U-shaped high-temperature waste recycling furnace

A waste and recycling technology, applied in the field of waste treatment, can solve the problems of excessive emission of toxic and harmful gases in exhaust gas, insufficient oxidation of exhaust gas, poor stability of working conditions, etc., to avoid local high temperature phenomenon, inhibit dioxin generation, Effects of high intensity treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

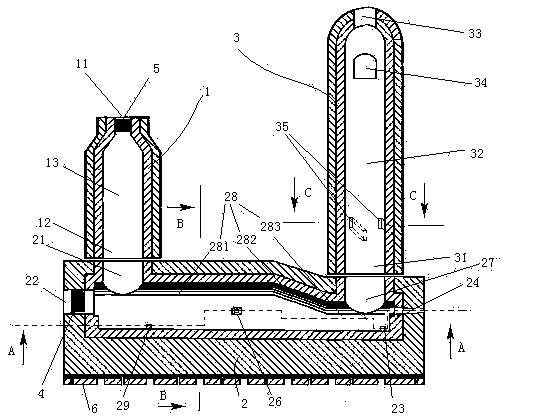

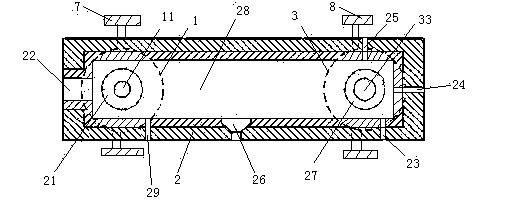

[0033] Embodiment one, see figure 1 , a U-shaped waste high-temperature recycling furnace, comprising a vertically arranged hollow combustion tower 1, a horizontally arranged hollow smelting pool 2 and a vertically arranged hollow disinfection tower 3.

[0034] A first smelting pool inlet 21 is provided on the top wall at the left end of the smelting pool 2 . A second smelting pool inlet 22 is provided on the left end wall of the smelting pool 2 . The right end of the rear side wall of the smelting pool 2 is provided with a copper discharge hole 23, and the left end is provided with an emergency copper discharge hole 29. The beneficial effect of designing the emergency copper discharge hole 29 is: when an abnormality occurs and the temperature drops, the molten copper can be discharged quickly to prevent the molten copper from solidifying in the smelting pool. A first observation hole 24 is provided on the right end wall of the smelting pool 2 . The beneficial effect of des...

Embodiment 2

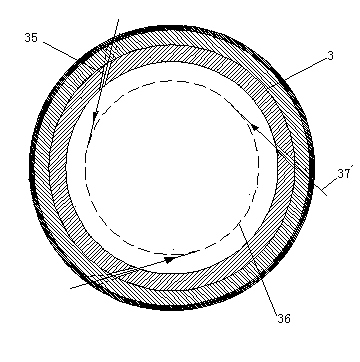

[0052] Embodiment two, see Figure 5 , The difference from Embodiment 1 is that the cross section of the inner cavity 28 of the smelting pool is circular.

[0053] In the above two embodiments, the combustion tower 1 and the disinfection tower 3 are all single-section structures. If the combustion tower 1 height is higher, the combustion tower 1 can be designed as multi-sections connected in series, and the weight of each section is directly borne by the combustion tower support frame 7, that is, the weight of the last section is not passed to the next section. After the joints are arranged with high-temperature refractory gaskets, they are connected by flanges, and the seals are airtight.

[0054]Equally if when disinfection tower 3 height is higher, disinfection tower 3 can be designed as multi-section series connection, and the weight of each joint is directly borne by disinfection tower support frame 8, that is, the weight of the last joint is not passed to the next joint...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com