Load control method for reducing cylinders of diesel engine

A diesel engine and load technology, applied in the direction of engine control, electrical control, fuel injection control, etc., can solve problems such as increased vibration, damage to the force balance of the diesel engine, and influence on the combustion of the working cylinder, so as to improve the operating economy and obvious economical efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings.

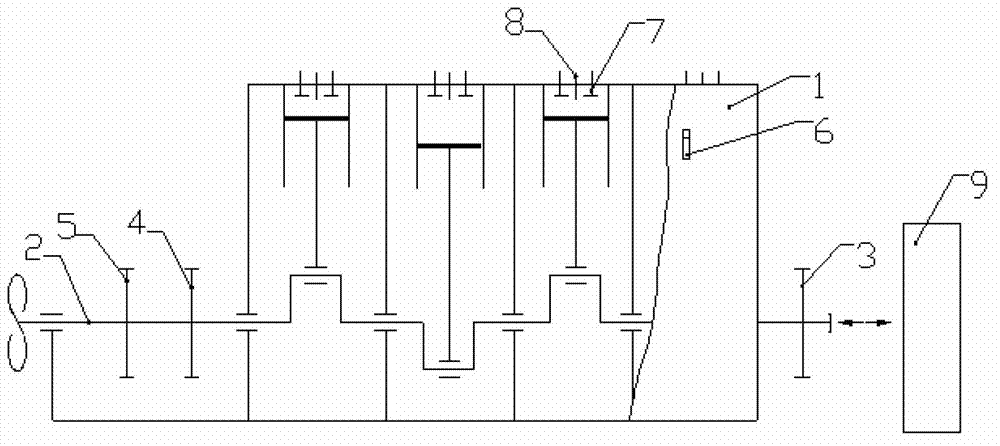

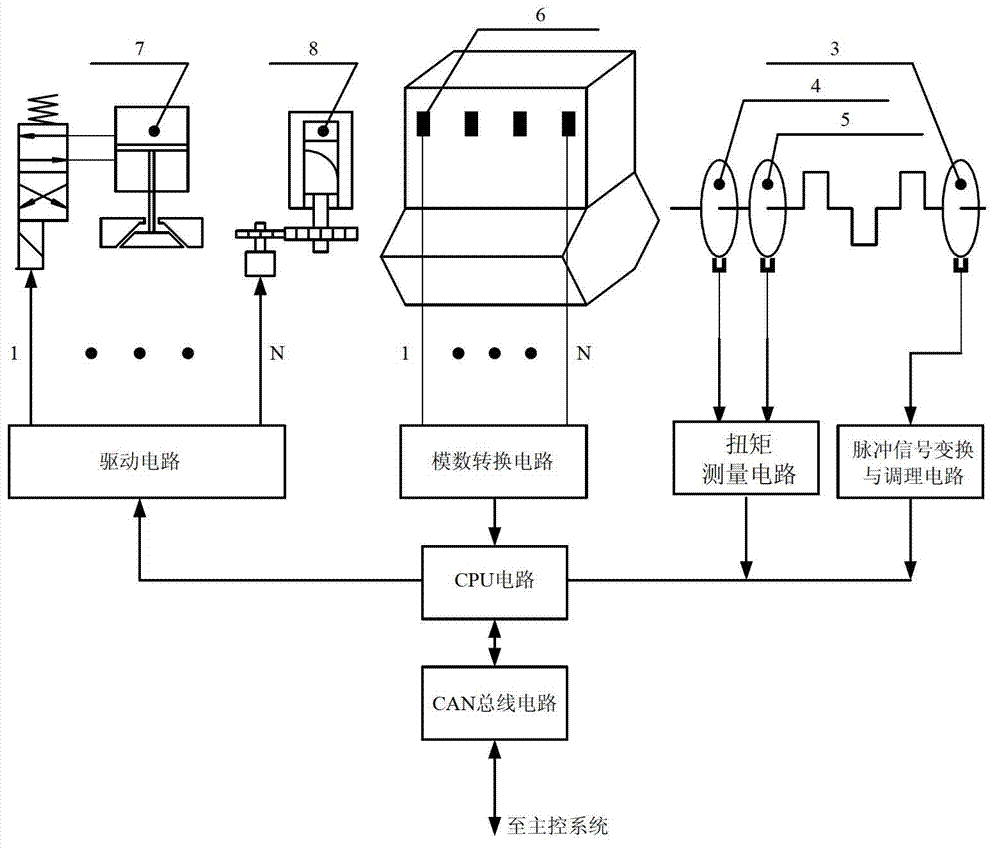

[0015] Such as figure 1 As shown, the cylinder reduction control load system consists of a diesel engine 1, a working machine 2, a speed measuring photoelectric encoder 3, a torque photoelectric encoder 4, 5, an acceleration sensor 6, a gas distribution mechanism 7, an injection mechanism 8, and a control system 9. The speed measuring photoelectric encoder 3 is installed on the free end of the diesel engine, and 714 holes are unevenly arranged in the circumferential direction of the code disc, wherein holes are punched every 1° around the bottom dead center, and the rest are punched every 0.5°. The 7 holes near the bottom dead center are used to determine the bottom dead center position. At the same time, the photoelectric encoder is used to detect the rotational speed of the diesel engine. Torque photoelectric encoders 4 and 5 are used to detect the torque of the di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com