Patents

Literature

187 results about "Combustion noise" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

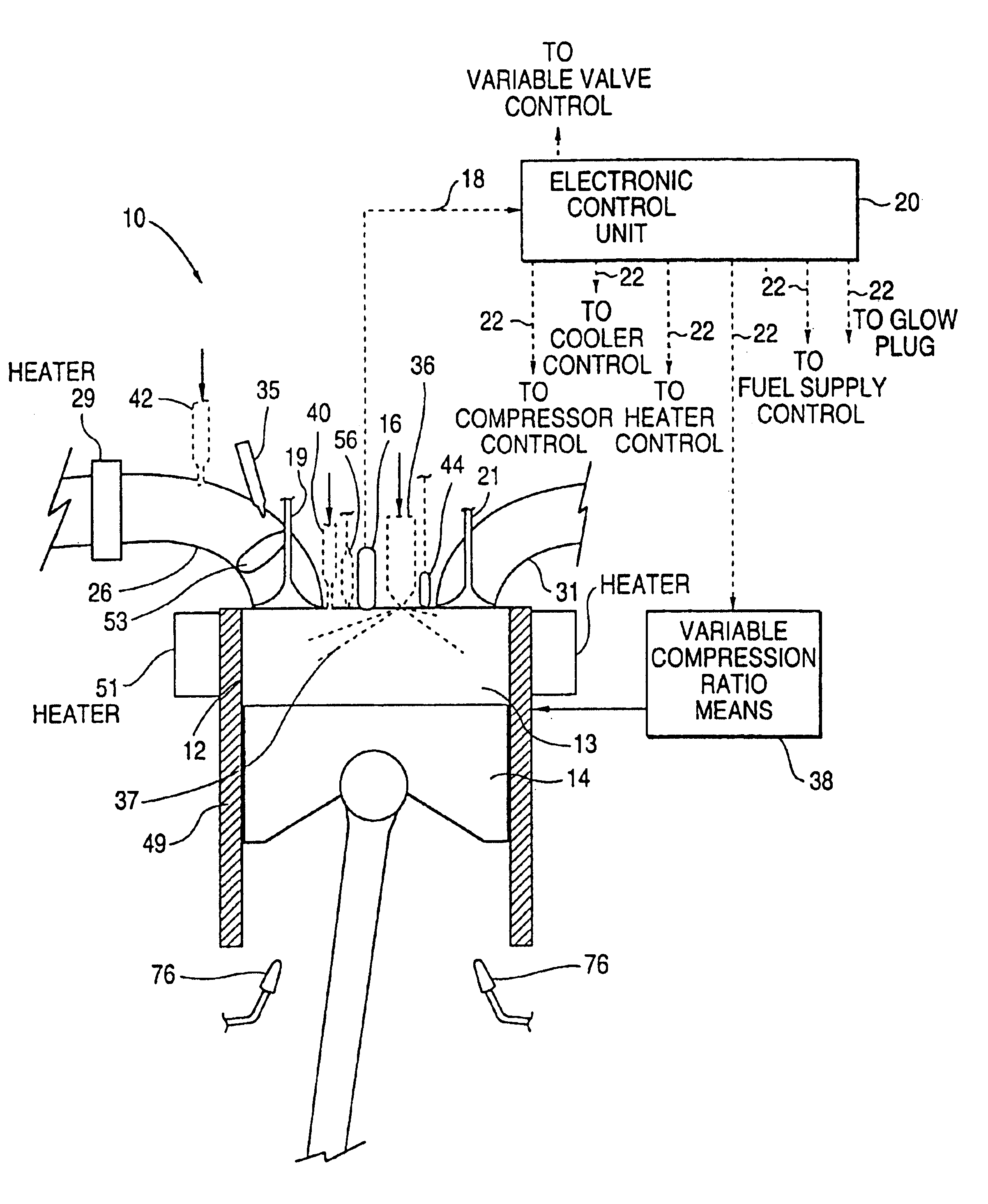

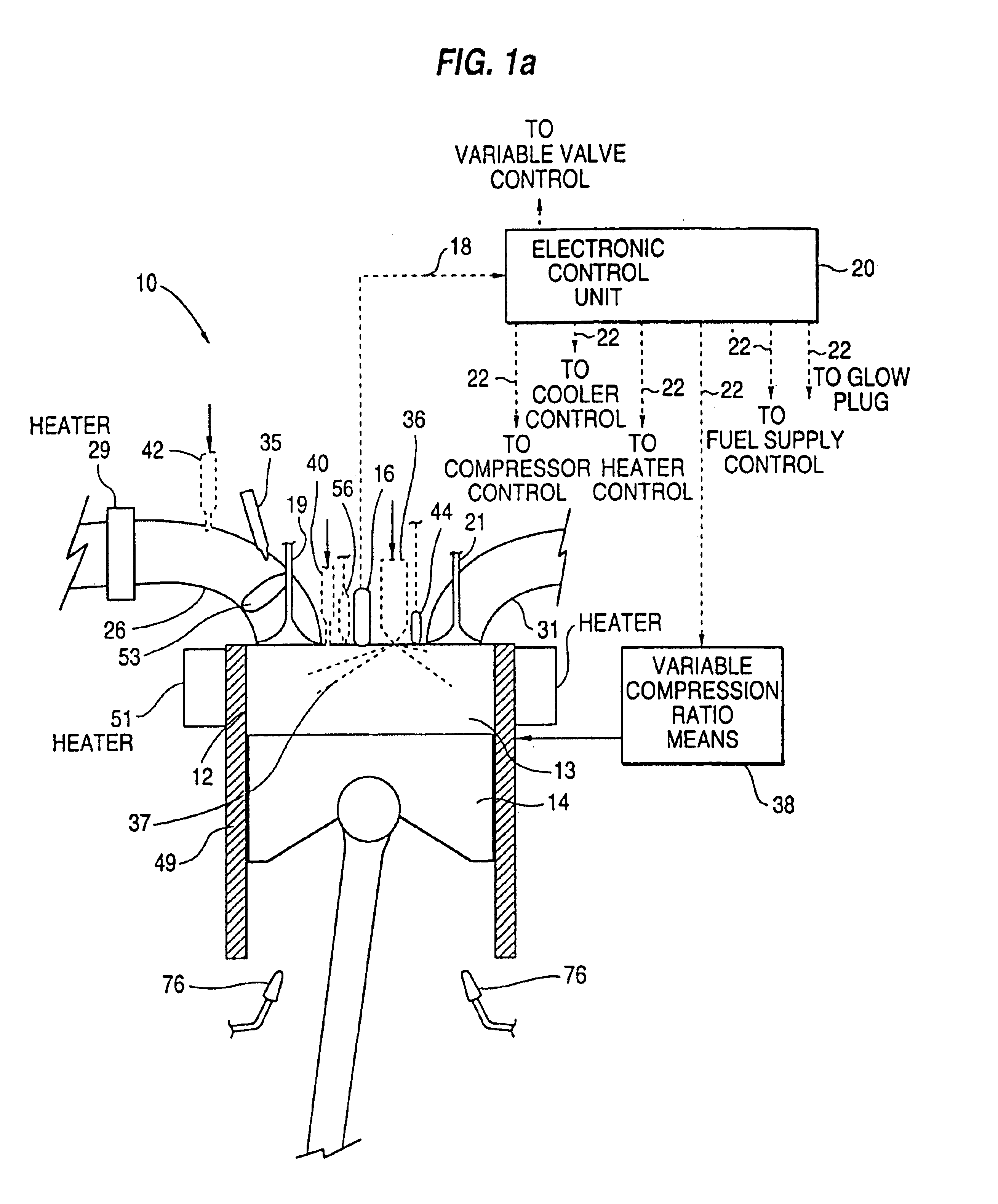

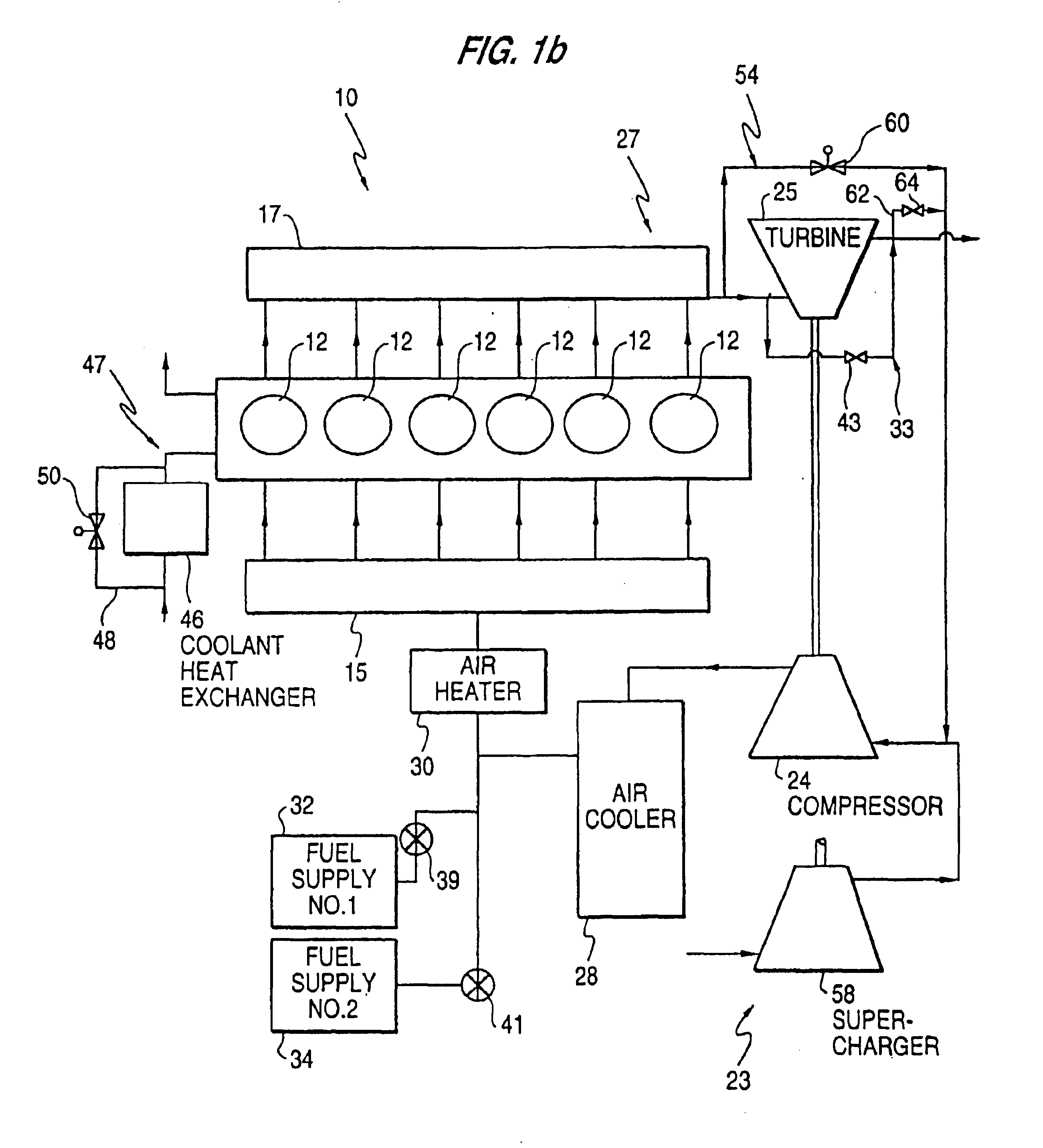

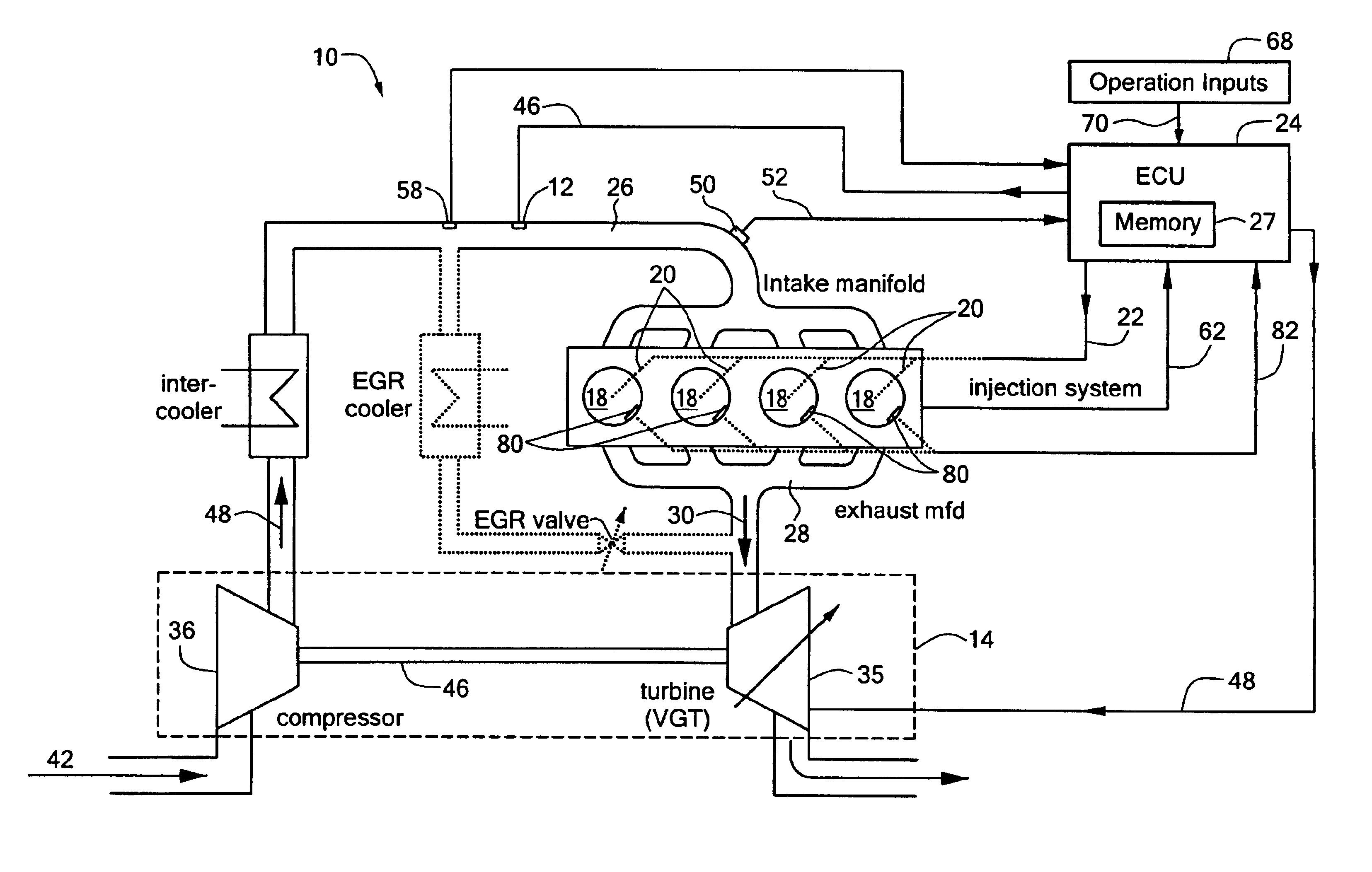

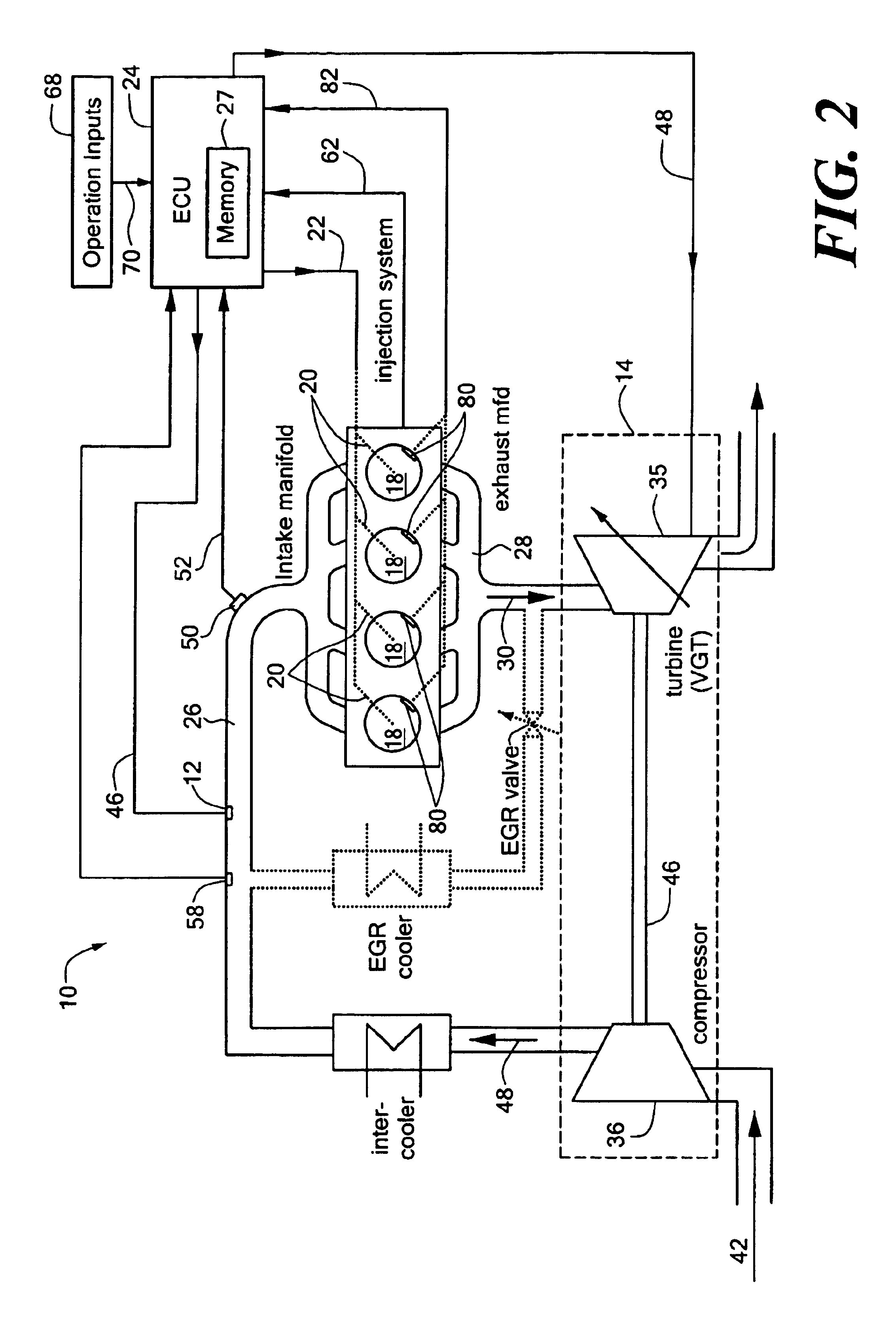

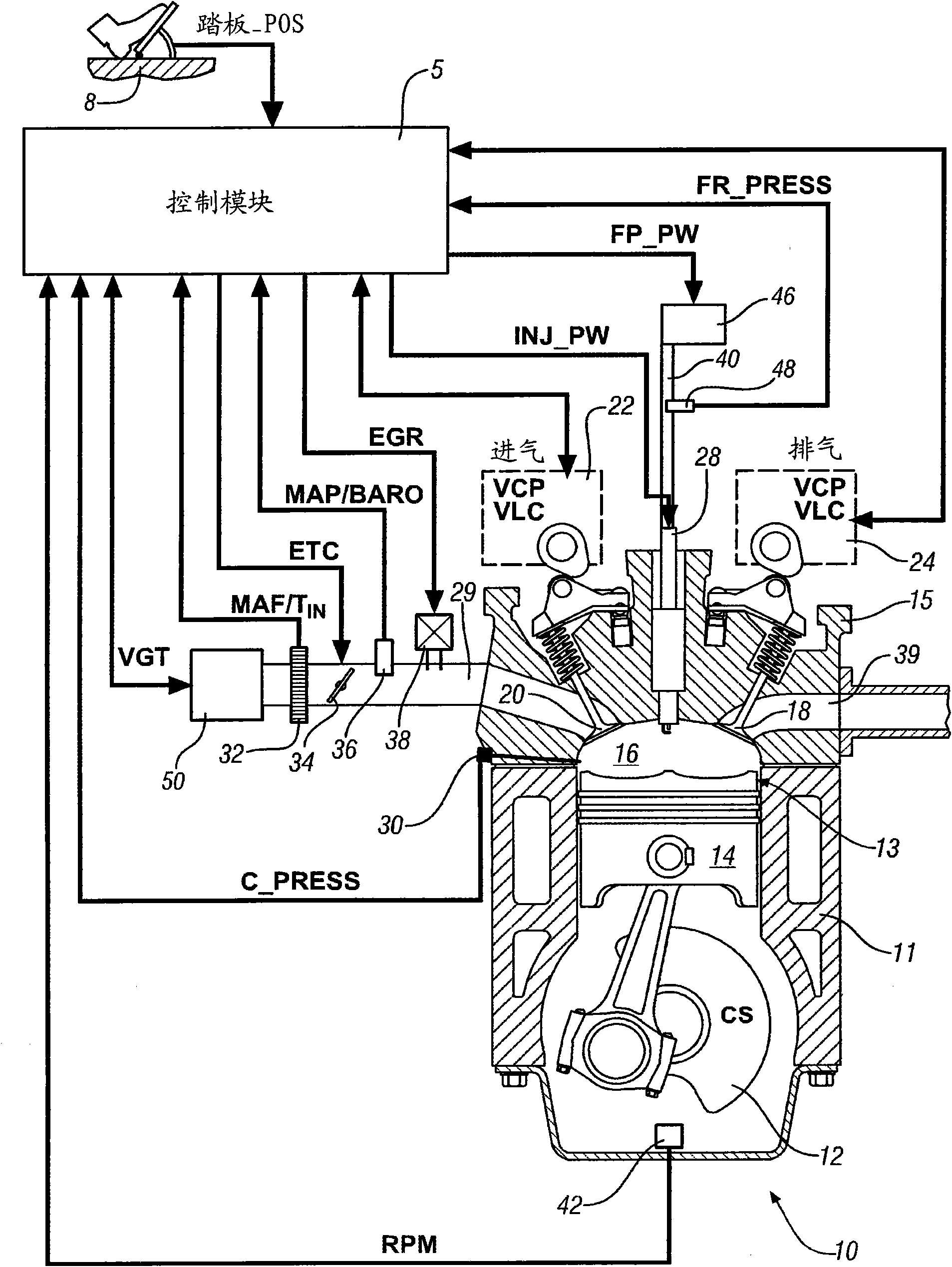

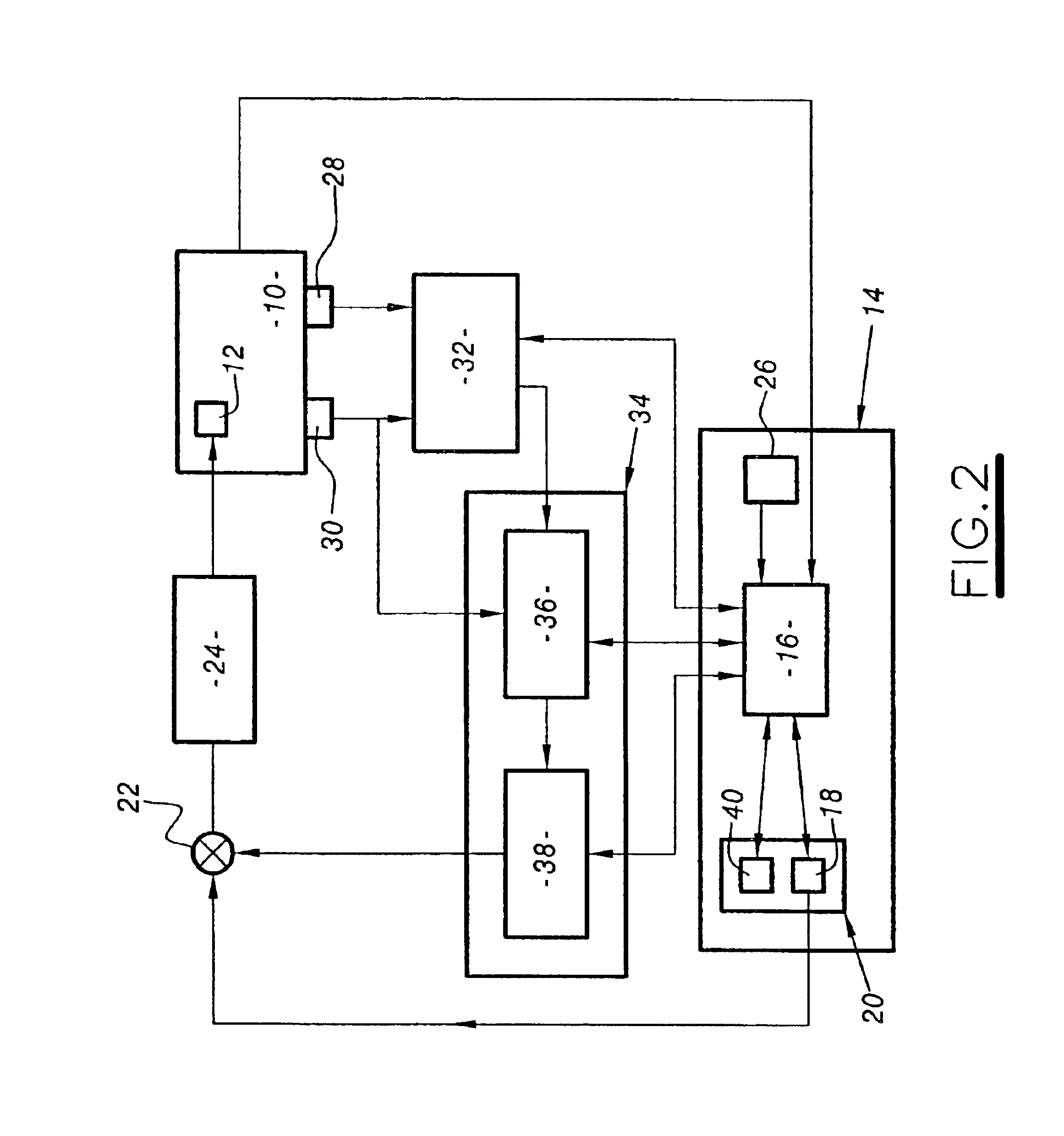

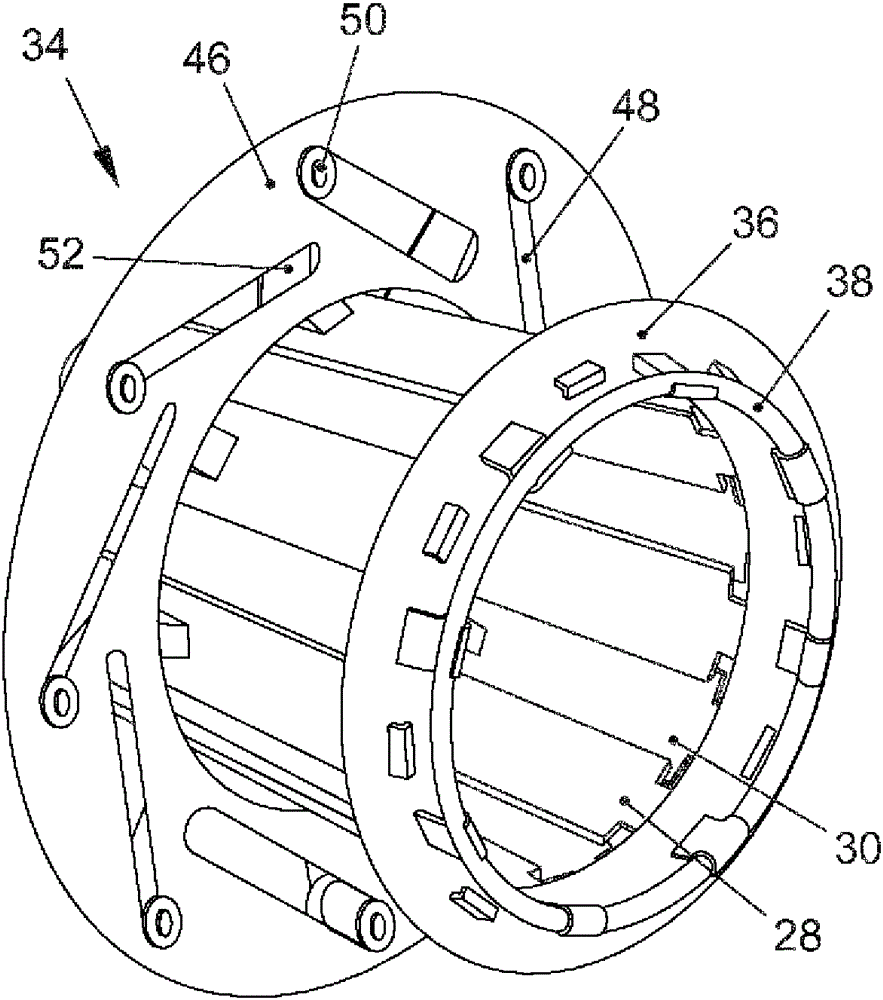

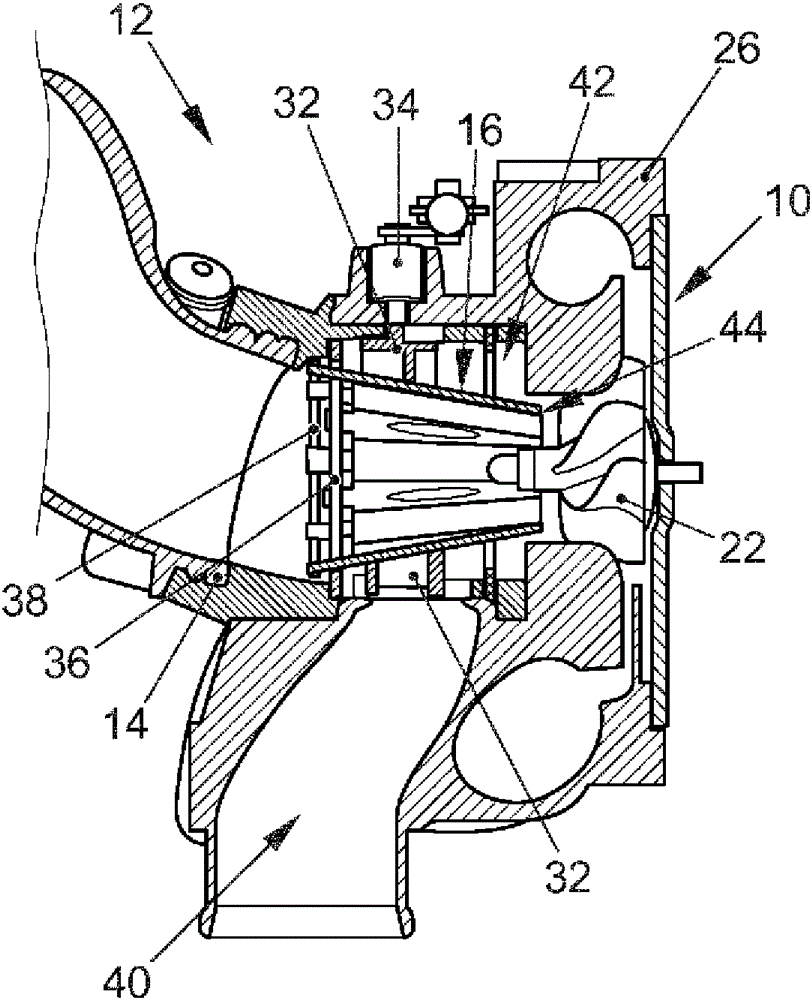

Premixed charge compression ignition engine with optimal combustion control

InactiveUS6915776B2Operate efficiently and effectivelyOvercome deficienciesElectrical controlNon-fuel substance addition to fuelCombustion noiseControl signal

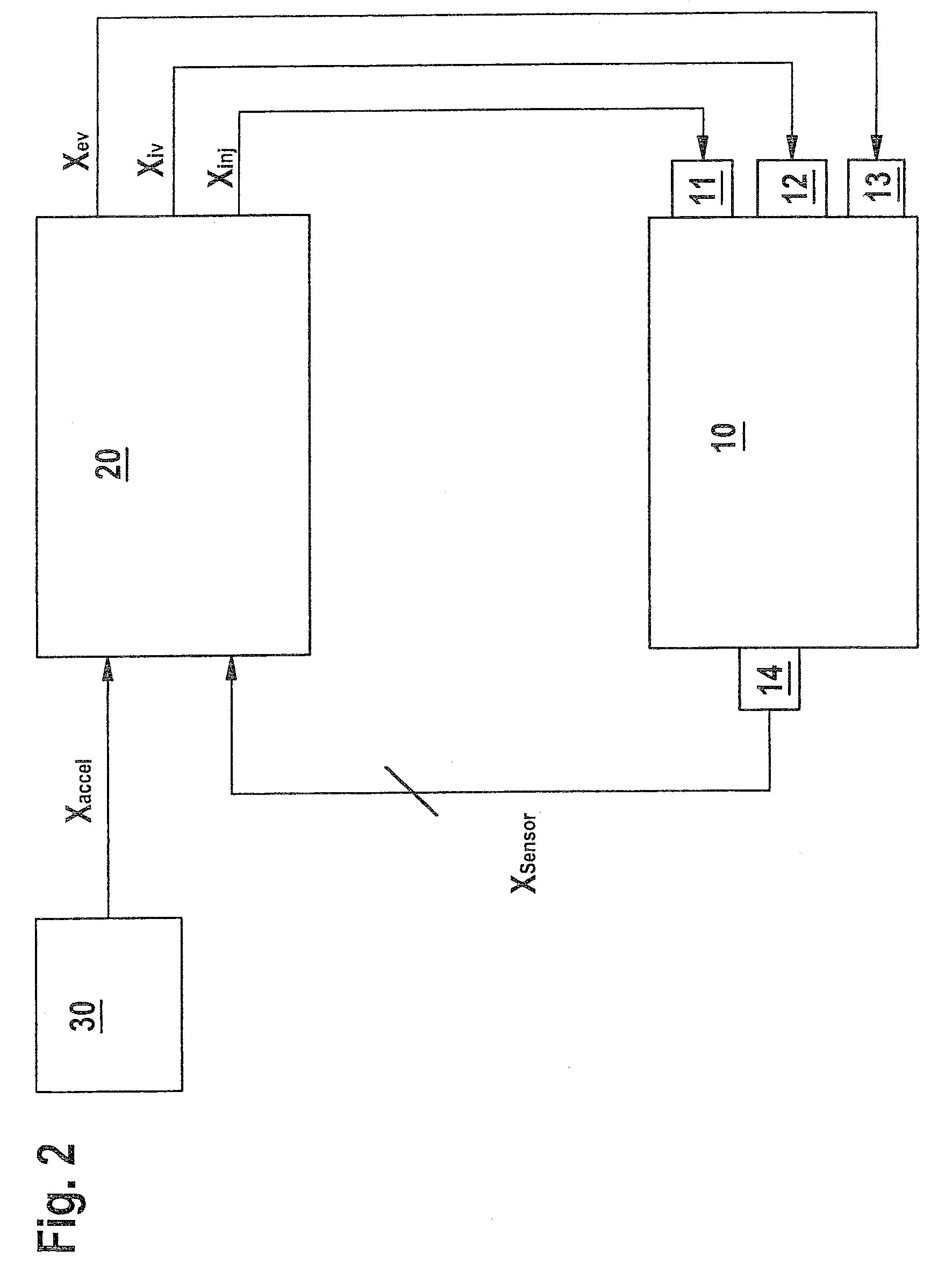

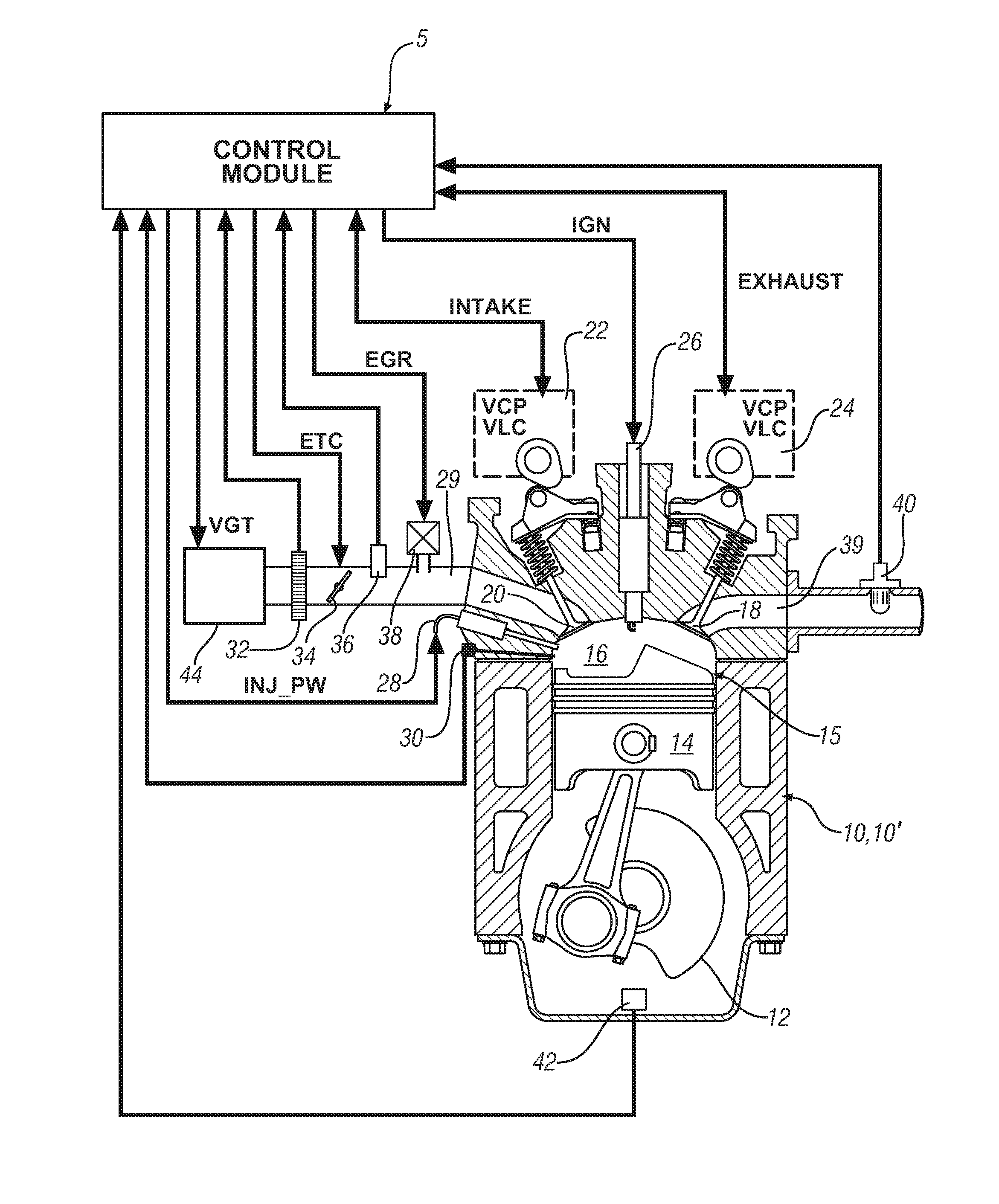

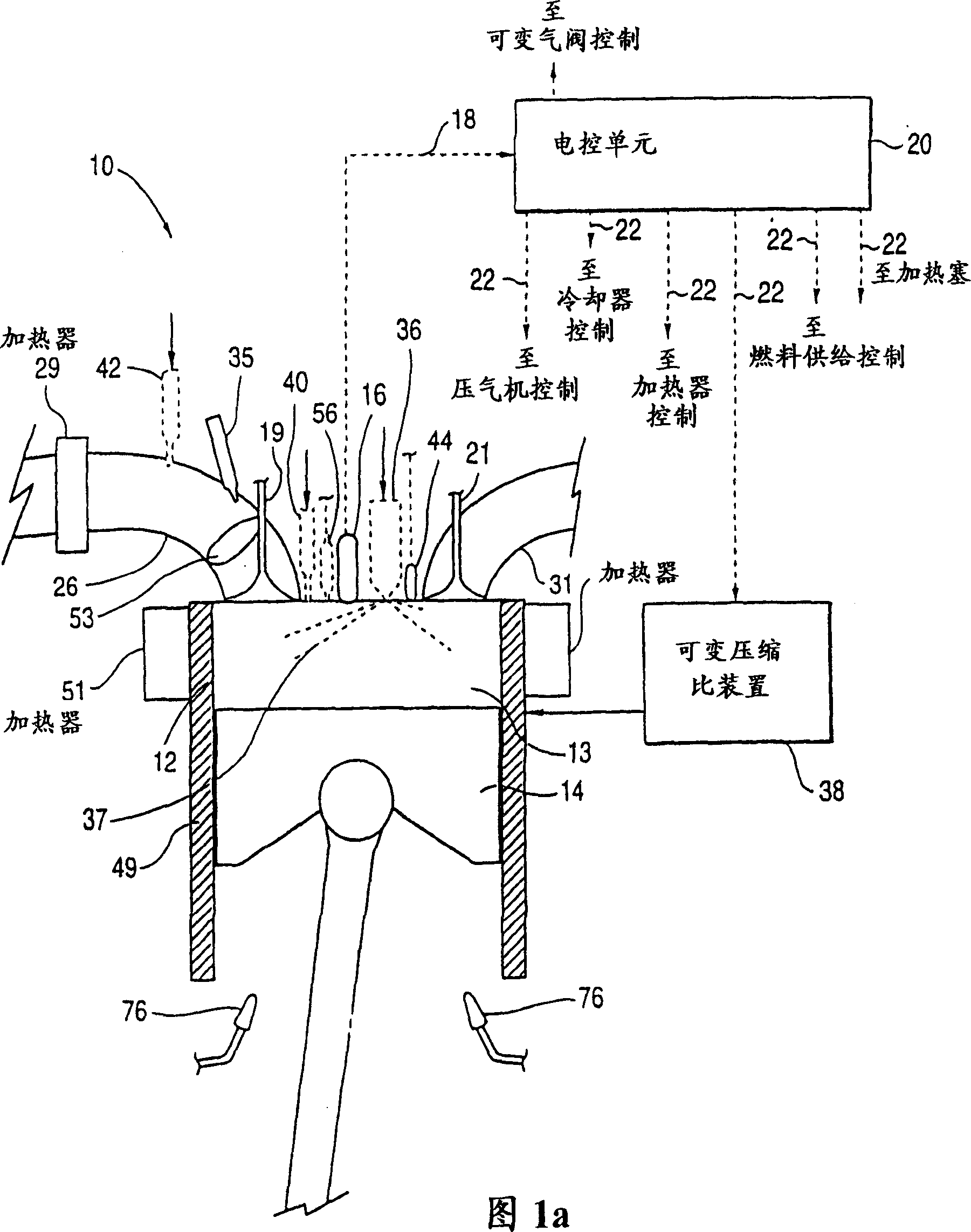

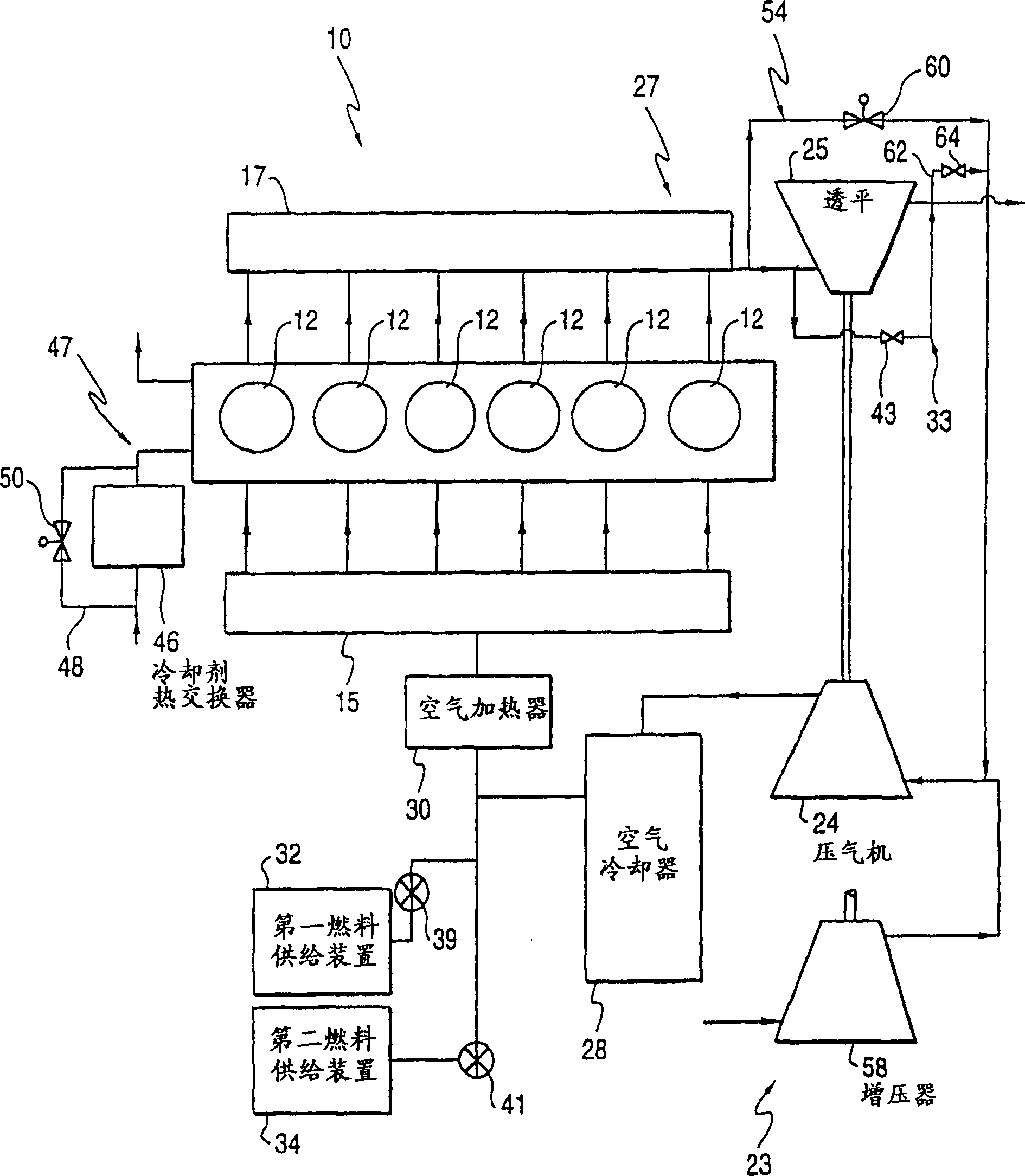

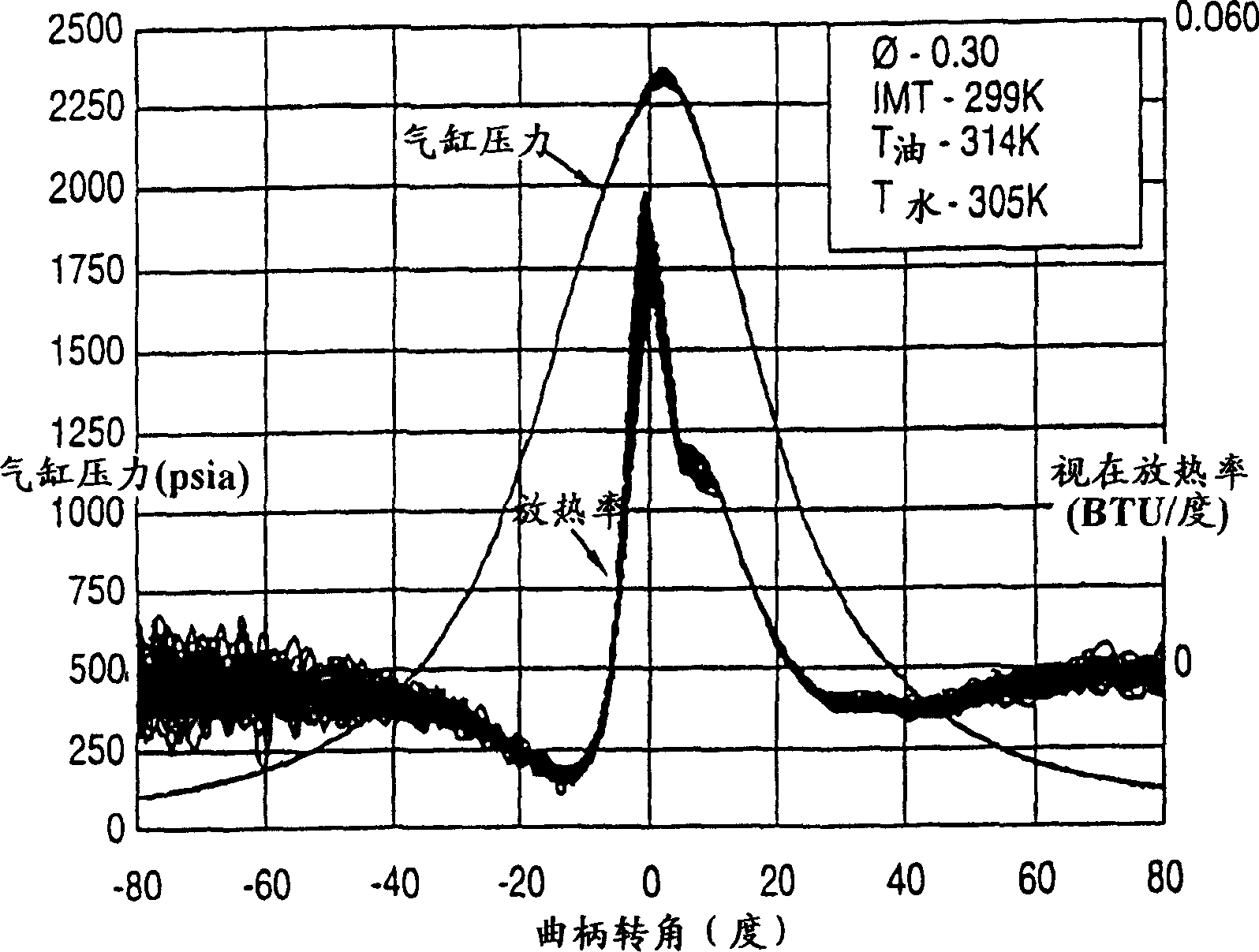

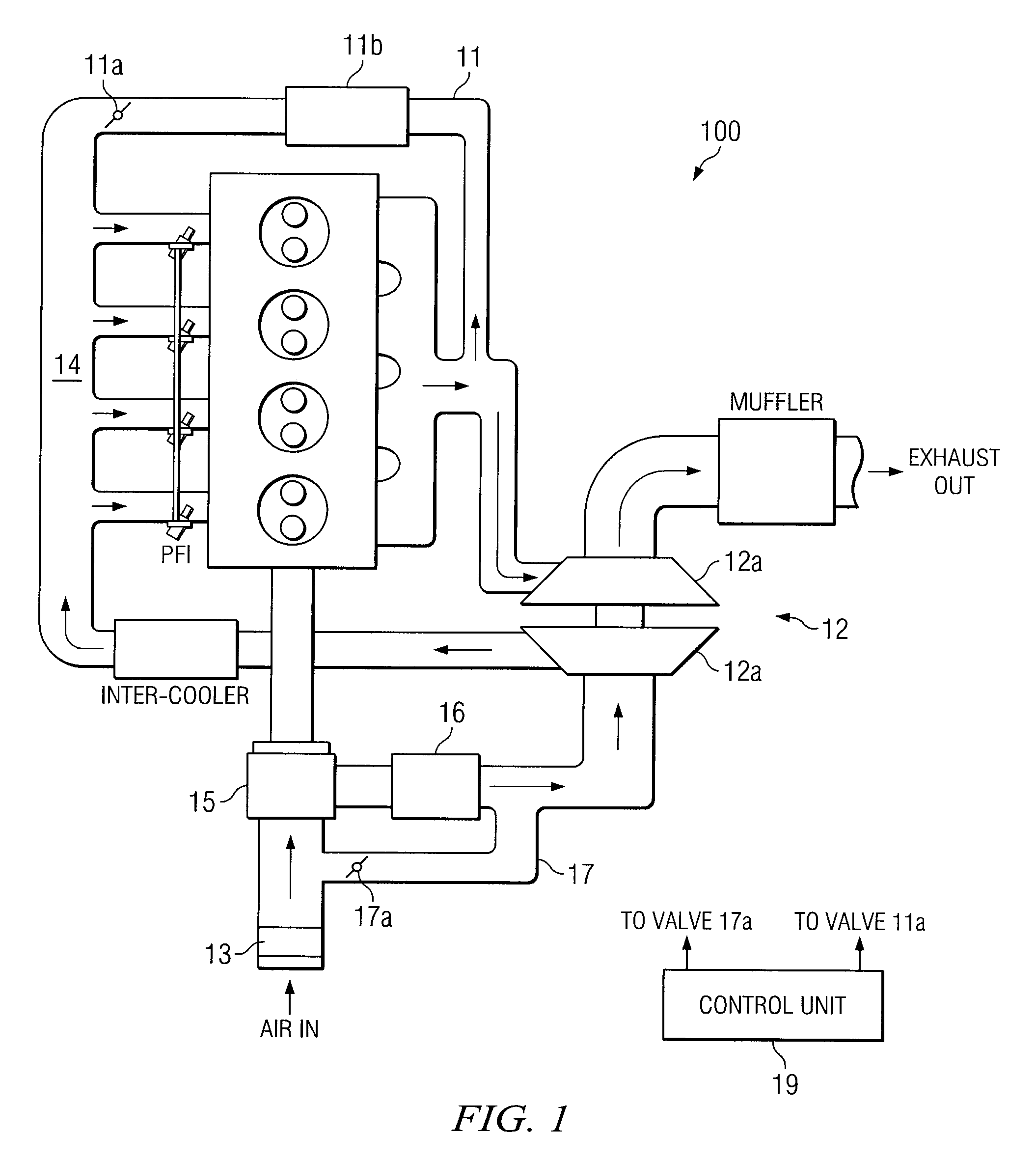

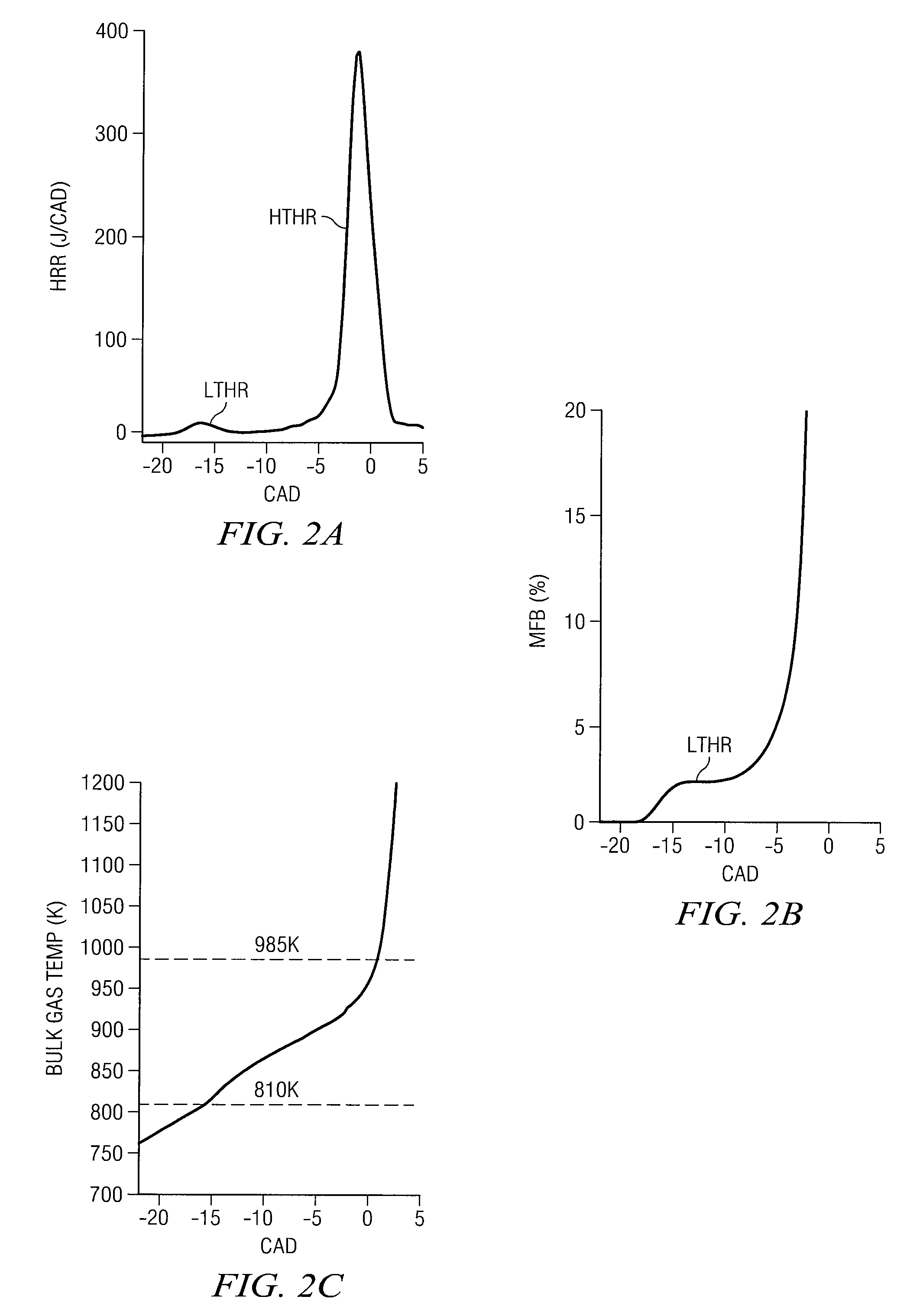

A premixed charge compression ignition engine, and a control system, is provided which effectively initiates combustion by compression ignition and maintains stable combustion while achieving extremely low nitrous oxide emissions, good overall efficiency and acceptable combustion noise and cylinder pressures. The present engine and control system effectively controls the combustion history, that is, the time at which combustion occurs, the rate of combustion, the duration of combustion and / or the completeness of combustion, by controlling the operation of certain control variables providing temperature control, pressure control, control of the mixture's autoignition properties and equivalence ratio control. The combustion control system provides active feedback control of the combustion event and includes a sensor, e.g. pressure sensor, for detecting an engine operating condition indicative of the combustion history, e.g. the start of combustion, and generating an associated engine operating condition signal. A processor receives the signal and generates control signals based on the engine operating condition signal for controlling various engine components to control the temperature, pressure, equivalence ratio and / or autoignition properties so as to variably control the combustion history of future combustion events to achieve stable, low emission combustion in each cylinder and combustion balancing between the cylinders.

Owner:CUMMINS INC

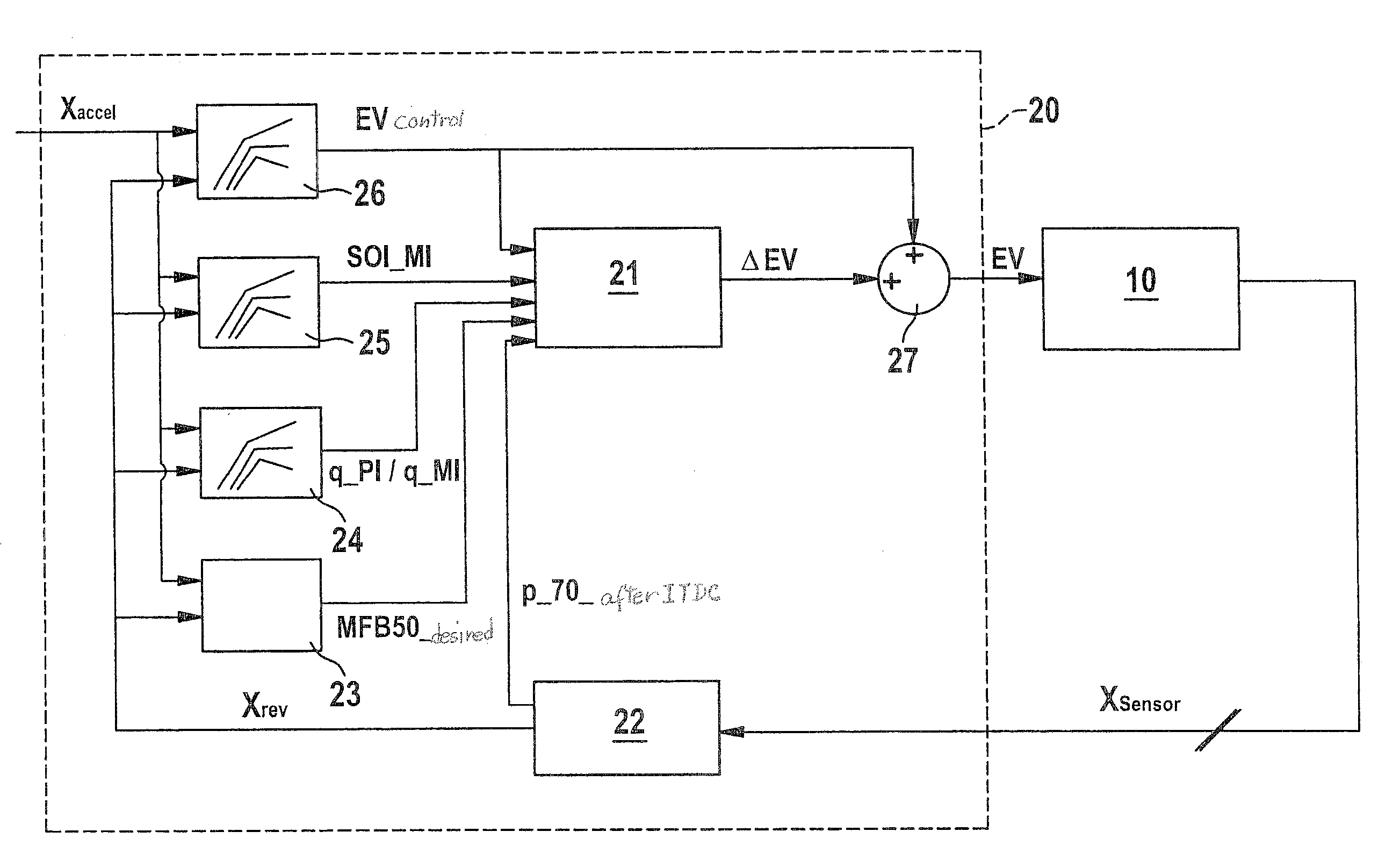

Method for operating an internal combustion engine, computer program and control unit

InactiveUS20090182484A1More constantInhibition transitionAnalogue computers for vehiclesElectrical controlCombustion noiseControl cell

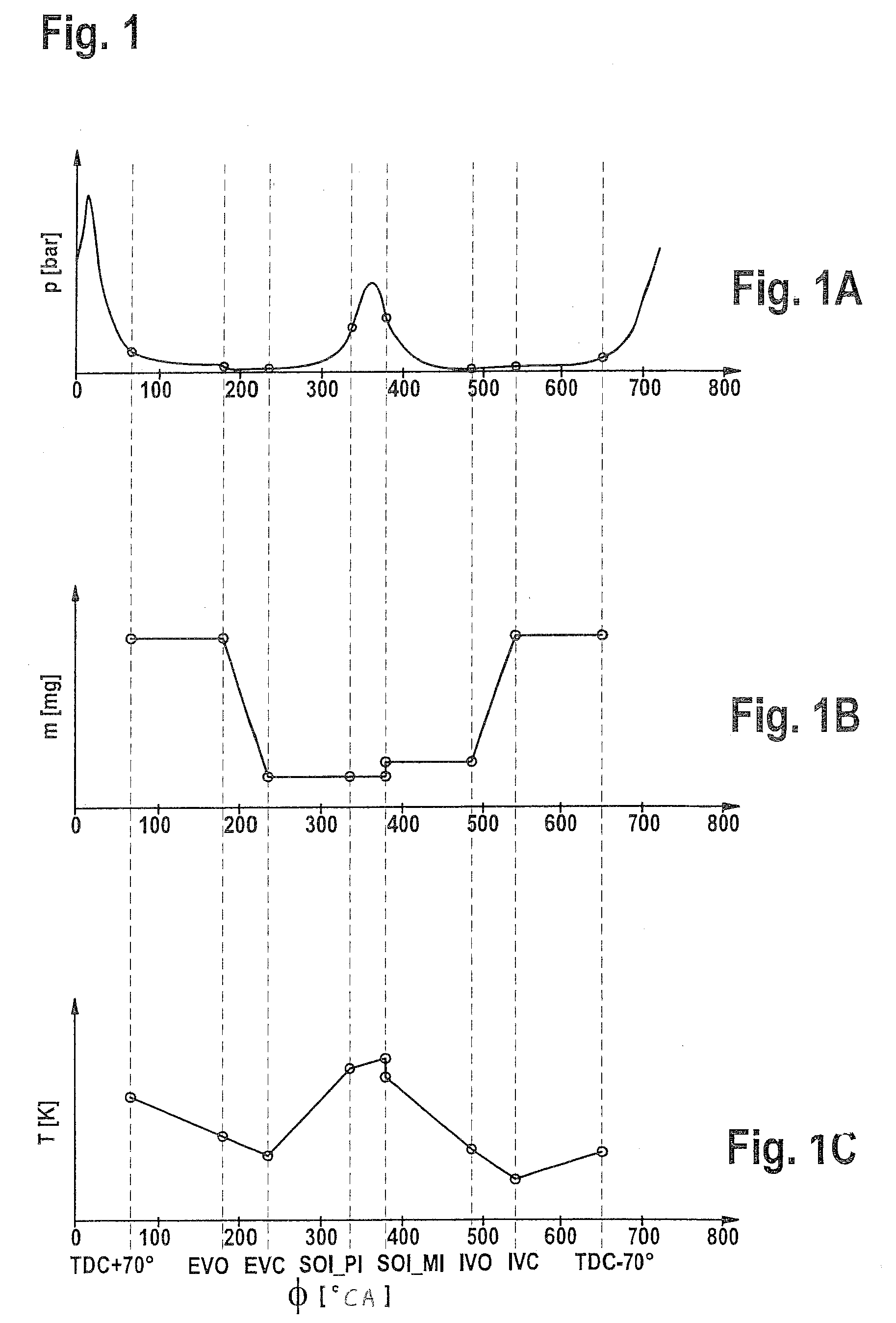

A method for operating an internal combustion engine, especially an internal combustion engine that is operable, at least in a part-load range, in an operating mode with auto-ignition, in which, at an abrupt change in load and / or at a changeover between an operating mode with auto-ignition and an operating mode without auto-ignition, a parameter of the combustion process correlating with the combustion noise is adapted stepwise over a plurality of combustion cycles from a first parameter value before the abrupt change in load or the changeover to a second parameter value after the abrupt change in load or the changeover, by influencing a combustion position of the combustion process.

Owner:ROBERT BOSCH GMBH

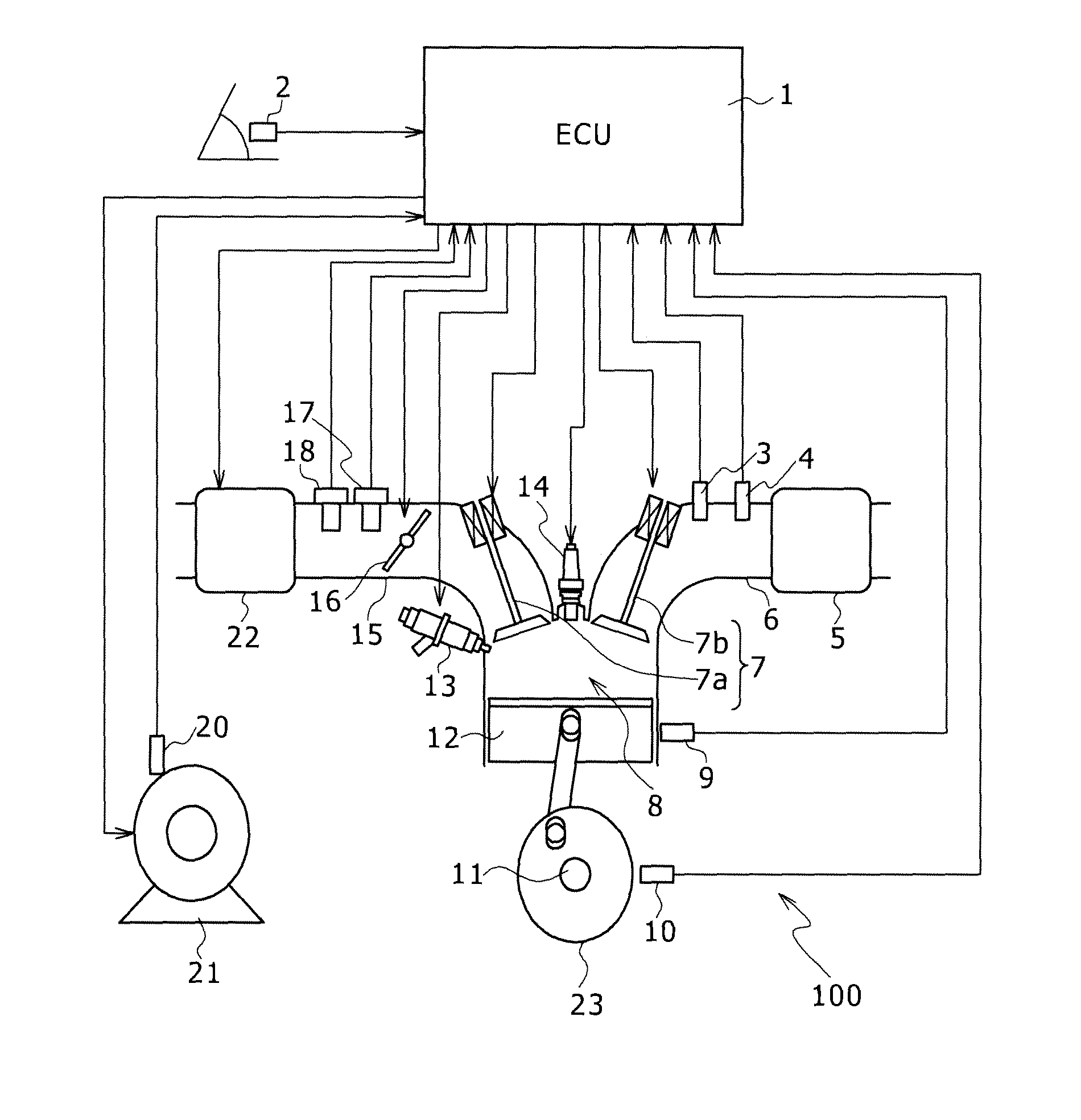

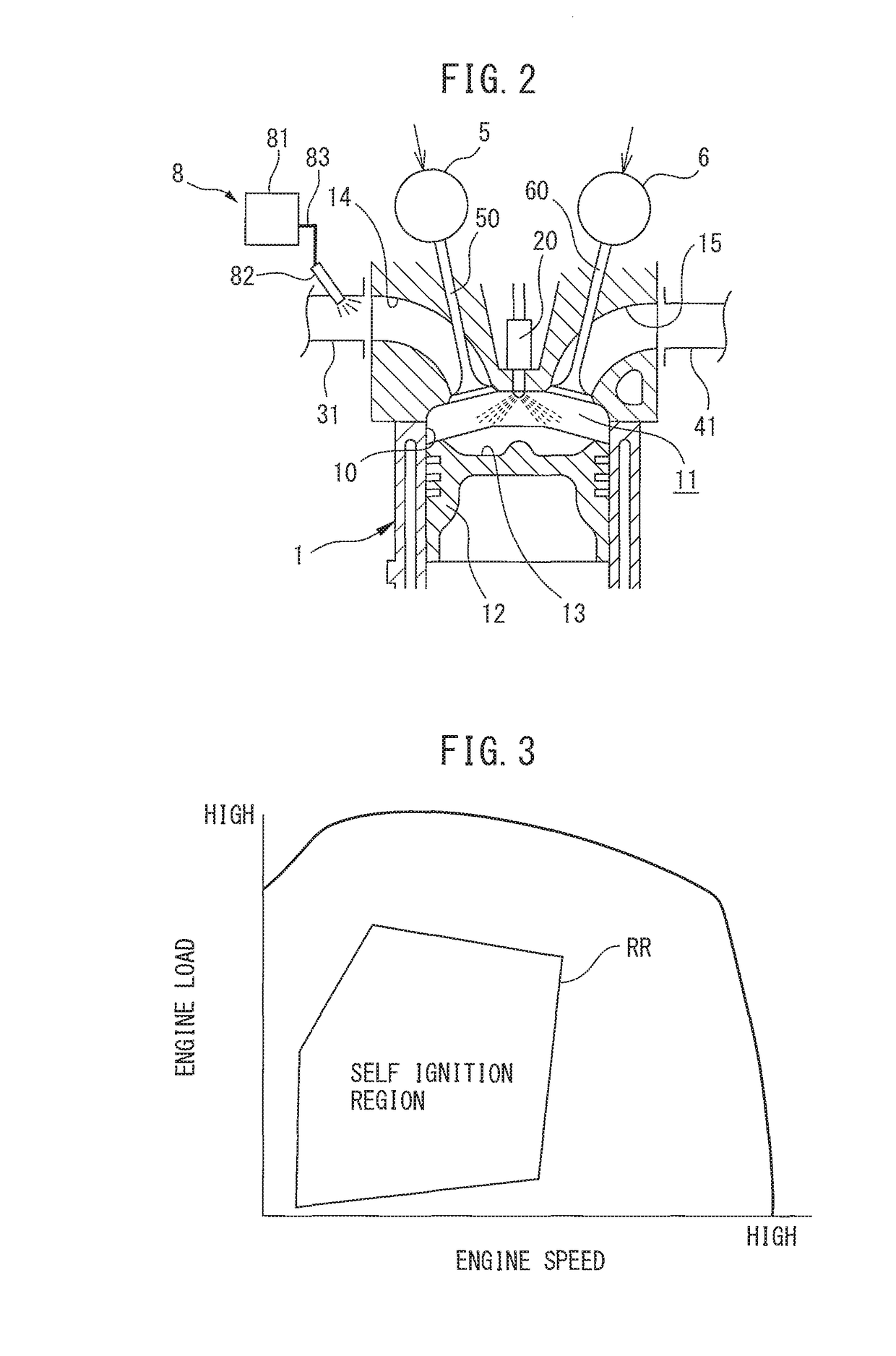

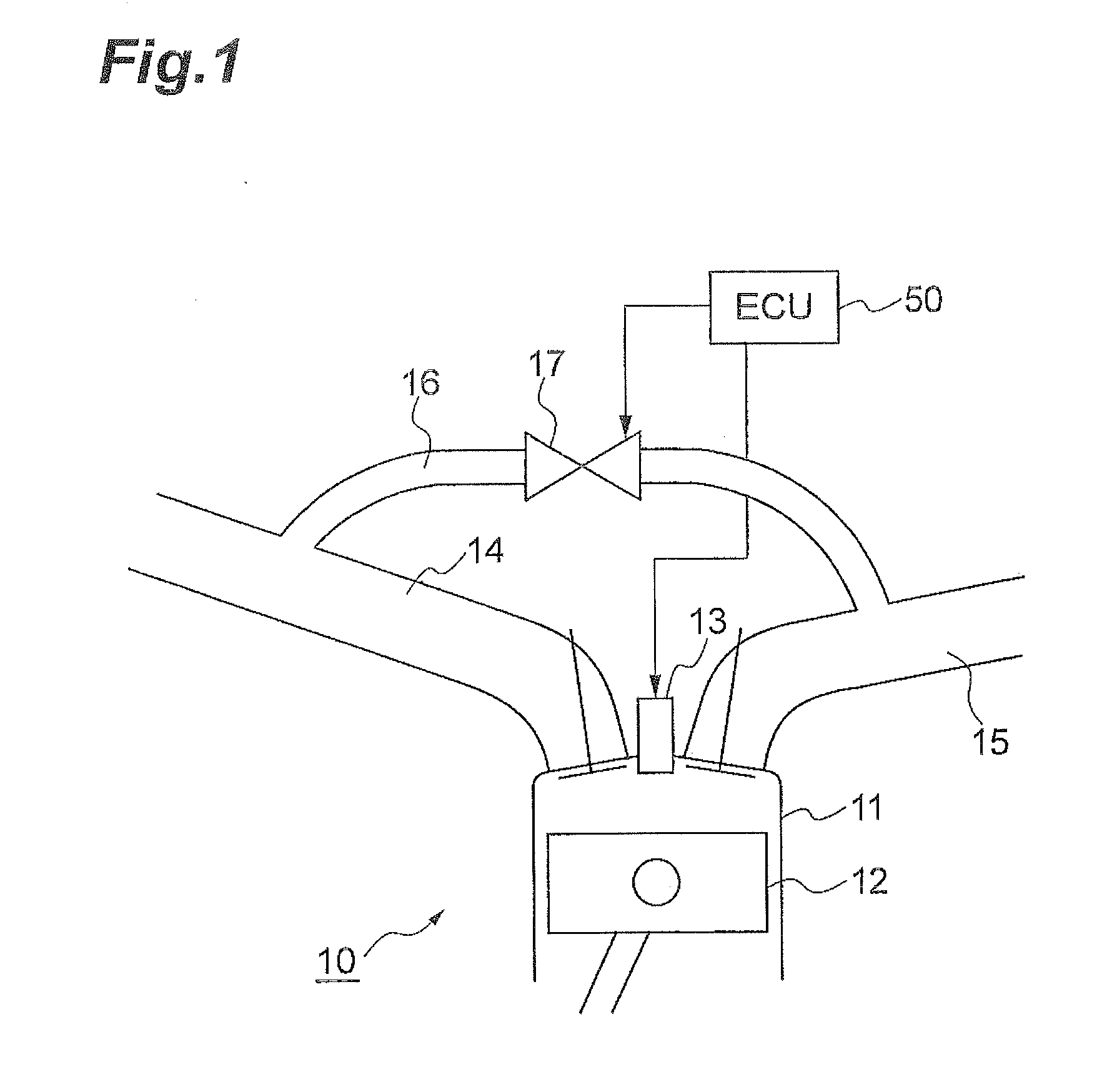

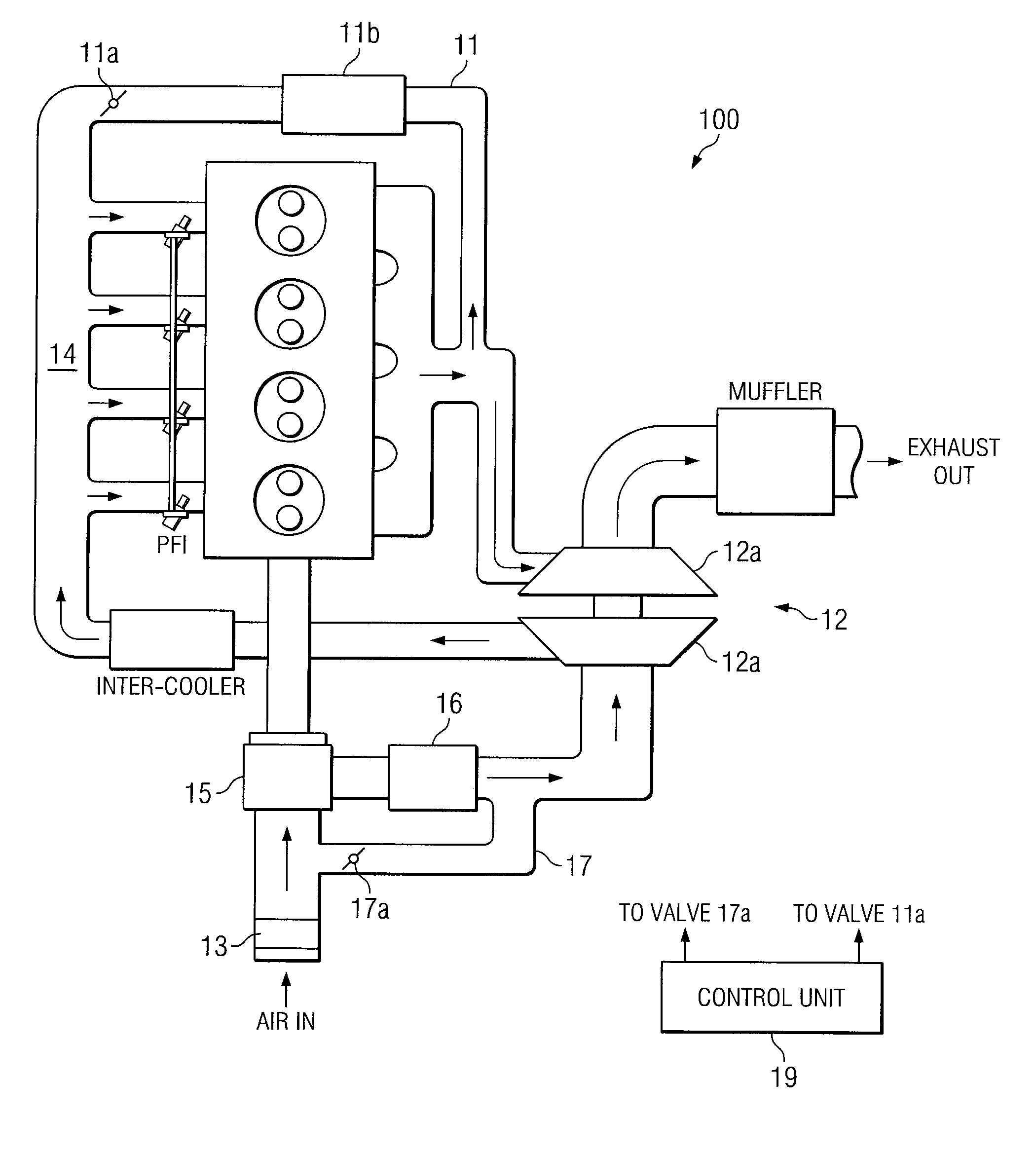

Control apparatus for an internal combustion engine capable of pre-mixed charge compression ignition

InactiveUS7421999B2Increase temperatureSystem can be simplified and lightenedElectrical controlNon-fuel substance addition to fuelHomogeneous charge compression ignitionCombustion noise

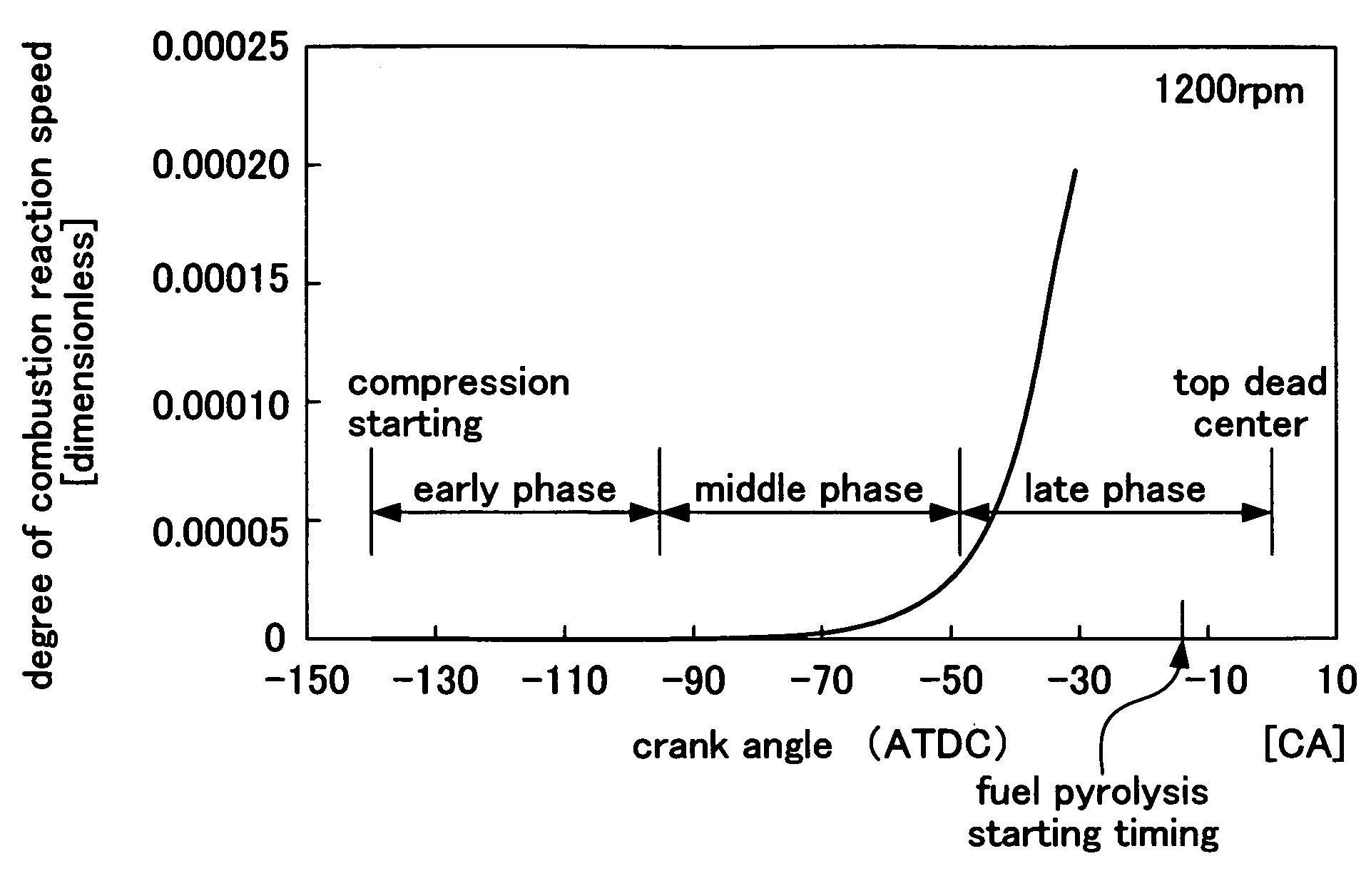

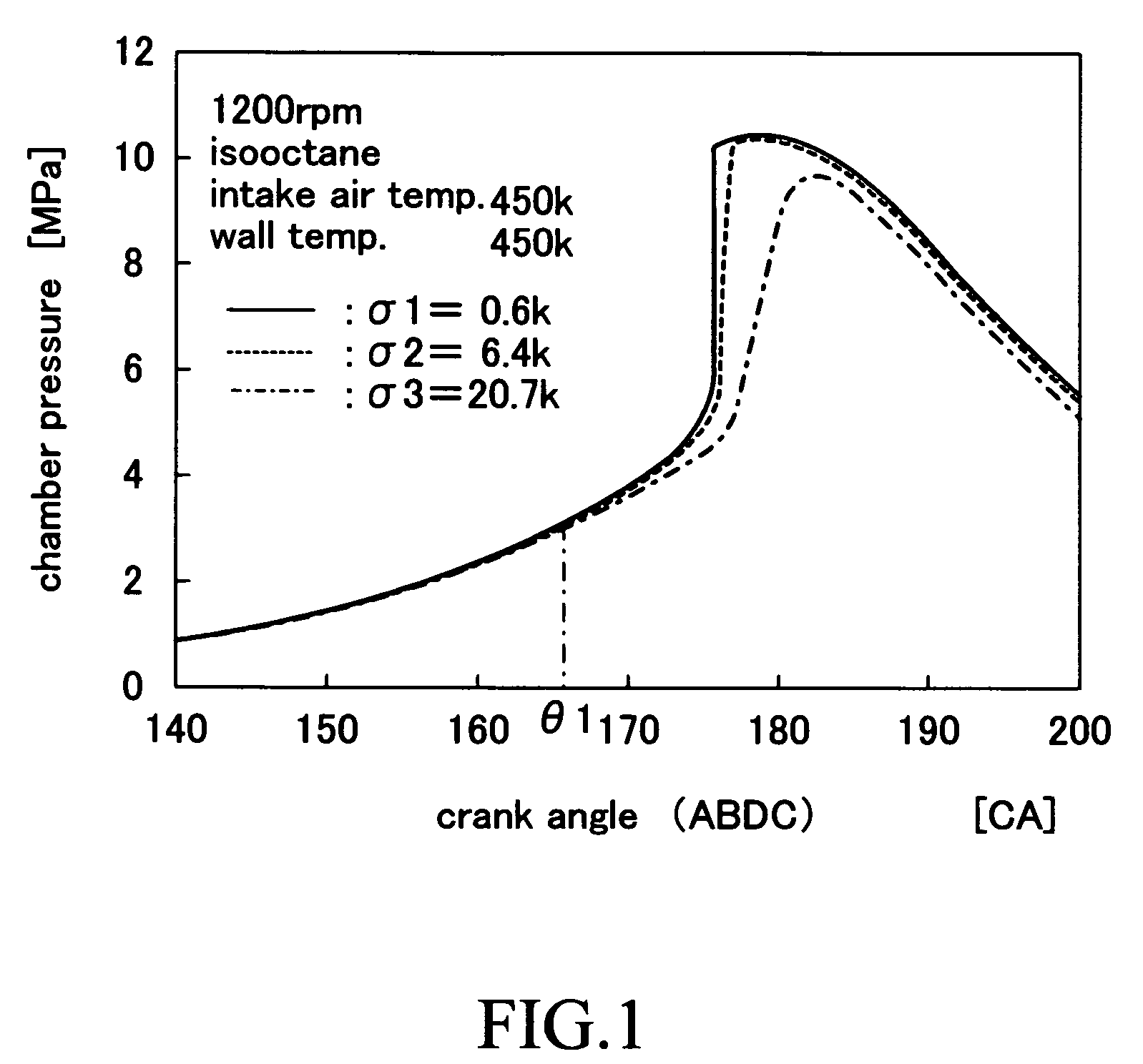

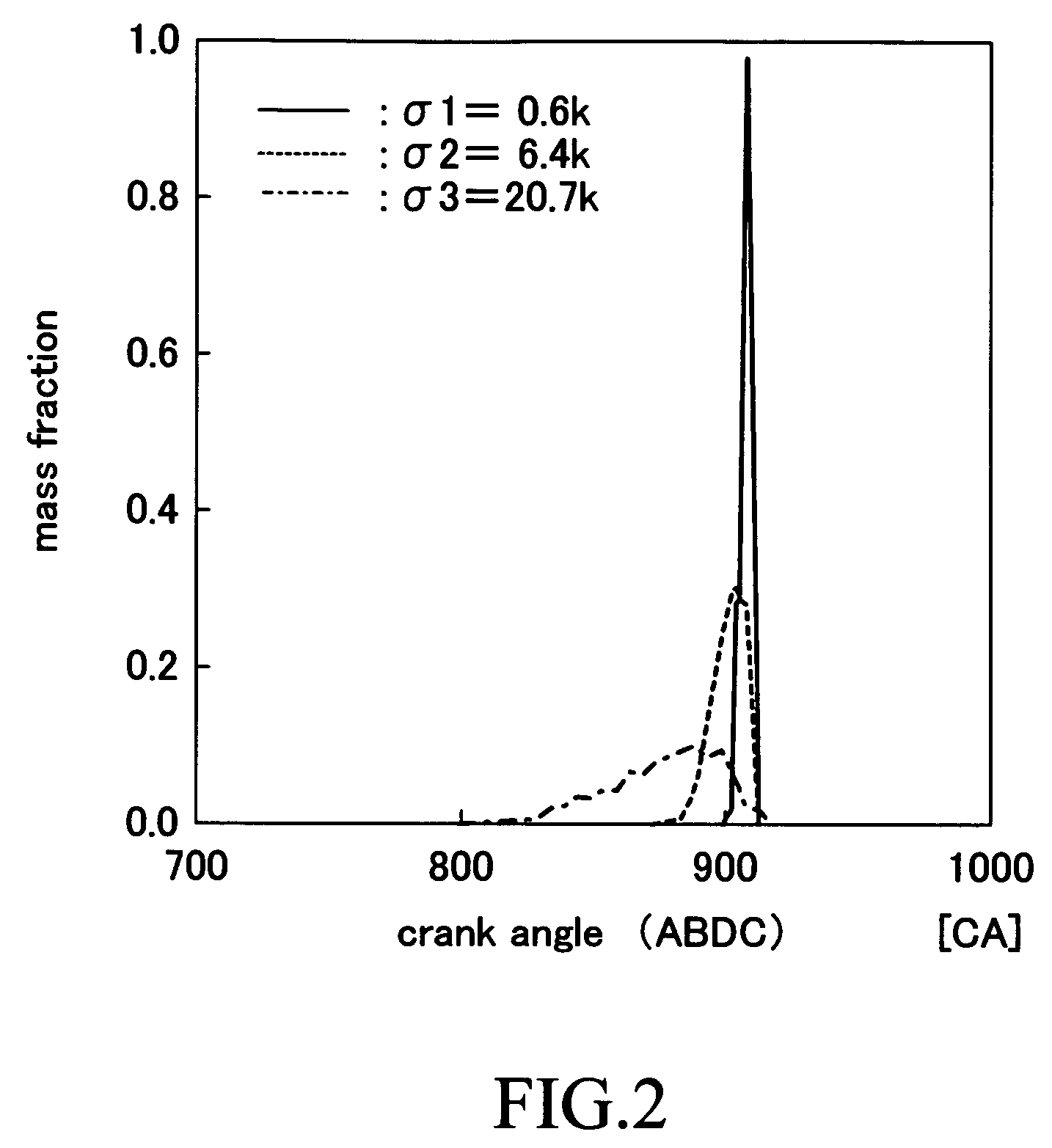

An electric control device 70 is applied to an internal combustion engine 10 capable of a pre-mixed charge compression ignition combustion in which air-fuel mixture gas including air and fuel injected from an injector 37 is formed in a combustion chamber 25, and the air-fuel mixture gas is self-ignited to be combusted by compressing the air-fuel mixture gas during a compression stroke. The electric control device injects high pressure fluid such as air from the air injection valve 38 into the air-fuel mixture gas at a predetermined acting timing within a compression stroke prior to fuel pyrolysis starting timing to enhance the temperature un-uniformity of the air-fuel mixture gas. This enables the temperature un-uniformity of the air-fuel mixture gas at the fuel pyrolysis starting timing to become larger than the temperature un-uniformity of the air-fuel mixture gas at the fuel pyrolysis starting timing obtained only by simply compressing the air-fuel mixture gas during the compression stroke. As a result, the combustion is moderated and the combustion noise is reduced.

Owner:TOYOTA JIDOSHA KK

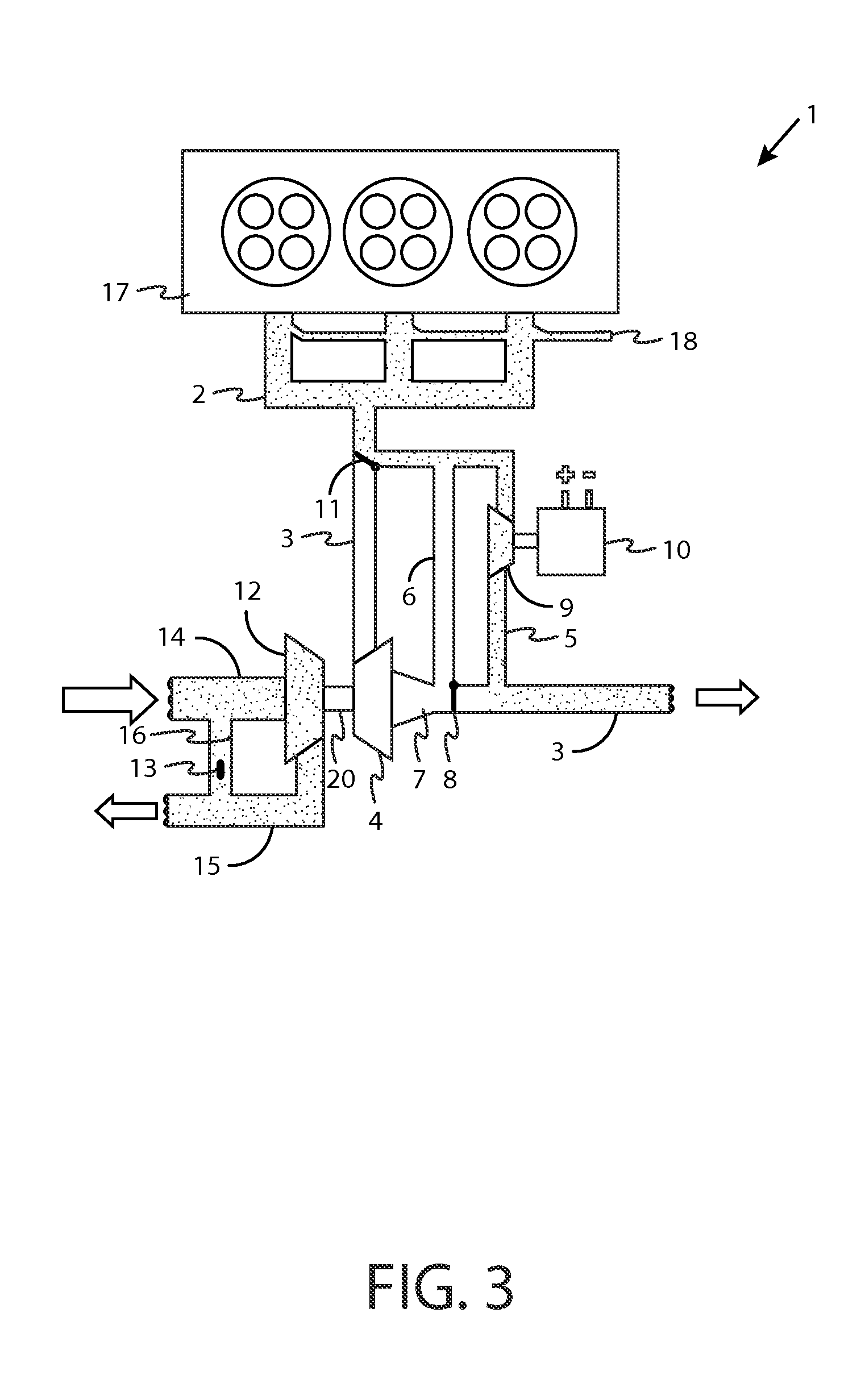

Transient combustion noise control in a hybrid powertrain including an hcci engine

ActiveUS20110276251A1Analogue computers for vehiclesElectrical controlCombustion noiseInternal combustion engine

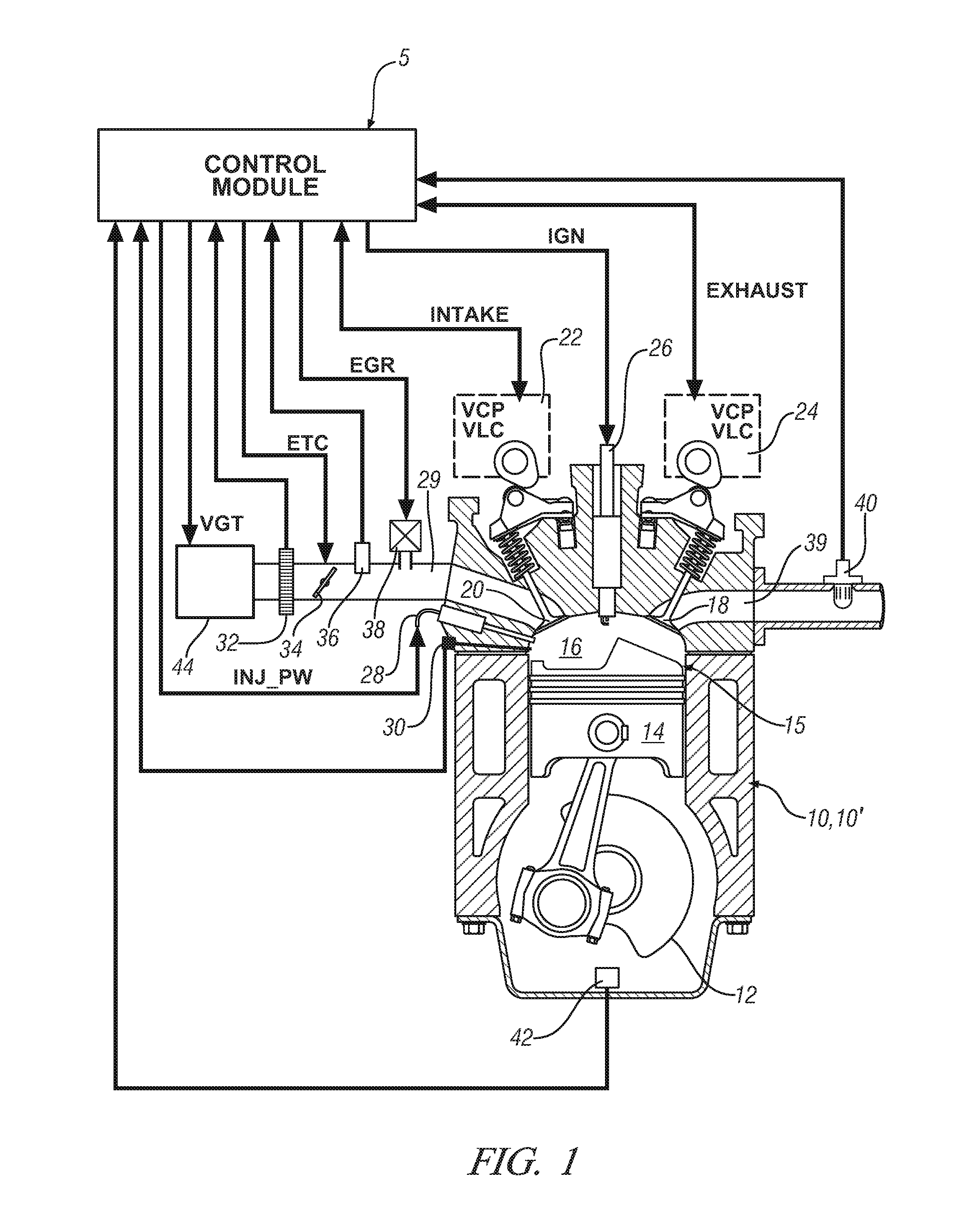

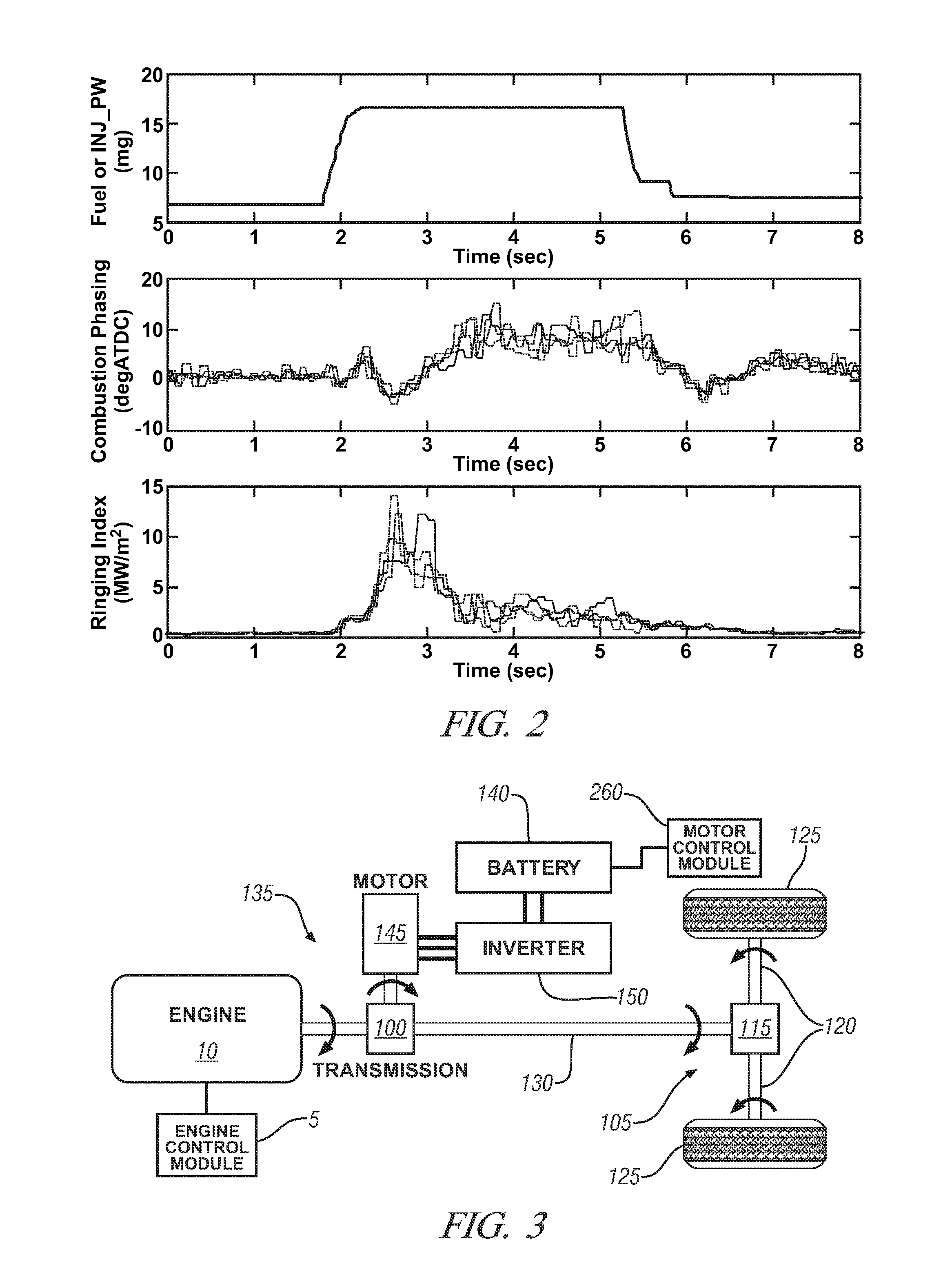

A method for controlling a direct injection internal combustion engine and a torque machine configured to transfer torque to a driveline responsive to an operator torque request includes operating the direct injection internal combustion engine to transfer torque to the driveline, monitoring the operator torque request, determining a time constant associated with the operator torque request, detecting a fast transient condition associated with the operator torque request, providing a restricted engine torque command as a function of the operator torque request and the time constant, and during fast transient conditions controlling engine operation to achieve the restricted engine torque command, and operating the torque machine responsive to a motor torque command, the motor torque command corresponding to a difference between the operator torque request and the restricted engine torque command.

Owner:GM GLOBAL TECH OPERATIONS LLC

Method for separating noise sources of automobile

ActiveCN103362598ASolve systemic problemsLow experience requirementSubsonic/sonic/ultrasonic wave measurementSilencing apparatusCombustion noiseEngineering

The invention discloses a method for separating noise sources of an automobile. The method comprises the following steps: firstly measuring exterior vehicle noise of an accelerating automobile under different working conditions so as to obtain first to fifth noise sound pressure level; secondly, calculating sound pressure level of tire noise, sound pressure level of power assembly mechanical noise, sound pressure level of power assembly combustion noise, sound pressure level of exhaust silencer housing noise and sound pressure level of exhaust port noise; and thirdly, calculating energy contribution ratio of tire noise, energy contribution ratio of power assembly mechanical noise, energy contribution ratio of power assembly combustion noise, energy contribution ratio of exhaust silencer housing noise and energy contribution ratio of exhaust port noise, so that five exterior noise sources of the accelerating automobile can be separated, the composition of the noise sources are accurately distinguished so as to accurately select adopted a denoising means and improve the denoising effect; the requirement on engineer experience through noise rectification is reduced, and the cost of manpower training for relevant enterprises is reduced; and a systematized solution is provided for the relevant enterprises through the noise rectification.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

Method for detecting combustion noise in internal combustion engine, combustion noise detection device, and device for controlling internal combustion engine

ActiveUS20140172280A1Improve accuracyImprove fuel efficiencyInternal-combustion engine testingAnalogue computers for vehiclesCombustion chamberCombustion noise

Although a method for changing a combustion method taking place in an internal combustion engine depending on running condition is proposed, it can be considered that conditions under which a combustion noise occurs naturally differ with different methods. A detection method of prior art is not compatible with different combustion methods and the accuracy of combustion noise detection was low. Accurate combustion noise detection is enabled by identifying a combustion mode taking place in the internal combustion engine, selecting a sensed frequency or frequency band of a combustion noise sensor that detects a combustion noise in a combustion chamber of the internal combustion engine according to the combustion mode, and detecting a combustion noise.

Owner:HITACHI ASTEMO LTD

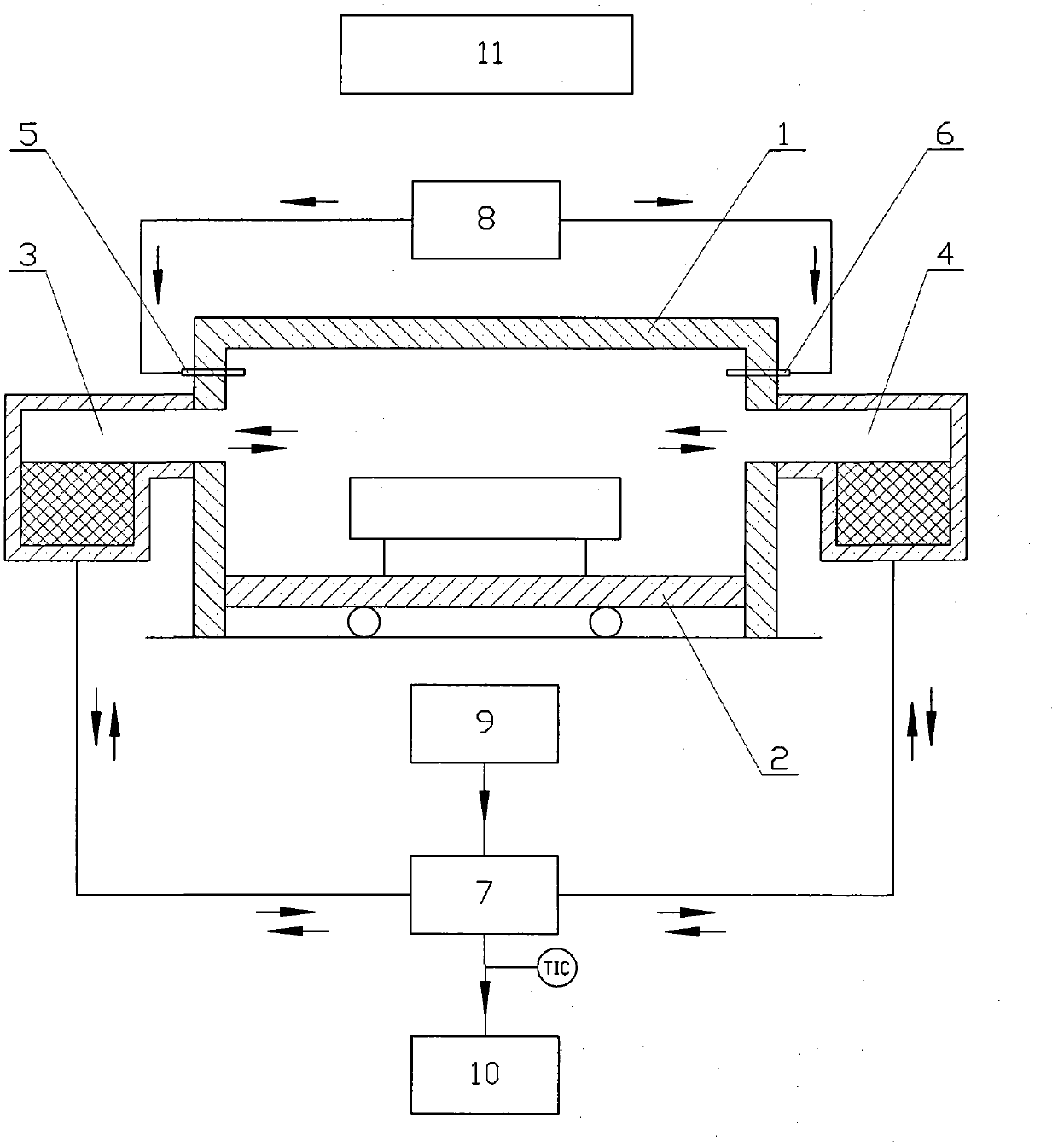

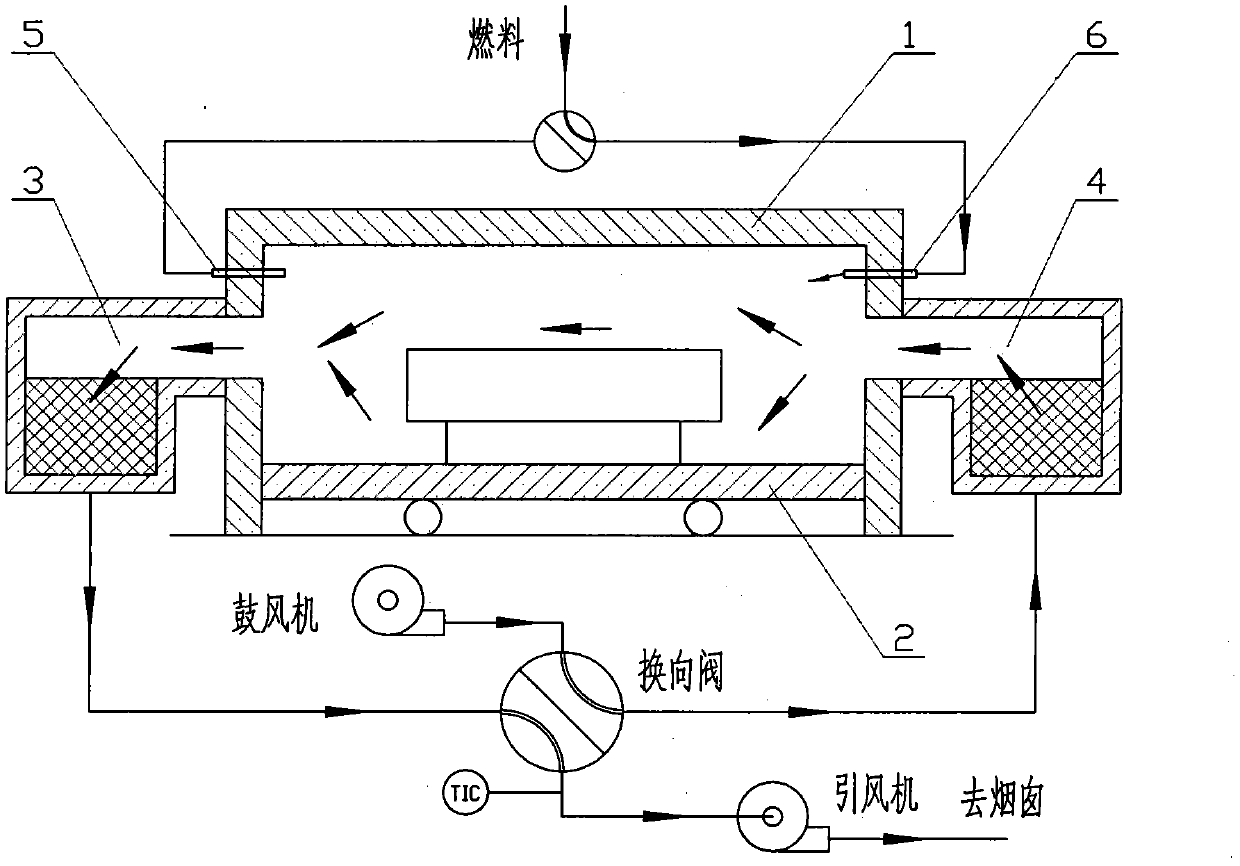

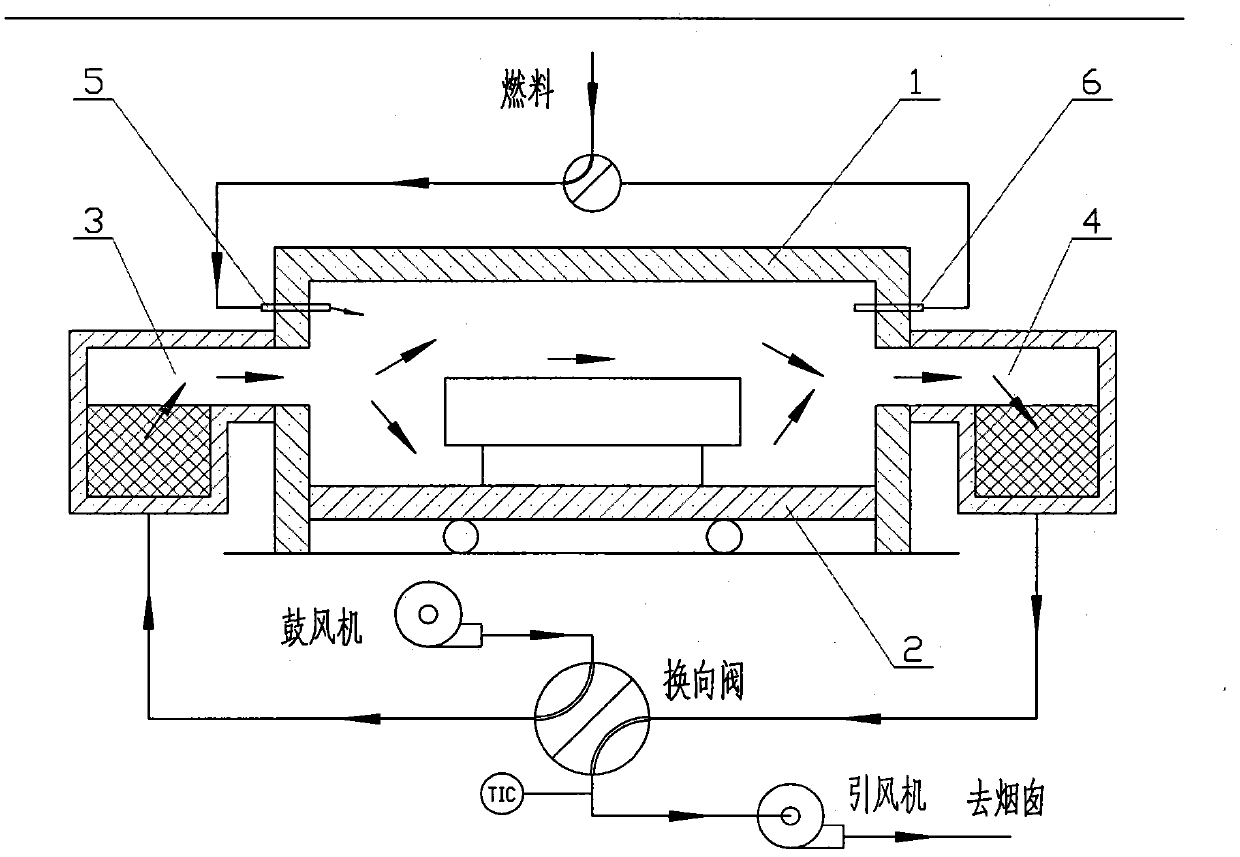

Regenerative high-temperature air combustion energy-saving environment-friendly shuttle-type kiln

InactiveCN102607267AResolve burning ignitionSolve the fire problemFurnace typesIncreasing energy efficiencySocial benefitsCombustion noise

The invention discloses a regenerative high-temperature air combustion energy-saving environment-friendly shuttle-type kiln, which is an efficient, energy-saving and combustion heating system comprising a kiln body, regenerative chambers or regenerative combustors and an air and flue gas reversing valve. The regenerative high-temperature air combustion energy-saving environment-friendly shuttle-type kiln adopts the novel regenerative HTAC (high-temperature air combustion) technology, enables the two regenerative chambers to be alternatively operated in the regeneration and heat release states by means of switching of the reversing valve to efficiently recover waste heat of flue gas, and leads combustion-supporting air to be preheated to be higher than 1,000 DEG C, so that fuel can be sufficiently combusted in the high-temperature oxygen-poor environment, the problem of fuel adaptability is effectively solved, the space of the whole hearth is filled with unique flames with no local high-temperature area, heat transfer in the kiln is more intense and uniform, output and heating quality of products are effectively improved, generation and total discharge amount of NOx (nitrogen oxides) and dioxin are restrained, and combustion noise is greatly reduced. The shuttle-type kiln has the advantages of high efficiency, energy saving, environmental protection, remarkable economic and social benefits and the like.

Owner:朱海生

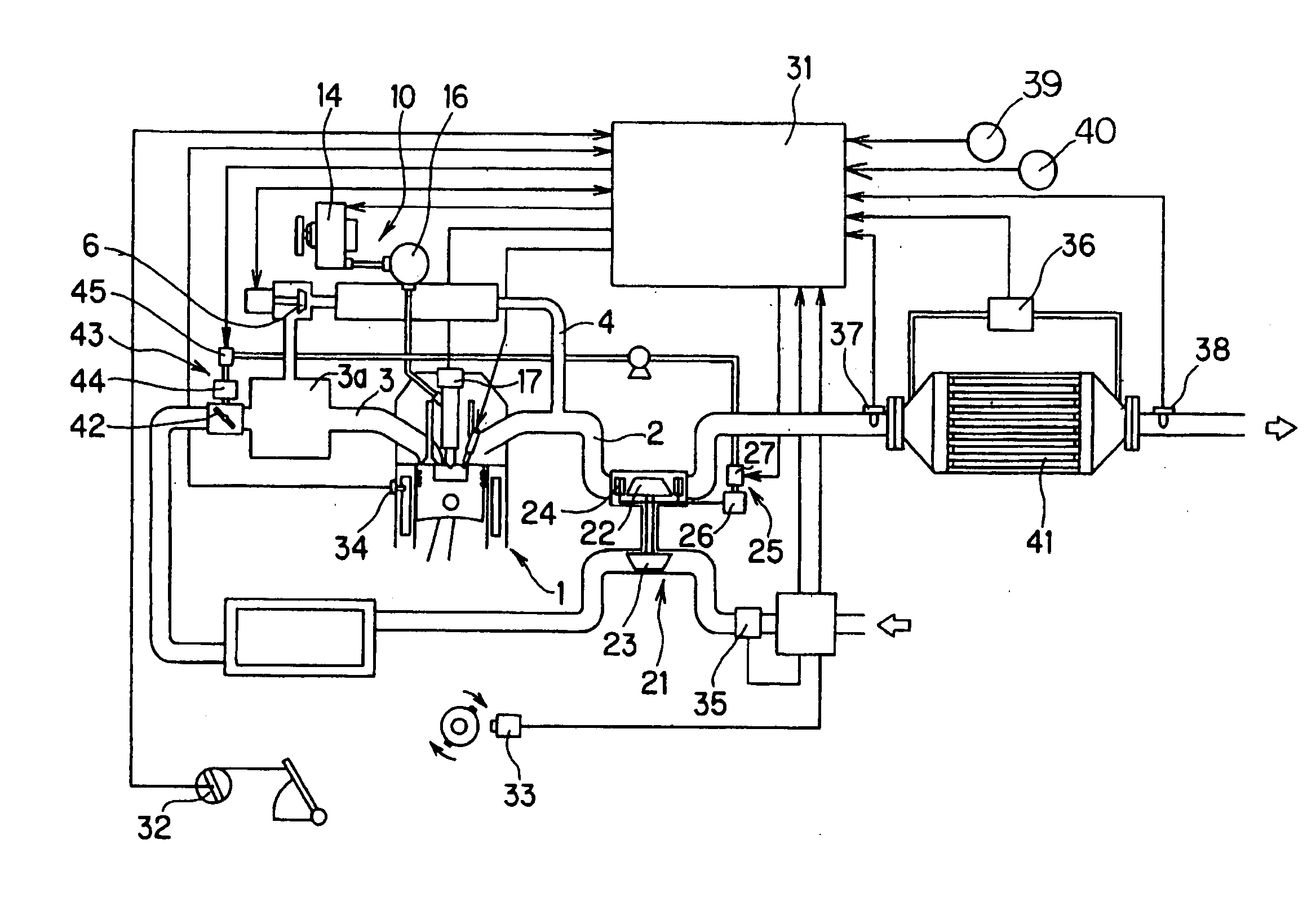

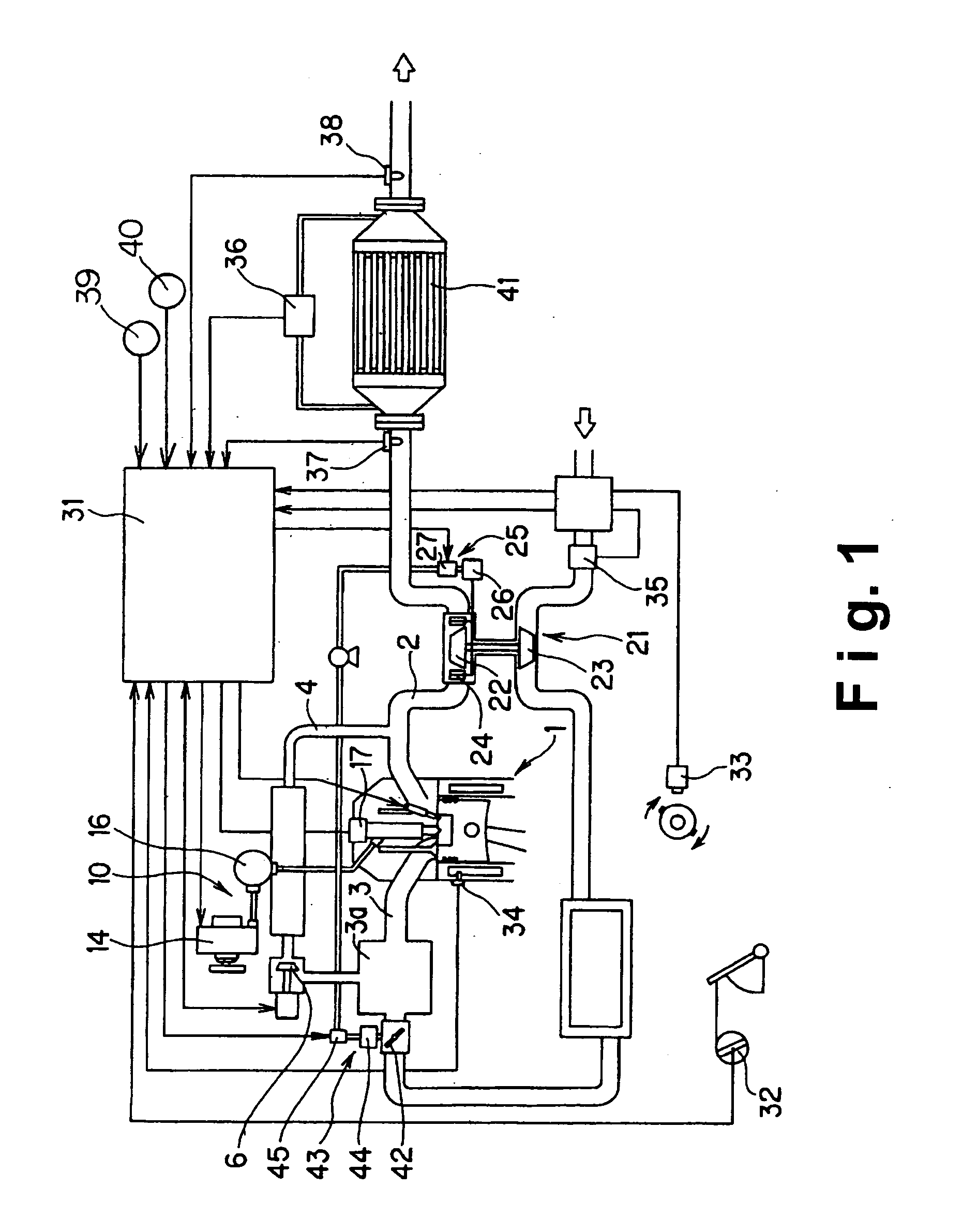

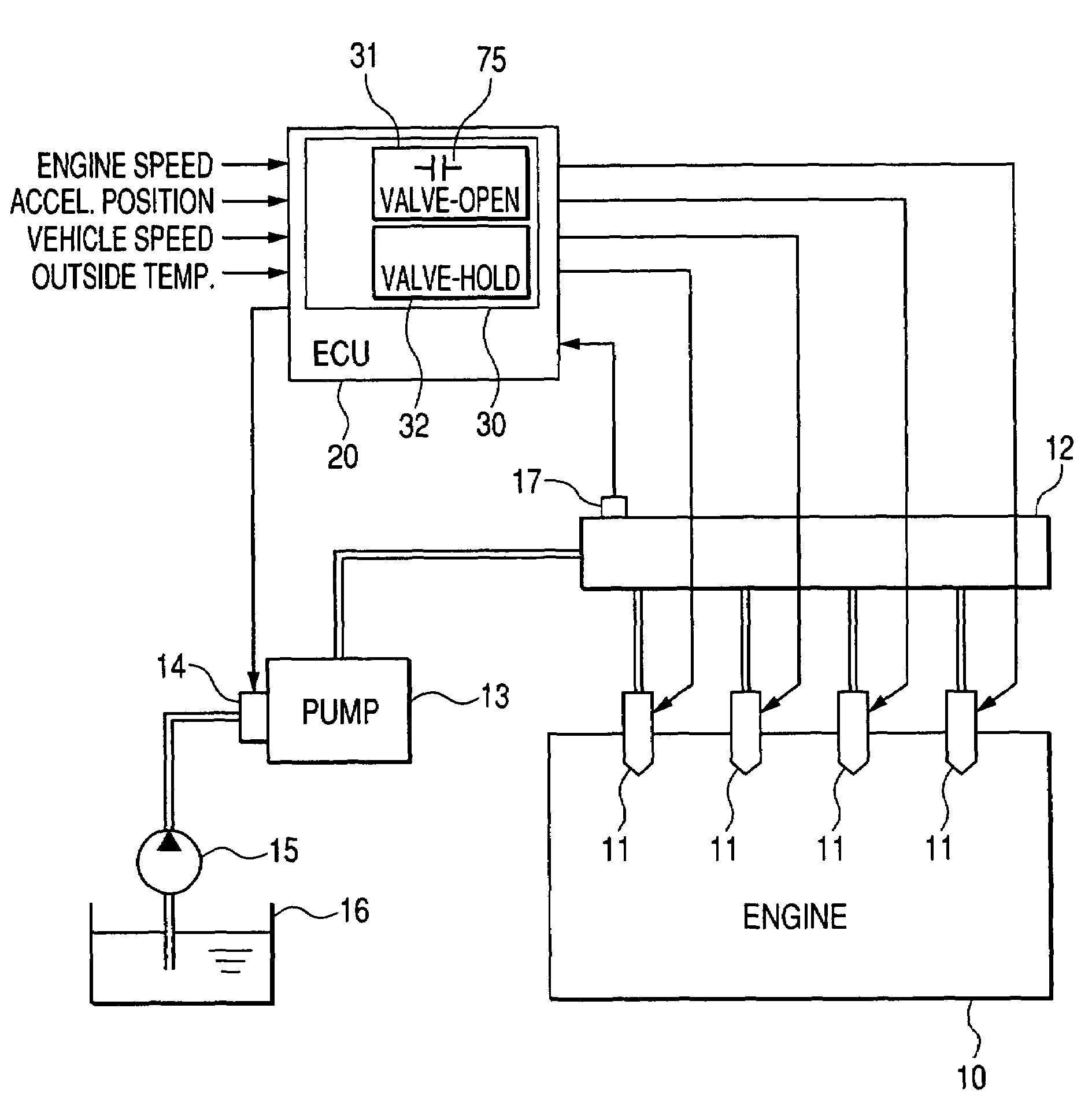

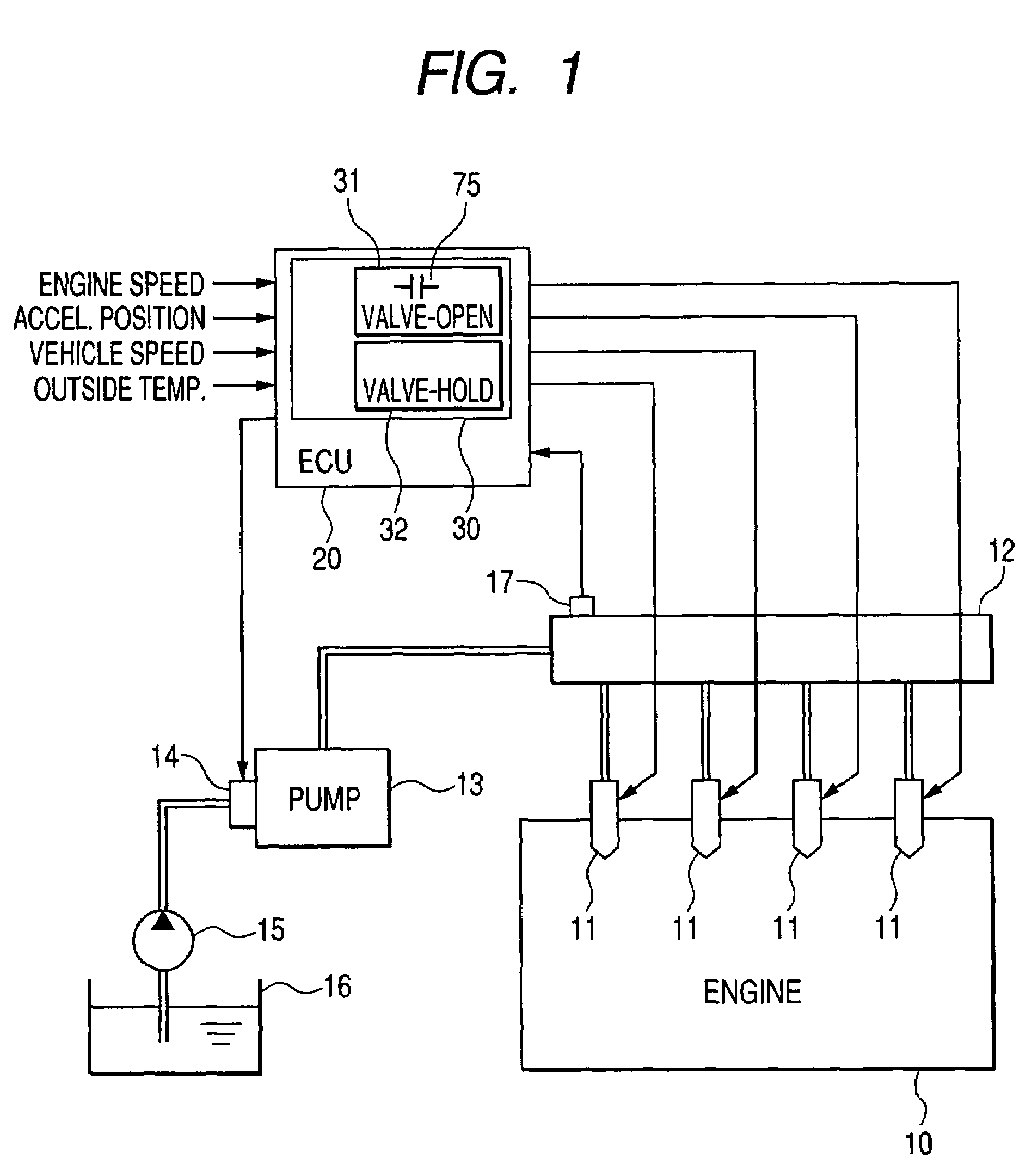

Engine fuel injection control method and engine fuel injection control apparatus

InactiveUS20070131203A1Deteriorate with timeElectrical controlInternal combustion piston enginesCombustion noiseOperant conditioning

An engine fuel injection control apparatus has a parameter setting section, a parameter changing section and a determining section. The parameter setting section is configured to set a parameter of fuel injected into an engine to a first injection parameter to control a state of combustion noise or exhaust emission to a target state when an engine operation condition is in a first operation region. The parameter changing section is configured to change the parameter of fuel injected into the engine from the first injection parameter to a second injection parameter when the engine operation condition remains in the first operation region. The determining section is configured to determine whether or not an actual state of the combustion noise or the exhaust emission of the engine changes when the parameter of fuel injected into the engine is changed from the first injection parameter to the second injection parameter.

Owner:NISSAN MOTOR CO LTD

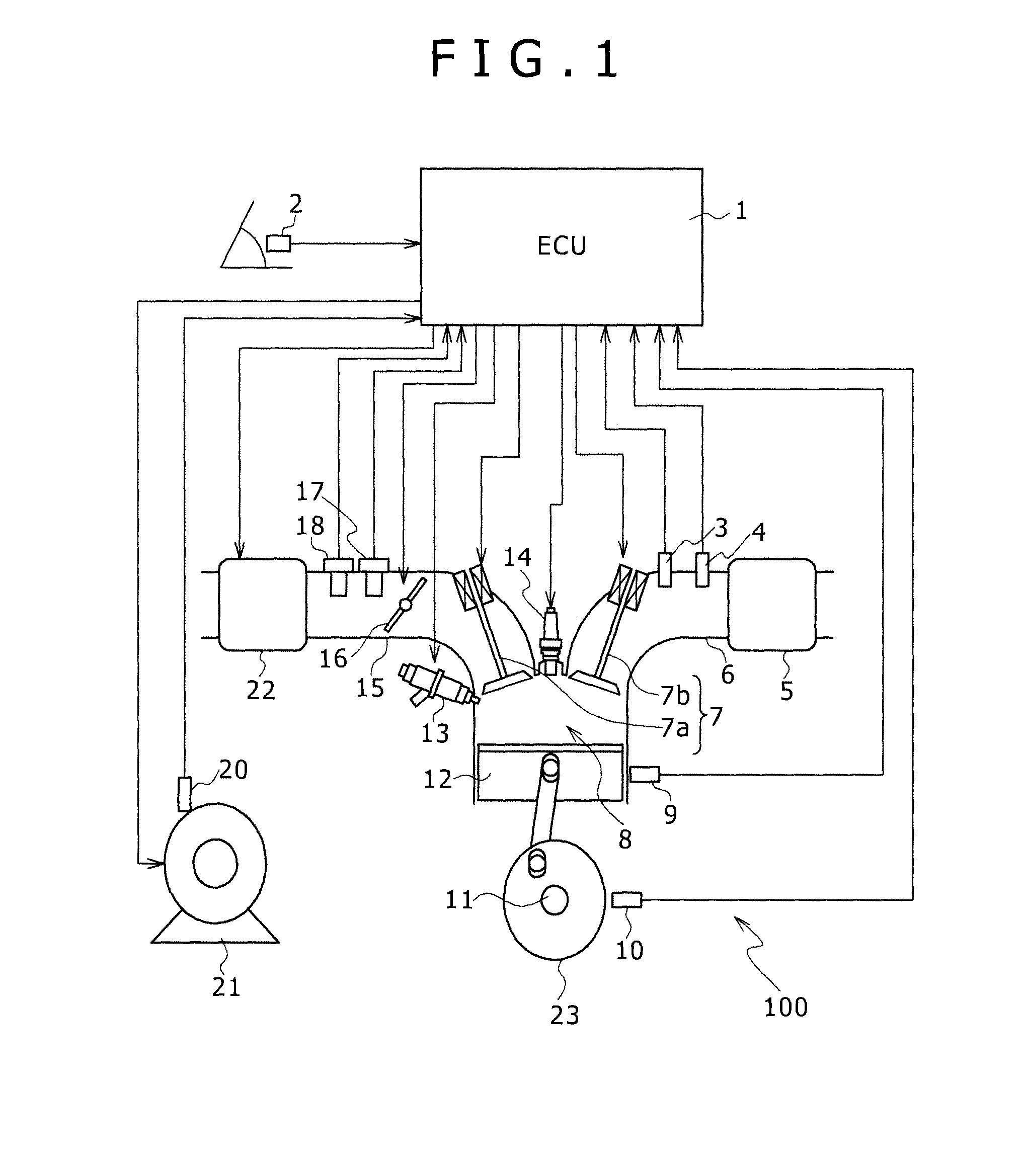

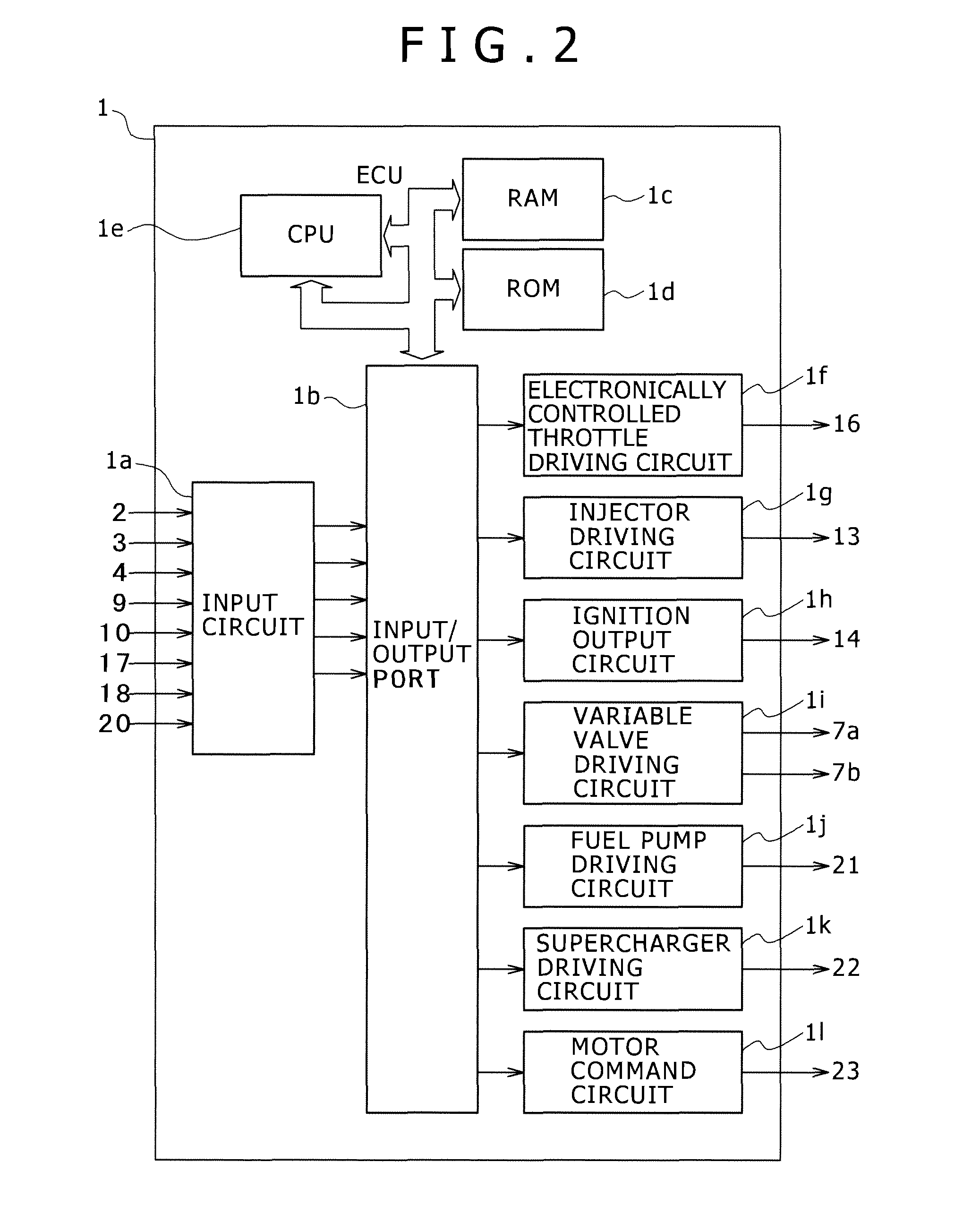

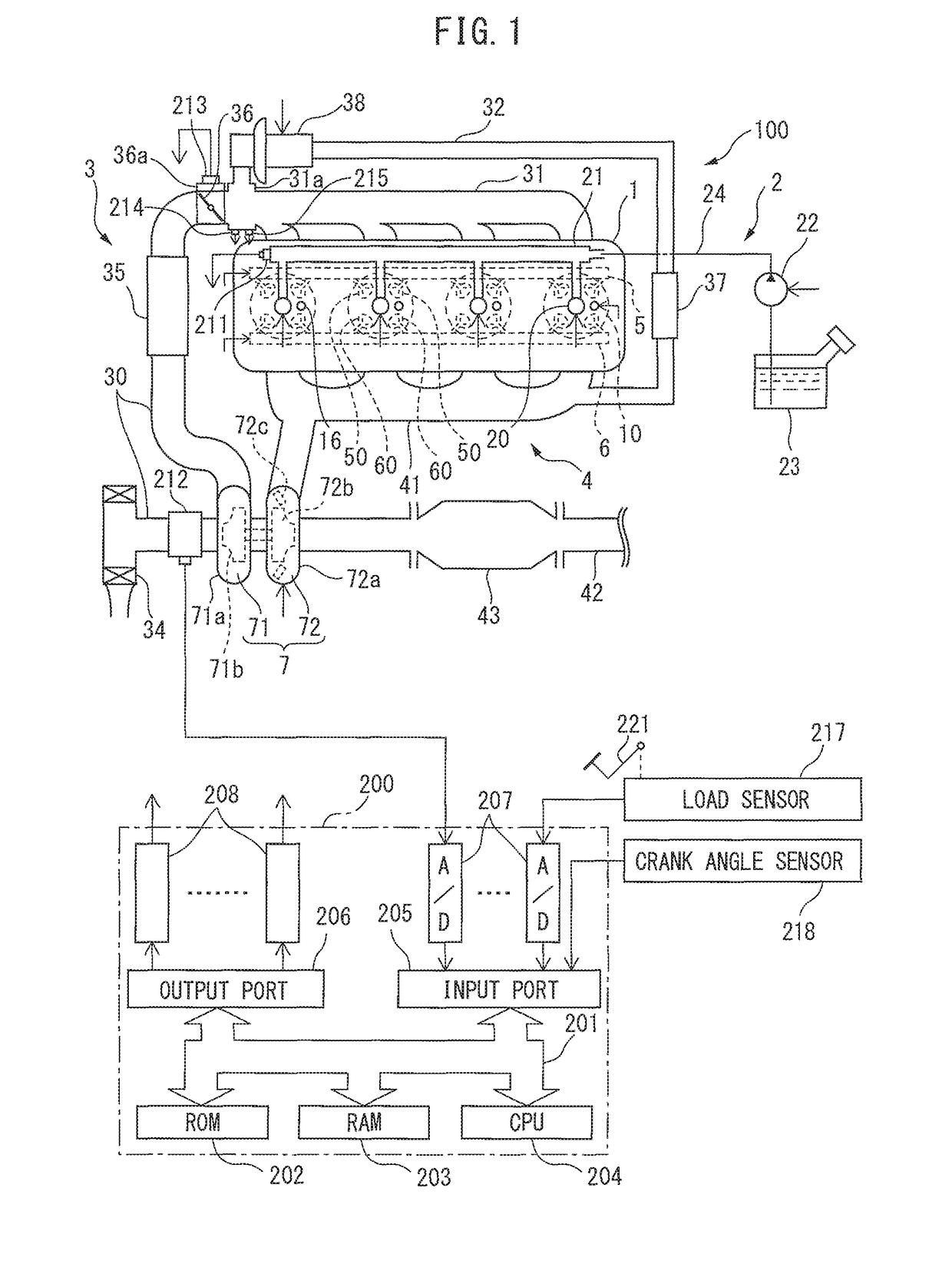

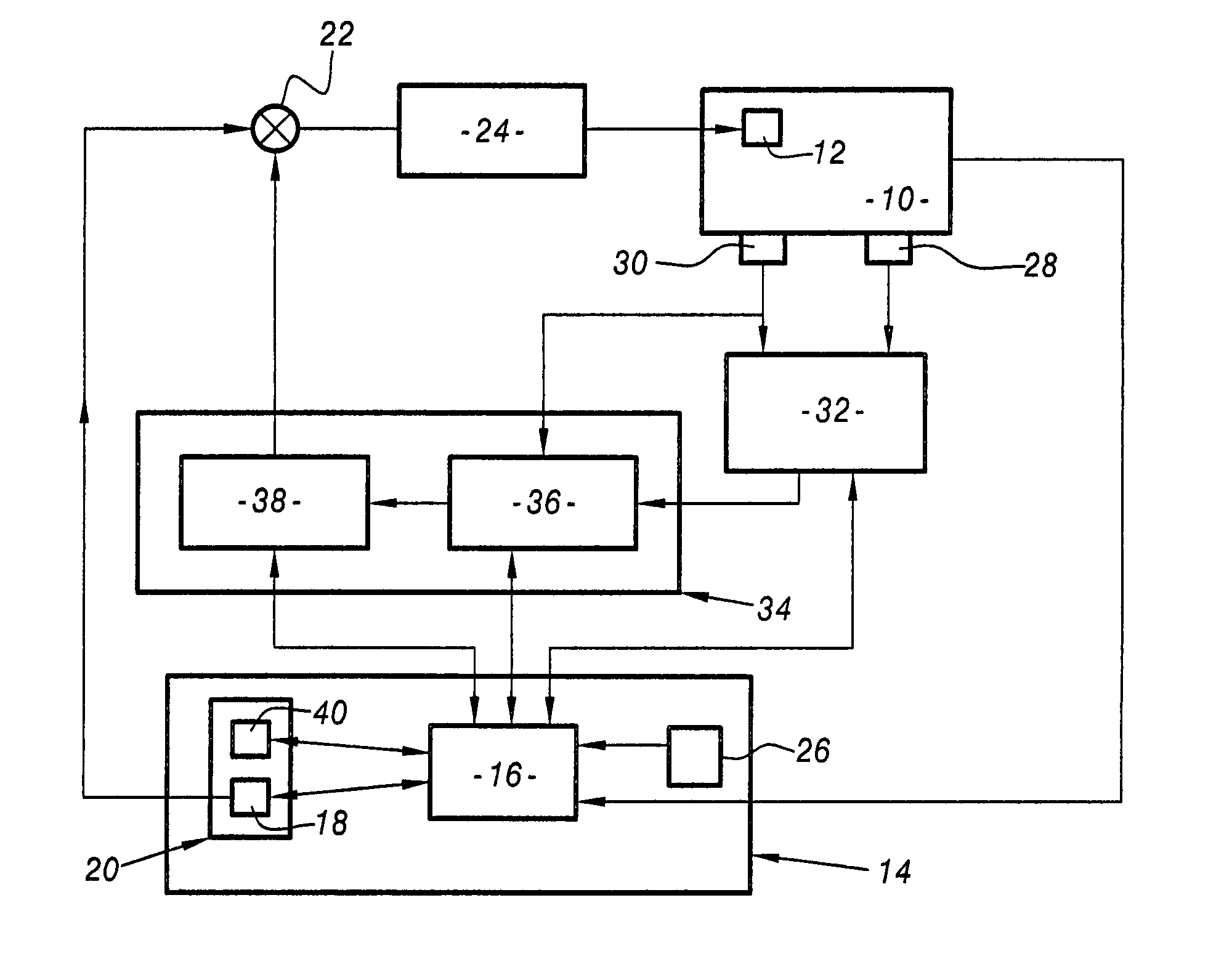

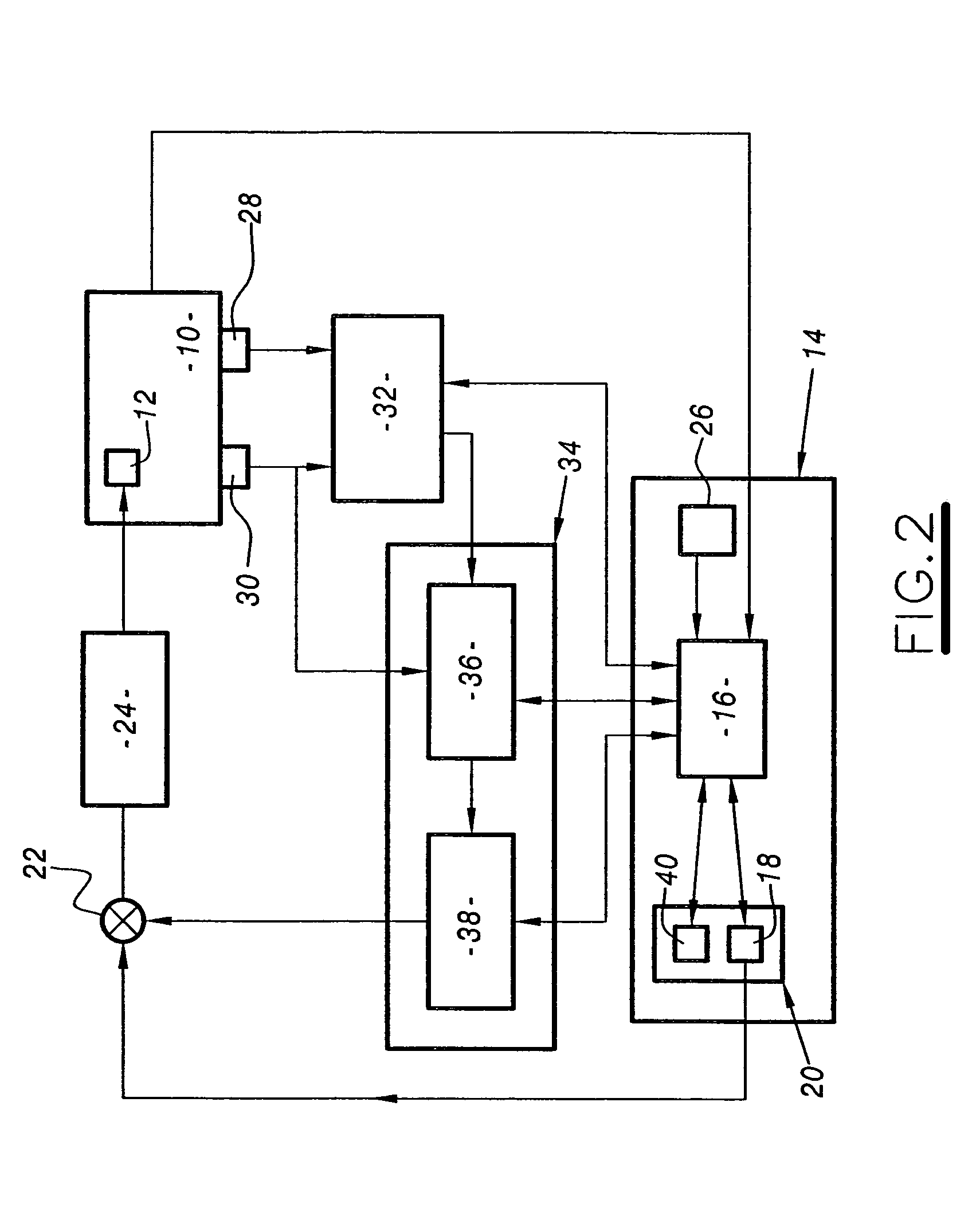

Premixed charge compression ignition engine with optimal combustion control

InactiveCN1624305AControl control systemEffective controlElectrical controlInternal combustion piston enginesTemperature controlActive feedback

The present invention provides a premixed charge compression ignition engine and control system (10), which can effectively trigger combustion and maintain stable combustion by means of compression ignition, while achieving extremely low nitrogen oxide emissions, good overall efficiency and Acceptable combustion noise and cylinder pressure. The engine and control system (10) of the present invention can effectively control the combustion process by controlling certain control variables of temperature control, pressure control, mixture self-ignitability control and equivalence ratio control, that is, the time of combustion initiation, the combustion rate , duration of combustion and / or completeness of combustion. The combustion control system (10) provides active feedback control of combustion and includes a sensor for detecting engine operating conditions representative of a combustion process, such as ignition of combustion, and generating a corresponding engine operating condition signal (18) , such as the pressure sensor (16).

Owner:CUMMINS INC

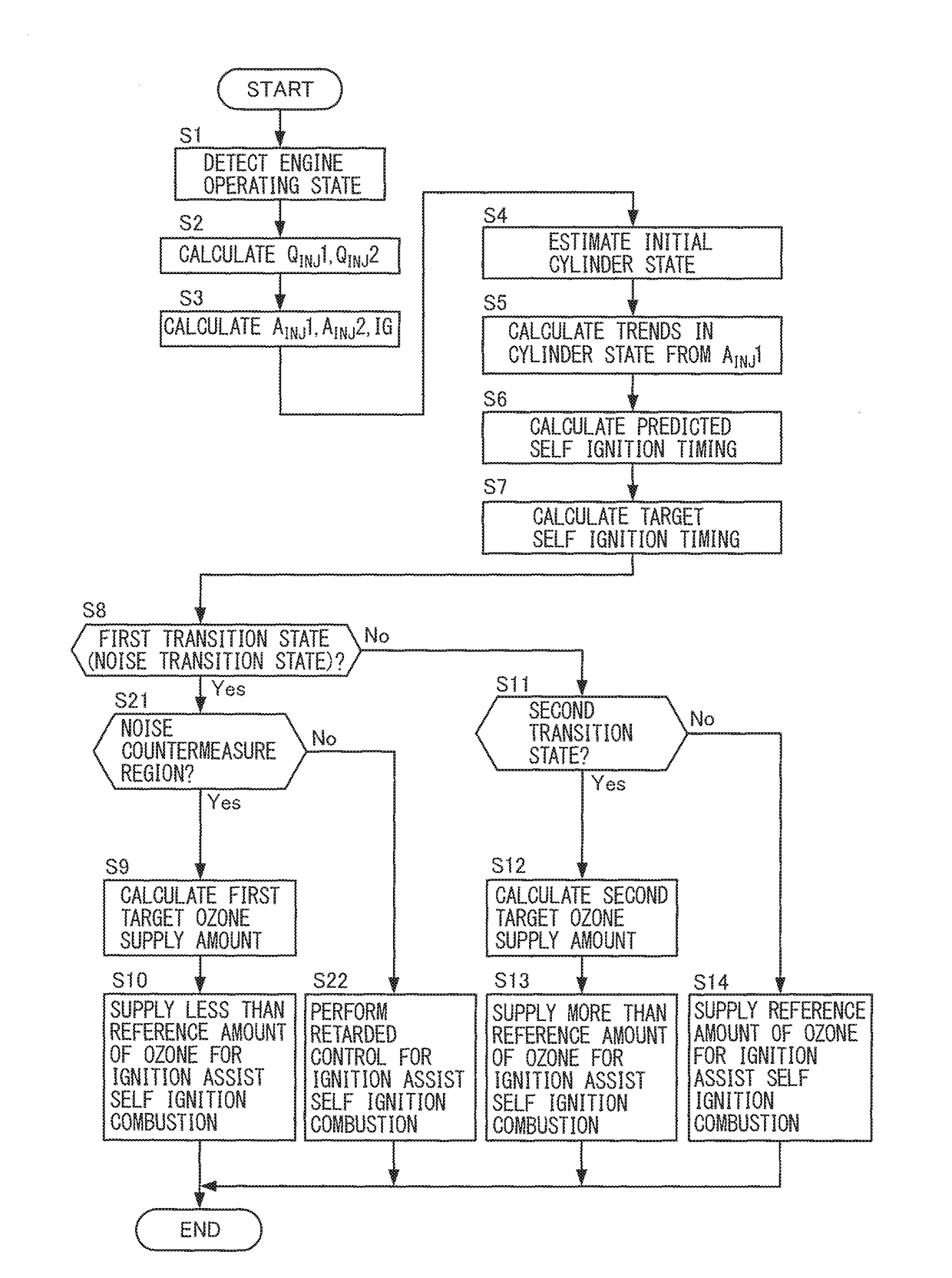

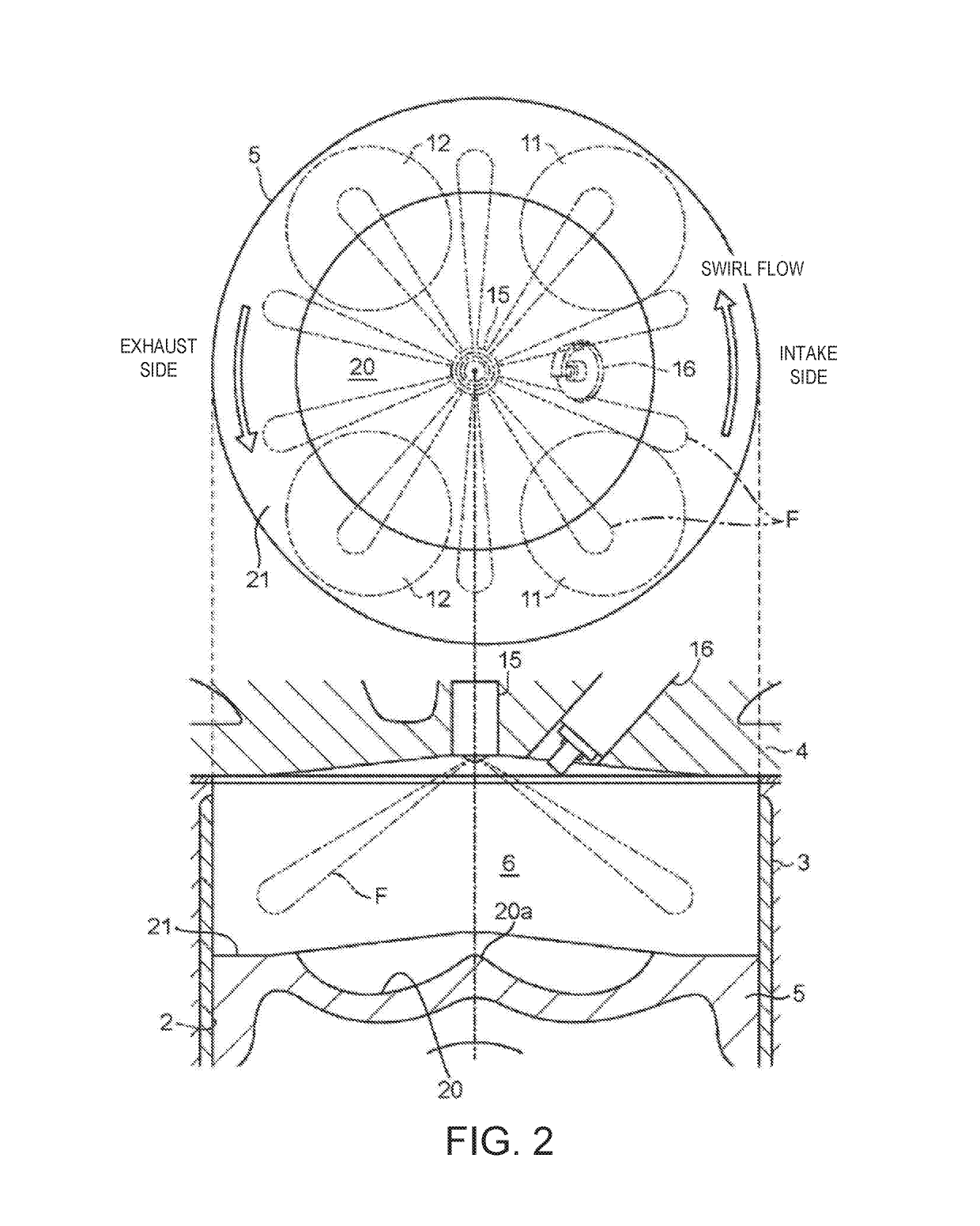

Control system for internal combustion engine

InactiveUS20170292462A1Suppress deterioration of combustion noiseElectrical controlInternal combustion piston enginesCombustion chamberCombustion noise

A control system for an internal combustion engine is provided with a combustion control part, an operating state judging part judging if an engine operating state is a steady state or a combustion noise is a noise transition state where the combustion noise increases over a predetermined allowable noise value when burning fuel by an ignition-assist self-ignition combustion, and an ozone supply control part controlling the amount of ozone supplied to the combustion chamber by the ozone supply system. The ozone supply control part controls the amount of supply of ozone to a predetermined reference amount when the state is judged to be the steady state and controls the amount of supply of ozone to an amount of supply smaller than the reference amount or makes the amount of supply of ozone zero when the state is judged to be the noise transition state.

Owner:TOYOTA JIDOSHA KK

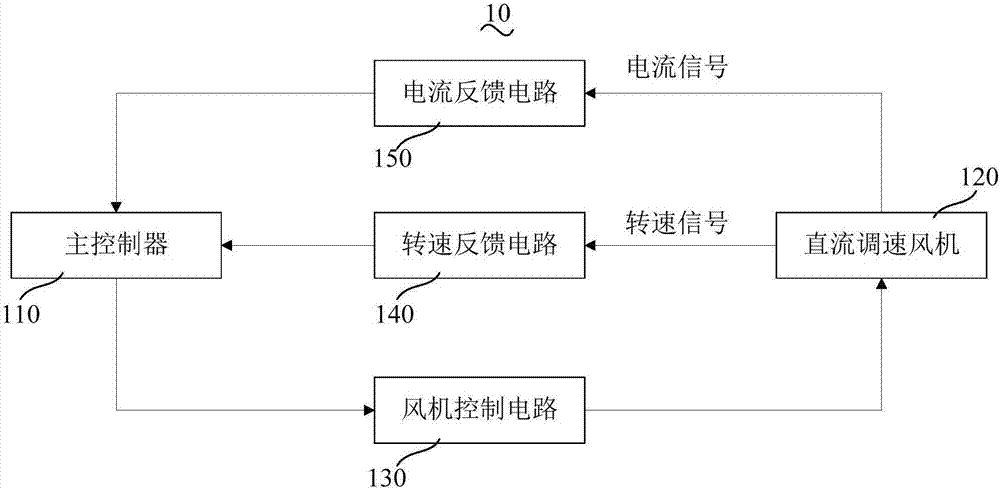

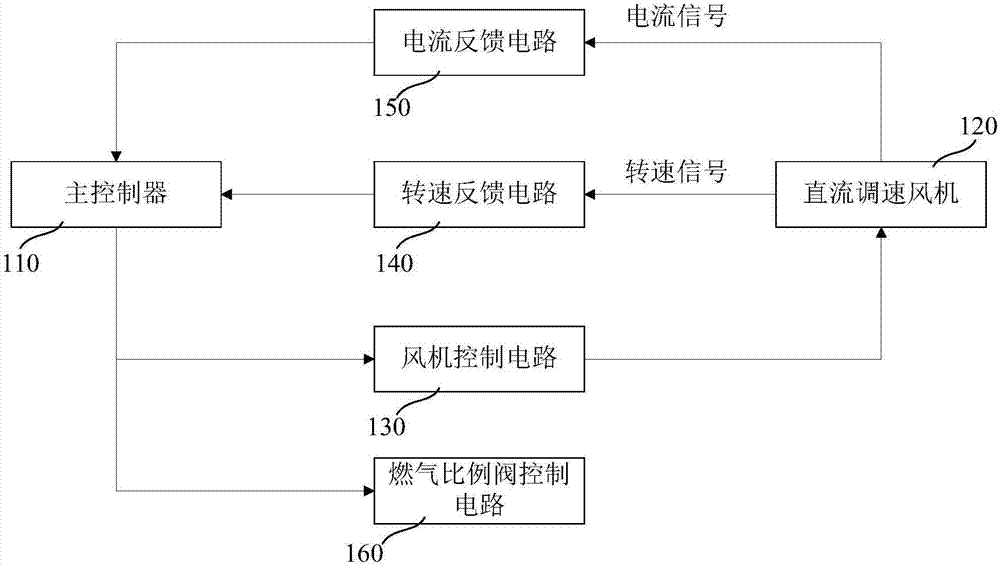

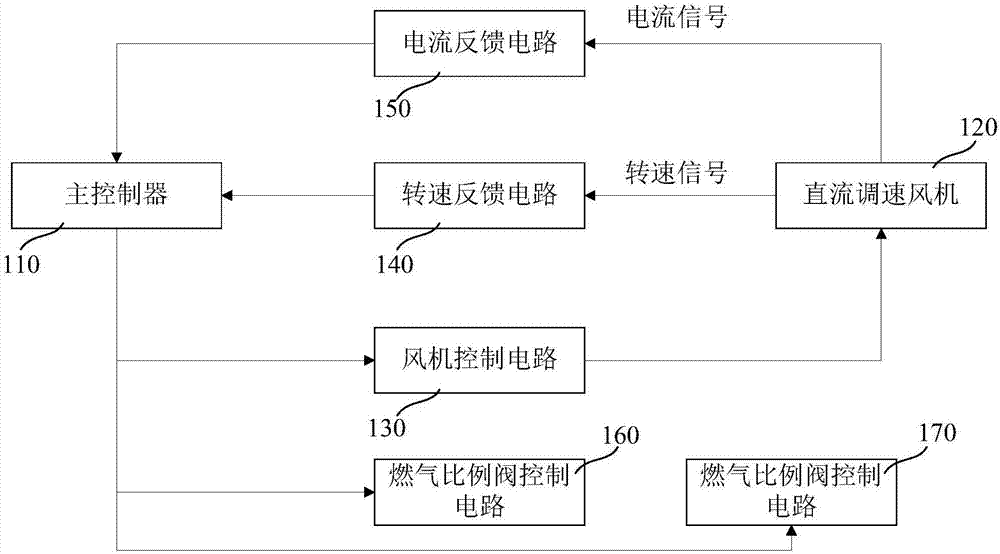

Gas water heater wind-pressure-resistance control system

The invention discloses a gas water heater wind-pressure-resistance control system. The gas water heater wind-pressure-resistance control system comprises a main controller, a direct current speed governing fan, a fan control circuit, a rotating speed feedback circuit and a current feedback circuit; the control end of the main controller is connected with the input end of the fan control circuit, and the output end of the fan control circuit is connected with the control end of the direct current speed governing fan; the input end of the main controller is connected with the output end of the rotating speed feedback circuit and the output end of the current feedback circuit; and the input end of the rotating speed feedback circuit and the input end of the current feedback circuit are connected with the output end of the direct current speed governing fan. Through the gas water heater wind-pressure-resistance control system, backflow of a lot of waste gas and flame overflowing are effectively avoided, noise and electric leakage hidden danger are well controlled, accordingly, the product adaptation and comfort of a gas water heater are further improved, and the effect that combustion noise, fumes and heat efficiency reach the best state is ensured.

Owner:GUANGDONG VANWARD NEW ELECTRIC CO LTD

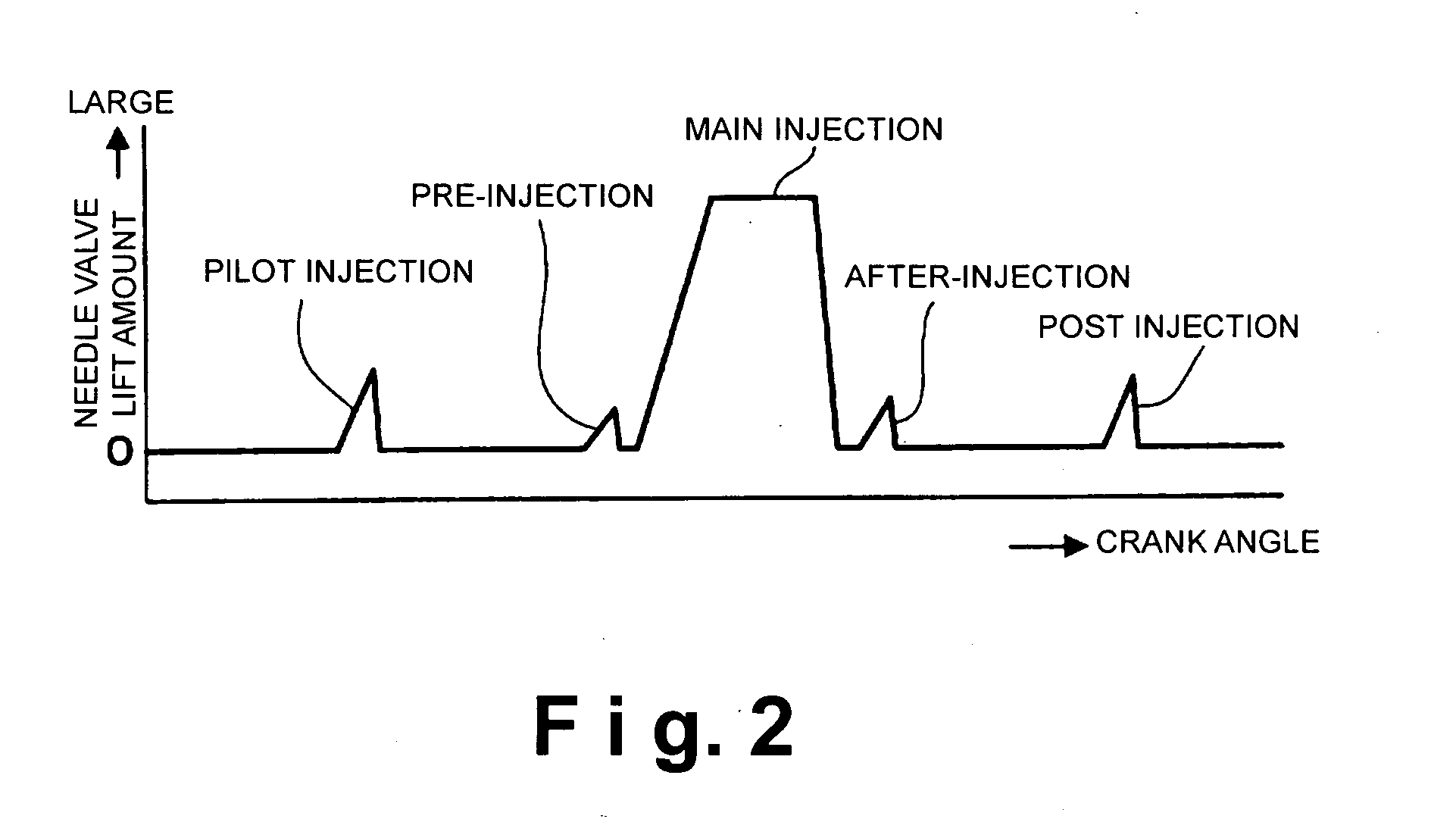

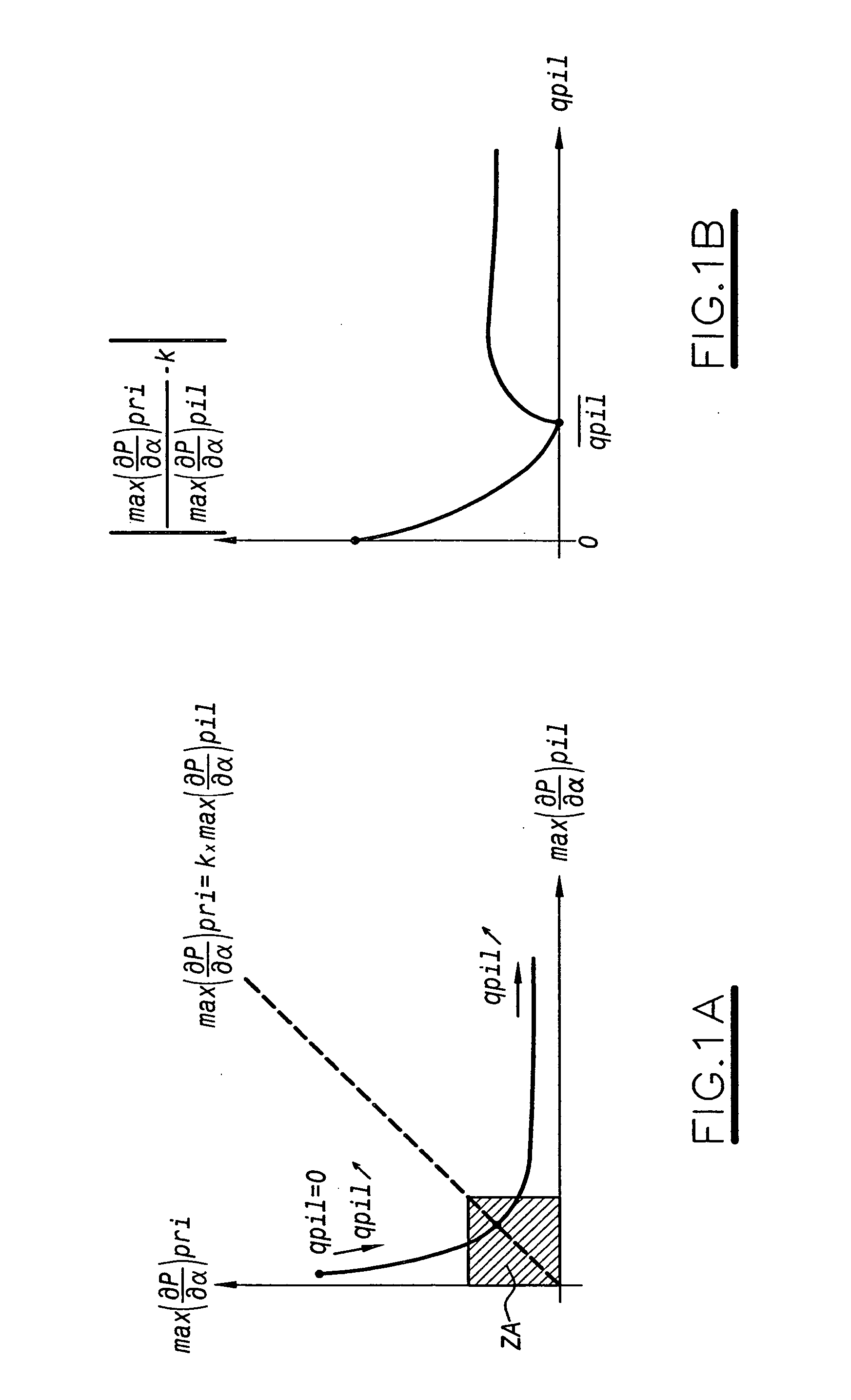

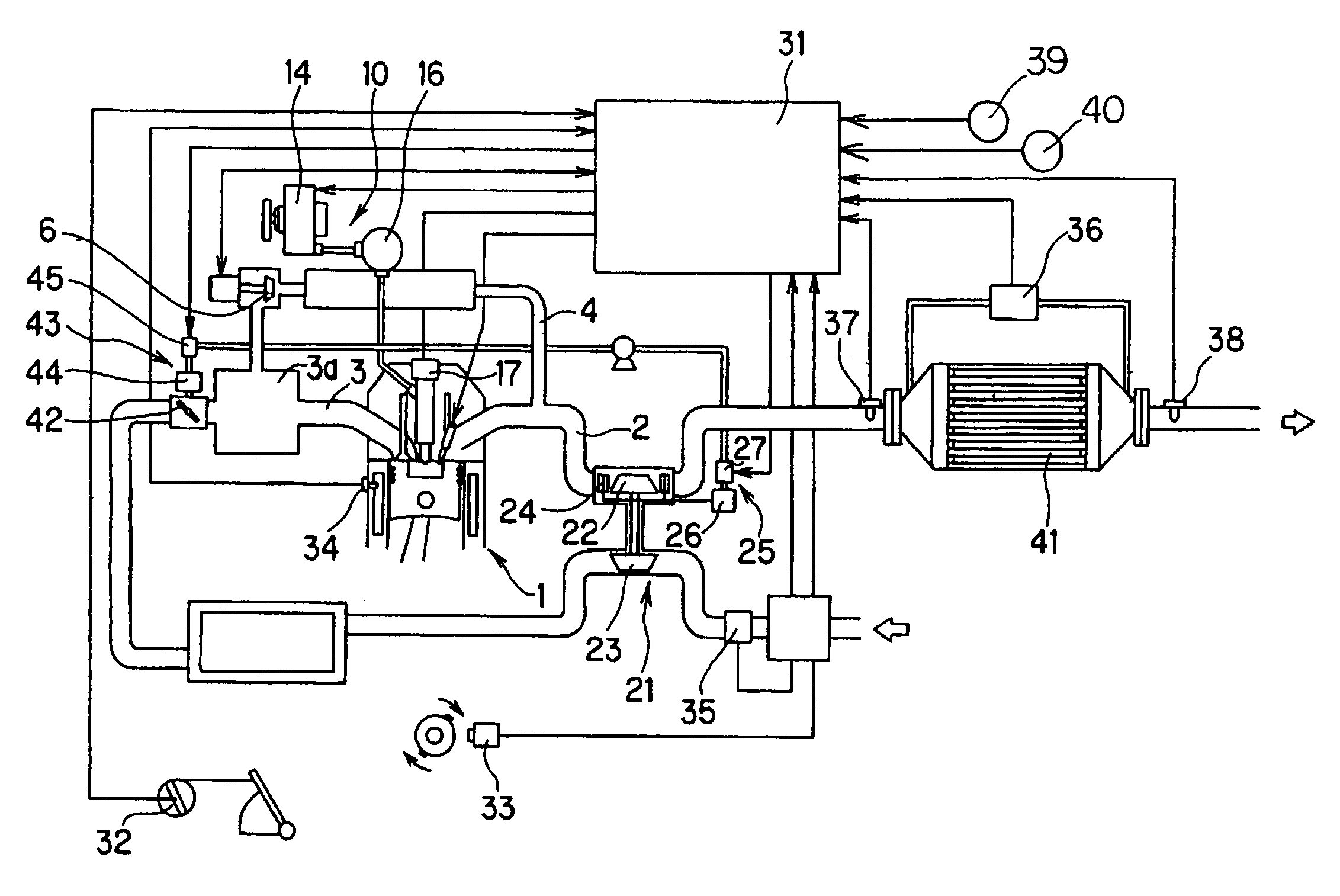

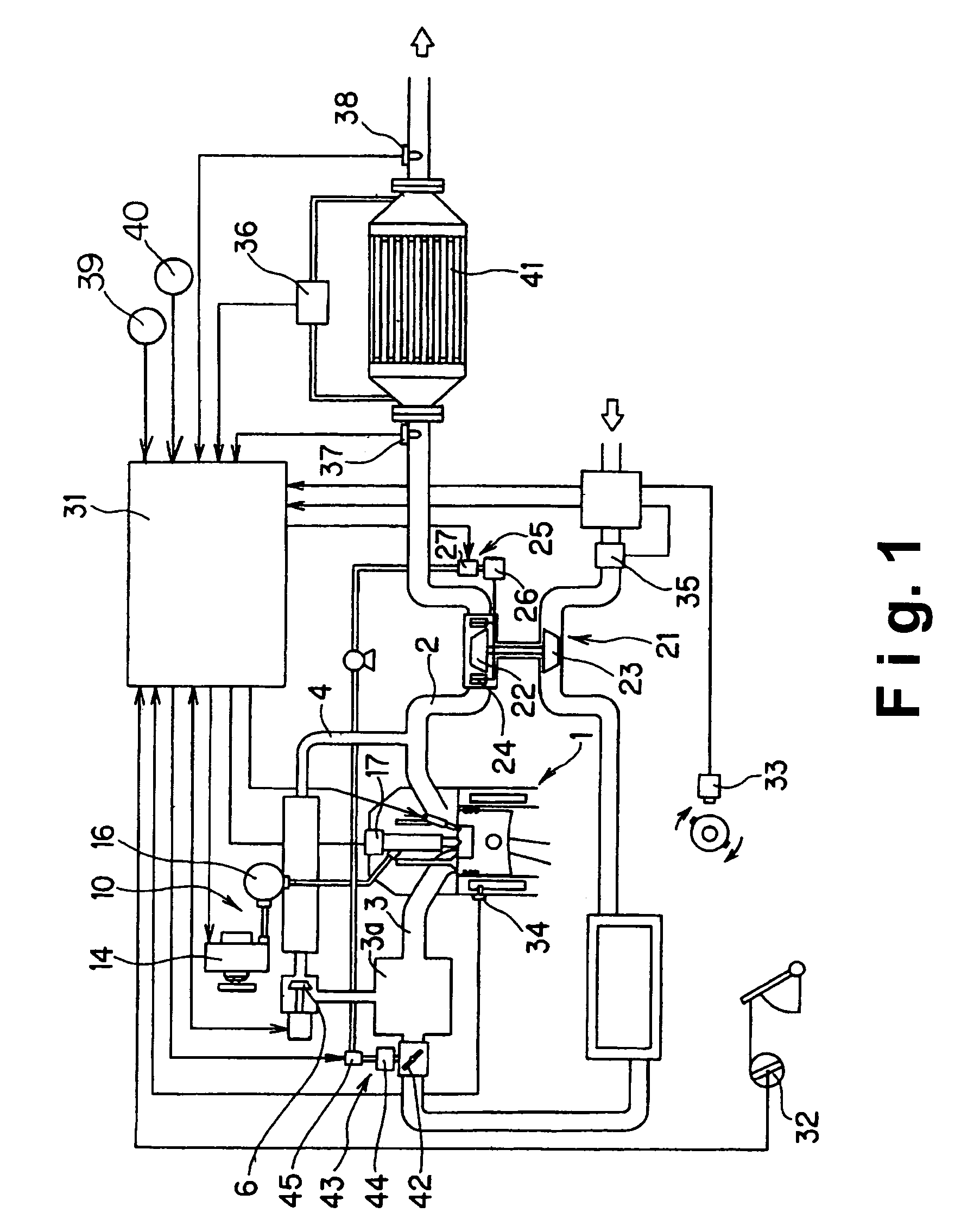

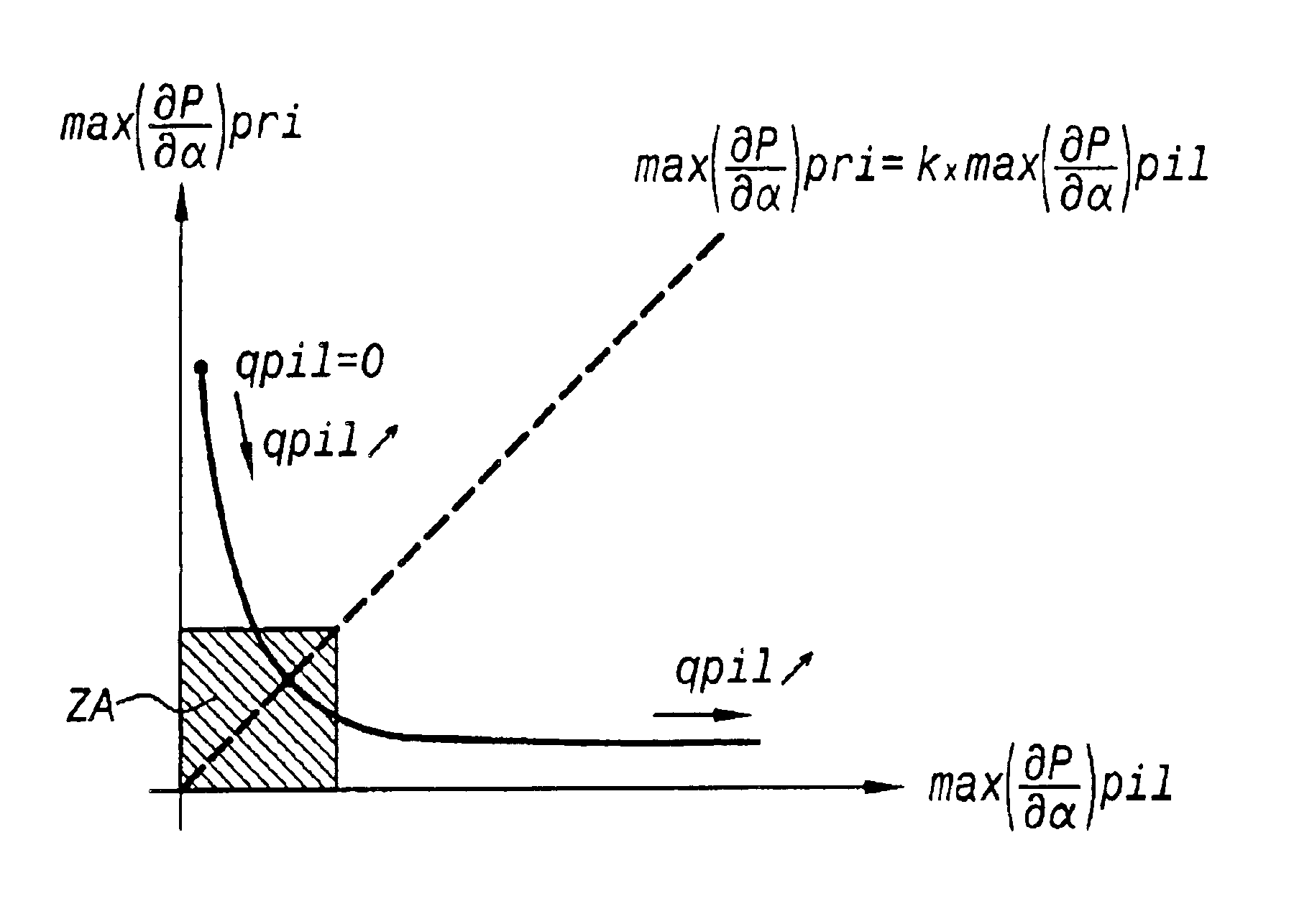

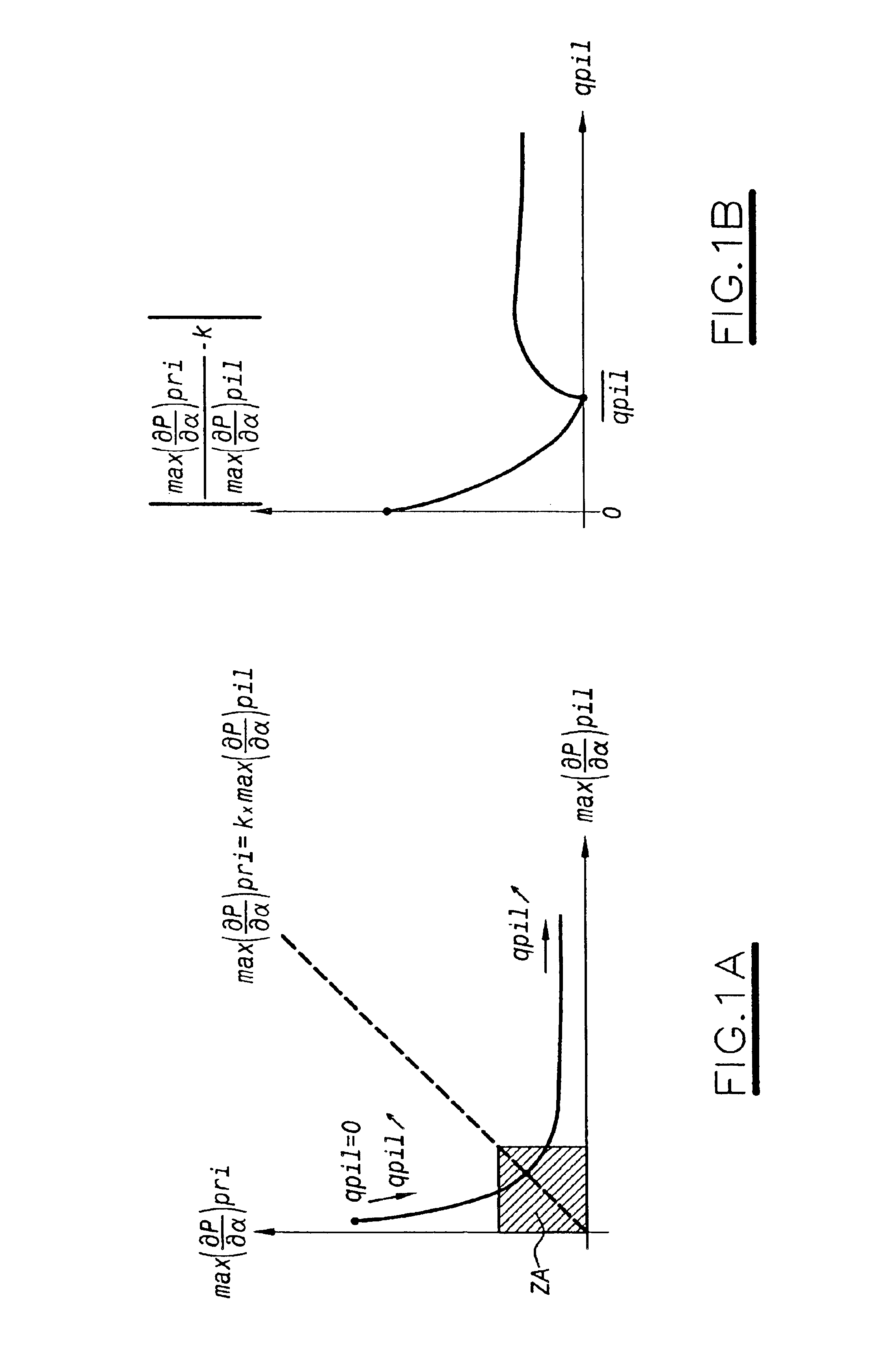

System for controlling the combustion noise a motor vehicle diesel engine

InactiveUS20050005902A1Minimizes operating noiseNoise minimizationElectrical controlInternal combustion piston enginesMultiple injectionCombustion noise

This system for controlling the combustion noise of a motor vehicle diesel engine of the type including means for feeding each of its cylinders with fuel by multiple injections of fuel, which means are adapted to trigger fuel feed into each cylinder in the form of at least one pilot injection and a main injection of fuel, comprises: means for determining pressure gradients in the engine cylinder while in operation, at least during the pilot and main injection stages; and means for determining the quantity of fuel to be injected into the cylinder during pilot injection for a predetermined quantity of fuel injected during main injection so as to optimize a criterion based on the ratio between the pressure gradients corresponding to the pilot and main injection stages, thereby optimizing the operating noise of the engine.

Owner:PEZHO SITROEN AUTOMOBILS SA +1

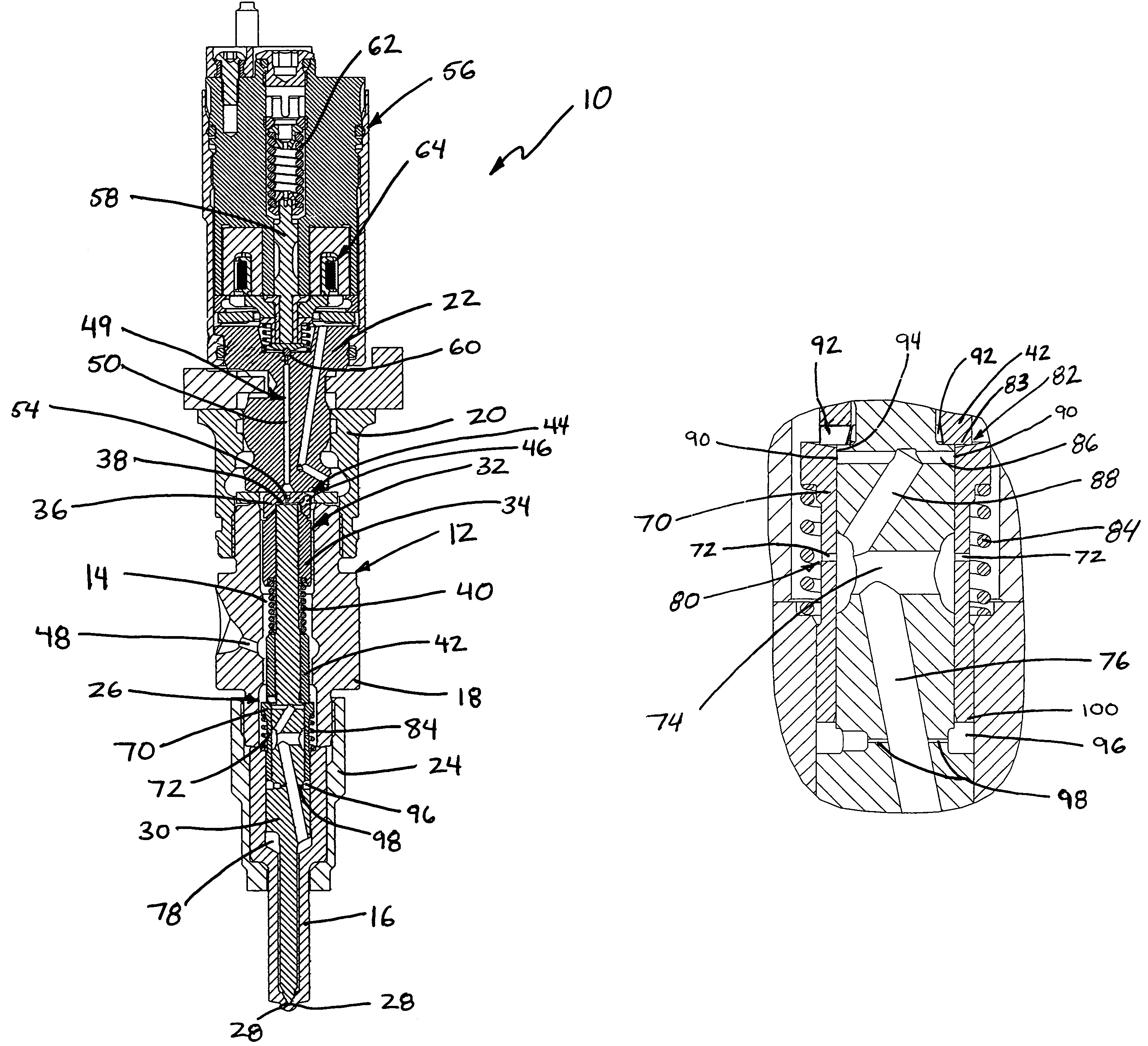

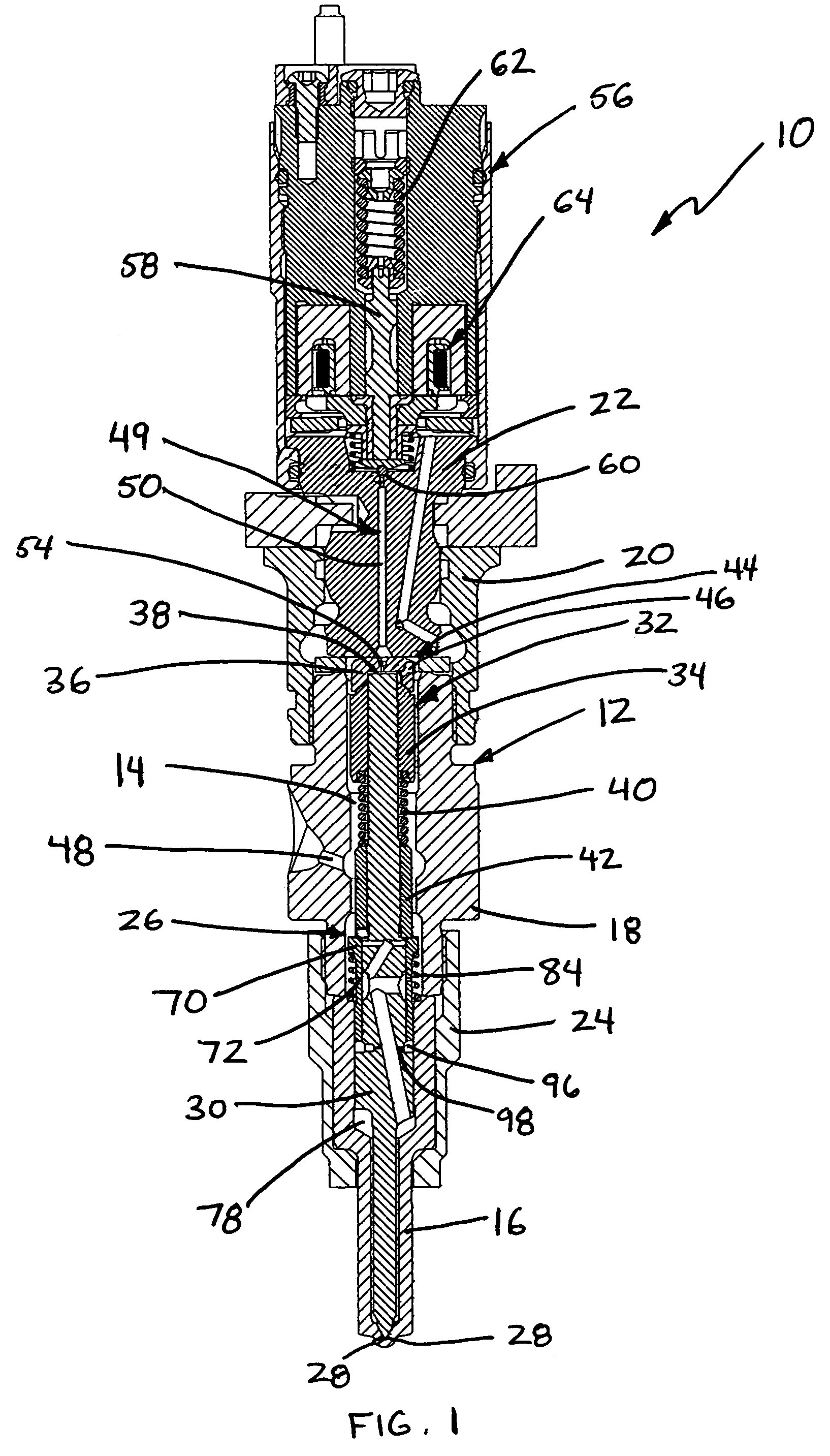

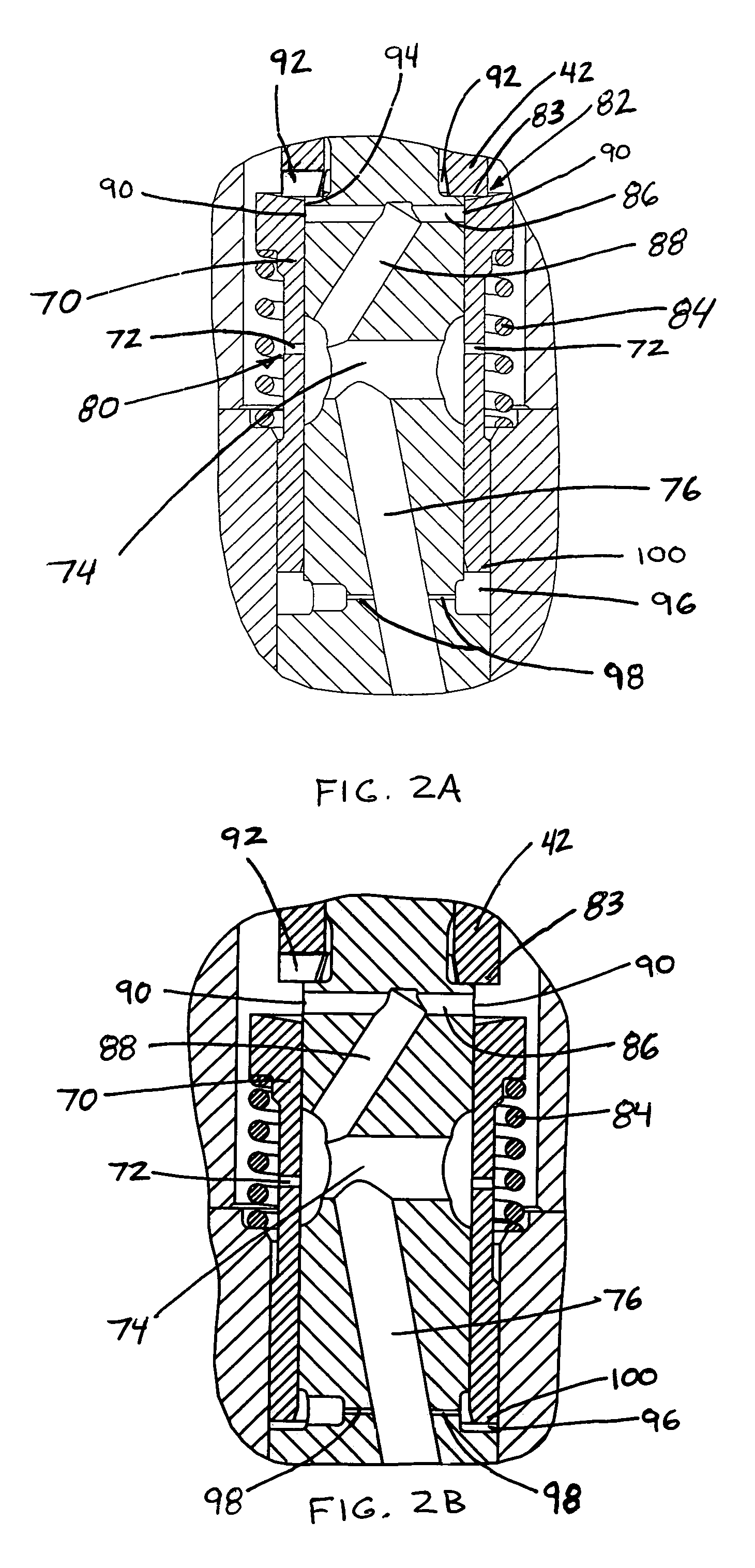

Fuel injector with injection rate control

ActiveUS7334741B2Cost-effective and efficient and flexible and responsiveReduce noiseFuel-injection pumpsSpray nozzlesCombustion noiseRate shaping

A closed nozzle fuel injector is provided which effectively controls the fuel injection flow rate, especially during an initial portion of an injection event, while also permitting accurate control over pilot and / or post injection flow rates at all operating conditions thereby advantageously reducing emissions and combustion noise. The injector includes a rate shaping orifice to restrict fuel flow during an initial portion of an injection event and a rate shaping sleeve mounted for movement to cause a greater flow of injection fuel during a later portion of the injection event. A damping chamber and orifice are also provided to control movement of the rate shaping sleeve.

Owner:CUMMINS INC

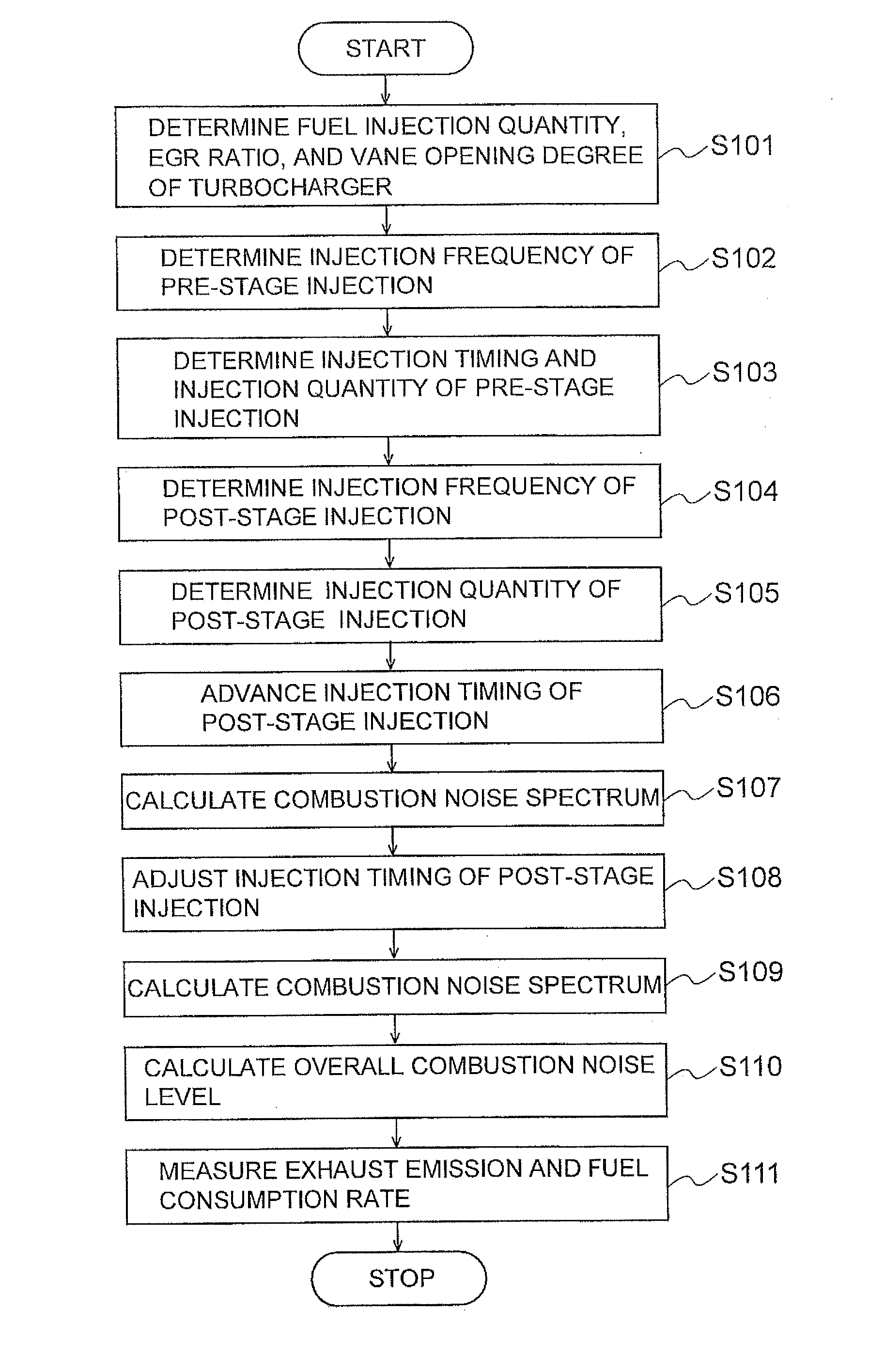

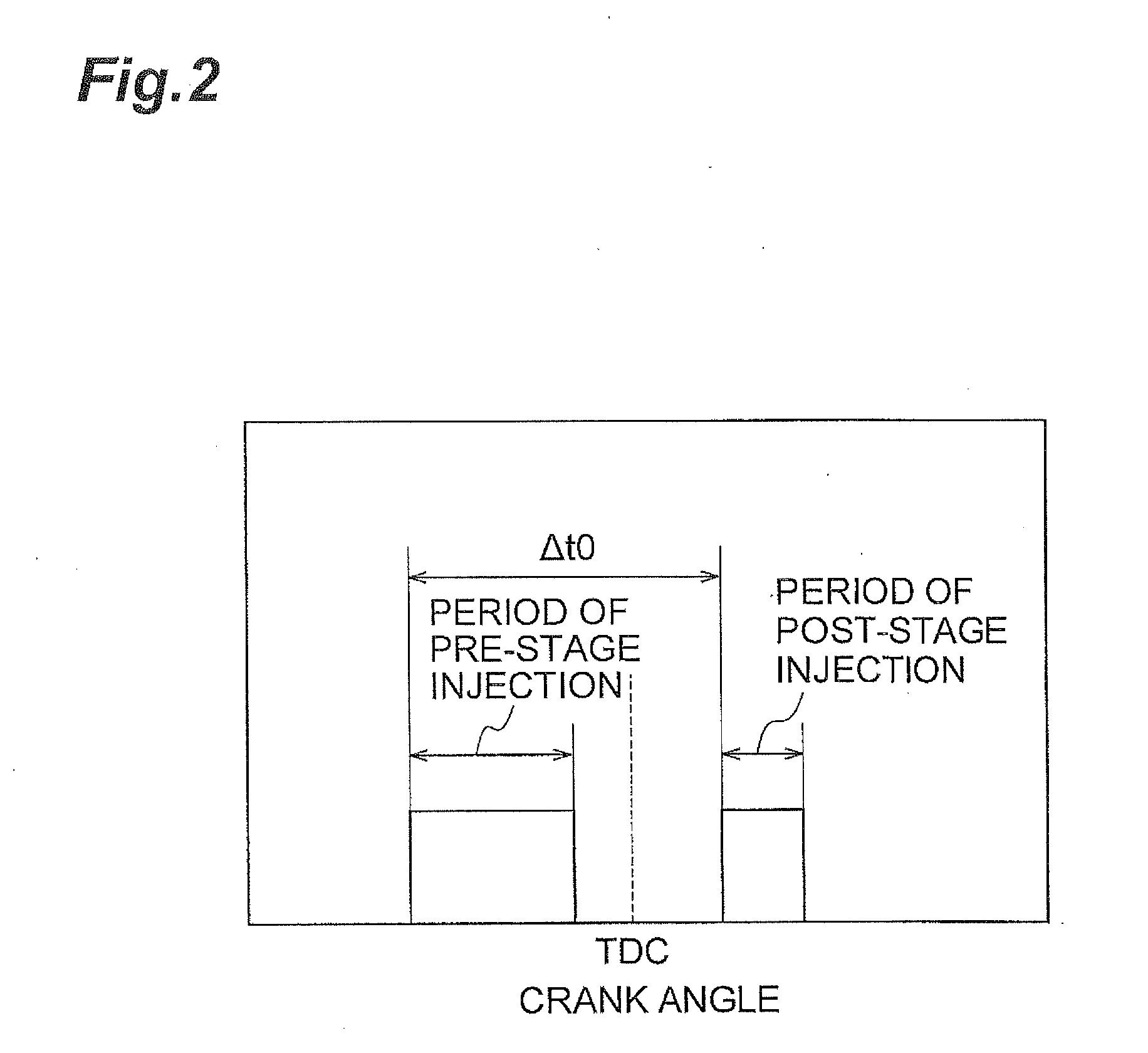

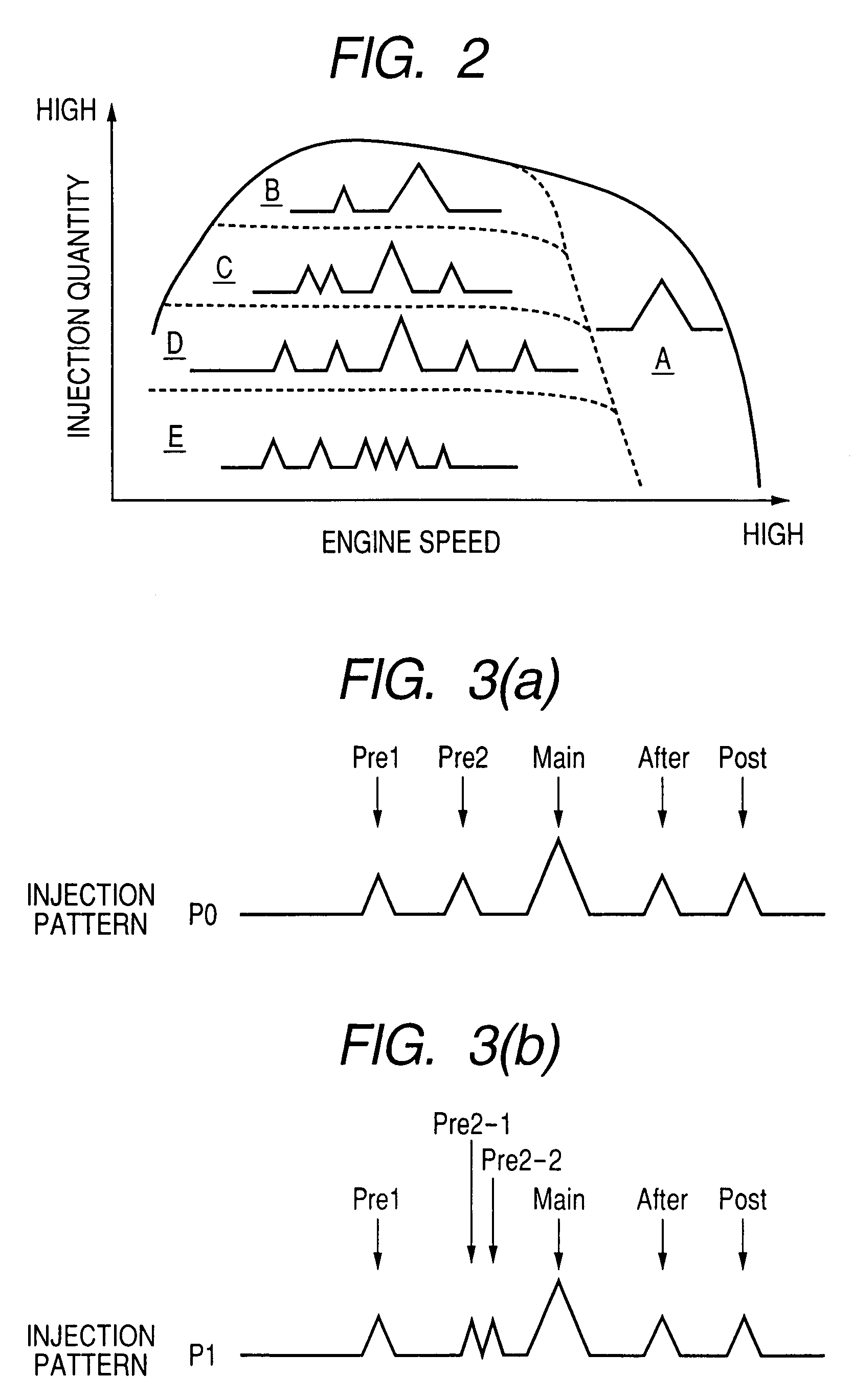

Fuel injection control apparatus and compression ignition type internal combustion engine

ActiveUS20150090217A1Improve reducibilityImprove noise levelElectrical controlInternal combustion piston enginesCombustion noiseInternal combustion engine

A fuel injection control apparatus of a compression ignition type internal combustion engine includes a controller adapted to control an injector so that pre-stage injection and post-stage injection are performed as fuel injection during one cycle. The controller controls an interval between the timing of the pre-stage injection and the timing of the post-stage injection so that an interval Δt1 between the timing of the pre-stage peak and the timing of the post-stage peak approximately satisfies a condition. The condition is that the interval Δt1 is 0.5 times an inverse number of the frequency f0 at which a combustion noise level becomes the maximum.

Owner:TOYOTA IND CORP

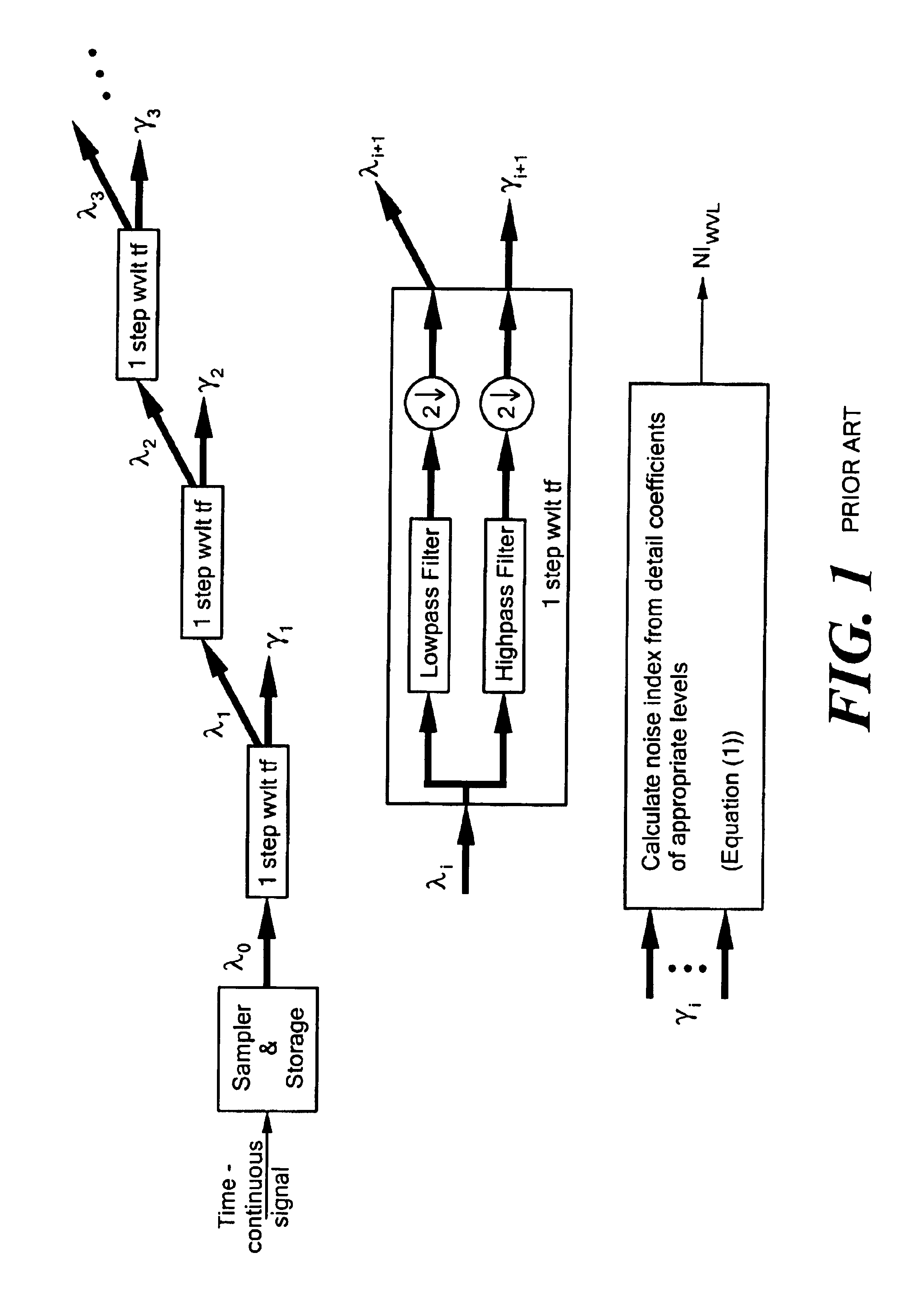

Method and system for assessing combustion noise in an internal combustion engine

InactiveUS6850836B1Internal-combustion engine testingAnalogue computers for vehiclesCombustionCombustion noise

A method for assessing noise generated during combustion in an internal combustion engine, such method comprising determining a noise index by processing a signal generated in a cylinder of such engine in accordance with a shift invariant wavelet transform.

Owner:FORD GLOBAL TECH LLC

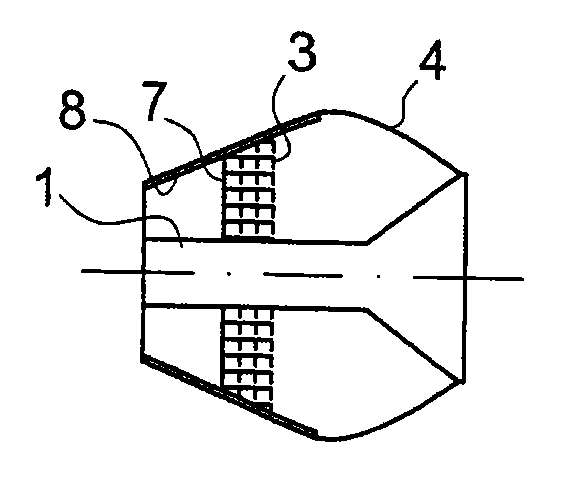

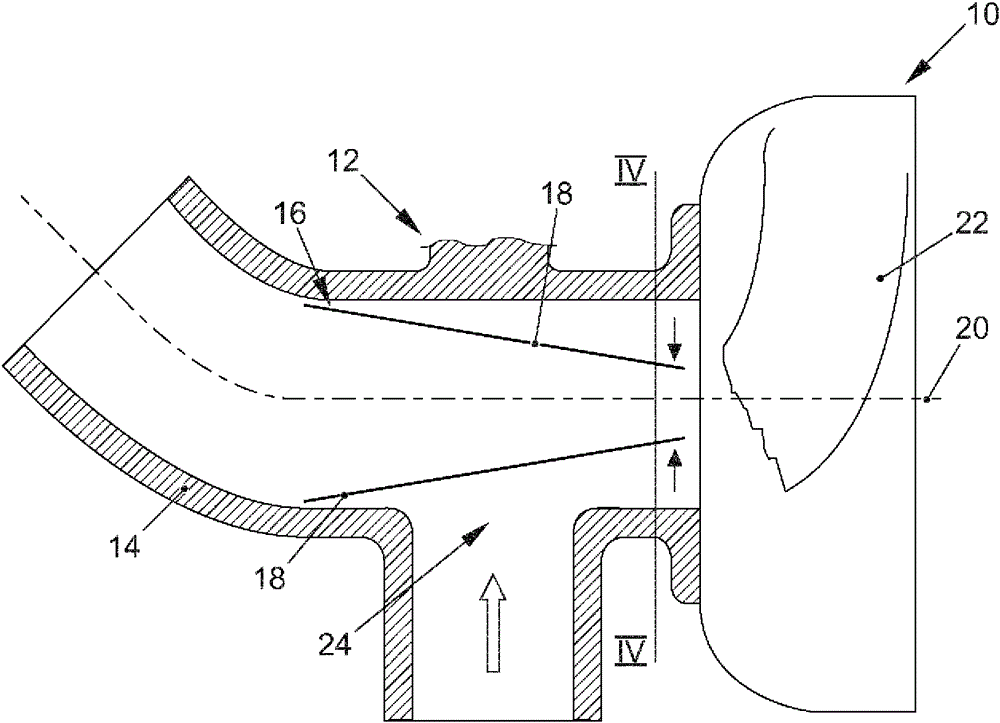

Acoustic treatment device for turbine and combustion noises

An acoustic treatment device for an internal primary ejection duct from a turbojet pod, including an upstream zone and a downstream zone relative to an airflow direction in the primary ejection duct, the upstream and downstream zones being located on each side of a separating wall with a first face on the side of the upstream side and a second face on the side of the downstream side. The separating wall is a micro-porous wall and the face of the separating wall located on the side of the downstream side is covered by a honeycomb structure to attenuate high frequency acoustic waves. Such a device may find application to treatment of combustion and turbine noises.

Owner:AIRBUS OPERATIONS (SAS)

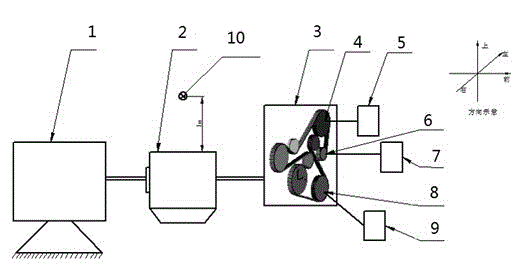

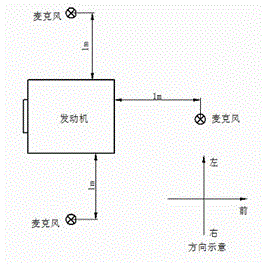

Noise measuring system for engine accessory system in hemi-anechoic room

ActiveCN103148927AAccurate evaluationReliable test resultsVibration measurement in solidsCombustion noiseDrive shaft

The invention relates to a noise measuring system for an engine accessory system in a hemi-anechoic room. A load is respectively applied to a power steering pump, an electric generator and an air compressor in an accessory system, thus each accessory is enabled to work under the load, and a measuring result is enabled to be closer to life. The accessory system (3) is arranged on a testing motor (2), the testing motor (2) is arranged on a bench in the semi-anechoic room, the testing motor (2) is connected with a power measurement machine (1) through a transmission shaft, a crankshaft of the testing motor (2) is driven to rotate by the power measurement machine (1), and the accessory system (3) is driven to work by the testing motor (2); and a microphone (10) is arranged around the testing motor (2) , the noise of the accessory system (3) at work is collected by the microphone (10), and the noise is provided to a processing unit for processing and collection. By adopting the noise measuring system, interference brought by combustion noise of the testing motor, noise of induction and exhaust, and mechanical noise of a motor body and the like are eliminated, and the noise of the engine system is measured more accurately.

Owner:CHERY AUTOMOBILE CO LTD

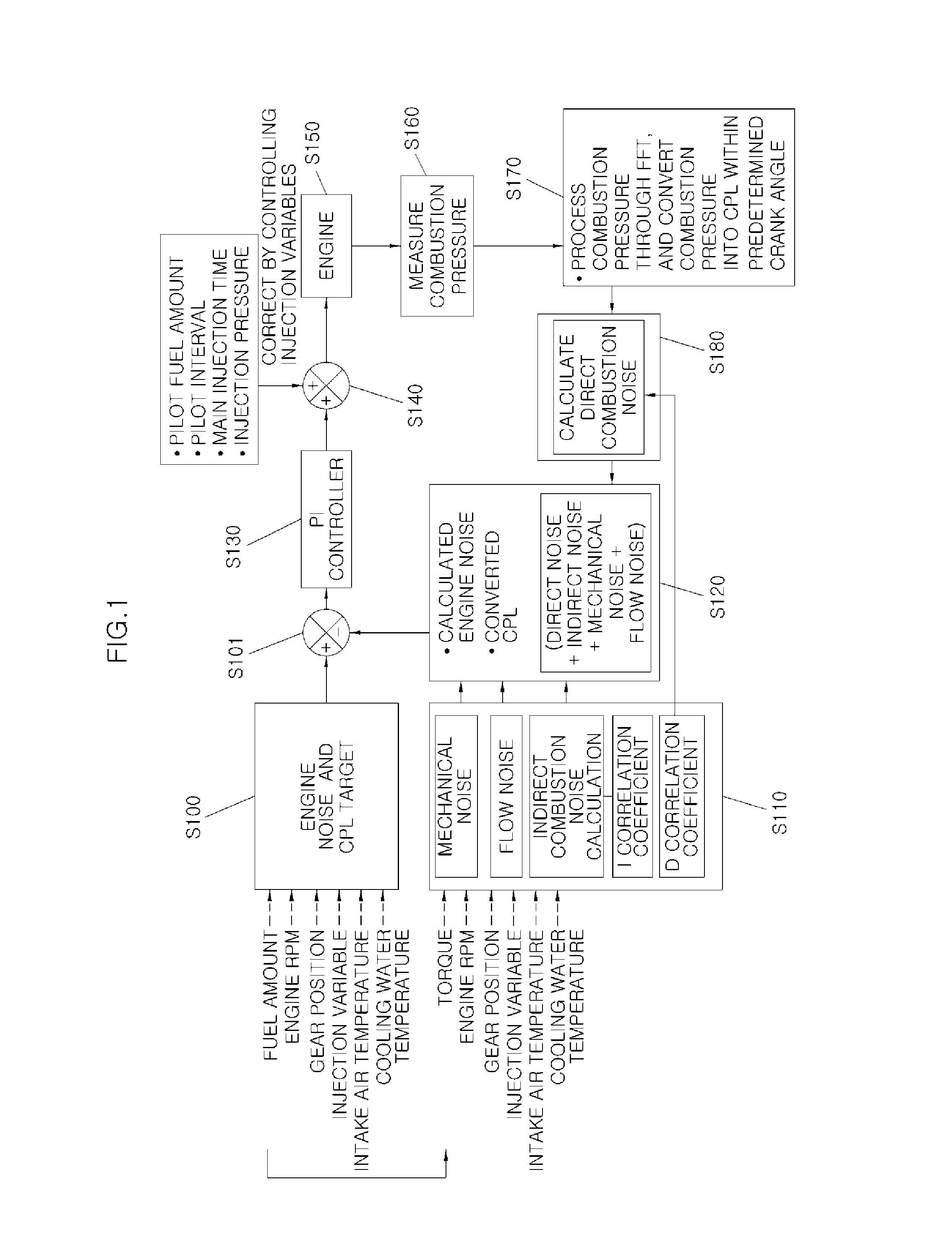

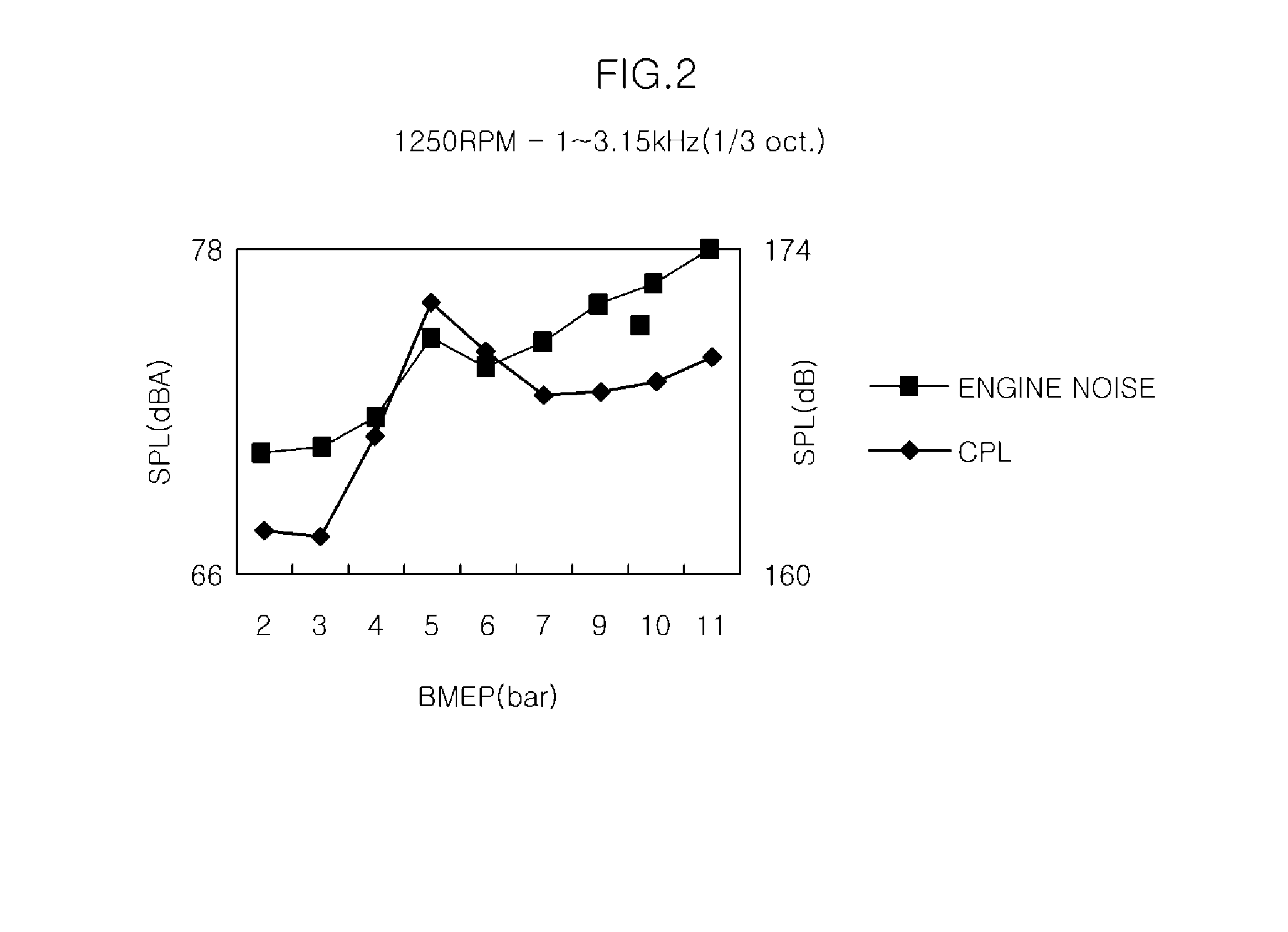

Method for controlling engine noise including combustion noise of internal combustion engine

ActiveUS20140012487A1Electrical controlInternal combustion piston enginesCorrelation coefficientCombustion noise

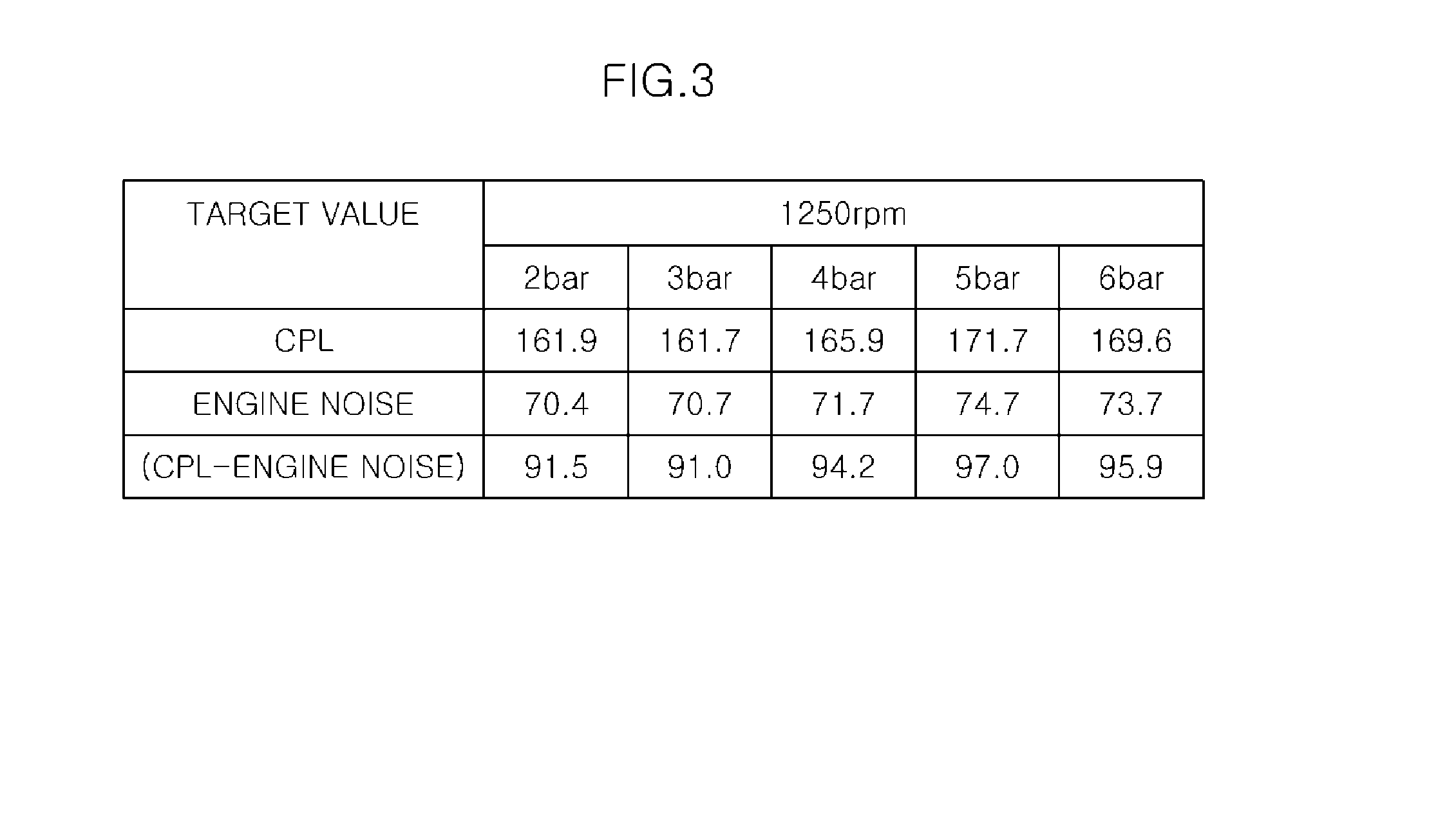

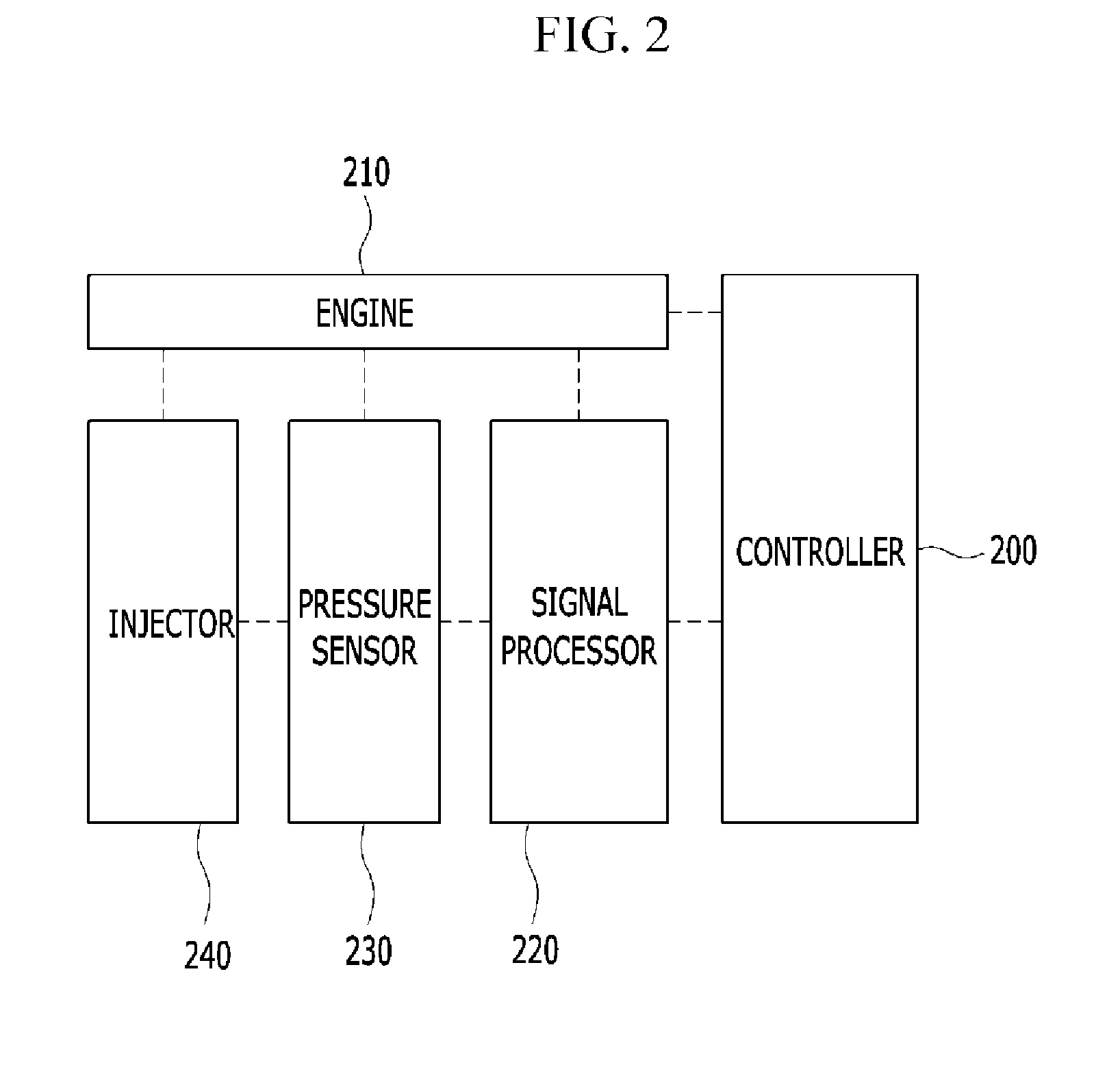

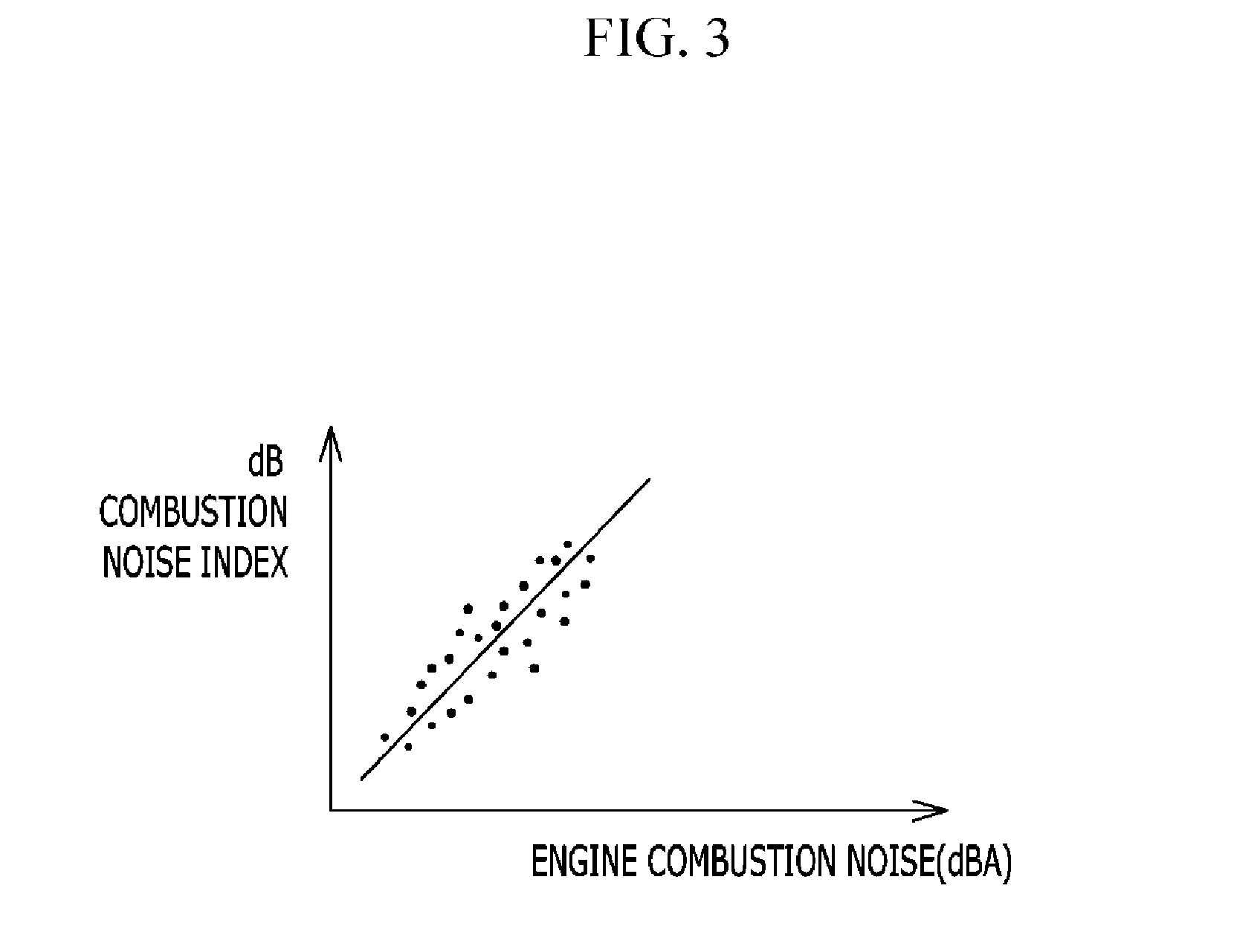

A method for controlling noise including combustion noise of an internal combustion engine includes (a) setting an engine noise target value and a cylinder pressure level target value, (b) determining a first comparison value by subtracting a measured cylinder pressure level from the cylinder pressure level, (c) receiving an engine noise parameter stored in an ECU, (d) determining the engine noise using the engine noise measured at step (c), (e) determining a direct correlation coefficient, an indirect correlation coefficient, mechanical noise, and flow noise through a proportional integral controller, (f) performing correction, (g) controlling the engine based on the value decided at step (f), (h) measuring a combustion pressure after step (g), (i) converting the combustion pressure into a cylinder pressure level within a predetermined crank angle after step (g), and (j) determining direct combustion noise of the engine noise after step (h).

Owner:HYUNDAI MOTOR CO LTD

Fuel injection amount compensating method

ActiveUS20140172276A1Reduce noiseReduce vibrationElectrical controlInternal combustion piston enginesCombustion chamberCombustion noise

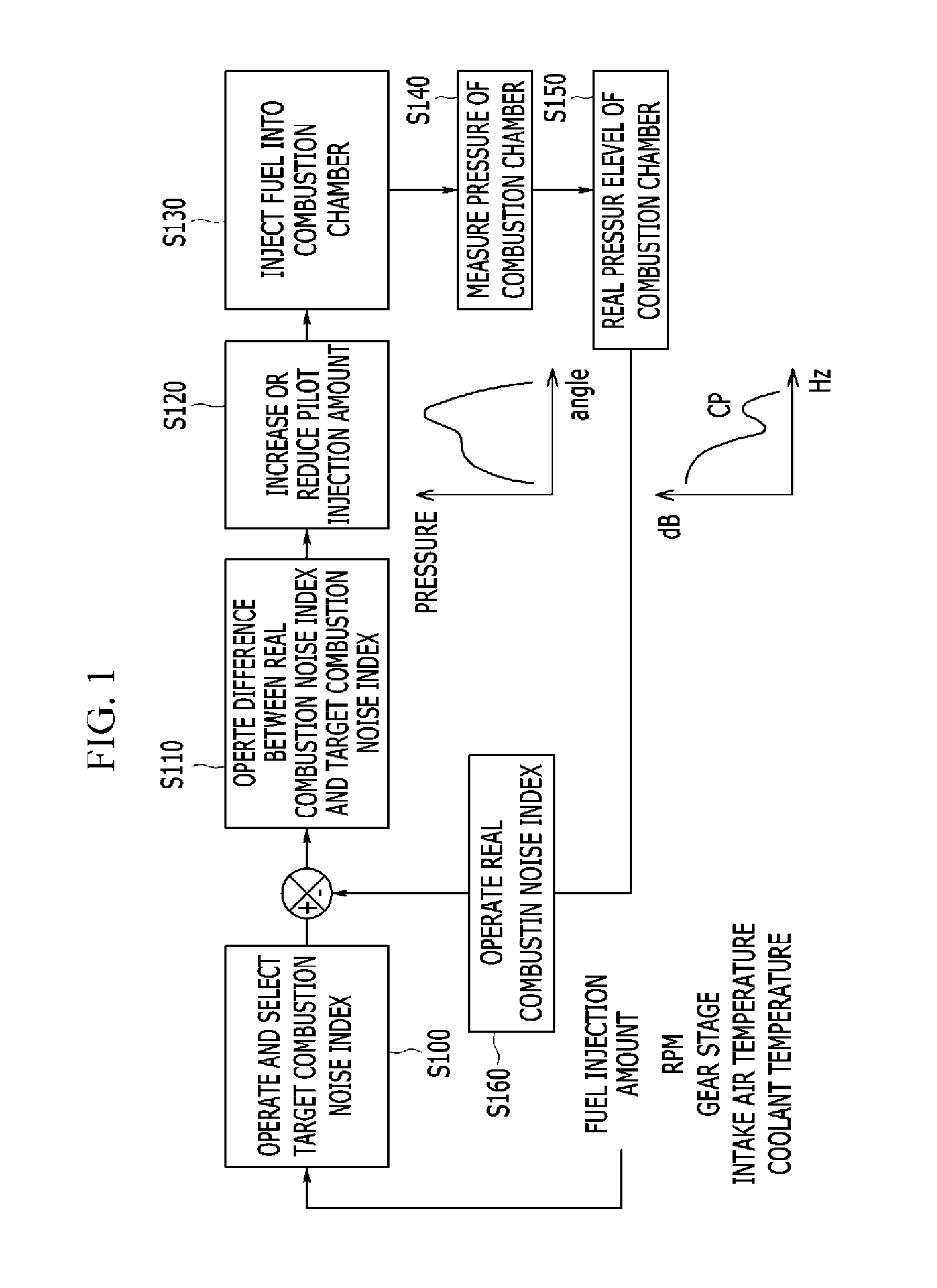

Disclosed is a fuel injection amount compensating method that may include measuring a real pressure of a combustion chamber, calculating a real pressure level of the combustion chamber based on the real pressure, calculating a real combustion noise index based on the real pressure level of the combustion chamber, calculating a target combustion noise index based on a driving condition, calculating a difference between the real combustion noise index and the target combustion noise index, and increasing or reducing a pilot injection amount of a fuel injector in accordance with the difference. Also disclosed is a fuel injection amount compensating system.

Owner:HYUNDAI MOTOR CO LTD

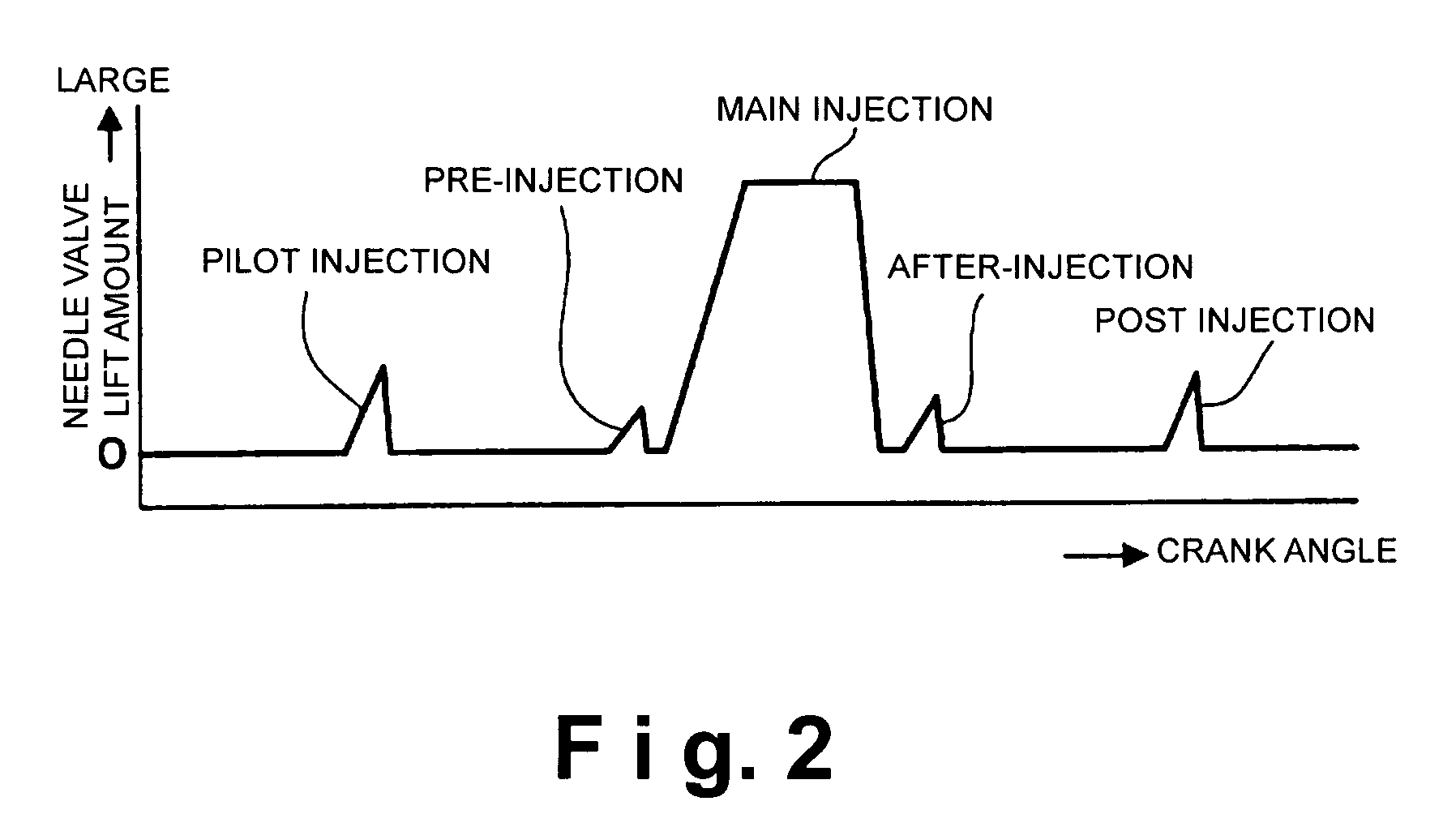

Fuel injection control apparatus designed to minimize combustion noise of engine

InactiveUS7415964B2Reduce combustion noiseIncrease the number ofElectrical controlInternal combustion piston enginesCombustion noiseCombustion

A fuel injection control apparatus for a diesel engine is provided which works to determine the number of a sequence of injection events to inject fuel into the engine in each operating cycle of the engine and increase it based on the temperature of an injector drive circuit. When the temperature of the injector drive circuit is relatively low, the apparatus increases the number of injection events to decrease the degree of combustion in the engine, thereby reducing the combustion noise of the engine.

Owner:DENSO CORP

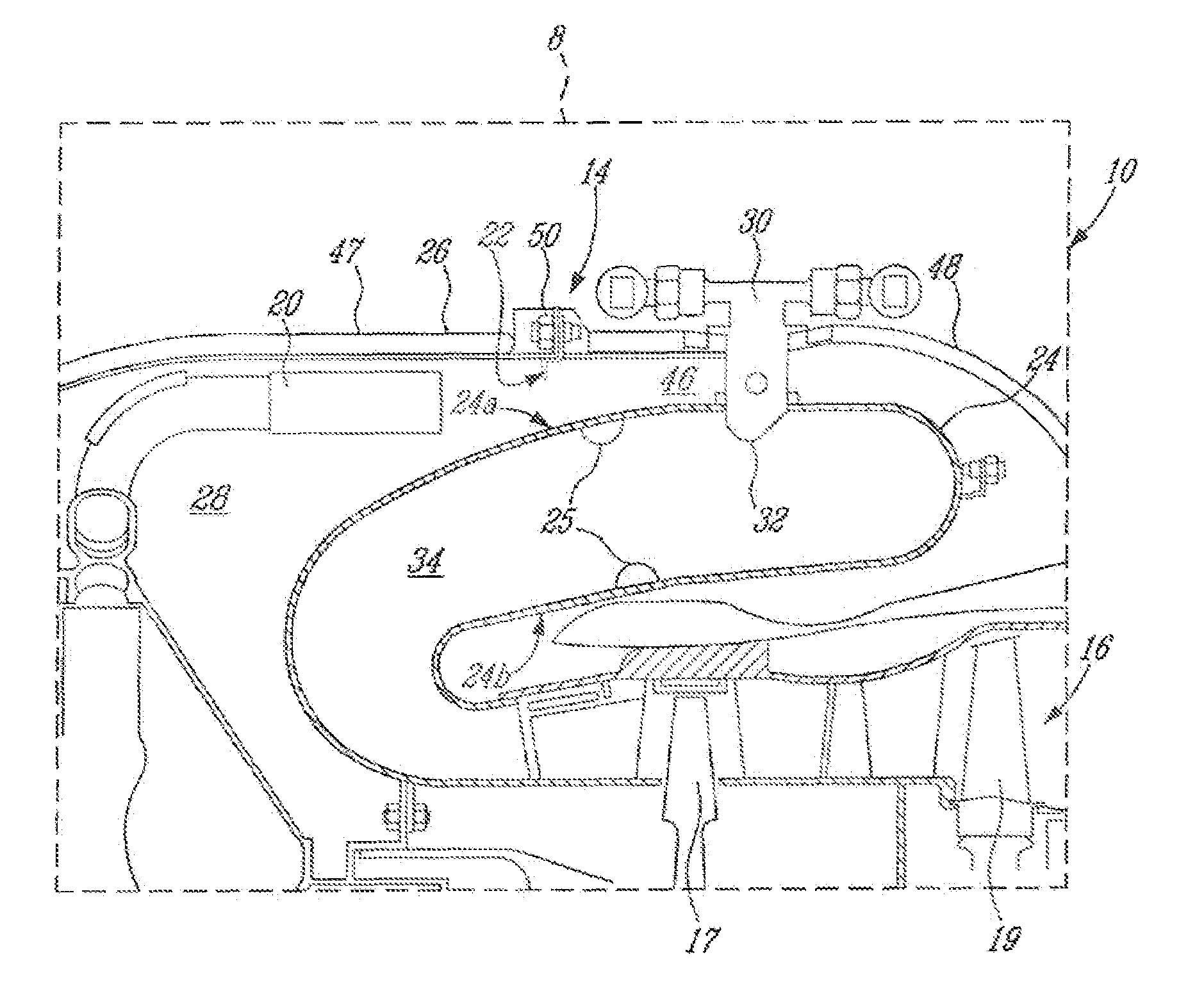

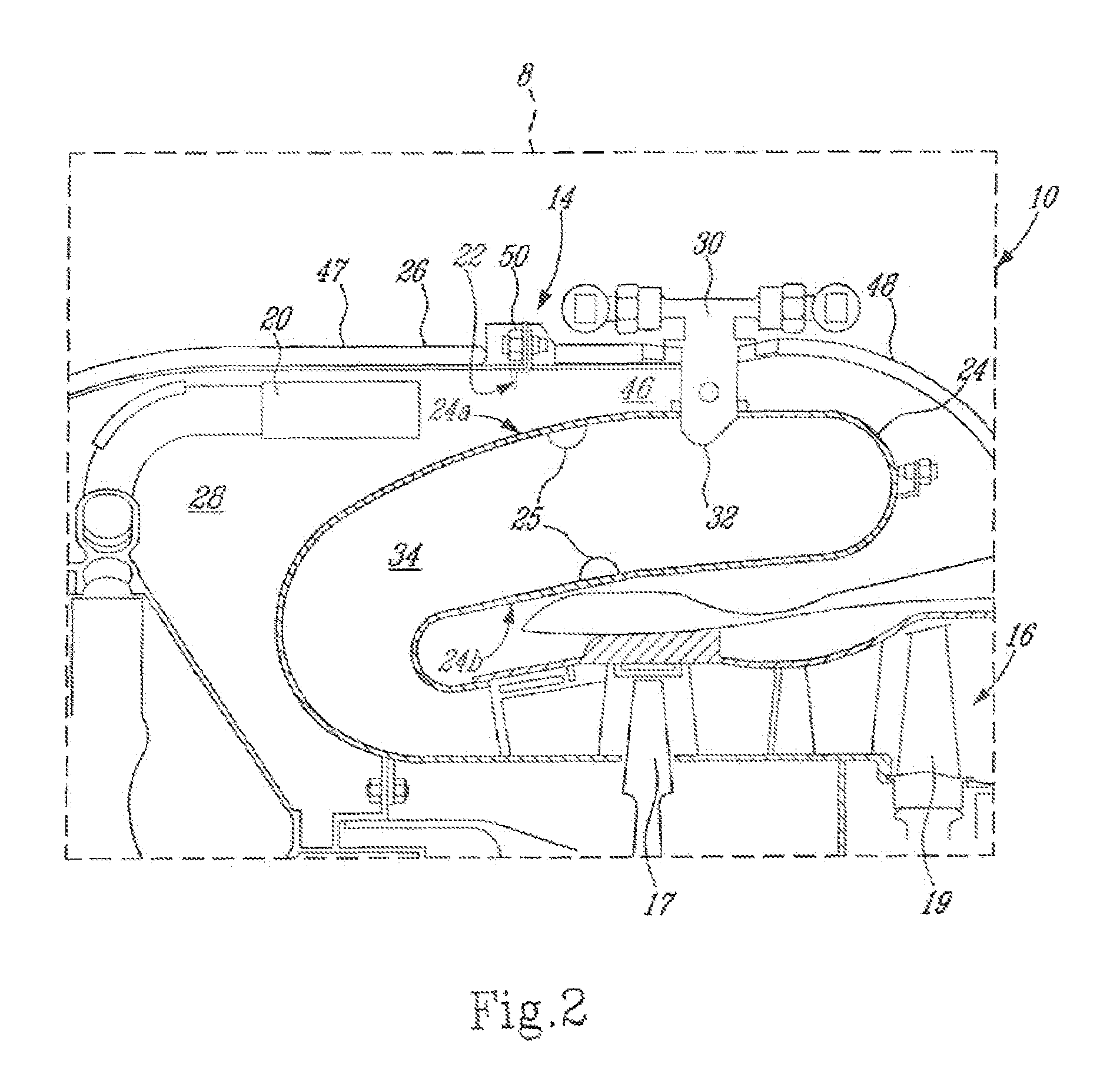

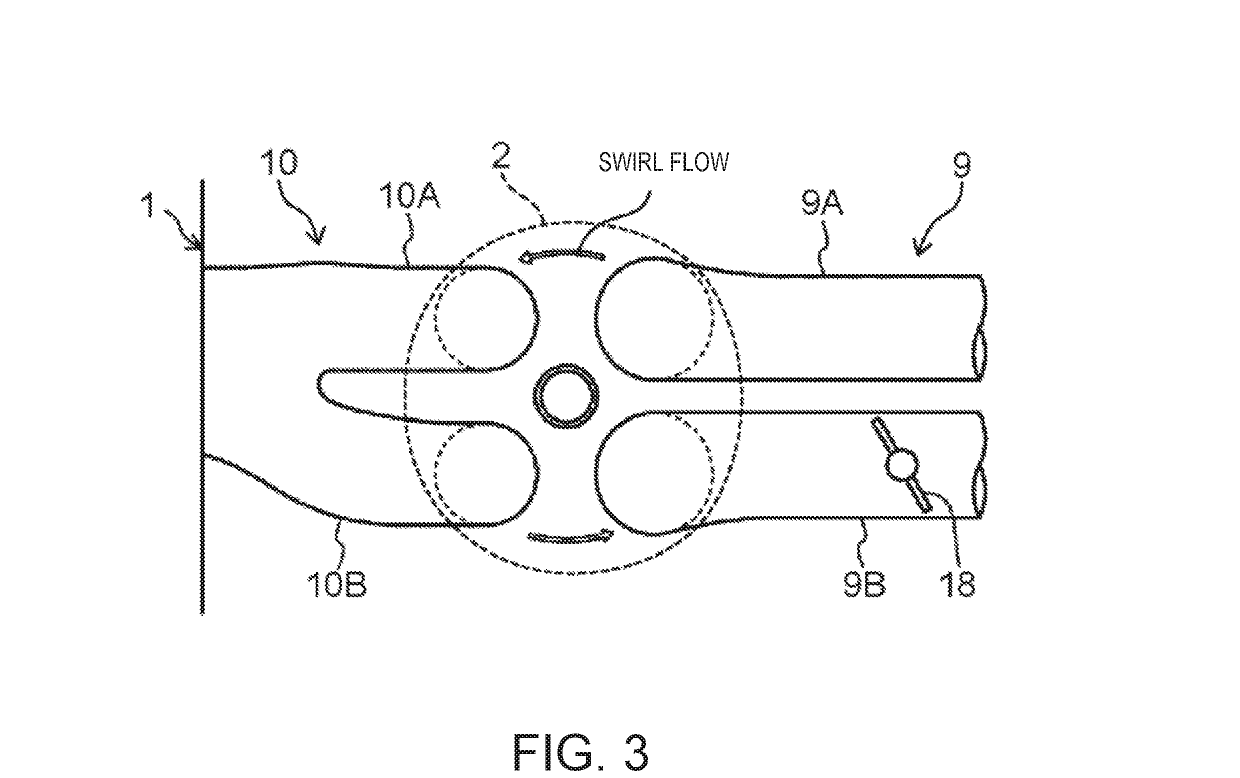

Hcci combustion timing control with decoupled control of in-cylinder air/egr mass and oxygen concentration

ActiveUS20090178405A1Easy to controlConsiderable combustion noiseElectrical controlNon-fuel substance addition to fuelPressure riseHcci combustion

A method of controlling homogenous charge compression ignition (HCCI) combustion timing and pressure rise rate. A constant volume air pump, such as a supercharger, is equipped to provide a variable amount of fresh air to a turbocharger. The also turbocharger drives a high pressure exhaust gas recirculation (EGR) loop. The fresh air intake and the EGR ratio are independently controlled. This combination of hardware allows for good control of combustion timing by providing for EGR variations without undue effect from varying oxygen concentration. Additionally, by adjusting the EGR ratio, the pressure rise rate during combustion can be controlled to reduce combustion noise.

Owner:SOUTHWEST RES INST

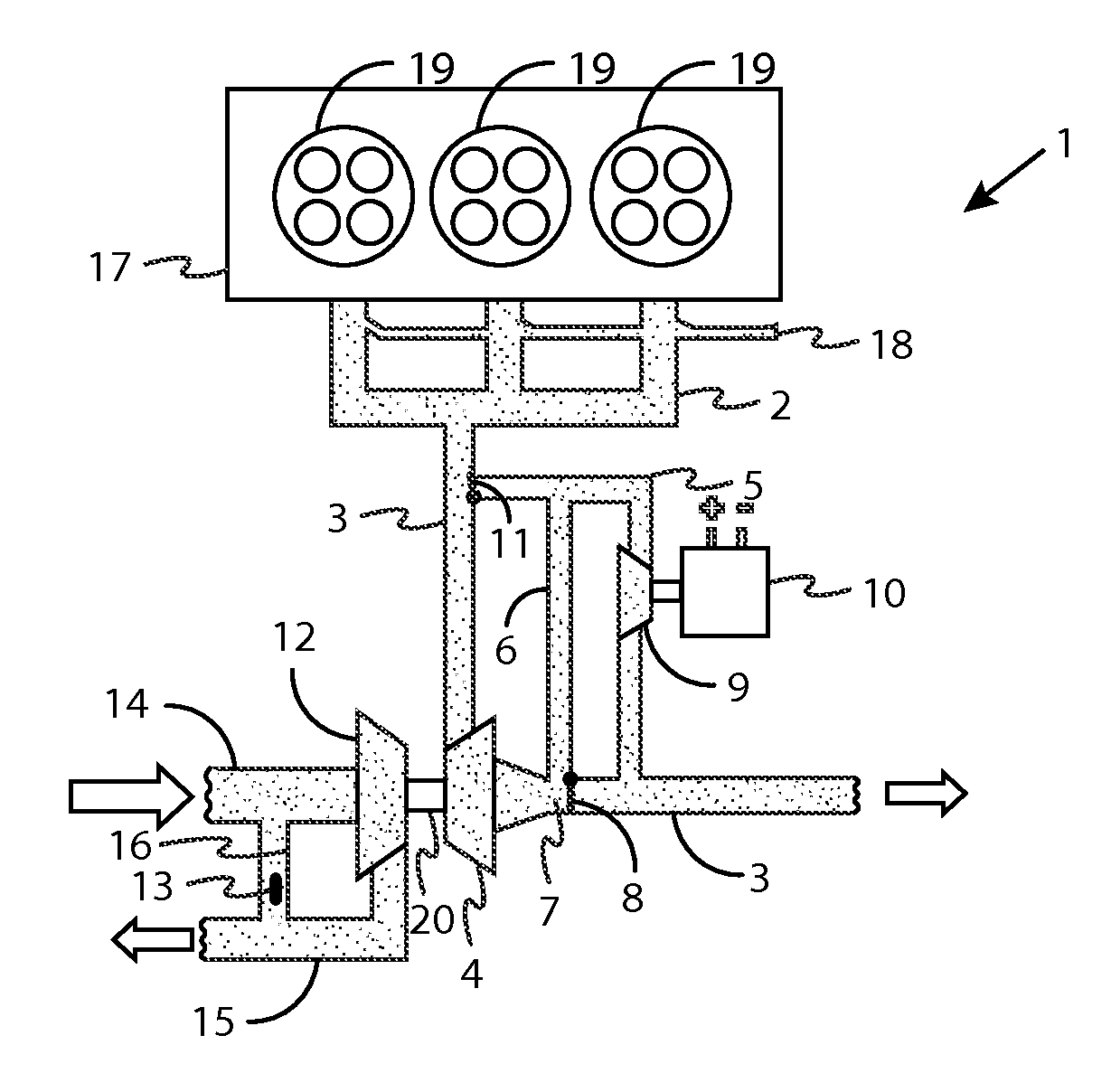

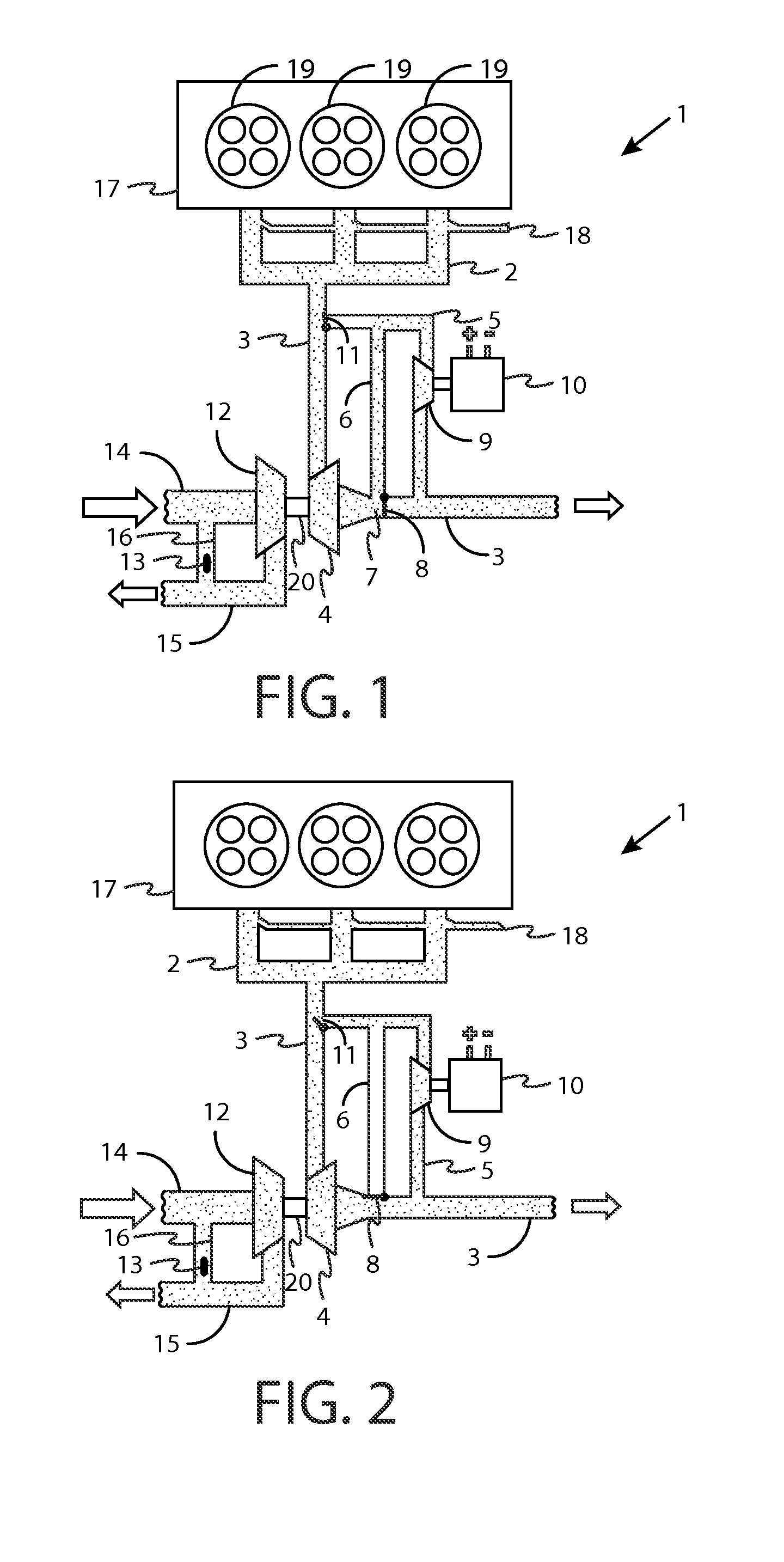

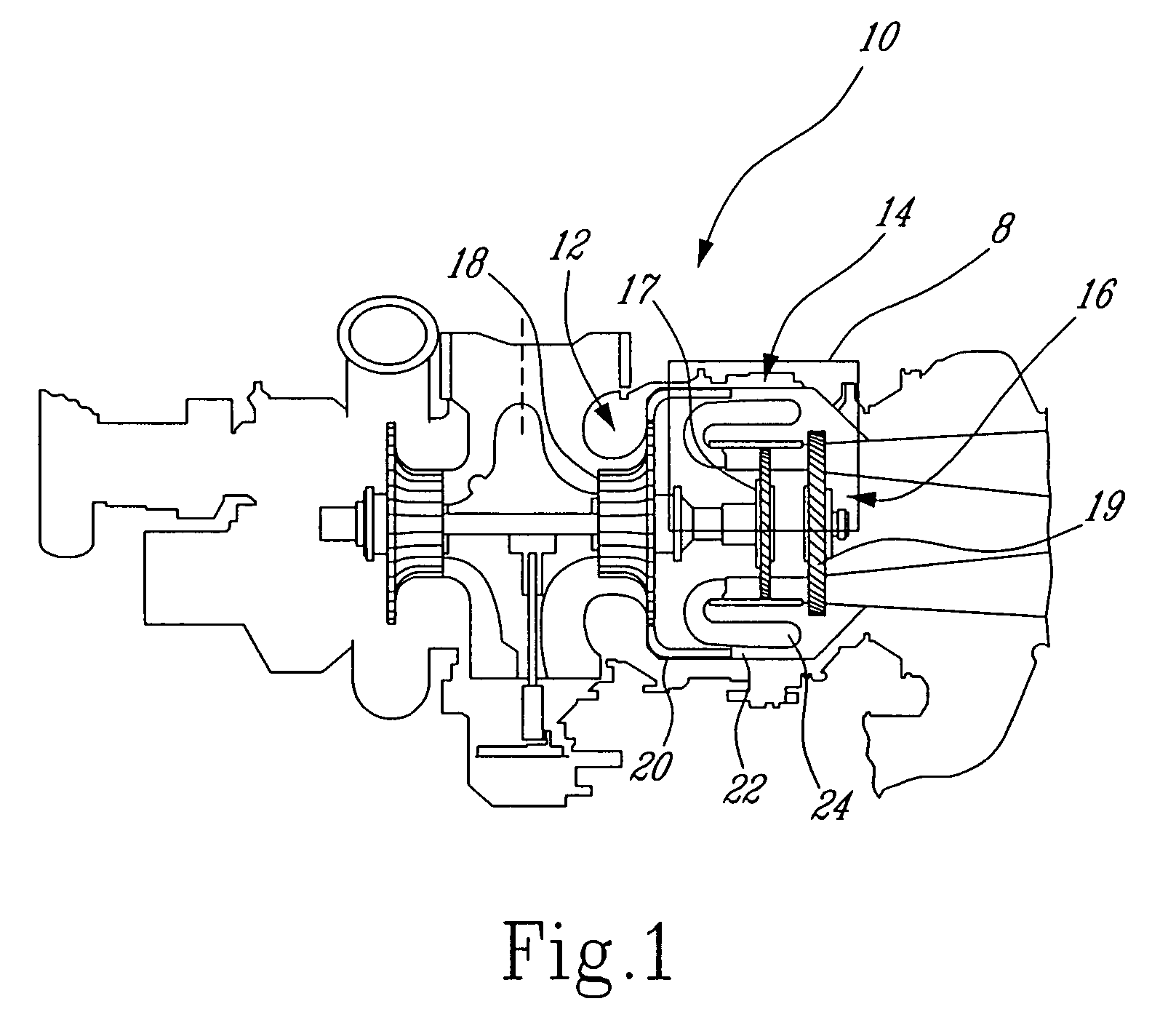

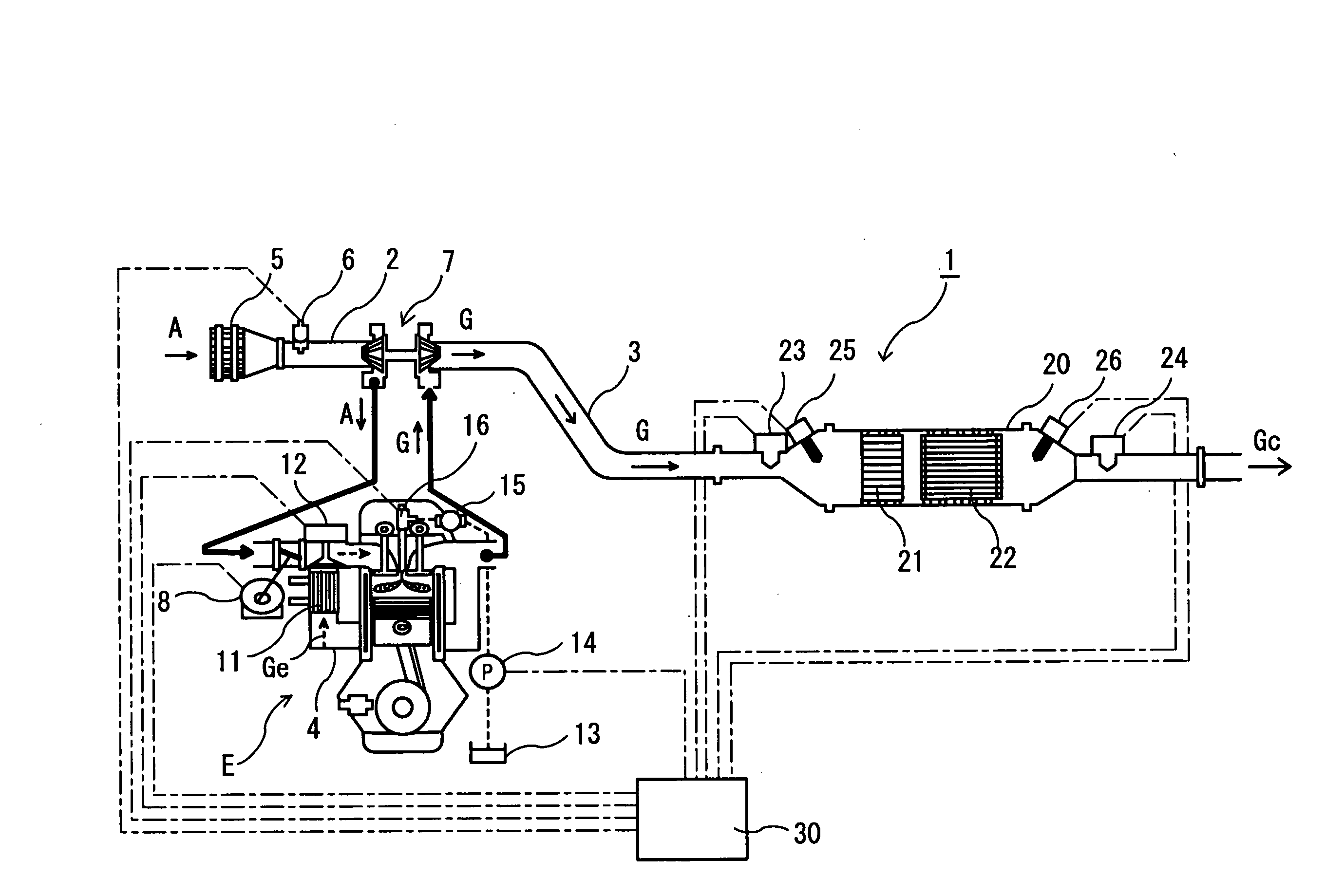

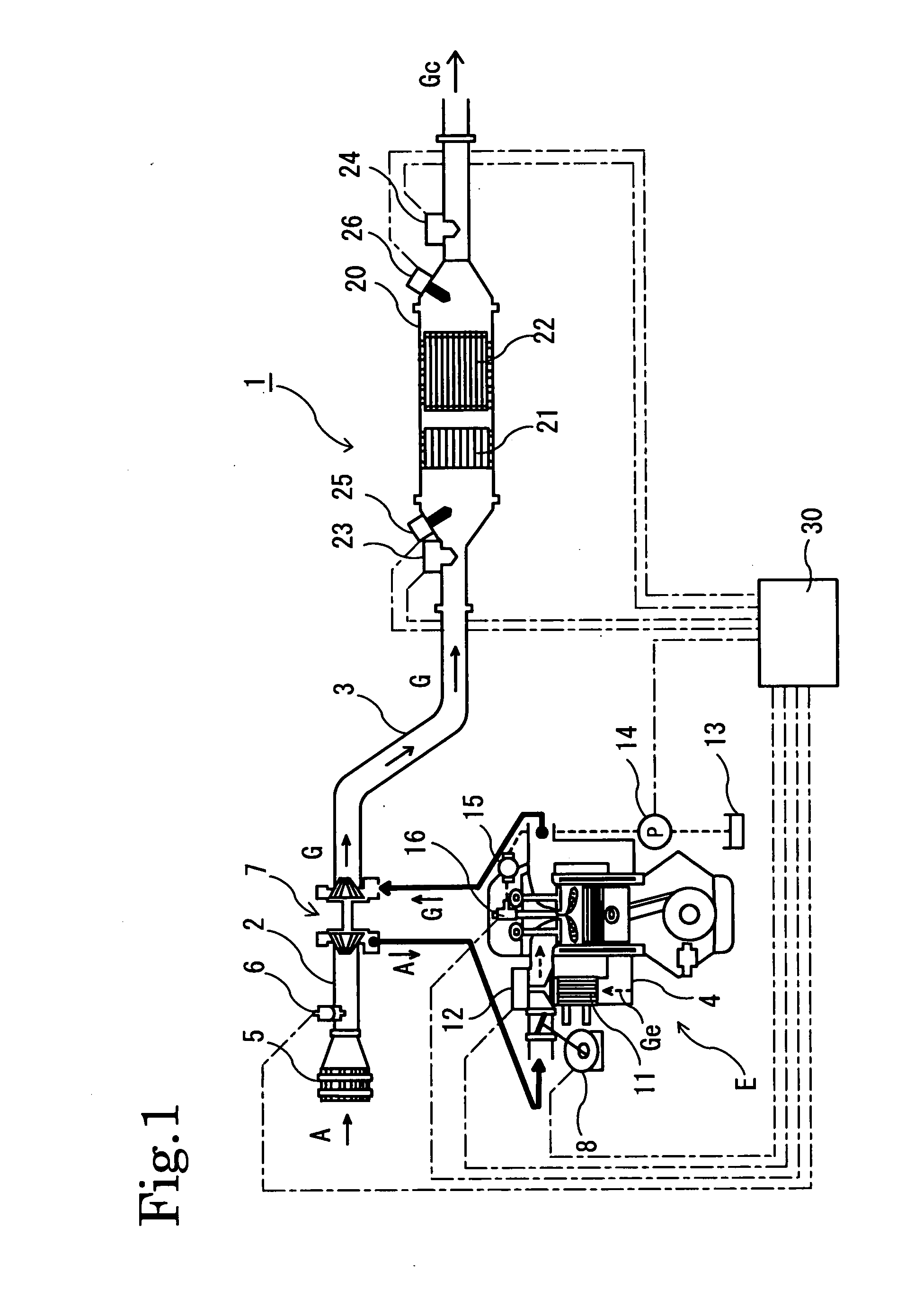

Internal combustion engine with exhaust gas turbocharger

ActiveUS8555636B2Increase profitInhibition formationInternal combustion piston enginesExhaust apparatusCombustionCombustion noise

An internal combustion engine with an exhaust gas manifold, an exhaust gas line, an exhaust gas turbocharger, by which the compressor provided to charge combustion air for the internal combustion engine is driven, and a bypass line, which branches from the exhaust gas line and in which a power turbine is arranged, wherein a short-circuit line branches from the bypass line and leads to a section of the exhaust gas line located downstream of the exhaust gas turbocharger. In addition, a first valve is positioned in the section of the exhaust gas line located downstream of the exhaust gas turbocharger in such a way that exhaust gas leaving the exhaust gas turbocharger is diverted into the short-circuit line and then to the power turbine.

Owner:DR ING H C F PORSCHE AG

Aerodynamic trip for a combustion system

ActiveUS7302802B2Reduce combustion noiseUniform temperature distributionBurnersContinuous combustion chamberCombustion systemCombustion noise

A apparatus and method for improving combustion by improving at least one of temperature distribution in the combustor, pressure distribution around the combustor and combustion noise level in the combustor, by redistributing air around the combustor to modify the structure of the air flow prior to entry into the combustor.

Owner:PRATT & WHITNEY CANADA CORP

Engine fuel injection control method and engine fuel injection control apparatus

InactiveUS7322340B2Deteriorate with timeElectrical controlInternal combustion piston enginesCombustion noiseOperant conditioning

An engine fuel injection control apparatus has a parameter setting section, a parameter changing section and a determining section. The parameter setting section is configured to set a parameter of fuel injected into an engine to a first injection parameter to control a state of combustion noise or exhaust emission to a target state when an engine operation condition is in a first operation region. The parameter changing section is configured to change the parameter of fuel injected into the engine from the first injection parameter to a second injection parameter when the engine operation condition remains in the first operation region. The determining section is configured to determine whether or not an actual state of the combustion noise or the exhaust emission of the engine changes when the parameter of fuel injected into the engine is changed from the first injection parameter to the second injection parameter.

Owner:NISSAN MOTOR CO LTD

Control device for compression-ignition engine

ActiveUS20190145337A1Raise the ratioHigh reference valueElectrical controlInternal combustion piston enginesCombustion noiseOn board

A control device for an on-board compression-ignition engine in which partial compression-ignition combustion including spark ignition (SI) combustion performed by combusting a portion of mixture gas inside a cylinder by spark ignition followed by compression ignition (CI) combustion performed by causing the rest of the mixture gas inside the cylinder to self-ignite is executed within at least a part of an operating range of the engine, is provided. The device includes a detector configured to detect a parameter related to noise caused by the combustion inside the cylinder, and a combustion controller configured to control the combustion inside the cylinder during the partial compression-ignition combustion based on a combustion noise index value identified by the detected parameter of the detector and a given reference value defined as an upper limit of the combustion noise index value, the reference value increasing as a vehicle speed increases.

Owner:MAZDA MOTOR CORP

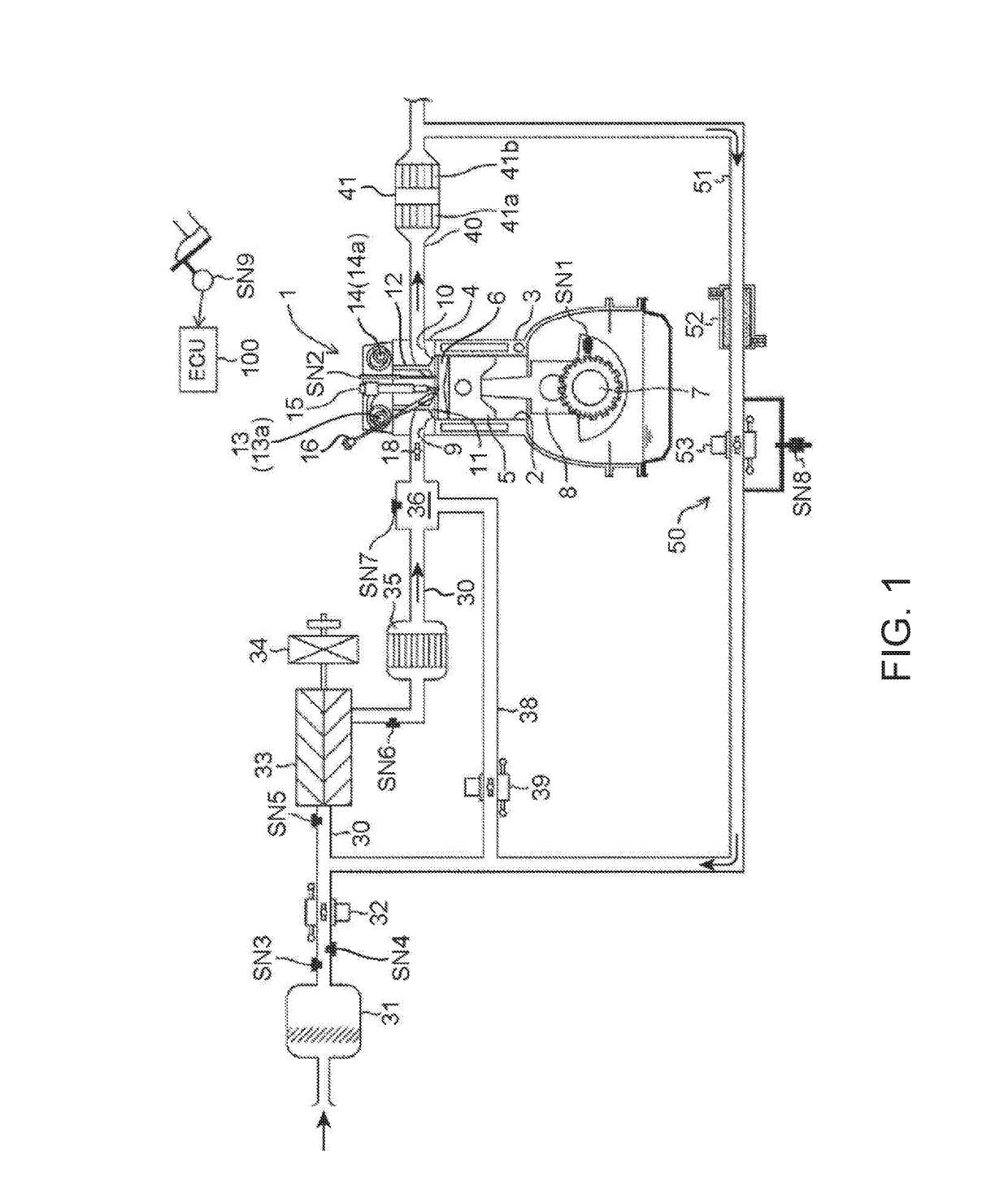

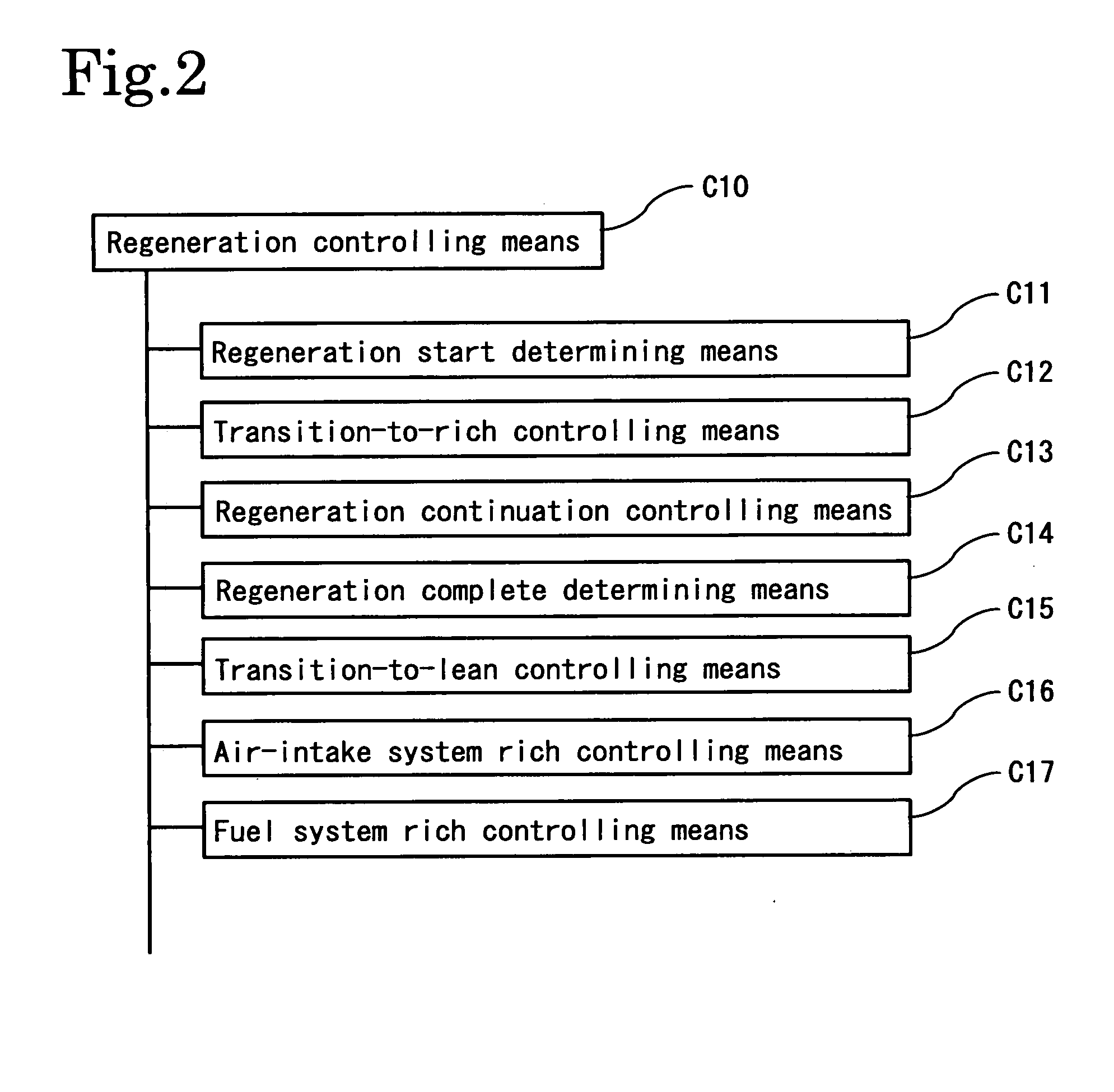

Exhaust Gas Purifying Method and Purifier

ActiveUS20080202098A1Avoid changePreventing in drivabilityElectrical controlExhaust apparatusCombustion noiseExhaust fumes

An exhaust gas purification system (1) performing regeneration control in a rich condition by using control of an intake system for reducing the quantity of intake air together with control of a fuel system for increasing fuel injection amount into a cylinder, wherein the timing (Tn) for injection fuel into the cylinder is varied in response to the continuous variation (λn) of air fuel ratio in the cylinder during the switching intervals (t1,t2) between lean condition and rich condition at the time of regeneration control of NOx purification catalyst (12). During a period of transition to rich condition or lean condition, misfiring, combustion noise, torque variation, deterioration in drivability, and the like, due to undue advance angle or lag angle in the timing for injecting fuel into the cylinder can thereby be prevented.

Owner:ISUZU MOTORS LTD

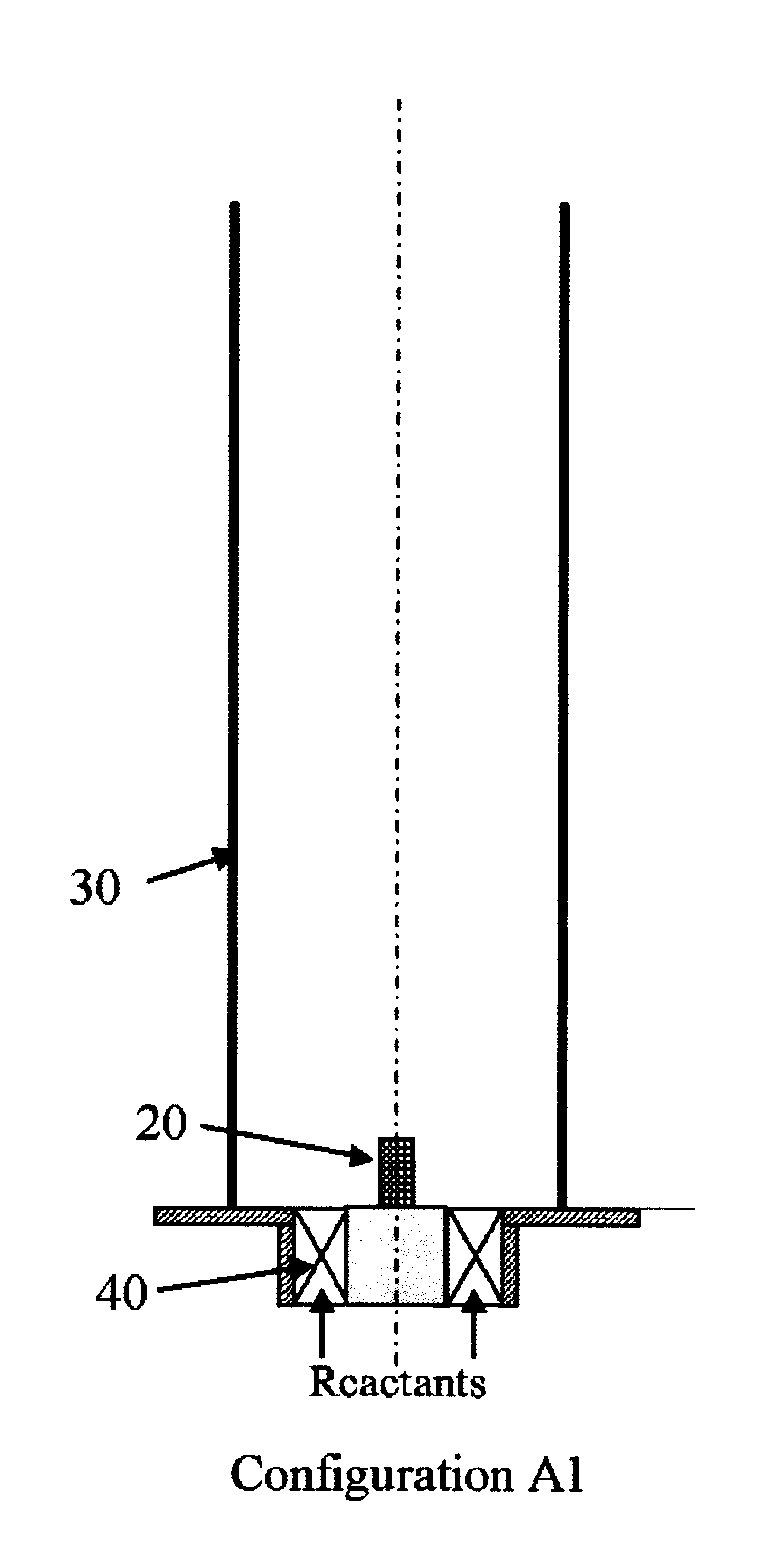

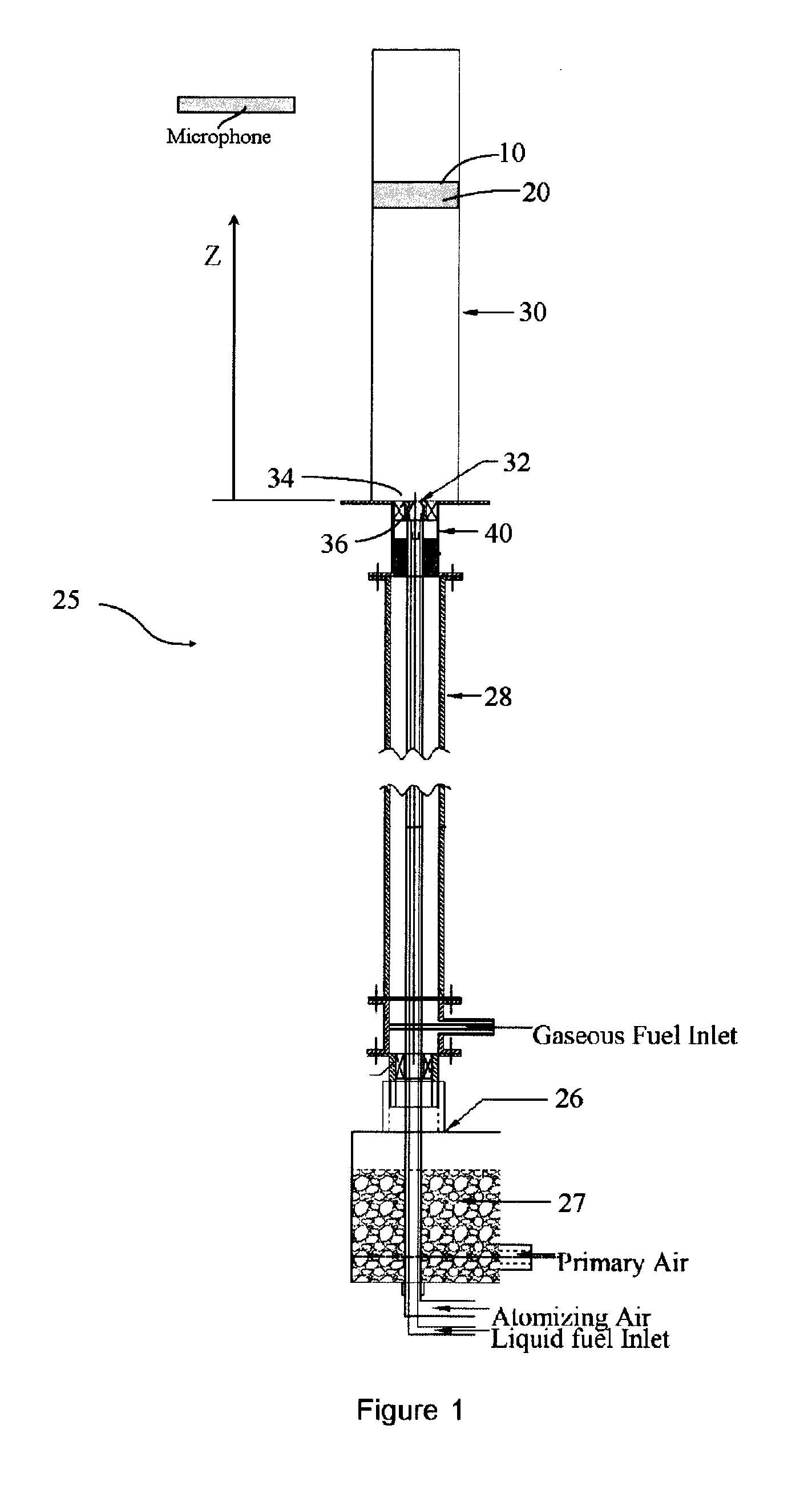

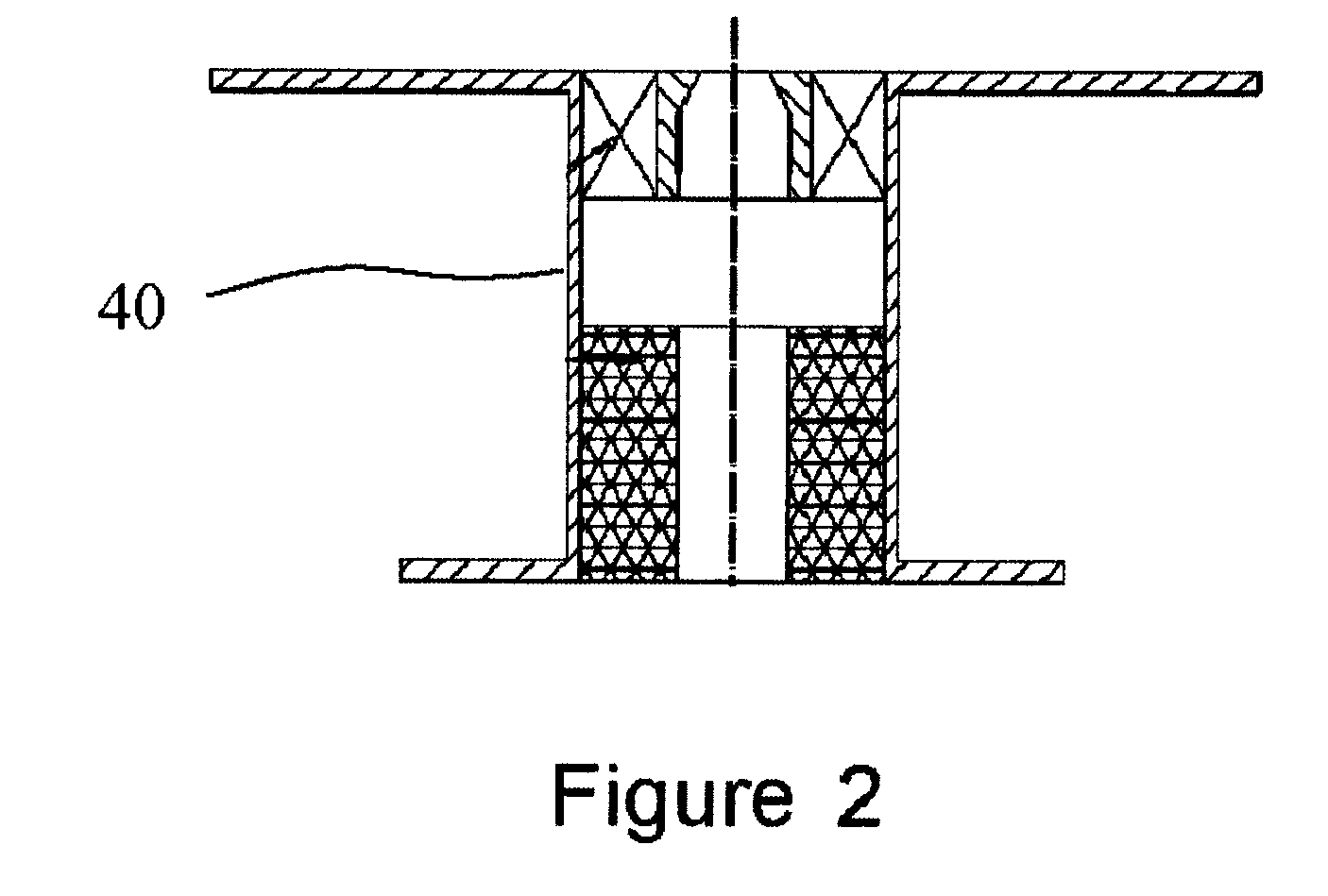

Passive noise attenuation system

ActiveUS20100059311A1Reduce combustion noiseReduce instability problemsContinuous combustion chamberSilencing apparatusCombustion systemCombustion noise

A passive noise attenuation device and system is provided having a reticulated open-cell porous structure configured to acts as a passive control device in order to mitigate combustion noise and instability problems in combustion systems. A porous inert media structure is placed downstream of the reaction zone of a combustion chamber to dissipate noise and / or instability generated upstream in the flame. The porous inert media also limits and / or disintegrates vortical structures in the flame to produce a homogeneous flow field to facilitate distributed reaction zones.

Owner:UNIVERSITY OF ALABAMA

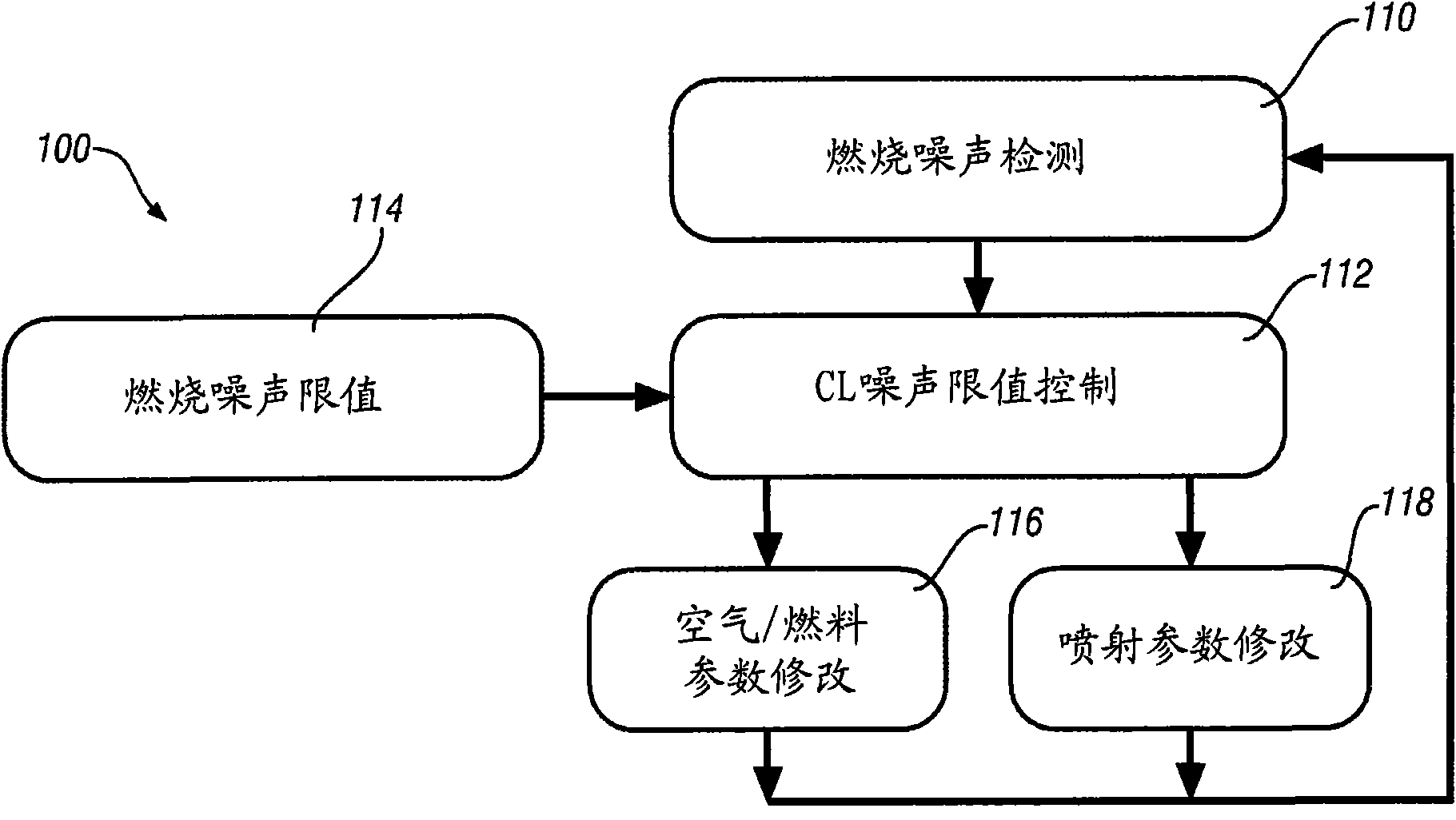

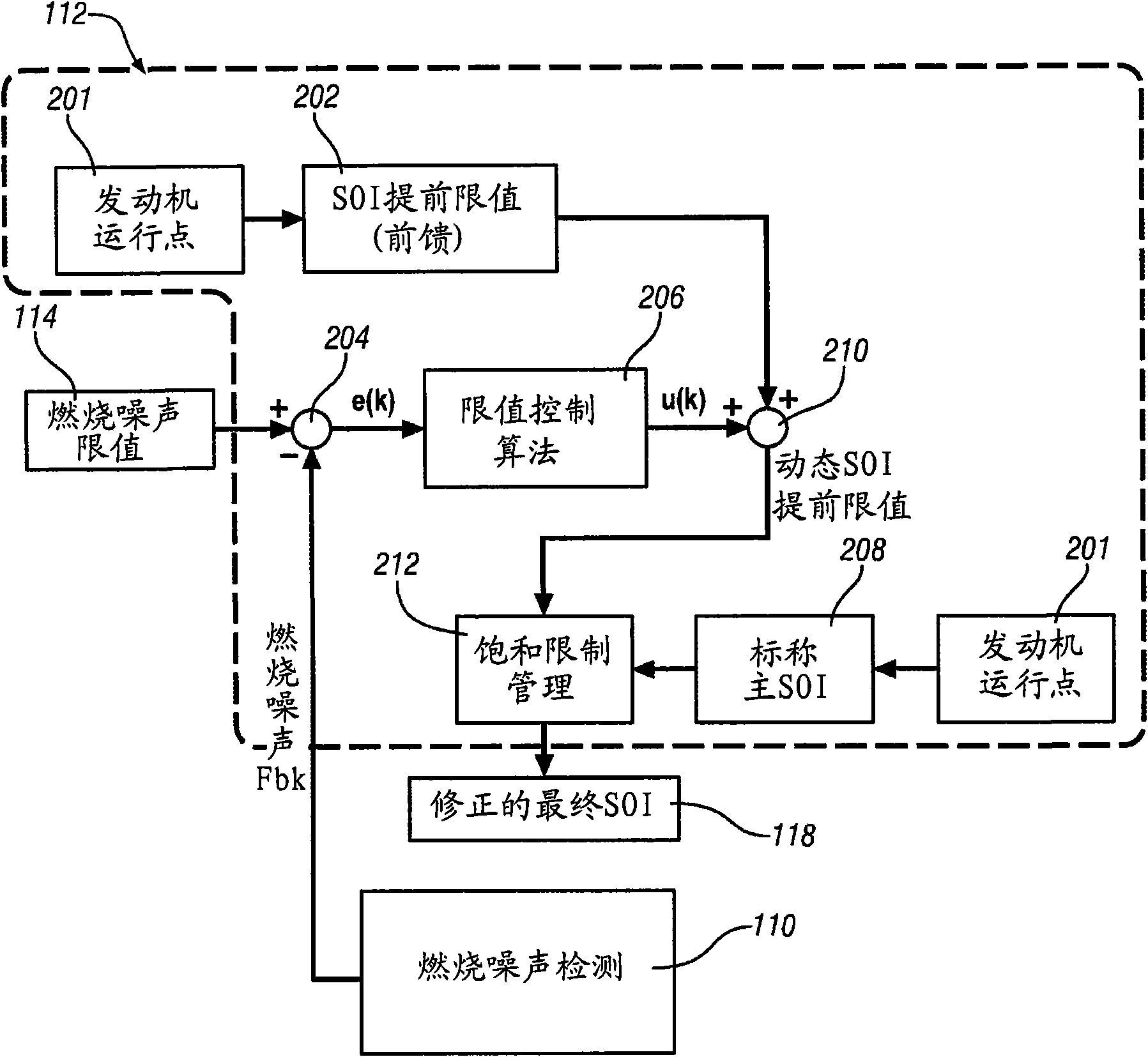

Method for controlling combustion noise in a compression-ignition engine

Combustion noise in a compression-ignition engine is controlled by measuring in-cylinder pressure of a cylinder of the compression-ignition engine, determining a combustion noise level based on the in-cylinder pressure measurement, and modifying a combustion control parameter based on the combustion noise level.

Owner:GM GLOBAL TECH OPERATIONS LLC

System for controlling the combustion noise a motor vehicle diesel engine

InactiveUS6854441B2Noise minimizationLow costElectrical controlInternal combustion piston enginesMultiple injectionCombustion noise

This system for controlling the combustion noise of a motor vehicle diesel engine of the type including means for feeding each of its cylinders with fuel by multiple injections of fuel, which means are adapted to trigger fuel feed into each cylinder in the form of at least one pilot injection and a main injection of fuel, comprises:means for determining pressure gradients in the engine cylinder while in operation, at least during the pilot and main injection stages; andmeans for determining the quantity of fuel to be injected into the cylinder during pilot injection for a predetermined quantity of fuel injected during main injection so as to optimize a criterion based on the ratio between the pressure gradients corresponding to the pilot and main injection stages, thereby optimizing the operating noise of the engine.

Owner:PEZHO SITROEN AUTOMOBILS SA +1

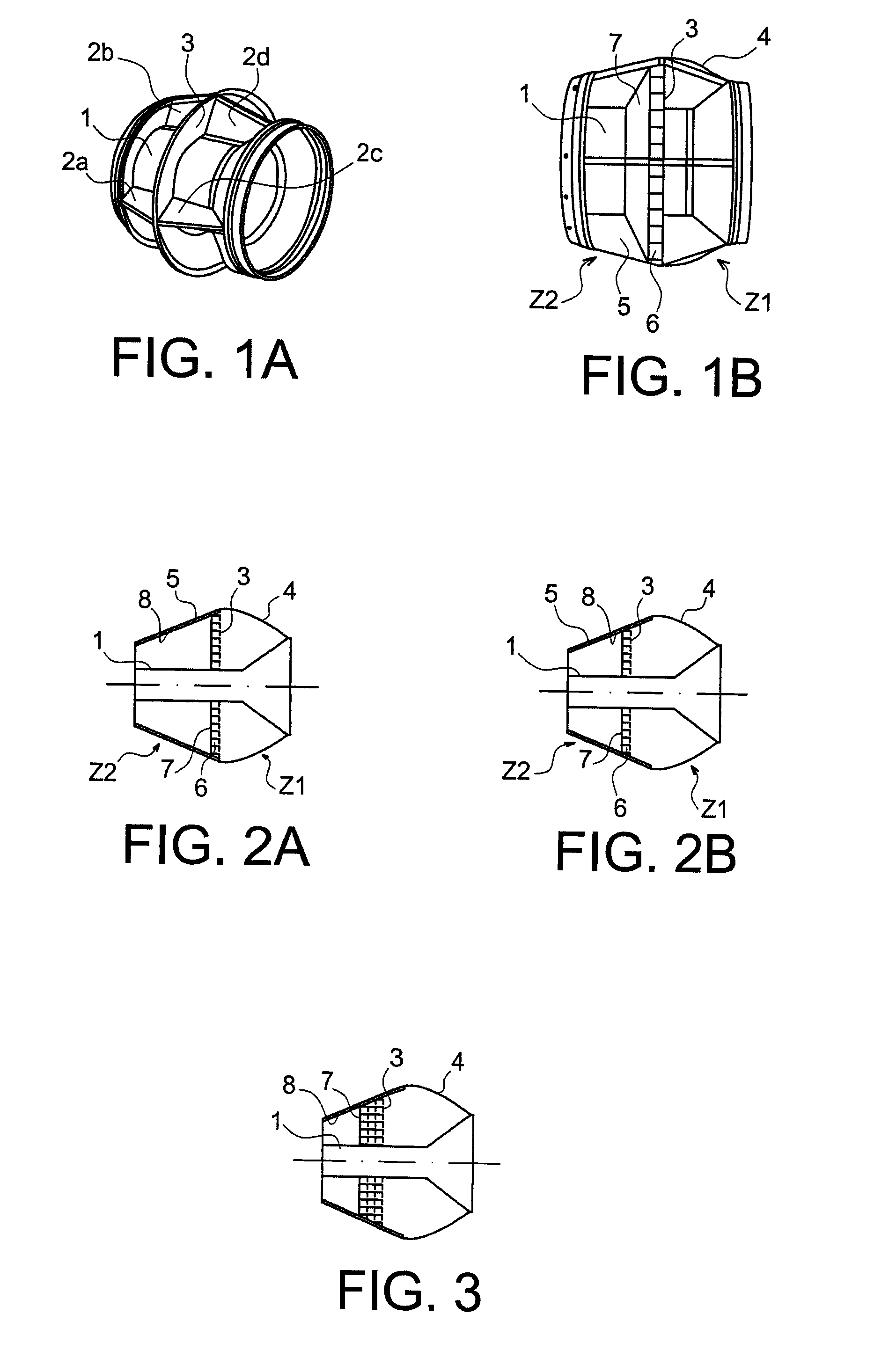

Internal combustion engine

ActiveCN105026743AAchieve regulationSimple structureEngine manufactureNon-fuel substance addition to fuelCombustion noiseTurbocharger

The invention relates to an internal combustion engine with a combustion engine, an exhaust gas line, a fresh gas line, a turbocharger with a turbine integrated into the exhaust gas line, a compressor integrated into the fresh gas line, and a trim plate (12), by means of which the cross section of the compressor inflow can be adjusted. The internal combustion engine is characterized by a low-pressure exhaust gas recirculation system, by means of which exhaust gas downstream of the turbine is removed from the exhaust gas line and can be introduced into the fresh gas line upstream of the compressor, wherein an opening of the low-pressure exhaust gas recirculation system is arranged in the region of the trim plate (12).

Owner:VOLKSWAGEN AG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com