Internal combustion engine

A technology of internal combustion engine and combustion engine, applied in the direction of internal combustion piston engine, combustion engine, liquid fuel engine, etc., to achieve the effect of avoiding throttling loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

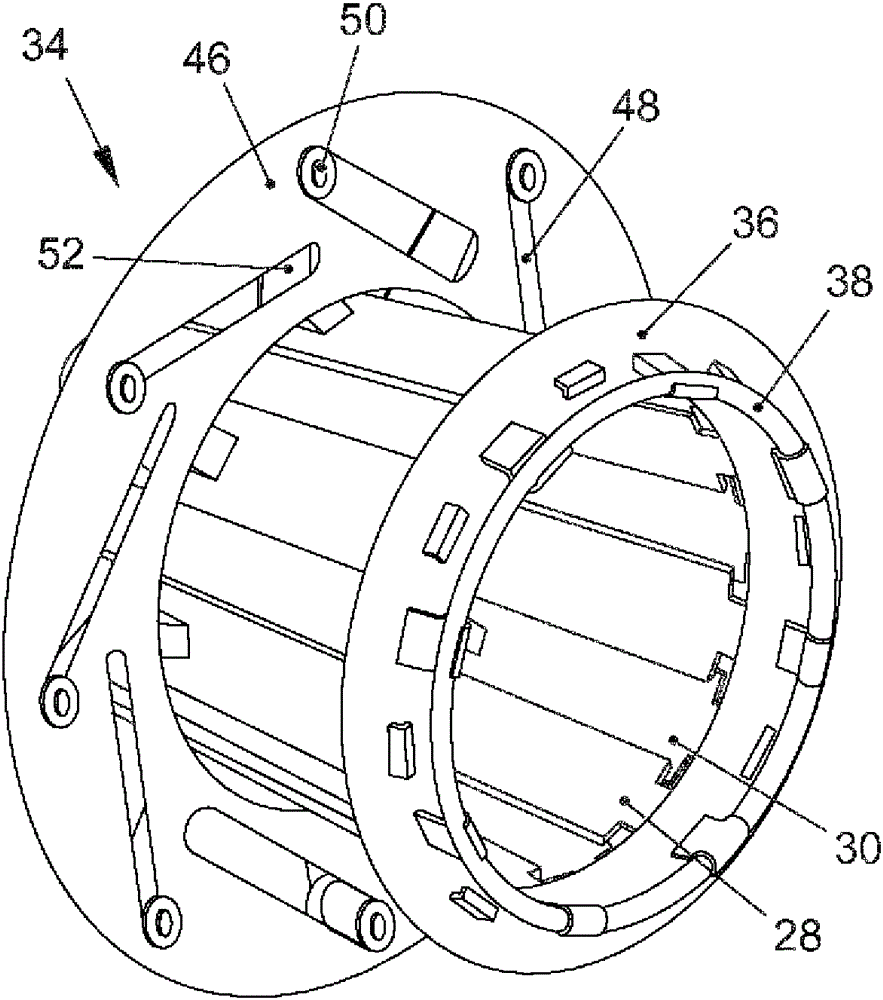

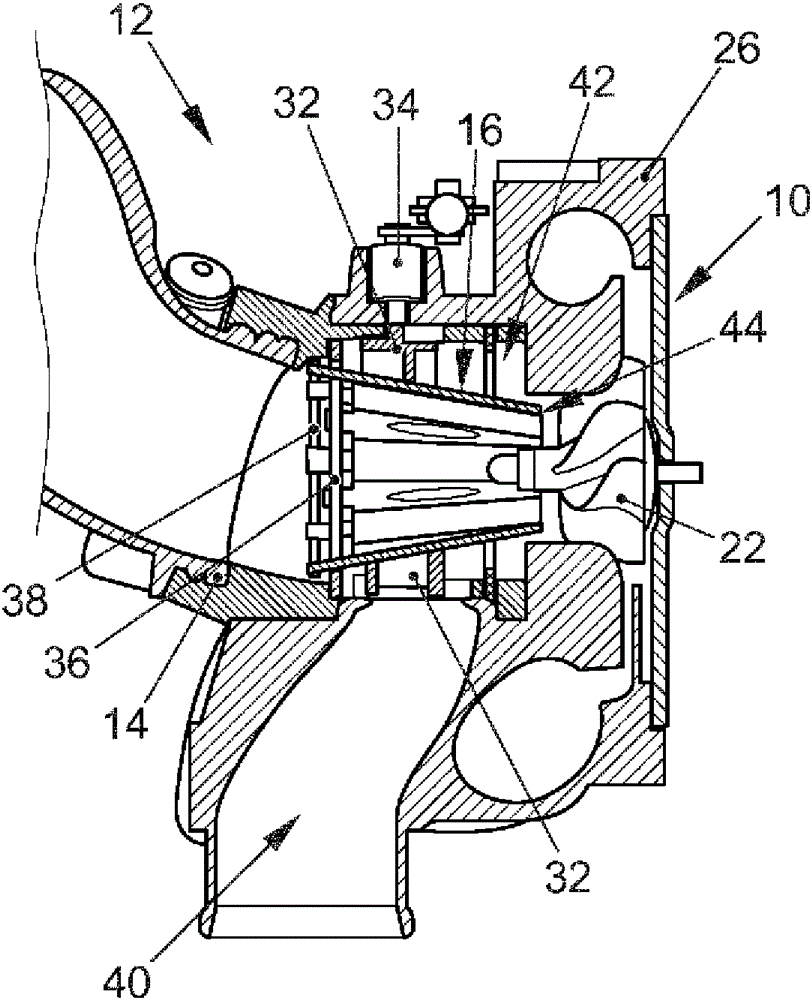

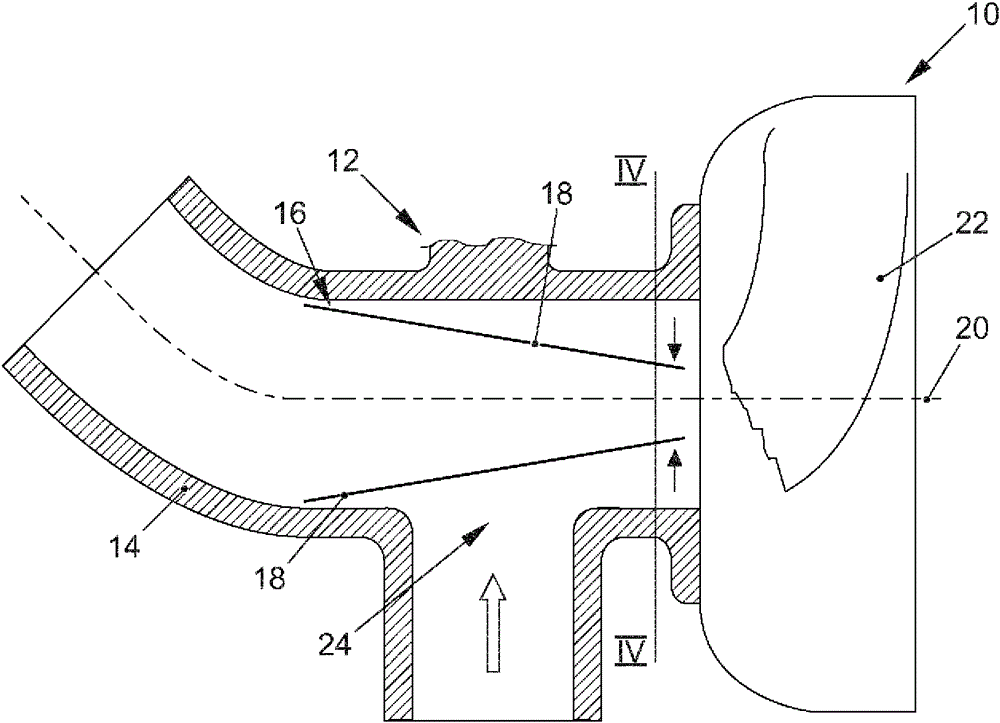

[0033] figure 1 with 3 A first embodiment of a radial compressor 10 and a regulator 12 for an internal combustion engine according to the invention is shown in schematic longitudinal section.

[0034] The regulator 12 includes a tubular housing 14 which can be integrated into the fresh gas line of the internal combustion engine upstream of the radial compressor 1 . In this case, the housing 14 is connected downstream directly on the inlet side to the radial compressor 10 . Inside the housing 14 is arranged a wall system 16 which in the present embodiment comprises two half-shell-shaped or vane-shaped wall elements 18 which are rotatably supported at their upstream ends on the inside of the housing 14 place. At these ends, the two wall elements 18 have an approximately semicircular cross-section. In the direction of the downstream end, the length of the partially circular cross-section of the wall element 18 decreases continuously, wherein, in Figures 1 to 4 The reduction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com