Plug valve assembly for embedded gas stove

A gas stove and plug valve technology, which is applied to multi-port valves, valve devices, engine components, etc., can solve problems such as incomplete dislocation opening, inability to ensure synchronization in step-by-step processing, and inability to intelligently control the linkage of electrical equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below in conjunction with the accompanying drawings.

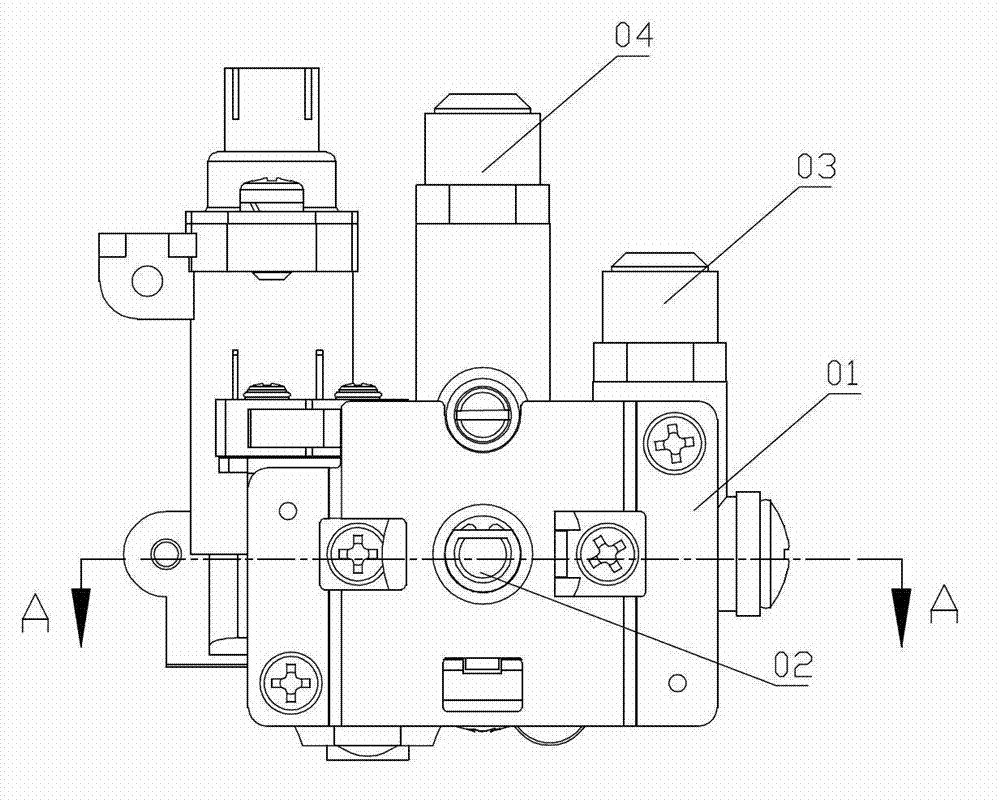

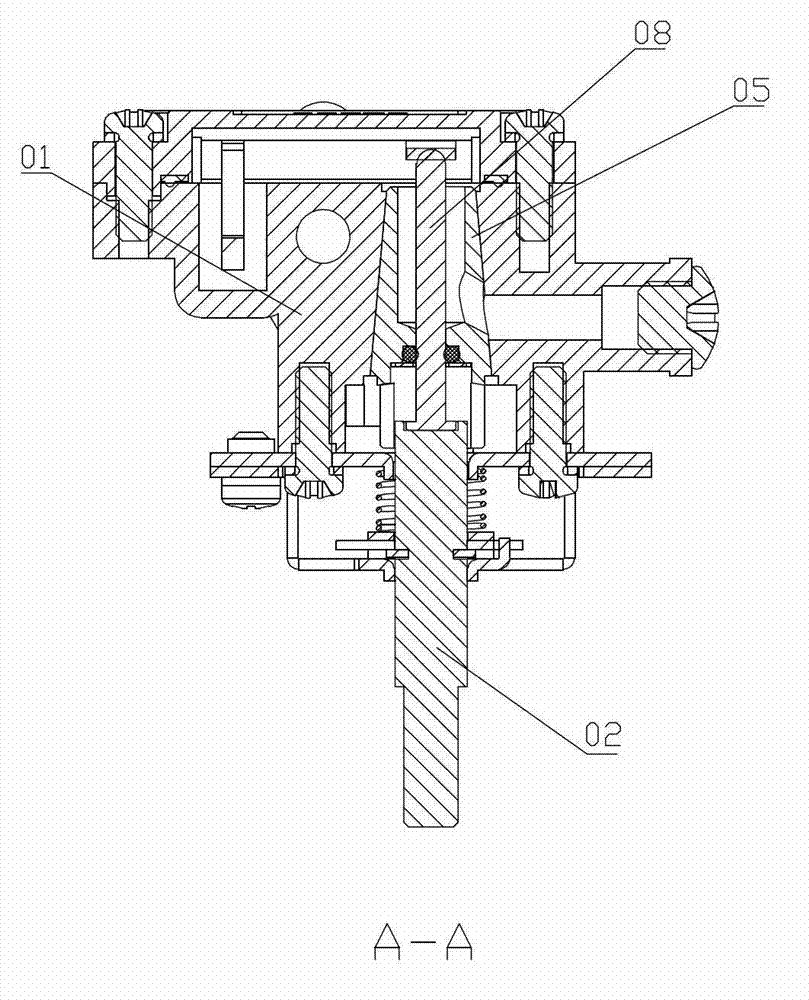

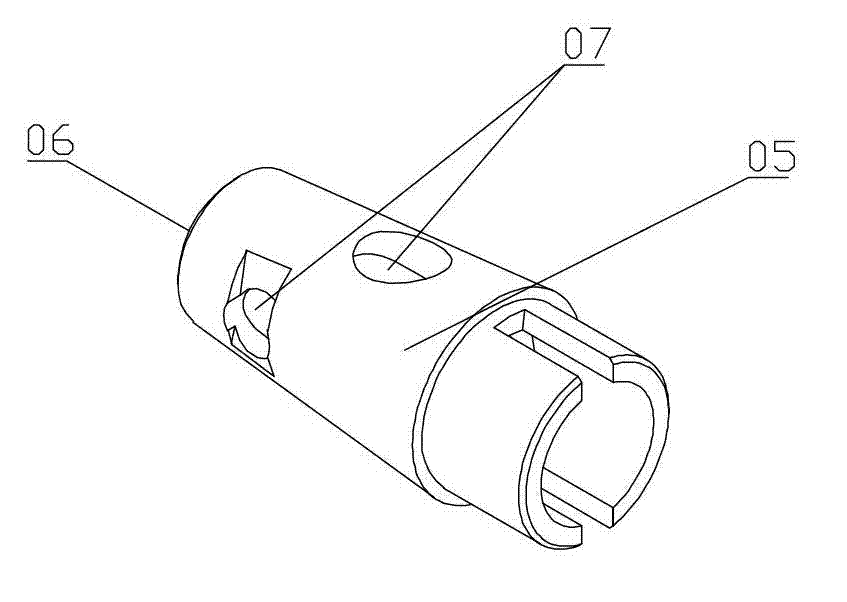

[0028] combined with Figure 5 to attach Figure 15 , a plug valve assembly for an embedded gas stove, which includes a valve body 1, a knob 2, a first trigger block 3, a first detection component 5 for detecting the state of the first trigger block 3, an air intake mouth, air outlet and spool 12; the first detection part 5, air inlet, air outlet and spool 12 are installed on the valve body 1, the spool 12 is located between the air inlet and the air outlet, the knob 2 and the valve The spool 12 is rotatably connected, the spool 12 is cylindrical or conical, the spool 12 is provided with an air inlet 13 and an air outlet 14, and the inside of the spool 12 is a cavity; the first trigger block 3 is installed on the knob 2, and the second A detection component 5 is located at a position where the state of the first trigger block 3 can be detected; the gas outl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com