Burner with multiple venturi tubes

A Venturi tube and burner technology, applied in the direction of burners, gas fuel burners, combustion methods, etc., can solve the problems of uneven combustion of nitrogen oxides, insufficient combustion power of fire row, etc., and achieve compact structure and high combustion power , can fully burn the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

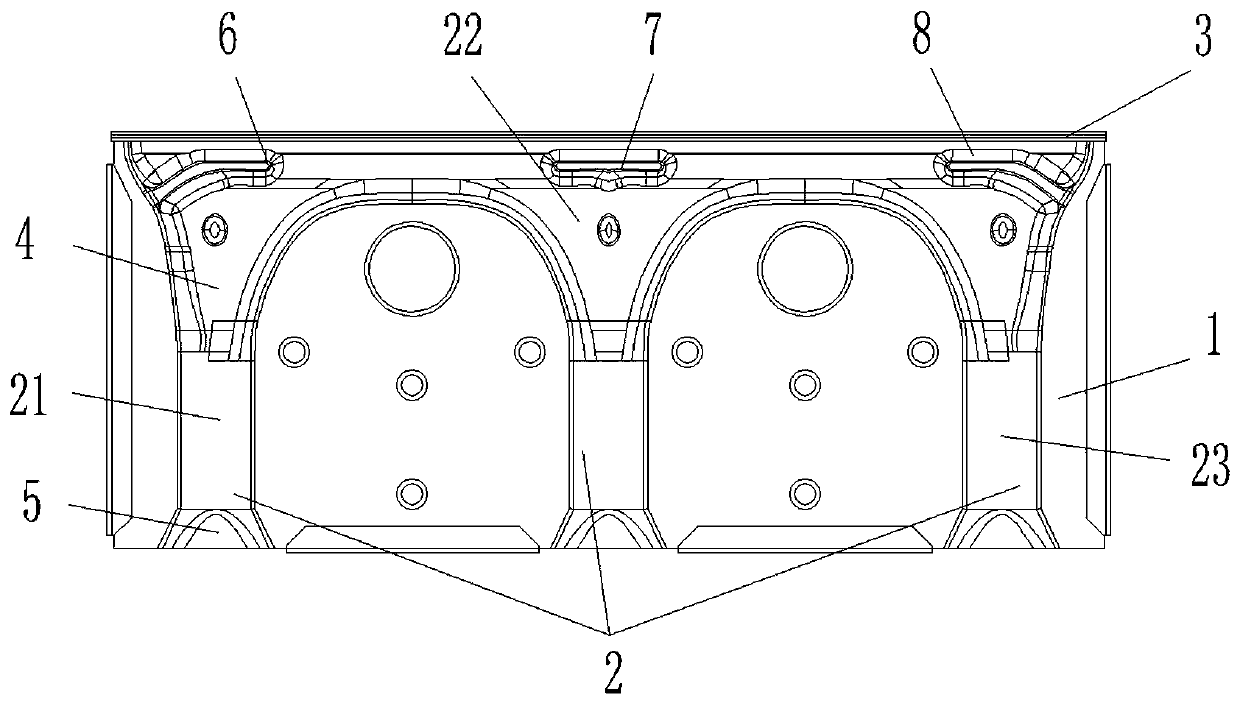

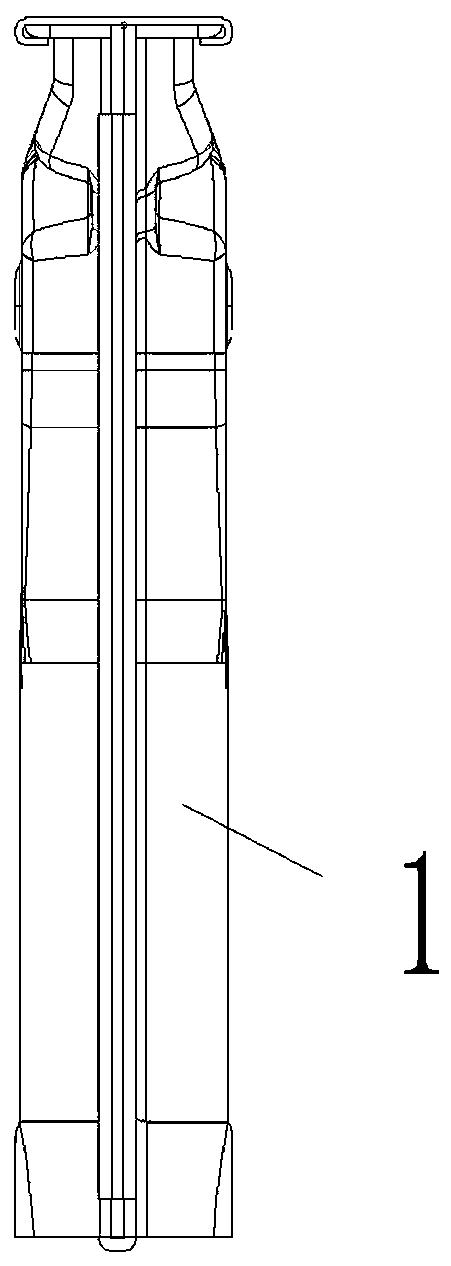

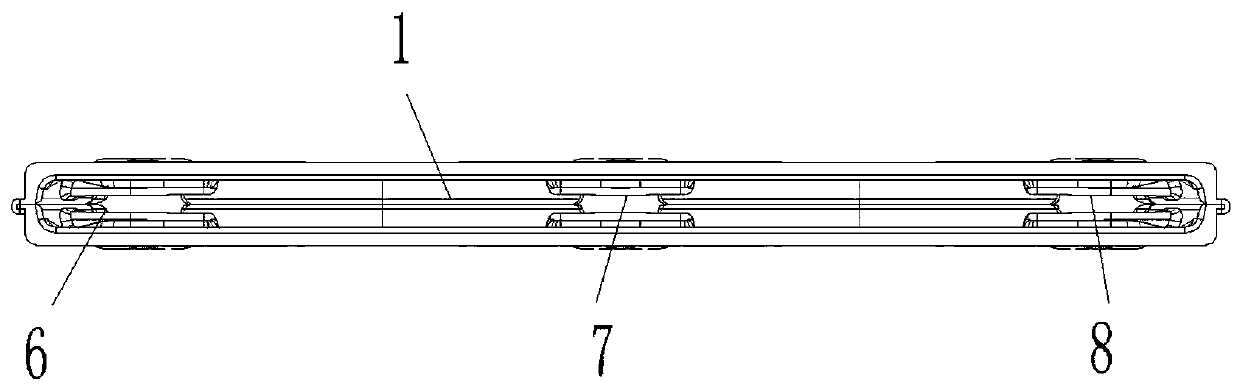

[0014] Such as Figure 1 to Figure 3 As shown, in this embodiment, the present invention includes several fire rows 1 arranged in sequence, and at least three venturi tubes 2 are arranged in several of the fire rows 1, and the upper ends of the three venturi tubes 2 are all connected, and the upper end surface of the fire row 1 is equipped with a cooling plate 3 . Compared with the conventional technology, generally only one or two venturi tubes are provided and the combustion power of the fire row is insufficient, the setting of at least three venturi tubes 2 increases the power of the fire row 1, and the structure is more efficient. It is compact and more sufficient when injecting air, so that the combustion of gas is more complete and the emission of smoke pollutants is reduced, so that the present invention has the advantages of compact structure, high combustion power and sufficient combustion.

[0015] In this embodiment, the number of the Venturi tubes 2 is three.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com