Hydrogen combustion chamber based on axial vortex opposite arrangement mixing

A combustion chamber, axial technology, applied in the combustion chamber, continuous combustion chamber, combustion method, etc., can solve the complex structure of the transverse jet micro-mixing combustion chamber, the difficulty of burning high-concentration hydrogen and pure hydrogen, and the high design and test costs. problems, to achieve the effect of improving the combustion power per unit volume, fast processing speed, and cheap geometric modeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

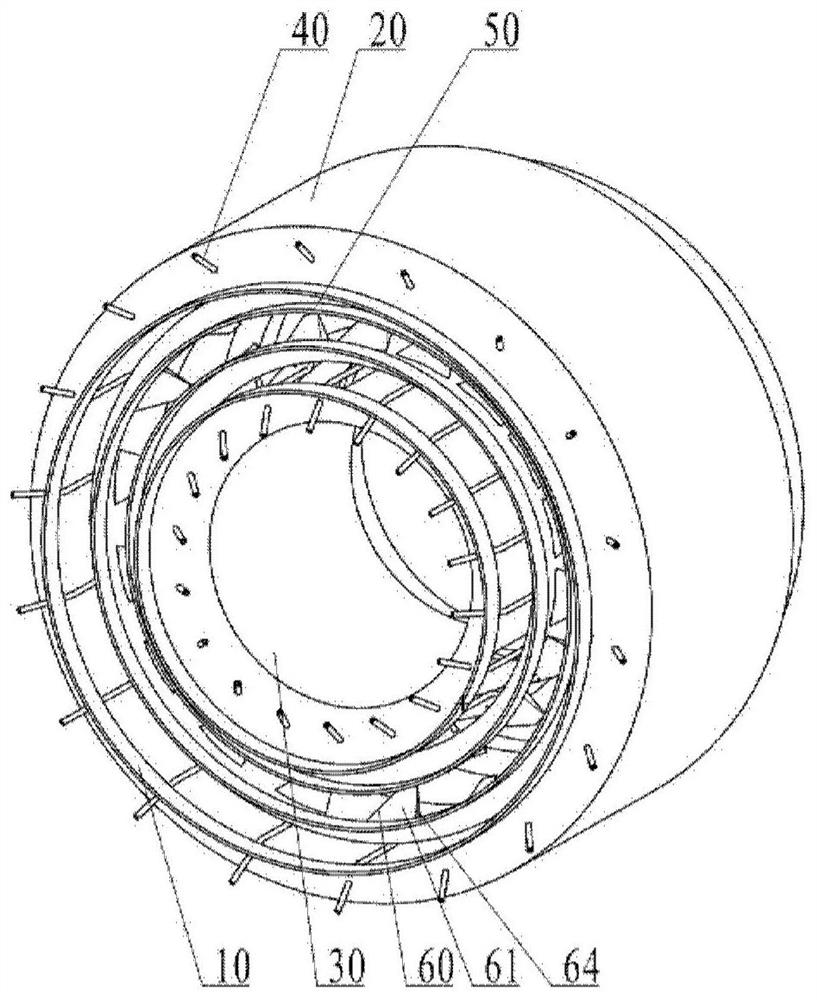

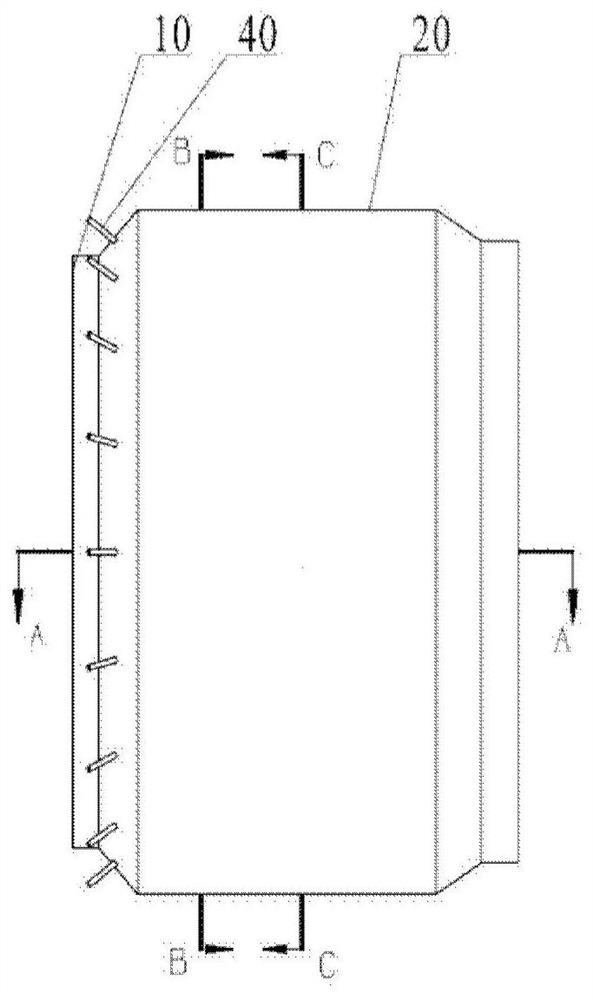

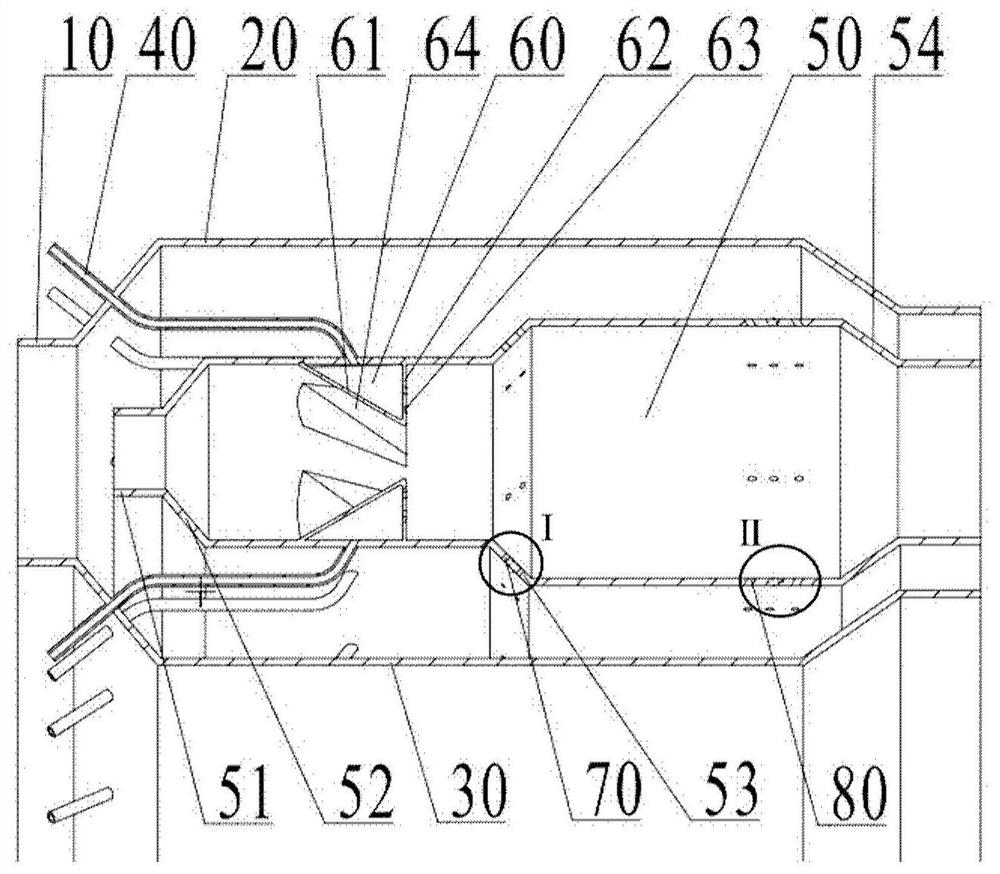

[0059] The present disclosure provides a hybrid hydrogen combustor based on an axial vortex pair arrangement, including a flame cylinder, an outer casing, an inner casing, and at least two axial vortex generators. The flame tube includes an outer ring and an inner ring; the outer casing and the outer ring of the flame tube form an air circulation channel; the inner casing is fixedly connected to the inside of the outer casing, and the inner casing and the inner ring of the flame tube form an air circulation channel. aisle. The axial vortex generator is a tetrahedral cavity, and the axial vortex generators are fixedly connected to the outer ring and the inner ring of the flame tube respectively, which is suitable for generating axial vortex so that hydrogen fuel can be effectively mixed and burned without blowing out , Tempering and other issues. The hydrogen combustor based on the axial vortex arrangement in this disclosure for blending proposes a design scheme combining the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com