Complete-upper-air-intake combustor with centrally-arranged mixing cavity

A burner and mixing chamber technology, applied in burners, gas fuel burners, combustion methods, etc., can solve problems such as poor gas adaptability, airflow interference, and lack of promotion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

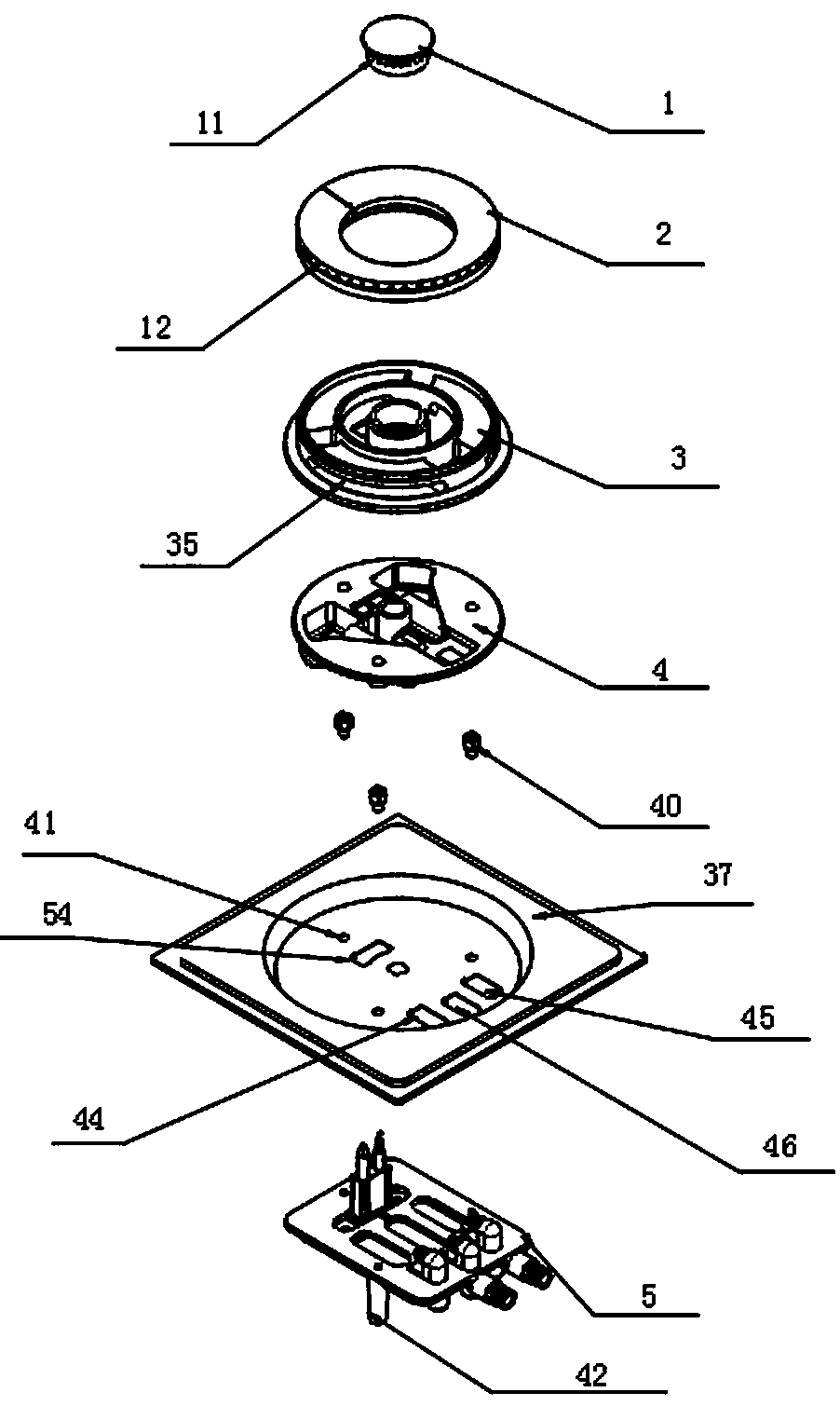

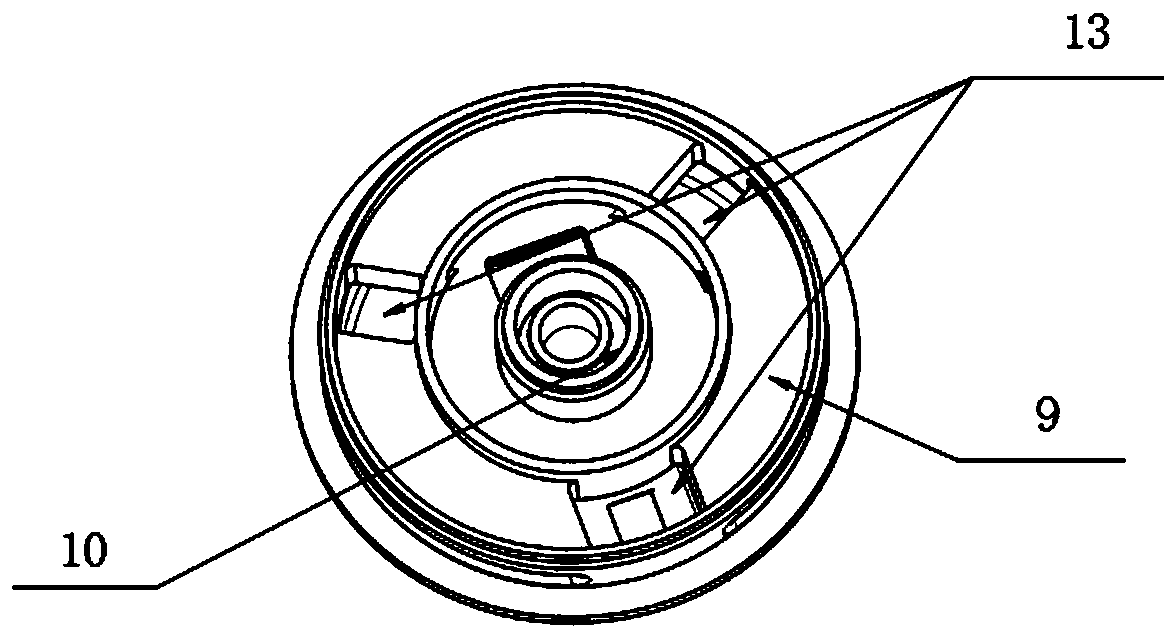

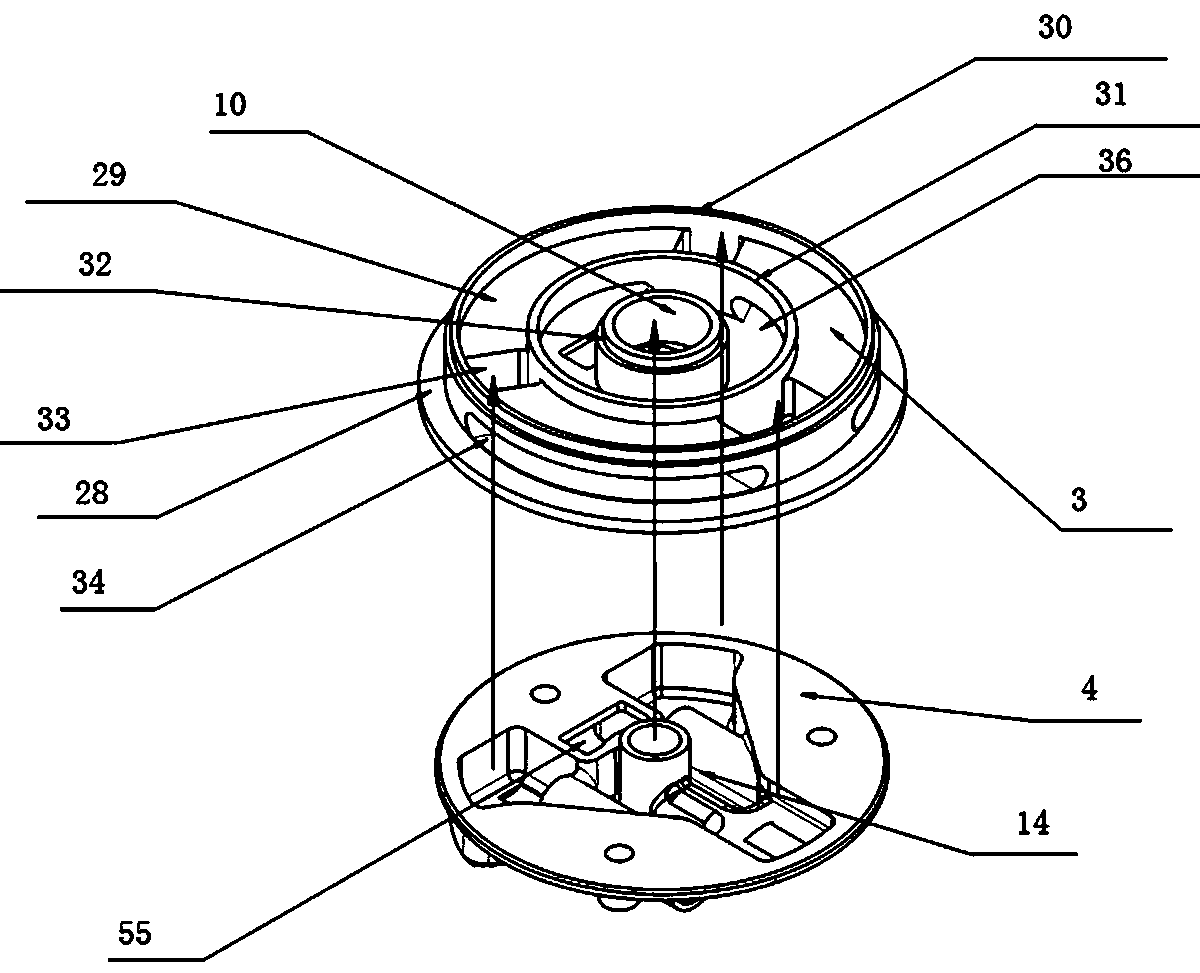

[0065] refer to Figure 1-Figure 13 , the complete upper air intake burner in the middle of the mixing chamber, including the central fire cover 1, the outer ring fire cover 2, the burner head 3, the burner bottom 4, the burner support 5, the central fire injector 6, the first The main fire ejector 7, the second main fire ejector 8, the burner head 3 is provided with an outer ring fire distribution chamber 9 and a central fire mixing chamber 10, and the central fire cover 1 is provided with a central fire outlet hole 11 , the central fire cover 1 covers the central fire mixing chamber 10, the outer ring fire cover 2 is provided with an outer ring fire outlet hole 12, the outer ring fire cover 2 is covered on the outer ring fire distribution chamber 9, and the burner head 3 There is also a gas distribution channel 13 inside, the upper end of the gas distribution channel 13 communicates with the fire distribution chamber 9 of the outer ring fire, the bottom 4 of the burner is pr...

Embodiment 2

[0097] The difference between this embodiment and embodiment 1 is:

[0098] refer to Figure 14-Figure 16 , the complete upward air intake burner also includes an anti-dry heating probe 65, the head of the anti-dry heating probe 65 passes through the burner support 5, the flange 38 at the bottom of the burner 4, and the middle partition of the burner head 3 Stretch out the central fire cover 1 upper surface after 28. At this time, the burner support 5, the flange 38 of the burner bottom 4, the middle partition 28 of the burner head 3, and the central fire cover 1 are all provided with anti-dry probe penetration holes (not shown in the figure). out).

[0099] The inlet port 61 of the central fire ejector 6 is positioned at one side of the lower surface of the burner bottom 4, and the inlet port 71 of the first main fire ejector 7 and the inlet port 81 of the second main fire ejector 8 are all located at the combustion chamber. The other side of the lower surface of the devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com