Intelligent heating system for centrifugally casting ultra-long thin-walled slim tubes

A centrifugal casting and intelligent heating technology, which is applied in the field of temperature control of ultra-long thin-walled thin tubes in the centrifugal casting process, can solve the problems of low qualified rate of finished products, inconsistent temperature, low casting yield, etc., to improve efficiency and product quality quality, preventing the temperature from dropping too fast, and heating evenly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The following examples are used to illustrate the present invention, but are not used to limit the scope of the present invention, all equivalent technical solutions also belong to the category of the present invention, and the patent protection scope of the present invention should be defined by each claim.

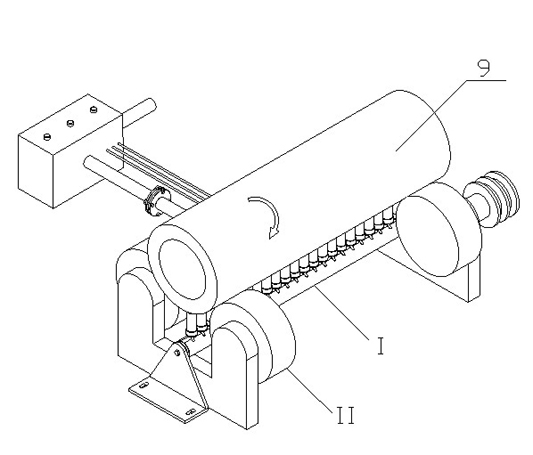

[0023] from figure 1 It can be seen from the figure that an intelligent heating system for centrifugally casting ultra-long thin-walled thin tubes is installed under the centrifugal mold cover 9 of the centrifugal casting equipment. I is an intelligent heating system for centrifugally casting ultra-long thin-walled thin tubes, and II For centrifugal casting equipment.

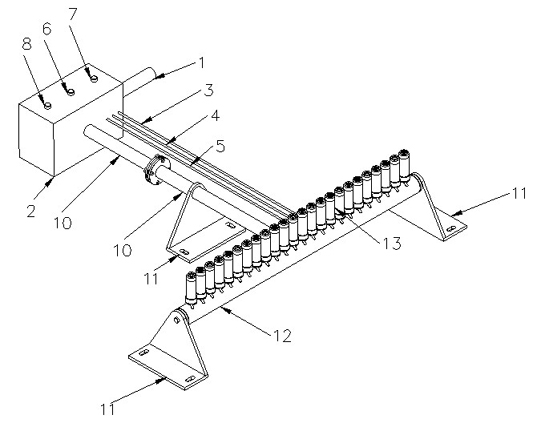

[0024] from figure 2 It can be seen from the figure that the intelligent heating system for centrifugal casting ultra-long thin-wall thin tubes includes a control box 2, an intake pipe 1, a gas output pipe 10, a gas mixing pipe 12, an ignition system 3, a fixing seat 11 and a standpipe burner 13...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com