High Efficiency Burner Assembly

A burner and assembly technology, which is applied in the field of high-efficiency burner assemblies, can solve the problems of large gas power limitation and small scope of application, and achieve the effects of simple structure, wide application scope and high energy efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

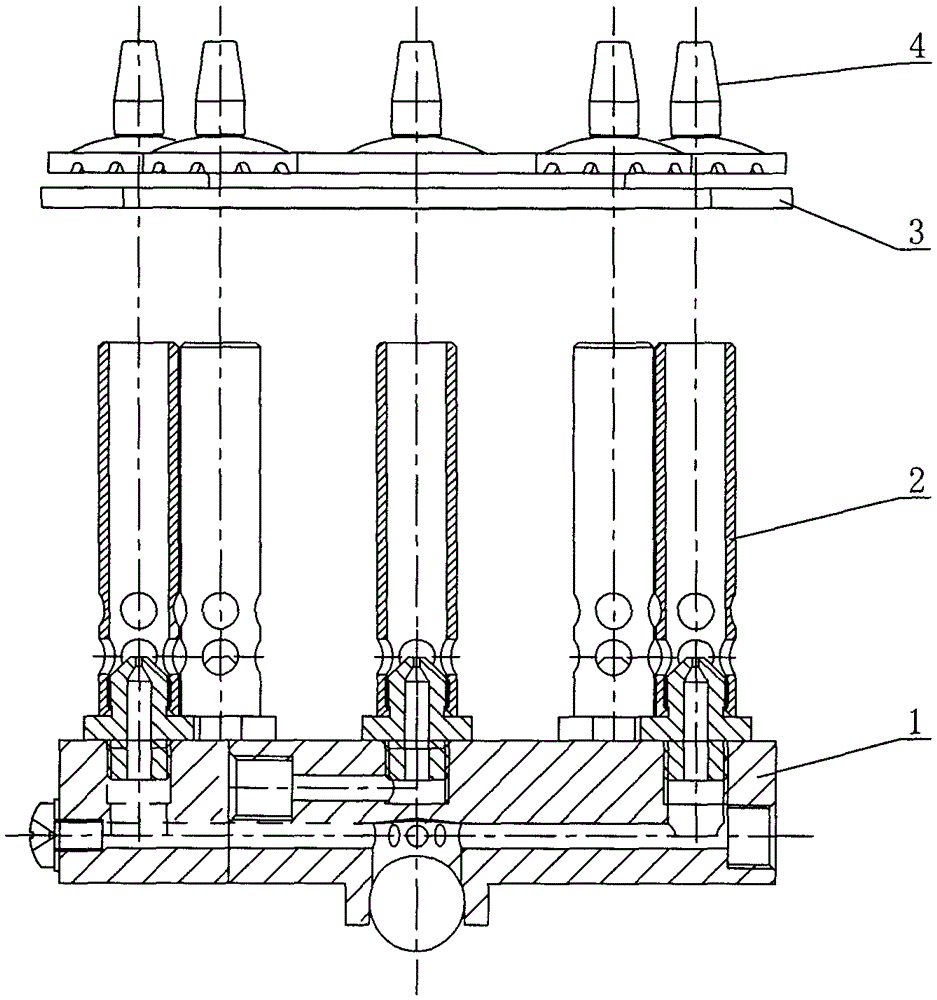

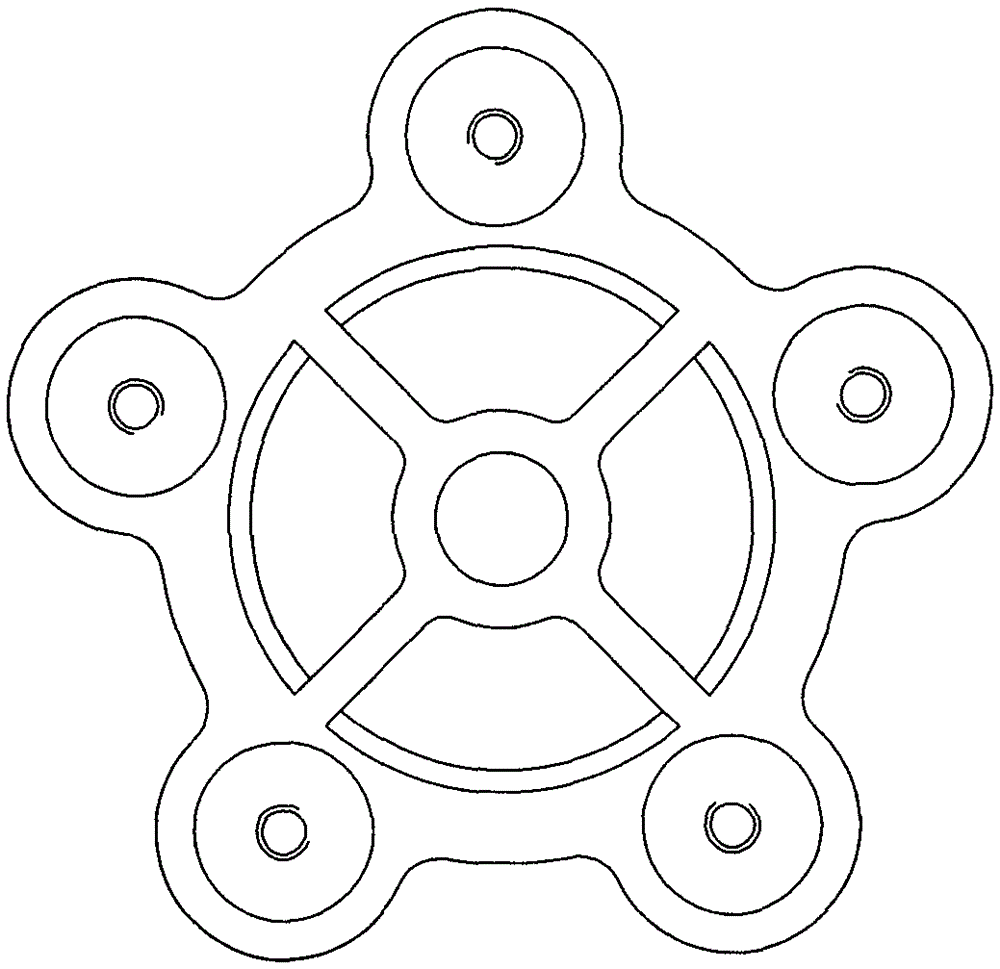

[0024] see Figure 3-Figure 4 , the high-efficiency burner assembly includes a fire distributor and a burner gas distribution seat (not shown in the figure) corresponding to the gas path of the fire distributor. A central flame layer is formed, and a central fire cover (not shown in the figure) can also be provided at the center of the fire distributor to meet the requirements of use. The fire distributor and the peripheral air duct 10 form a peripheral flame layer; the peripheral flame layer is at least divided into two layers , The fire distributor includes a fire distributor upper cover 31 and a fire distributor lower cover 32.

[0025] In this embodiment, the peripheral flame layer is divided into two layers, which are inner and outer layers. Wherein, the fire distributor also includes a fire distributor middle cover 33 arranged between the fire distributor upper cover 31 and the fire distributor lower cover 32, and the fire distributor upper cover 31 and the fire distrib...

no. 2 example

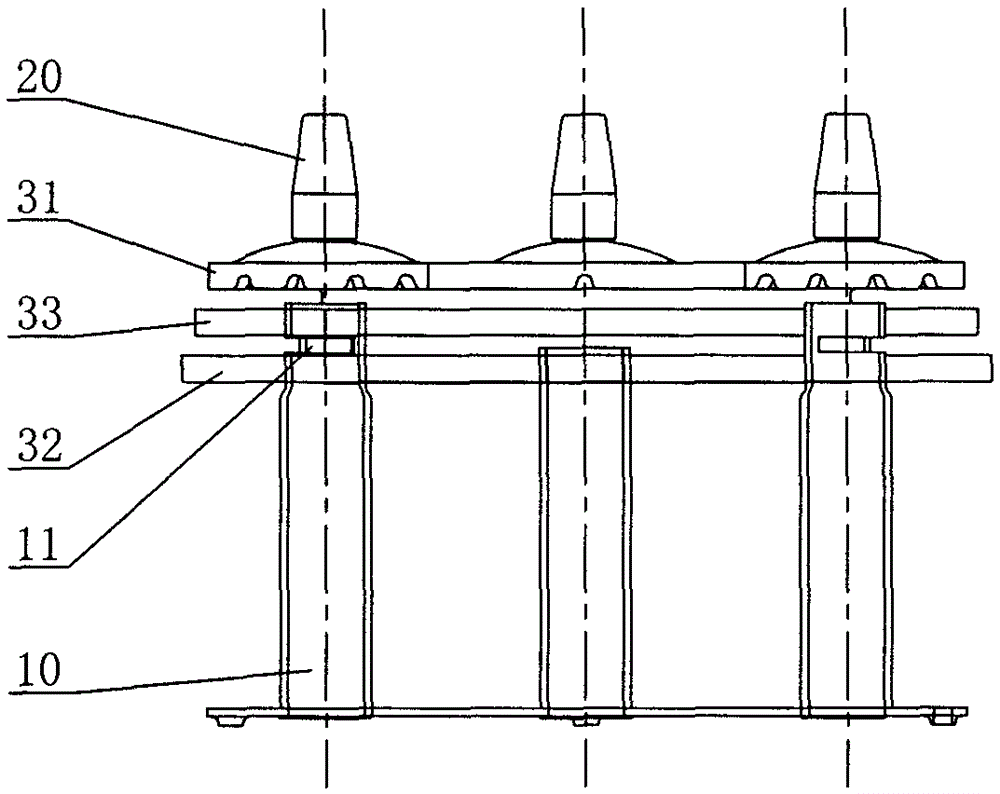

[0030] see Figure 5-Figure 6 , the main difference between the high-efficiency burner assembly and the first embodiment is that the upper cover 31 of the fire distributor and the lower cover 32 of the fire distributor are stacked in dislocation, that is, the inner and outer flames will be respectively equipped with air ducts 10 ( Peripheral airway tube 10 totally 8 groups), therefore, the airway tube 10 top that is positioned at periphery is open and can meet the requirement of supplying air (oxygen), simplifies the processing procedure of airway tube 10. In this embodiment, the two ends of the section of the fire distributor are stepped and gradually decrease from top to bottom, that is, the peripheral flame layer is layered up and down. Compared with the first embodiment, the combustion area of this embodiment can be improved more effectively. Therefore, this embodiment is especially suitable for use in hotel kitchens (for large pots and stoves).

[0031] In addition, th...

no. 3 example

[0034] see Figure 7 , The main difference between the high-efficiency burner assembly and the second embodiment is that the two ends of the cross-section of the fire distributor are stepped from top to bottom and outwards, that is, the peripheral flame layer is layered inside and outside. This embodiment is particularly suitable for use at home (for small pots and stoves).

[0035] Other parts not described are the same as the second embodiment and will not be repeated.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com