Self-adaptive control method and device for premixed combustion and gas equipment

An adaptive control, premixed combustion technology, applied in the field of wall-hung boilers, can solve the problems of poor combustion conditions and the inability to adjust the air-fuel ratio adaptively, so as to avoid potential safety hazards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

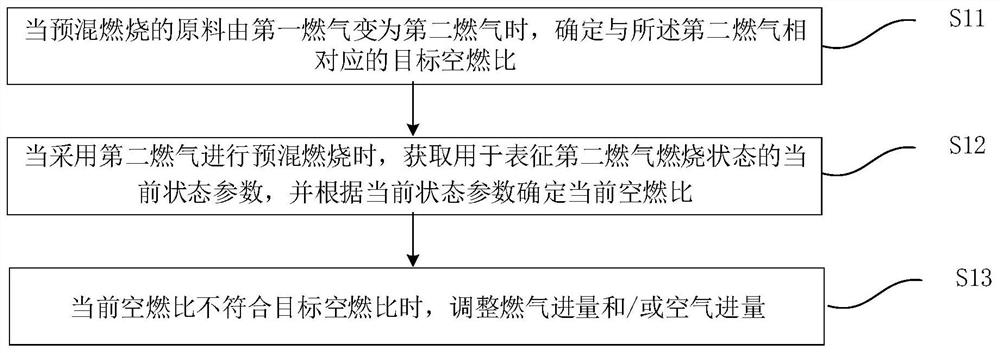

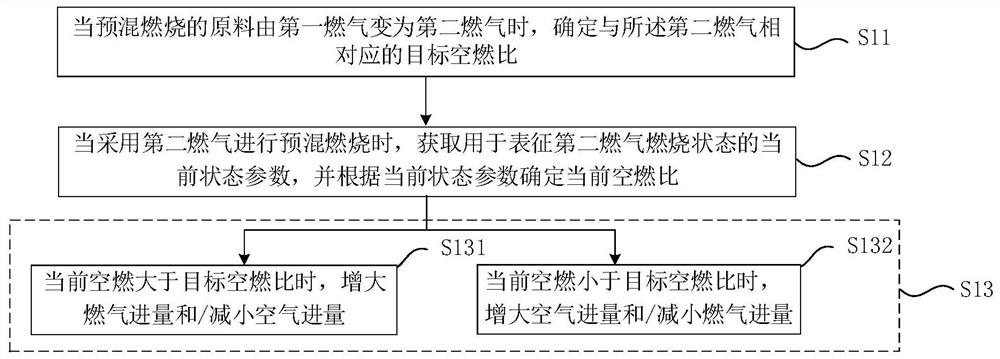

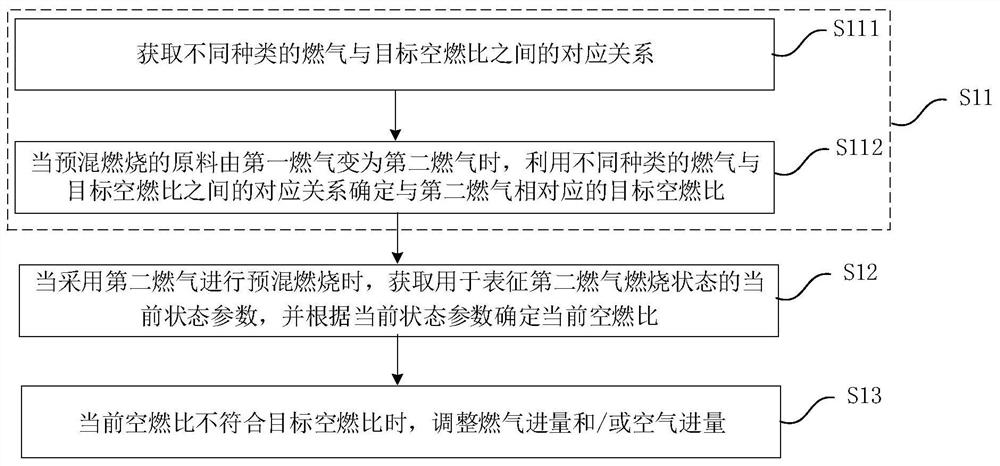

[0028] This embodiment provides an adaptive control method for premixed combustion, which is applied to the gas settings used by users, such as fully premixed condensing gas wall-hung boilers (full premixed wall-hung boilers for short), to avoid changes in gas types When the current air-fuel ratio is different from the most reasonable air-fuel ratio corresponding to the current type of gas, the problem that the fully premixed wall-hung boiler cannot achieve the best combustion conditions, such as figure 1 As shown, the adaptive control method of the premixed combustion includes the following steps:

[0029] S11. When the raw material for premixed combustion is changed from the first gas to the second gas, determine a target air-fuel ratio corresponding to the second gas.

[0030] Exemplarily, the target air-fuel ratio is the ratio between the corresponding air volume and the gas volume when the gas is in an optimal combustion state. The first gas is the historical gas used by...

Embodiment 2

[0073]This embodiment provides an adaptive control device for premixed combustion, which is applied to the gas settings used by users, such as fully premixed condensing gas wall-hung boilers (full premixed wall-hung boilers for short), to avoid changes in gas types When the current air-fuel ratio is different from the most reasonable air-fuel ratio corresponding to the current type of gas, the problem that the fully premixed wall-hung boiler cannot achieve the best combustion conditions, such as Figure 4 As shown, the adaptive control device for premixed combustion includes the following steps:

[0074] The determination module 21 is configured to determine the target air-fuel ratio corresponding to the second gas when the raw material for premixed combustion changes from the first gas to the second gas. For detailed description, refer to the relevant description of step S11 in the foregoing embodiment, and details are not repeated here.

[0075] The acquiring module 22 is c...

Embodiment 3

[0101] This embodiment provides a kind of gas equipment, such as Figure 5 As shown, the gas equipment includes a processor 31 and a memory 32, wherein the processor 31 and the memory 32 can be connected via a bus or in other ways, Figure 5 Take connection via bus as an example.

[0102] The processor 31 may be a central processing unit (Central Processing Unit, CPU). Processor 31 can also be other general-purpose processors, digital signal processor (Digital Signal Processor, DSP), graphics processing unit (Graphics Processing Unit, GPU), embedded neural network processor (Neural-network Processing Unit, NPU) or other Dedicated deep learning coprocessor, application specific integrated circuit (Application Specific Integrated Circuit, ASIC), field programmable gate array (Field-Programmable Gate Array, FPGA) or other programmable logic devices, discrete gate or transistor logic devices, discrete hardware components and other chips, or a combination of the above-mentioned t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com