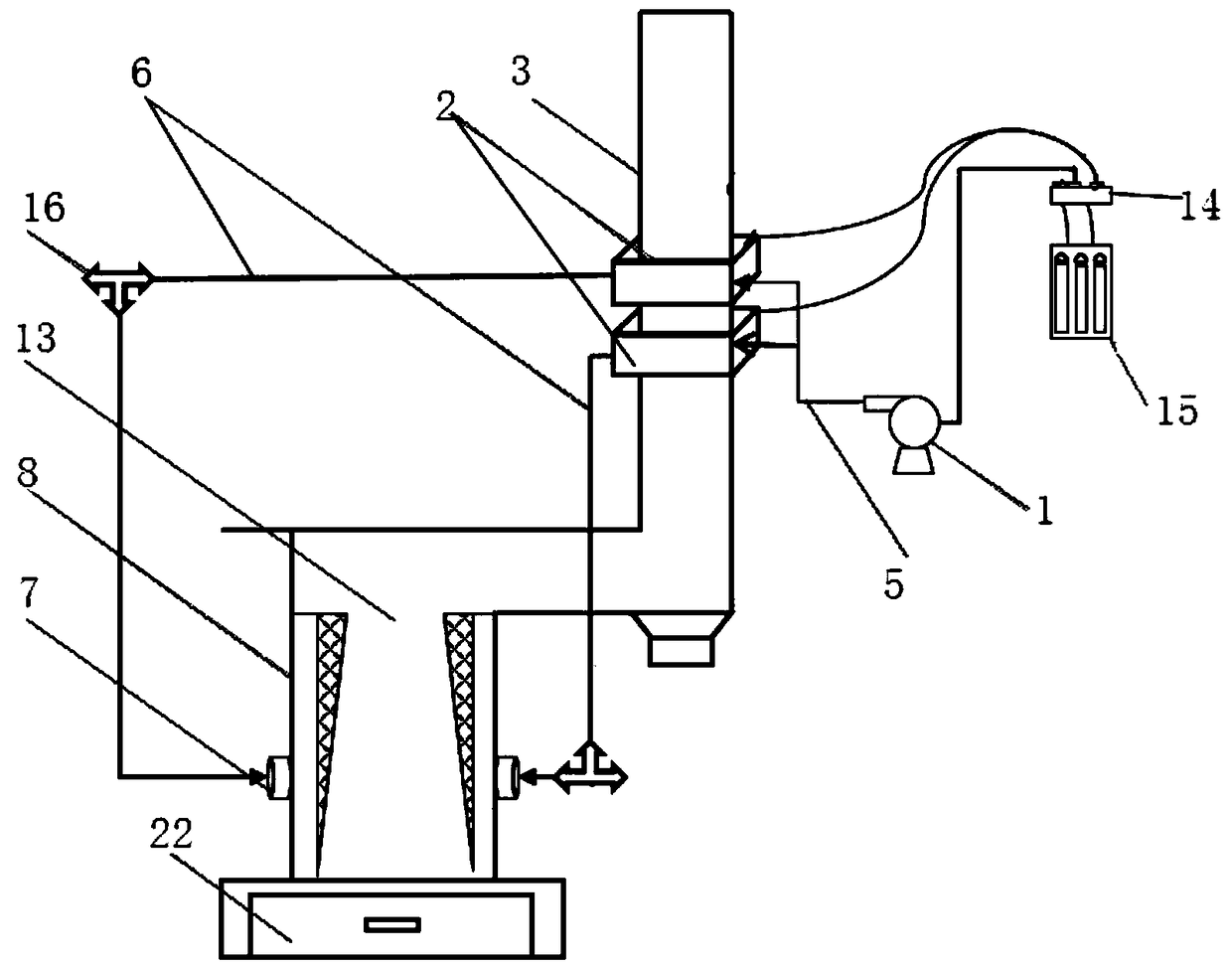

Blowing system of self-powered biomass direct fired furnace

InactiveCN108692330AStable combustionLower cold junction temperatureNon-combustible gases/liquids supplyGenerators/motorsPollutant emissionsEngineering

The invention discloses a blowing system of a self-powered biomass direct fired furnace. The system comprises an air blower and a temperature difference generator, wherein the temperature difference generator is annularly and fixedly mounted on a chimney, an annular air duct is arranged out of the temperature difference generator, an air inlet of the annular air duct is connected to the air blowerthrough an air inlet pipe, an air outlet of the annular air duct is connected to a secondary tuyere communicating to a hearth through an air outlet pipe, and the secondary tuyere is arranged in the lower part of the biomass direct fired furnace. According to the system disclosed by the invention, the air blower blows air to the cold end of the temperature difference generator mounted on the chimney and hot air passing the temperature difference generator is fed into the secondary tuyere communicating to the hearth, so that on the one hand, the temperature of the cold end of the temperature difference generator can be reduced, the temperature difference between the cold end and the hot end is increased, and the generating efficiency is improved; and on the other hand, the temperature of secondary air from the annular air duct of the temperature difference generator is increased to achieve preheating and the secondary air is fed into the hearth, so that stable combustion in the hearth is achieved, and the discharging amount of pollutants is reduced. Heat of exhaust air in the chimney is utilized effectively, and the efficiency of the biomass direct fired furnace is improved.

Owner:GUIZHOU UNIV

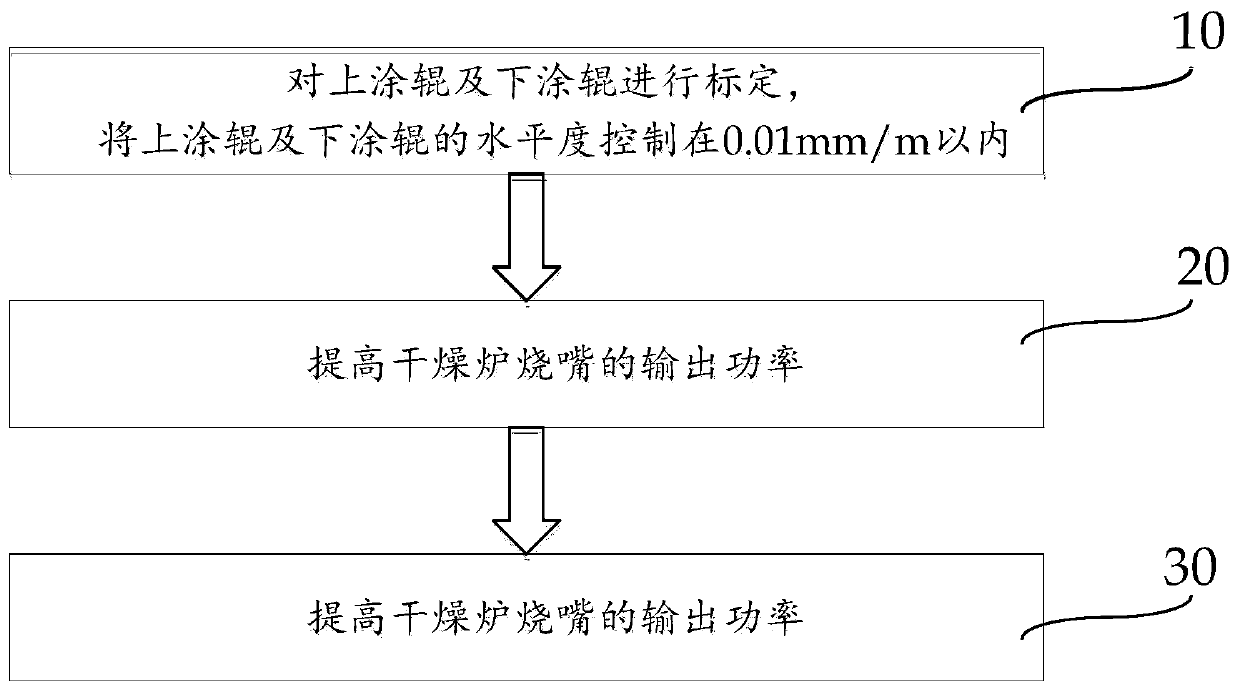

A kind of control method of coiling tower shape of silicon steel magnesia coating

ActiveCN106622837BIncrease output powerIncrease combustion powerLiquid surface applicatorsCoatingsEngineeringTower

The invention relates to the technical field of metallurgy, in particular to a control method for the telescope of a silicon-steel magnesium oxide coating. The control method comprises the steps of calibrating an upper coating roller and a lower coating roller, controlling the level degrees of the upper coating roller and the lower coating roller to within 0.01mm / m; improving the output power of a drying oven nozzle; and controlling the deviation between a steel reel rolling diameter calculated value and a real-time diameter of a steel reel to within 1 / 1000. According to the control method for the telescope of the silicon-steel magnesium oxide coating provided by the invention, the technical problem that the telescope occurs easily due to the influence of the magnesium oxide coating during silicon steel production in the prior art is solved, the steel reel is prevented from becoming a scrap, and the phenomenon that the production is influenced since the steel reel cannot smoothly move out from a mandrel of a reeling machine is avoided.

Owner:SHOUGANG ZHIXIN QIAN AN ELECTROMAGNETIC MATERIALS CO LTD

Mixed gasoline cleaning agent and preparation method thereof

InactiveCN108949257AImprove powerIncrease profitLiquid carbonaceous fuelsAntioxidantCleansing Agents

The invention discloses a mixed gasoline cleaning agent and a preparation method thereof. Gasoline, an antioxidant, a carbon deposition eliminator, a power promoter and a corrosion inhibitor which serve as primary raw materials are mixed and stirred in a certain proportion, the cleaning agent is added into the gasoline to be mixed for use, and in the gasoline combustion process, the power performance of the gasoline can be improved by 5-10%, 30% is the optimum adding proportion and 50% of the addition amount can ensure that the power performance can fully meet the state gasoline standard. A product prepared from the raw materials can increase the travelling power of an automobile, reduce tail gas of the automobile, reduce the carbon deposition of the automobile engine, reduces the gasolineadditive for reducing oil consumption of the automobile and improves the grade. The cleaning agent can protect parts in a long-acting manner. Indexes after the cleaning agent is used are superior tothose of common gasoline.

Owner:刘雪源

Fire distribution structure of two-cavity direct injection burner

The invention discloses a fire distribution structure of a two-cavity direct injection burner. The fire distribution structure comprises a burner cap seat which is provided with an external fire ringand a center fire ring; the external fire ring is connected with an external ring burner cap in a covered manner; the center fire ring is connected with a center burner cap in a covered manner; an external ring gas inlet is formed in the position, corresponding to the external fire ring, of the bottom of the burner cap seat; the external ring gas inlet communicates with the external fire ring; a center gas inlet is formed in the bottom center of the burner cap seat; the center gas inlet communicates with the center fire ring through a plurality of center gas inlet channels formed in the periphery of the center gas inlet; the bottom of the center gas inlet is closed; and an inverted-cone-shaped gas-distributing cone is arranged at the parts, corresponding to the connecting parts of the center gas inlet and the center gas inlet channels, of the inner bottom of the center gas inlet. The gas-distributing cone can allow a gas mixture of air entering from the center gas inlet and gas to generate turbulence, the air is mixed with the gas fully, the gas mixture is uniformly conveyed to the center gas inlet channels, the center fire ring and the center burner cap, the gas mixing effect of the gas mixture entering the center burner cap is good, and sufficient combustion can be guaranteed.

Owner:GUANDDONG JIBAO ELECTRICAL APPLIANCE TECH CO LTD

a fuel heater

InactiveCN105003366BFast ignitionIncrease heatMachines/enginesThermal treatment of fuelEngineeringCarbon dioxide

Owner:宁波中创机电有限公司

Complete upper inlet air burner

PendingCN111102571AHigh working reliabilityWell mixedGaseous fuel burnerHome appliance efficiency improvementThermodynamicsCombustor

Owner:陈毅

A Hydrogen Combustor Based on Axial Vortex-to-column Mixing

ActiveCN113137631BEfficient combustionSimple structureContinuous combustion chamberIndirect carbon-dioxide mitigationCombustion instabilityThermodynamics

The present disclosure provides a hydrogen combustor based on an axial vortex pairing arrangement, including: a flame tube, the flame tube includes an outer ring and an inner ring; an outer casing, and the outer ring of the flame tube encloses an air circulation outer channel ; The inner casing is fixedly connected to the inside of the outer casing, and the inner casing and the inner ring of the flame tube form an air circulation inner channel; at least two axial vortex generators, and the axial vortex generator is a tetrahedral cavity The axial vortex generators are fixedly connected to the outer ring and the inner ring of the flame tube respectively, and are suitable for providing axial vortex to make fuel mixed and burned. The hydrogen combustor based on the axial vortex arrangement in this disclosure for blending proposes a design scheme combining the axial vortex and the tiny tangential jet. The tetrahedral structure is used to generate the axial vortex for blending. Compared with the non-reflux zone and low-velocity zone, the combustion chamber of the recirculator can effectively burn pure hydrogen, and overcome the problems of flashback, self-ignition and combustion instability.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

Burner with multiple venturi tubes

PendingCN109959002AIncrease combustion powerBurn fullyGaseous fuel burnerCombustorStructural engineering

Owner:GTC GAS TECH COMPONENTS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com