Fully premixed combustion gas heating water heater

A gas-fired heating and fully premixed technology, which is applied in the direction of burners, combustion methods, and combustion types, can solve problems such as thermal efficiency decline, poor combustion conditions of gas-fired heating water heaters, and normal use of users.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

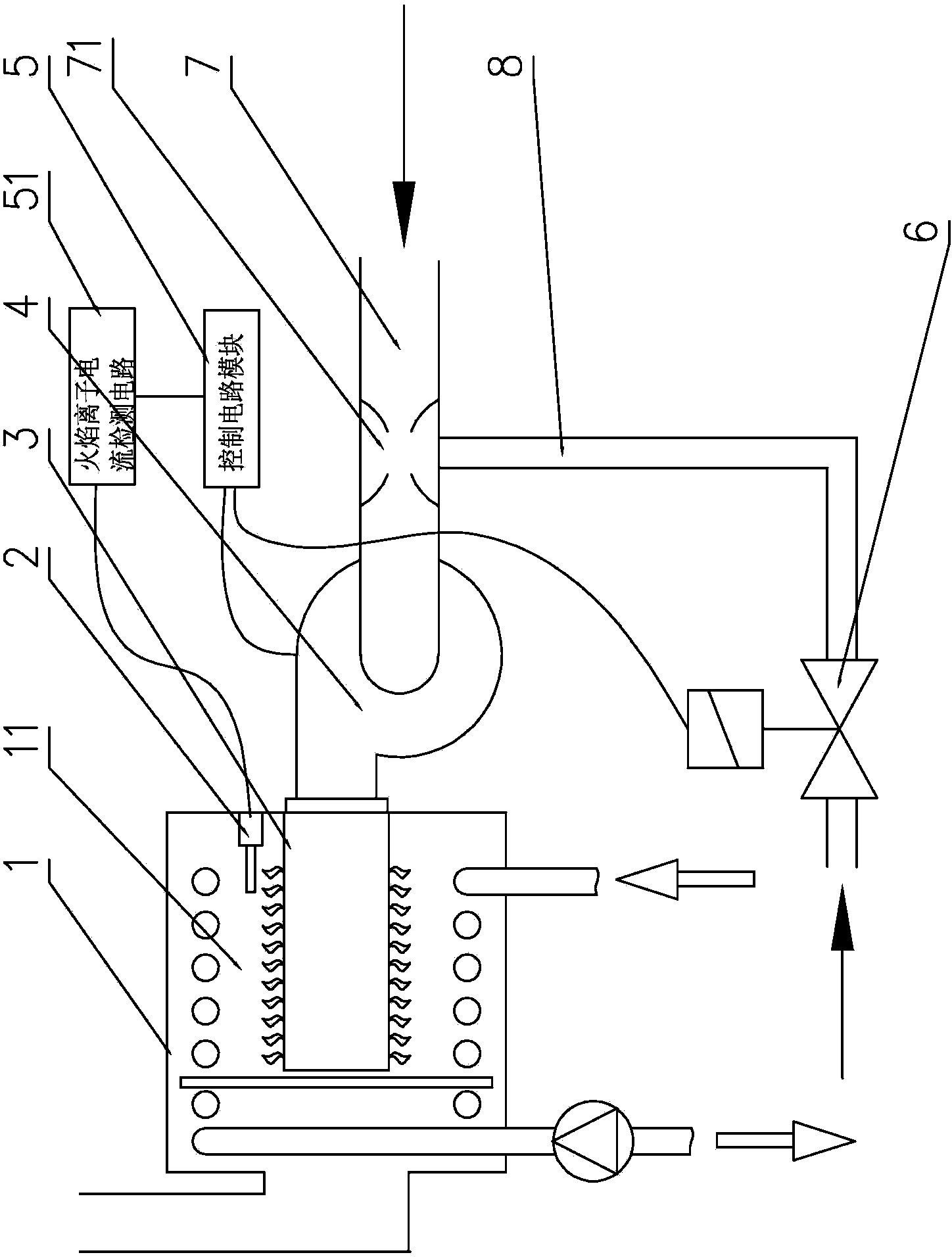

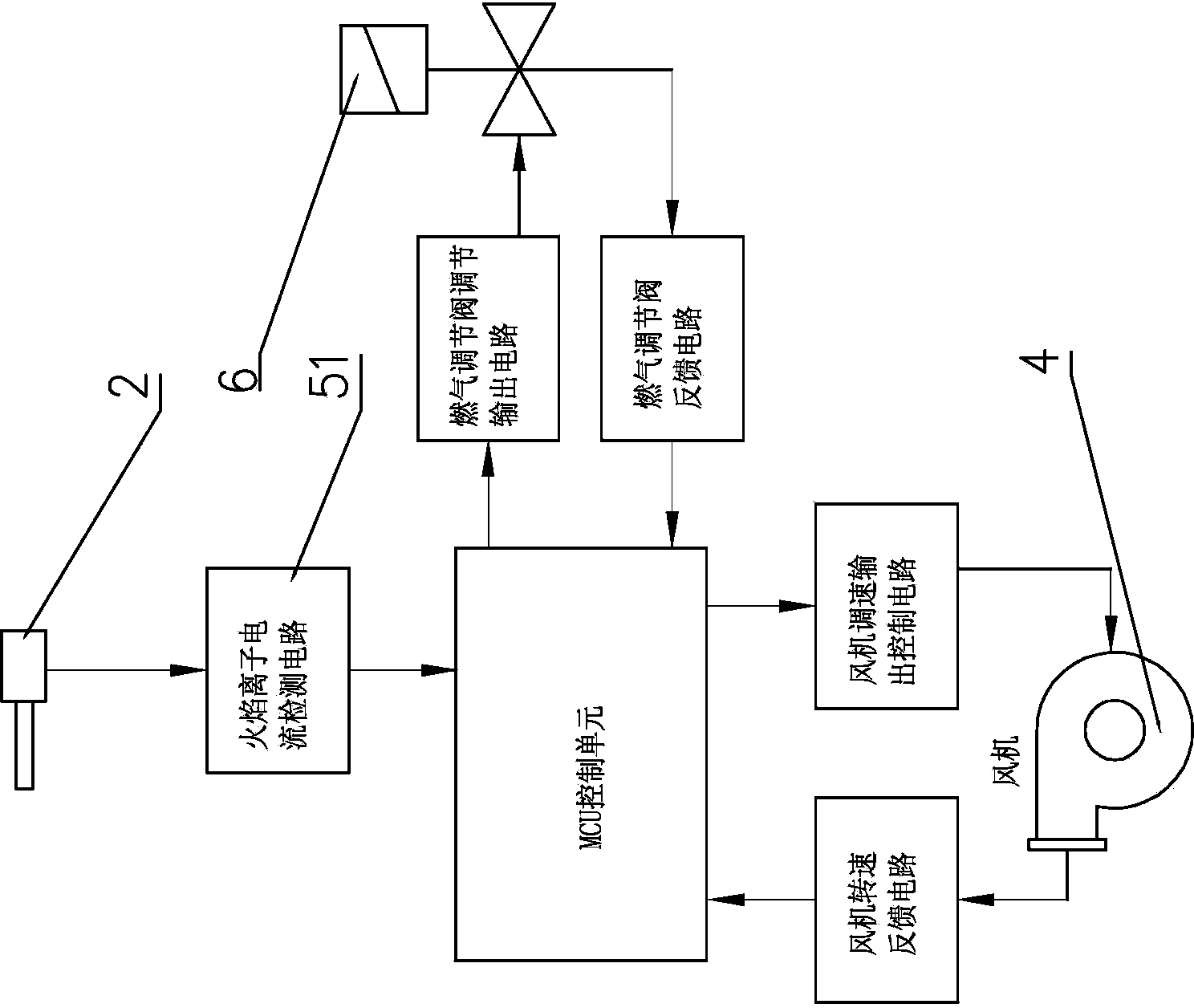

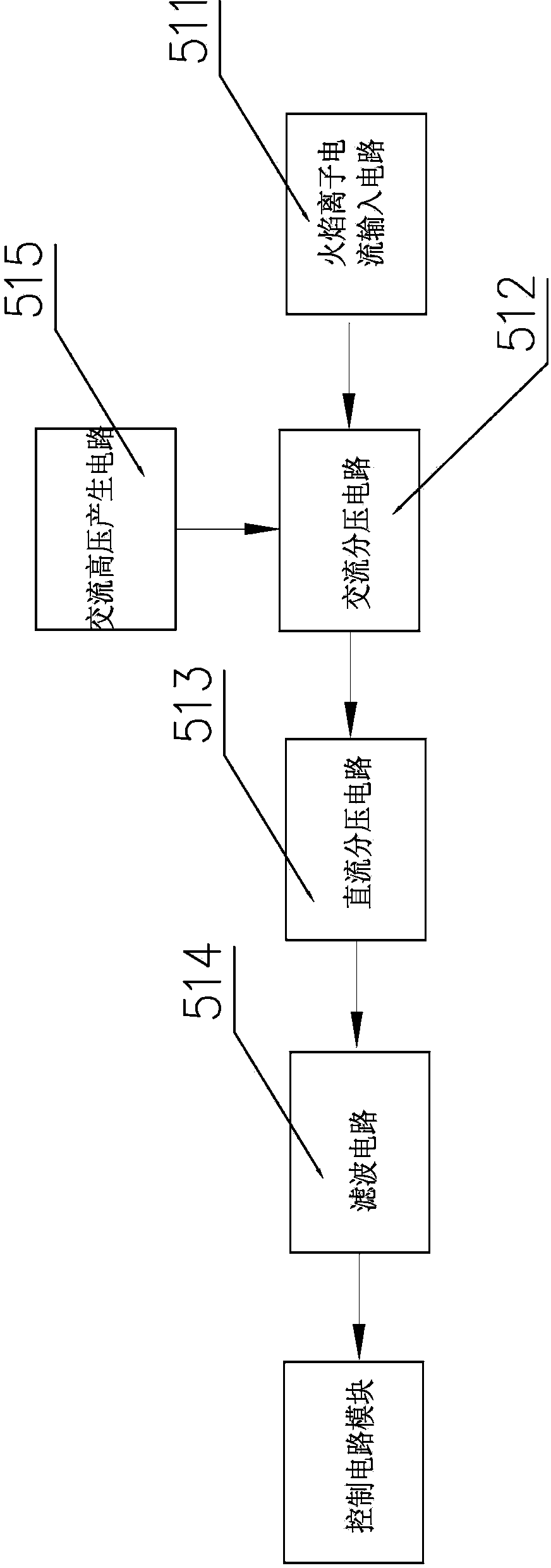

[0019] Specific implementation method: see attached figure 1 , attached figure 2 As shown, this embodiment includes a heat exchanger 1, an ion current feedback needle 2, a burner 3, a fan 4, a control circuit module 5, an air pipe 7, a gas pipe 8, a gas regulating valve 6, and the inner chamber of the heat exchanger 1 A closed combustion chamber 11 is formed, the burner 3 is arranged in the closed combustion chamber 11, the air outlet of the fan 4 communicates with the air inlet of the burner 3, the gas pipe 8 and the air pipe 7 communicate with the air inlet of the fan 4, and the gas The regulating valve 6 is connected in series on the gas pipe 8, the ion current feedback needle 2 is installed in the closed combustion chamber 11, the ion current feedback needle 2 is electrically connected with the flame ion current detection unit 51, the flame ion current detection unit 51, the gas regulating valve 6 , The fan 4 is electrically connected to the control circuit module 5 .

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com